Quote Title: Generator, Transfer Switch, Fire Pump and Industrial

advertisement

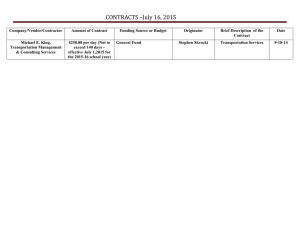

Washoe County School District Request for Quote (RFQ) – SERVICE Purchasing Department 14101 Old Virginia Road, Room 0 Reno, Nevada 89521 Phone (775) 850-8025 ● Fax (775) 857-3175 Email: purchasing@washoeschools.net Buyer Name: Pam Homentowski Quote Title: Generator, Transfer Switch, Fire Pump and Industrial Engine Annual Maintenance and Repair Quote #: PH-1071-16 Washoe County School District (WCSD) is soliciting for formal quotes for certain SERVICES, which may also include products/goods, identified on the QUOTE PRICE SCHEDULE/SPECIFICATION SHEET included in accordance with all defined terms and conditions in this document. RFQ submittals must be submitted on this form only and received in a sealed envelope or emailed directly to: purchasing@washoeschools.net for award consideration. RFQs that are received via facsimile, any other email other than that listed above, or outside of a sealed envelope will NOT be accepted. Posting Date: Due Date: January 22, 2015 February 9, 2016 at 10:00 A.M. (PST) -------------------------------------------------------------------------------------------------------------------------------------------GENERAL TERMS & CONDITIONS OF QUOTE -------------------------------------------------------------------------------------------------------------------------------------------1. FORMS: Vendor must submit quote on this form only. 2. LATE QUOTES: Quotes received after the due date and time will not be accepted. The WCSD reserves the right to reject any quote not in compliance with all prescribed public procedures and requirements and to reject for good cause any or all quotes upon finding that it is in the WCSD’s best interest to do so. 3. FIRM PRICING: Vendor shall hold prices firm for a period of two (2) years from date of award. 4. CONTRACT: Vendor will receive a WCSD Purchase Order (PO); the General Terms and Conditions of this RFQ are hereby incorporated by reference. Acceptance of WCSD’s PO includes all terms, prices, delivery, specifications and conditions stated therein. Contract term is for two (2) years with two (2) additional one (1) year renewals, providing the terms and conditions remain unchanged. WCSD reserves the right to terminate this agreement in whole or in part upon providing Vendor thirty (30) days written notice. 5. QUANTITY: The WCSD intends to purchase the quantities listed on the QUOTE PRICE SCHEDULE/SPECIFICATION SHEET; however, the WCSD’s requirements may change prior to issuing a PO and the WCSD reserves the right to increase or decrease quantities at its discretion. 6. INVOICING AND PAYMENT: Vendor must issue a separate invoice for each shipment. Invoice is to be issued upon delivery only, not before. Payment terms are Net 30 upon receipt of a proper invoice. The WCSD is tax exempt and does not pay state/local taxes or interest or late fees. 7. ITEM SPECIFICATIONS: If applicable, specifications contained herein may reflect items of known quality and are acceptable to the WCSD. If the item specifications indicate “or equal,” Vendor may offer other than the specified item if the item offered is equal in general style, type, quality, workmanship, economy of operation, performance, characteristics and suitability for the purpose intended. Vendor must identify the name brand offered, provide descriptive literature and be prepared to provide samples if requested for evaluation purposes. Failure to provide adequate descriptive literature may be cause to declare the quote non-responsive and reject the quote. If there is any doubt as to the suitability of a product offered on an “or equal” basis, the product will be rejected in favor of an offer to provide the product specified. Date: 12/23/15; Rev. D PUR-F235 Page 1 of 13 8. SHIPPING INTRUCTIONS: The price quoted for each line item shall include all shipping and handling charges to the F.O.B. destination listed on the PO. POs issued are for “prompt or immediate shipment” of the goods contained thereon. Unless otherwise specified, delivery will be made not later than thirty (30) calendar days after receipt of a PO. The WCSD reserves the right to cancel any order if not filled within the contract time. The PO number must appear on all invoices, packing lists, packages, shipping notices and correspondence. All shipments of hazardous material must be accompanied by Safety Data Sheets (SDS). 9. INSTALLATION: If applicable, services that require installation, Vendor shall perform the installation in accordance with manufacturer specifications in a professional manner. Vendor shall leave work area clean and free of all packaging and any debris created by the work and shall make food, to the satisfaction of WCSD’s Facilities Management Department, any damage to the work of other trades caused by any installation. 10. AWARD: WCSD reserves the right to award this RFQ in whole or in part, by item, group of items, or by section where such action would serve WCSD’s best interest. Quotes identified on the basis of “All or Nothing” will be excluded from this provision. In the event of a tie, low quote shall be determined by extending prices out to the third decimal. If a tie still exists, award shall be determined by lottery. 11. CERTIFICATES OF LIABILITY: The awarded Vendor(s) shall not render any services or provide goods/products requested under this RFQ until satisfactory proof of all insurance certificates and supporting documentation has been approved by the WCSD Purchasing Department (refer to Section 13). All documentation must be submitted to: Washoe County School District The Brown Center – Purchasing Department 14101 Old Virginia Road, Room 0 Reno, Nevada 89521 12. REQUIRED INSURANCE COVERAGE & VERIFICATION: The awarded Vendor shall, at the awarded Vendor’s sole expense, procure, maintain and keep in force for the duration of the contract insurance conforming to the minimum limits as specified in this Bid. The awarded Vendors hall furnish WCSD with a Certificate of Insurance (COI) form with Additional Insured Endorsement(s) effecting coverage required. The authorized Insurer(s) of the awarded Vendor and/or subsequent insurance company(s) issuing the policy(s) shall have no recourse against the WCSD for payment of any premiums, costs or assessments under any form of policy. The awarded Vendor’s authorized Insurer(s) shall have no right of recovery or subrogation against WCSD. The required insurance shall be in effect prior to any services rendered and/or products procured from the awarded Vendor by WCSD and shall continue in force as appropriate until the completion of the contract term. The “ACCORD 25 Certificate of Insurance Form” or a form substantially similar must be submitted by the awarded Vendor to WCSD to evidence the insurance policies and coverages required. The COI must be signed by a person authorized to bind coverage on the behalf of the awarded Bidder. The COI must name WCSD as the “Certificate Holder” as follows: Washoe County School District 425 E. Ninth Street Reno, Nevada 89512 For the purpose of substantiating the requirement of the WCSD to be named as an “Additional Insured,” the COI’s “Description of Operations/Locations/Vehicles” section shall state the following: The WCSD, its officers, employees and volunteers are to be named as an “Additional Insured” on the awarded Proposer’s general liability. The coverages shall contain no special limitations on the scope of protection afforded to the WCSD, its officers, employees, agents or volunteers. The COI shall state that any of the described policies be cancelled before the expiration date thereof, notice will be delivered in accordance with the policy provisions. Furthermore, each insurance policy shall not be suspended, voided, canceled or non-renewed by either the awarded Proposer or the authorized Insurer without a replacement COI being provided to WCSD during the life of the contract. Upon renewal of the policies listed, awarded Vendor or authorized Insurer(s) shall furnish the WCSD with replacement certificates. The awarded Vendor shall furnish WCSD with COI with Additional Insured Endorsement(s) effecting coverage required. All COIs and relative endorsements are to be received upon written request by WCSD to the awarded Vendor and must be reviewed and approved by the WCSD’s Purchasing Department prior to any services being rendered and/or products procured. Although not a standard practice of WCSD, WCSD reserves the right to require of the awarded Vendor to make available to WCSD for review complete, “certified” copies of all required insurance policies at any time. The awarded Vendor’s insurance coverage shall be the primary insurance. Any insurance or selfDate: 12/23/15; Rev. D PUR-F235 Page 2 of 13 insurance maintained by the WCSD, its officers, employees, agents or volunteers shall be in excess of the awarded Proposer’s insurance and shall not contribute with it in any way. Any failure of the awarded Vendor to comply with the reporting provisions of the policies shall not affect coverage provided to the WCSD, its officers, employees, agents, or volunteers. 13. INSURANCE LIMITS: GENERAL LIABILITY INSURANCE During the term of this agreement, the awarded Vendor providing service to WCSD shall maintain comprehensive General Liability Insurance with the following coverages through an insurance carrier(s) licensed to do business in the State of Nevada and having a current A.M. Best rating of A-:VII or better and approved by the WCSD: (A) Premises-Operations; (B) Independent Contractor’s Protection; (C) Products and Completed Operations; (D) Broad Form Property Damage; (E) Personal Injury (with Employee Exclusion deleted); (F) Blanket Contractual Liability; and (G) Property Damage Liability. Limits shall be equal to the amount carried by the successful Bidder, but shall not be less than one million dollars ($1,000,000) per occurrence combined single limits with no less than two million dollars ($2,000,000) aggregate. AUTOMOBILE LIABILITY INSURANCE During term of this agreement, the awarded Vendor shall maintain comprehensive Automobile Liability Insurance to include all owned autos, non-owned autos, and hired autos coverage through an insurance carrier(s) licensed to do business in the State of Nevada and having current A.M. Best rating of A-:VII or better and approved by the WCSD. Limits shall be equal to the amount carried by the successful Bidder, but shall not be less than one million dollars ($1,000,000) per occurrence. WORKERS’ COMPENSATION INSURANCE During the term of this agreement, the awarded Vendor shall have Workers’ Compensation coverage as required by law for the duration of the contract to include Employer’s Liability Coverage (noted at Statutory Limits) with minimum limit of one million dollars ($1,000,000). PROFESSIONAL LIABILITY INSURANCE If applicable, during the term of this agreement, the awarded Vendor shall maintain Professional Liability Insurance (Errors & Omissions) with minimum limits of at least one million dollars ($1,000,000) per occurrence. The insurance required above may be proved under primary policies or by a combination of primary and excess policies. Professional Liability is not covered under additional Umbrella Liability coverage. 14. LICENSE AND CERTIFICATION: Awarded Vendor must be licensed or incorporated to do business in the State of Nevada. Awarded Vendor shall possess all applicable licenses and/or certifications to perform the type of service being requested. If applicable, awarded Vendor shall possess appropriate city and/or county business licenses. * * * * * * * * * * * * * * * END OF GENERAL TERMS & CONDITIONS OF THE QUOTE * * * * * * * * * * * * * * Date: 12/23/15; Rev. D PUR-F235 Page 3 of 13 Quote Title: Generator, Transfer Switch, Fire Pump and Industrial Engine Annual Maintenance and Repair Quote #: PH-1071-16 -------------------------------------------------------------------------------------------------------------------------------------------SPECIAL GENERAL TERMS & CONDITIONS OF QUOTE -------------------------------------------------------------------------------------------------------------------------------------------15. SCOPE OF WORK: WCSD is seeking quotations to establish an annual contract for the preventative maintenance and repair of its generators, transfer switches, fire pump and industrial engines. The purpose of this contract will be to maintain the equipment in good operating condition to avoid breakdown and to perform scheduled maintenance and parts replacement before the equipment fails. This contract will also include repairs on an as-needed basis. 16. LOCATIONS/EQUIPMENT: The following locations will be covered under this maintenance contract. Specific contact information will be issued by WCSD’s Facilities Management Department to the awarded vendor. Administration Office 425 East Ninth St. Reno, NV 89512 Type/Model: DMT Model 600D S/N: 850215, Spec 5081 Contact: Site Facility Coordinator WCSD Nutrition Services 585 Spice Island Court Sparks, NV 89434 Type/Model: DMT Model 600D S/N: 95-7420-10 Contact: Site Facility Coordinator Damonte Ranch High School 10500 Rio Wrangler Parkway Reno, NV 89521 Type/Model: Onan DGFC5567333 S/N: H020406504 Contact: Site Facility Coordinator McQueen High School 6055 Lancer Street Reno, NV 89523 Type/Model: Onan DGCA-5780456 S/N: K060993184 Contact: Site Facility Coordinator Galena High School 3600 Butch Cassidy Way Reno, NV 89511 Type/Model: Kohler 80RZ272/Size 80KW S/N: K34890 Amps 150, 480v Contact: Site Facility Coordinator Date: 12/23/15; Rev. D PUR-F235 Page 4 of 13 North Valley High School 1470 East Golden Valley Road Reno, NV 89506 Type/Model: DMT ZTG2K40EC-6/Size 200KW S/N: 1327340-Amps Type/Model: Synergy ATS ZTG2K40EC-7 S/N: 400-277/480v Contact: Site Facility Coordinator Washoe Inspire Academy 1155 Corporate Blvd. Reno, NV 89502 Type/Model: Caterpillar Genset Cat #3408 SR4 350KW/526 Amps 480v S/N: 6CA00667 Contact: Site Facility Coordinator Reed High School 1350 Baring Blvd. Sparks, NV 89436 Type/Model: Onan 450EM-15R/9518D S/N: 274758670 Contact: Site Facility Coordinator Spanish Springs High School 1065 Eagle Canyon Dr. Sparks, NV 89436 Type/Model: DMT 200JDB/Size 200KW S/N: 00-210234-1 Spec 12454 Contact: Site Facility Coordinator Gerlach High School 555 East Sunset Blvd. Gerlach, NV 89412 Type/Model: Generator D100P15 S/N: OLY00000LNPS00920 Type/Model: Generator YB51044 S/N: U804663J Contact: Site Facility Coordinator Clayton Middle School 1295 Wyoming Avenue Reno, NV 89503 Type/Model: Kohler 5RM82 S/N: 255752 Contact: Site Facility Coordinator Pine Middle School 4800 Neil Road Reno, NV 89502 Type/Model: Onan 50.0DDB-15R S/N: 0175920323, Spec 2072A Contact: Site Facility Coordinator Date: 12/23/15; Rev. D PUR-F235 Page 5 of 13 O-Brien Middle School 10500 Stead Blvd. Reno, NV 89506 Type/Model: Onan 50.0DDB-R/2072A/Size 200KW S/N: 0175920322, Spec 2072A Type/Model: Clark-GM MD3-1224 S/N: 226-3-16819 Contact: Site Facility Coordinator 17. INCLUDED SERVICE REQUIREMENT: The following items should be included, but not limited to the Preventative Maintenance Program. 17.1 Electric System AC & DC: All cables will be checked, cleaned and tightened as required. Batteries will be checked for correct specific gravity and distilled water added if necessary. External battery charger and/or battery charging alternator will be inspected and tested for proper operation. Control panel, control components, warning systems and emergency shutdowns will be checked for proper operation. Awarded vendor will be responsible for recommending to WCSD staff any equipment replacements necessary. 17.2 Fuel System: Fuel tanks on liquid fueled units should be checked for water contamination and noted on the service report. Fuel lines shall be checked for leaks and all fuel filters replaced during major service. The fuel day tank shall be checked for proper operation and water condensation. 17.3 Engine: All spark plugs to be cleaned and adjusted or replaced when necessary (natural gas, LP and gasoline). Ignition condensers and points to be adjusted and cleaned or replaced when necessary. Where needed, the equipment will be lubricated. 17.4 Lubrication System: Lube oil and filters will be changed yearly during the major service. 17.5 Cooling System: Check entire system for the proper chemical balance of rust inhibitor and anti-corrosive additives. Replace anti-freeze as required. Inspect all hoses, hose clamps, belts and jacket water heater connections. Inspect city water cooled and heat exchangers for leaks and proper operation. Expansion tank level check plus the addition of rust inhibitor and anti-corrosive additives with coolant replacement should also be checked. Inspect, clean and check for proper operation all air cooled sets, cooling fins, fans, shrouds, etc. 17.6 Air System: Inspect complete air intake and exhaust systems including louver/shutters for correct operation whenever generator or engine is running either in manual or automatic mode. Check engine air filters(s) condition; change if required. 17.7 Exhaust System: Open and drain condensation traps. Check for any exhaust restriction. Inspect system for leaks and check all mounting hardware and tighten as necessary. Check rain cap condition and proper operation when engine is running. 17.8 Generator Sets: Manually operate generator set at no load and verify that generator is producing rated AC voltage and frequency and that all control panel instruments and gauges are functioning. 17.9 Transfer Switch: Inspect and test transfer switch to insure that it automatically starts the generator and is transferring properly, plus insure that all options such as “time delay emergency to normal: “time delay cool down”, “plant exerciser”, etc., are performing in accordance with WCSD requirements. 17.10 General: Visually inspect for any fluid or exhaust leaks, vibration isolators, duct work, weatherproof enclosures, worn and/or rubbing parts and components; in addition check for any unusual engine or generator noises. 17.11 Reports: Provide a detailed report describing the work performed and recommendations for corrective maintenance that may not be covered by the Preventative Maintenance Agreement. Date: 12/23/15; Rev. D PUR-F235 Page 6 of 13 17.12 Parts Included in the Preventative Maintenance Program: Parts that should be included in the cost of the Preventative Maintenance Program should be: • Coolant and lube oil filters • Lube oil • Anti-freeze • Spark plugs for gaseous, gasoline engine driven generator sets 17.13 Fuel Levels: The awarded Vendor will be responsible for checking the fuel levels in the day tanks and to then notify the Facilities Management Department if the tanks are in need of fuel. WCSD will be responsible for providing the fuel. At the time of award the awarded Vendor will be given the contact person name and phone number to contact at each site. 18. GENERAL REQUIREMENTS: All work activities under this contract shall be coordinated with the requirements of the WCSD Facilities Management Department. The WCSD shall be contacted prior to any service shutdown, and advised when such shutdown shall be commenced. It is the Vendor/Contractors responsibility to shut water off and/or on in response to any repairs directed by the WCSD Facilities Management Department representative. The Contractor will be required to maintain a neat and orderly operation and to limit or keep noise and nuisance to a minimum. • • • • • • • • • • • • WCSD reserves the right to remove any person from the property for the safety and security of the facility. It is a felony to transport any alcoholic beverages, drugs, weapons or ammunition of any kind on WCSD property. Any contact or conversation with students is prohibited. Smoking is prohibited on all WCSD property. Working hours inside the existing perimeter and existing building will be coordinated with WCSD. Operations shall be confined to the areas permitted under the contract. Areas beyond indicated work areas are not to be disturbed. Vendor must conform to site rules and regulations affecting the work. Driveways and entrances serving the premises shall be kept clear and available at all times. These areas are not to be used for parking or storage of materials. Passenger cars, trucks and motorized construction equipment, when parked and unattended, shall be locked and the ignition key removed. No such vehicle shall be left with the motor running. Limitations on site usage, as well as specific requirements that impact site utilization are indicated on the drawings and any other contract documents when required. Deliveries shall be scheduled to minimize space and time requirements for storage of materials and equipment. Work schedules will be developed and submitted to the Facilities Management Department forty-eight (48) hours in advance of any work. All refuse will be removed daily. It is also the responsibility of the Contractor to maintain a database of all repairs and/or modifications to WCSD plumbing systems. Upon request the Contractor must provide to WCSD within forty-eight (48) hours a yearly, itemized usage report. 19. WATER SYSTEM DISTURBANCE: The work may involve the disturbance of a facilities water distribution system and, as such, the Contractor is required to comply with the Water System Disturbance Permit Appendix section of the Material, Water & Lead Disturbance Permit for any work impacting a facility water system, “Exhibit 2”. The Contractor shall carefully comply with all requirements of the Material, Water & Lead Disturbance Permit and shall be aware of this process prior to bid preparation and any construction. The permit requirements are hereby made a part of this specifications and contract to the same extent as if bound herein and shall apply to all Contractors and Subcontractors. The Contractor shall be responsible for all costs incurred by the WCSD including consultant, sampling and testing, cleanup, replacement of effected equipment, materials, etc., and any legal action that may result from an unauthorized disturbance of a water system caused by the Contractor or his/her Subcontractors resulting in a cross connection or backflow incident. If Contractors have any questions regarding the requirements of the Water System Disturbance Permit please call: Environmental Compliance Officer at (775) 851-5675. 20. ASBESTOS DISTURBANCE: The work may involve disturbance of materials which contain asbestos as such, the project may involve “small scale, short duration” asbestos disturbance also termed “attachments and penetrations”. In these instances, the Contractor is required to use a hole saw or drill with the appropriate tools as specified. In the event Date: 12/23/15; Rev. D PUR-F235 Page 7 of 13 the Contractor cannot use a hole saw or drill, said Contractor shall notify WCSD Facilities Management Representative. If the WCSD finds the information provided by the Contractor to be accurate and true, the WCSD will make the necessary arrangements to abate the area needed. It will be the Contractor’s responsibility to clearly mark the area needed for abatement and to accommodate the necessary schedule and work areas needed for the WCSD to complete the abatement. If the WCSD finds that the attachment and penetration can be completed with a hole saw or drill, it shall be the Contractor’s responsibility to either perform said work if qualified or have the option to hire a qualified Subcontractor. The Asbestos Hazard Emergency Response Act of 1986 required a minimum of 16 hours of "awareness" training for personnel performing the disturbance. The Contractor shall be responsible for assurances that the personnel doing the work have been properly trained. The Contractor shall submit to the Owner copies of Certificates of Completion of training for those personnel doing the work. These certificates will not be returned, but rather kept for the WCSD’s records. The Contractor shall carefully comply with all items of the Building Materials Disturbance Permit, “Exhibit 2” and shall review the permit and become familiar with its contents prior to bid preparation and any construction. The permit as well as the Asbestos Hazard Emergency Response Act (AHERA) Management Plan are hereby made a part of this specification and contract to the same extent as if bound herein and shall apply to all Contractors and Subcontractors. Building materials that may be disturbed during the course of construction and/or demolition will be tested for the presence of asbestos. These materials have been identified as asbestos containing or non-asbestos containing on the building material disturbance permit(s) by the management planner. This sheet(s) must be referred to before any work commences. All asbestos containing material must be handled by Contractors and/or individuals trained and certified in the removal of asbestos containing building materials. No asbestos containing materials shall be disturbed prior to authorization from the owner. If any material is encountered that is not listed on sheet(s) it shall immediately be brought to the attention of the management planner of the WCSD (775) 851-5675 before any work continues that might disturb this material. If any building material listed in the disturbance permit as containing asbestos is improperly disturbed, in the opinion of the WCSD, by the Contractor or his/her Sub-Contractor, the WCSD will immediately hire a third party asbestos consultant to investigate possible asbestos contamination and an asbestos Contractor to perform any recommended clean-up. The Contractor shall be responsible for all costs incurred by the WCSD including consultant, sampling and testing, cleanup, replacement of effected equipment, materials, etc., and any legal action that may result from an asbestos fiber release incident, caused by the Contractor or his/her Sub-Contractors. Air sampling results, if required by the Material Disturbance Permit will be supplied to the RS&A Department and the Project Manager within 72 hours of the completion of a disturbance. Laboratory results will be faxed to (775) 851-5695 directly from the laboratory providing analysis within the 72 hour period. Hand written results will not be allowed. The Building Materials Disturbance Permit shall be in the following form, “Exhibit 2”. The pages of the permit are also located on one sheet of the drawings if applicable. The Contractor and his/her workmen shall be responsible to compare the materials listed and follow the instruction given. John Nolan, Regulated Systems and Assessment Supervisor Washoe County School District (775) 851-5675 21. LEAD – LEAD IN PAINTS AND COATING IN WCSD FACILITIES PRE-1978: Paint and coating sampling has shown that most paints and coatings contain some levels of lead in the WCSD Pre-1978 facilities. Therefore, all persons performing any disturbance to coatings or paints in our Pre-1978 constructed facilities must utilize lead safe work practices. In addition, any person performing any disturbance to paints or coatings must have taken an OSHA lead action level training class from a WCSD RS&A Department approved training provider. If the facility is a kindergarten through 6th grade elementary school, the Contractor must also comply with the Renovation, Repair and Painting Regulation Section listed below. Lead safe work practices are identified in the EPA guidance document titled “Steps to lead safe renovation, repair and painting”, pages 12 thru 23. This document is available electronically at http://www.epa.gov/lead/pubs/steps.pdf. The Contractor shall submit lead safe work practice procedures and all OSHA action level training certificates to the project manager. The project manager must submit a copy to the RS&A Department for approval of these documents prior to any disturbance. The RS&A Department will notify the Contractor upon approval of these documents. Date: 12/23/15; Rev. D PUR-F235 Page 8 of 13 Once this approval is received, the Contractor may schedule work, but must notify the RS&A Department immediately prior to conducting work that disturbs lead containing materials. The Contractor shall provide this notice by calling the RS&A Department at (775) 851-5675. RS&A Department personnel, project managers, assistant project managers, and other WCSD personnel may conduct site visits to ensure compliance with the Contractor’s submitted and approved procedures. 22. LEAD – POST 1978 WCSD BUILDINGS: Paints and coatings on materials other than metal surfaces and ceramic wall tile, typically do not contain significant amounts of lead in WCSD post – 1978 constructed facilities. It is ok to disturb these materials without sampling unless the Contractor determines sampling is in their best interest. Such sampling will be paid for by the Contractor. Ceramic wall tile glaze typically contains high lead concentrations. Paint or coatings on metal surfaces typically contain lead in WCSD facilities; therefore ceramic tile and paints/coatings on metal will be treated as containing lead unless sampling proves otherwise. Contractor is responsible for paying for any sampling necessary to prove these materials do not contain lead. The Contractor must submit sampling results to the project manager who must submit the results to the RS&A Department for approval prior to any disturbance of the material. The Contractor has the option to assume the paint on metal surfaces and ceramic tile glaze contains lead instead of sampling. The Contractor must utilize lead safe work practices if lead is present or assumed to be present in materials to be disturbed. The Contractor must ensure all persons performing any disturbance of lead containing materials must have taken an OSHA lead action level training class from a WCSD RS&A Department approved training provider. Lead safe work practices are identified in the EPA guidance document titled “steps to lead safe renovation, repair and painting”, pages 12 thru 23. This document is available electronically at http://www.epa.gov/lead/pubs/steps.pdf. The Contractor shall submit lead safe work practice procedures and all OSHA action level training certificates to the project manager. Project manager must submit a copy to the RS&A Department for approval of these documents prior to any disturbance. RS&A Department will notify the Contractor upon approval of these documents. Once this approval is received the Contractor may schedule work but must notify the RS&A Department immediately prior to conducting work that disturbs lead containing materials. Contractor shall provide this notice by calling the RS&A Department at (775) 851-5675. RS&A Department personnel, project managers, assistant project managers, and other WCSD personnel may conduct site visits to ensure compliance with the Contractor’s submitted and approved procedures. 23. RENOVATION, REPAIR & PAINTING REGULATIONS – 40 CFR PART 745.81: Effective April 22, 2010 Contractors will be required to be trained and registered with the EPA to conduct regulation applicable renovations, repairs and painting in all elementary schools or child occupied WCSD facilities constructed prior to 1978. In addition, Contractors must have a minimum of one supervisor on-site that has successfully attended and passed a one day Lead Renovation, Repair and Painting (RR&P) course before working in any elementary schools or child occupied WCSD facilities constructed prior to 1978. The supervisors training certification must remain current. Recertification requirements through the attendance of refresher courses are a requirement of this regulation. The supervisor must be on-site throughout the project. The certified supervisor is responsible for ensuring that lead safe work practices are utilized per this regulation as well as per all WCSD lead requirements and policies that may be more stringent then the EPA and OSHA regulations. Lead safe work practices are identified in the EPA guidance document titled “steps to lead safe renovation, repair and painting”, pages 12 thru 23. This document is available electronically at http://www.epa.gov/lead/pubs/steps.pdf. The Contractor shall submit lead safe work practice procedures and all RR&P, and OSHA action level training certificates to the project manager. The project manager must submit a copy to the RS&A Department for approval of these documents prior to any disturbance. The RS&A Department will notify the Contractor upon approval of these documents. Once this approval is received the Contractor may schedule work but must notify the RS&A Department immediately prior to conducting work that disturbs lead containing materials. The Contractor shall provide this notice by calling (775) 8515675. RS&A Department personnel, project managers, assistant project managers, and other WCSD personnel may conduct site visits to ensure compliance with the Contractor’s submitted and approved procedures. 24. INDOOR ENVIRONMENTAL QUALITY: Preventative job site practices will reduce the potential for residual problems with indoor air quality in completed buildings and reduce undue health risks for all workers. The following are the minimum standards required for on-site construction in the WCSD. Date: 12/23/15; Rev. D PUR-F235 Page 9 of 13 a. Existing HVAC System: When feasible, the HVAC system for the project area will be shut down for the duration of the project. If occupied spaces will be adversely affected by the shut-down of the system, construction area return registers should be sealed with polyethylene sheeting and secured as an alternative. Registers must be sealed prior to the start of work. b. Separating Occupied Spaces From Non-Occupied: Keep work areas separate from occupied spaces with polyethylene sheeting (or similar) if there are no other natural barriers in place OR in spaces where air exchange will occur around the barriers. c. Ventilation: During the installation of carpet, paints, furnishings and any other VOC emitting products, provide “spot” ventilation during application/installation and for at least 24 hours after the work is completed. In most cases, opening windows and doors will not be enough to effectively exhaust contaminants. It is recommended that an exhaust fan be used to pull polluted air out of the building. This can be accomplished by placing a fan in a window or door and temporarily sealing any opening around the fan with plastic. Additionally, a door or window at the opposite end of the room should be opened to allow fresh, outdoor air to flow across the work area and sweep polluted air out through the exhaust fan. As long as odors are present, the temporary exhaust ventilation must continue to operate. This may include nights and weekends as necessary. Ventilation should continue for a minimum of 24 hours after the completion of the project or until there are no more noticeable odors. d. Construction Dust: Minimize the amount of dust in the air and on surfaces. Examples include the use of vacuum assisted drywall sanding equipment and the use of vacuums instead of brooms to clean construction dust from floors. e. After Hours Scheduling: Schedule high dust generating operations or extreme noise generating activities for after normal working hours. (i.e., saw cutting, jack hammering) and install temporary barriers to confine dust as necessary. f. Gasoline/Diesel Powered Equipment: Electric powered equipment must be used in lieu of diesel or gasoline powered equipment. Gas and diesel equipment may not be used inside a WCSD building or near an outdoor fresh air building intake. g. Safety Data Sheets (SDS): SDS must be made be maintained onsite and made available upon request as required by federal law. h. Construction Completion: Prior to the occupancy of the building but after the installation of new furniture, carpet, etc., the building should be flushed with 100% outside air for one to three days. i. Air Filters: Replace all filtration media immediately at the conclusion of the job. j. Monitoring Air Quality: Indoor air quality monitoring will be conducted randomly throughout the project. Results and any recommendations will be communicated through the building inspector to construction management. k. Pre-Construction Work Area Inspection: Any overhead work including roof, the Contractor shall conduct a pre room condition walk through with WCSD Facilities Management Representative to determine the level of cleanliness that will be expected at completion of project. Contractor shall be responsible for cleaning all exposed surfaces within the facility beneath the work area. At the completion of the project, the Contractor shall clean all exposed surfaces within the facility beneath the aforementioned work area including but not limited to all shelving, duct, lighting, flooring, furniture, etc. 25. LOCK OUT TAG OUT (LOTO) PROCEDURE: Contractor will be responsible for the isolation and termination of all building systems that may be impacted by the scope of work within this contract. Contractor will coordinate all shutdown processes with the construction manager prior to any shut downs up to and including Lock Out Tag Out procedures 24 hours prior to any shut downs. WCSD will make the final determination of which systems and location shall be isolated. All Lock Out Tag Out will be performed at main service panel. Date: 12/23/15; Rev. D PUR-F235 Page 10 of 13 21. PERSONNEL SAFETY CHECK APPLICATION: The awarded Vendor of this quote shall report to the WCSD all required information for every employee who will be on a WCSD sites. Please see “Exhibit 1” for requirements, instructions and application. 22. AWARD: WCSD’s intent is to award to one (1) vendor meeting the services outlined in the Special Terms and Conditions listed on pages 4 -10 of this quote and has submitted the lowest and most advantageous pricing identified on page 12 of this quote, along with being deemed as responsible, qualified, and capable to provide annual maintenance services and repairs as outlined above. Primary consideration for award will be based on the combined total of Items 1 and 2 of the QUOTE PRICE SCHEDULE/SPECIFICATION SHEET below. The secondary consideration will be the average combined total of Items 4 and 5. All other mitigating information provided on Items 3 and 6 will be considered based on the best interest of WCSD. This quote will be awarded on an “ALL OR NOTHING” basis. Date: 12/23/15; Rev. D PUR-F235 Page 11 of 13 Quote Title: Generator, Transfer Switch, Fire Pump and Industrial Engine Annual Maintenance and Repair Quote #: PH-1071-16 -------------------------------------------------------------------------------------------------------------------------------------------QUOTE PRICE SCHEDULE / SPECIFICATION SHEET -------------------------------------------------------------------------------------------------------------------------------------------Scheduled Annual Maintenance Pricing: Please provide the annual cost for Minor and Major inspections to be performed as scheduled once per year. ITEM 1 2 DESCRIPTION/SPECIFICATION Minor Inspection, performed 1 time annually Major Service, oil & filters performed 1 time annually ANNUAL COST $ $ Unscheduled/Emergency Maintenance Mileage/Labor Rate Pricing: Please provide mileage, standard and non- standard hourly rates for unscheduled /emergency maintenance up to and including repairs. Standard and non-standard rates are defined as: *Standard Hourly Rate defined as between the hours of 8:00 A.M. to 5:00 P.M. ** Non-Standard Hourly Rate defined as any hours outside of the Standard Hourly Rate including Saturday and Sunday. ITEM 3 4 5 DESCRIPTION/SPECIFICATION Mileage Rate Standard Hourly Service Rate (per service, per person) * Emergency Hourly Service Rate (per service, per person) ** MILEAGE/HOURLY RATE $ $ $ Unscheduled/Emergency Maintenance Parts Discount Schedule: Please provide discount from list pricing for any parts required due to unscheduled or emergency maintenance up to and including repairs. ITEM 6 DESCRIPTION/SPECIFICATION Discount from list price for parts replacement requirements % DISCOUNT Vendor Name: _____________________________________________________________________________ Date: 12/23/15; Rev. D PUR-F235 Page 12 of 13 Quote Title: Generator, Transfer Switch, Fire Pump and Industrial Engine Annual Maintenance and Repair Quote #: PH-1071-16 23. EXCEPTIONS TO THE TERMS, CONDITIONS AND SPECIFICATIONS: Exceptions to the Terms, Conditions and Specifications of this RFQ must be noted in the space provided. Failure to note said exceptions shall be interpreted to convey that Vendor shall propose to perform in the manner described and/or specified. If more space is required, please attach additional sheet(s) referencing RFQ Title and Number. This form must be signed regardless if exceptions are noted. __________________________________________________________________________________________________ __________________________________________________________________________________________________ __________________________________________________________________________________________________ __________________________________________________________________________________________________ __________________________________________________________________________________________________ __________________________________________________________________________________________________ __________________________________________________________________________________________________ __________________________________________________________________________________________________ __________________________________________________________________________________________________ 24. RFQ SIGNATURE & DELIVERY: In compliance with this RFQ and subject to all the terms and conditions thereof, the undersigned authorized agent offers and agrees, if this quote is accepted to furnish any or all of the items herein at the prices, terms and delivery stated. Company Name: __________________________________________________________________________________ Address: _________________________________________________________________________________________ City: ____________________________________ State: ________________________ Zip Code: ________________ Phone: _______________________________ Fax: __________________________________ Company E-Mail Address: ___________________________________________________________________________ Delivery will be completed within: _______________________ Payment Terms________________________________ ________________________________________________________________________________________________ Authorized Agent Signature ________________________________________________________________________________________________ Authorized Agent Name (Printed) ________________________________________________________________________________________________ Title ___________________________________________________________ Date ________________________________ Direct Email Date: 12/23/15; Rev. D PUR-F235 Page 13 of 13 EXHIBIT 1 Exhibit 2 WASHOE COUNTY SCHOOL DISTRICT MATERIAL, WATER, AND LEAD DISTURBANCE PERMIT FACILITY AND MATERIAL LOCATION: Districtwide Disturbance Permit – TBD DESCRIPTION OF WORK TO BE PERFORMED: Emergency Generator Service IT IS THE RESPONSIBILITY OF THE CONTRACTOR/WORKER TO IDENTIFY MATERIAL TYPE PRIOR TO DISTURBANCE. ONLY MATERIALS LISTED ON THIS PERMIT MAY BE DISTURBED. ANY NEW MATERIAL DISCOVERED OR ANY MATERIAL WHOSE EXACT NATURE OR CHARACTER IS UNCERTAIN REQUIRES A NEW PERMIT PRIOR TO DISTURBANCE. CITATIONS/ASBESTOS CONTAMINATION RESULTING FROM THE IMPROPER OR UNAUTHORIZED DISTURBANCE OF ASBESTOS MATERIALS IS SOLELY THE RESPONSIBILITY OF THE CONTRACTOR. A COPY OF THIS PERMIT MUST BE SIGNED BY THE CONTRACTOR AND SUBMITTED TO THE DISTRICT. THIS PERMIT IS ISSUED TO CONTRACTORS FOR REPAIR TYPE SERVICES WHERE BUILDING MATERIALS ARE NOT SLATED FOR DISTURBANCE. IF MATERIALS LISTED AS ASBESTOS CONTAINING ON THIS PERMIT REQUIRE DISTURBANCE THIS PERMIT CANNOT BE USED AND A NEW SITE SPECIFIC PERMIT MUST BE ISSUED FOR THAT PROJECT PRIOR TO STARTING THE PROJECT – NO EXCEPTIONS! ITEM #1 MATERIAL DESCRIPTION: GYPSUM BOARD BUILDING SYSTEM (SHEETROCK) AHERA MATERIAL NUMBER: M-01 & M-01A CONTAINS ASBESTOS ?: YES/NO MATERIAL DISTURBANCE INSTRUCTIONS: DO NOT DISTURB, KNOWN TO CONTAIN ASBESTOS. IF THIS MATERIAL MUST BE DISTURBED AN UPDATED, A SPECIFIC DISTURBANCE PERMIT MUST BE REQUESTED AND RECEIVED PRIOR TO ANY DISTURBANCE TO THIS MATERIAL. LEAD REQUIREMENTS LEAD PAINT AND COATING REQUIREMENTS ARE LISTED IN THE LAST SECTION OF THIS PERMIT. ITEM #2 MATERIAL DESCRIPTION: BLOCK/CONCRETE AHERA MATERIAL NUMBER: M-02 KNOWN TO CONTAIN ASBESTOS ?: NO MATERIAL DISTURBANCE INSTRUCTIONS: DO NOT DISTURB, KNOWN TO CONTAIN ASBESTOS. IF THIS MATERIAL MUST BE DISTURBED AN UPDATED, A SPECIFIC DISTURBANCE PERMIT MUST BE REQUESTED AND RECEIVED PRIOR TO ANY DISTURBANCE TO THIS MATERIAL. ITEM #3 MATERIAL DESCRIPTION: METAL BUILDING MATERIALS AHERA MATERIAL NUMBER: M-03 KNOWN TO CONTAIN ASBESTOS ?: NO MATERIAL DISTURBANCE INSTRUCTIONS: OK TO DISTURB. ITEM #4 MATERIAL DESCRIPTION: TRANSITE WALL/WINDOW PANELS AHERA MATERIAL NUMBER: M-04 KNOWN TO CONTAIN ASBESTOS ?: YES MATERIAL DISTURBANCE INSTRUCTIONS: DO NOT DISTURB. ABSOLUTELY NO DISTURBANCE IS AUTHORIZED. POSITIVE ID OF ALL MATERIALS MUST BE MADE PRIOR TO DISTURBANCE. TRANSITE IS A MATERIAL MADE OF ASBESTOS AND CONCRETE. PAGE #1 OF 11 WASHOE COUNTY SCHOOL DISTRICT MATERIAL, WATER, AND LEAD DISTURBANCE PERMIT CONTINUATION PAGE ITEM #5 MATERIAL DESCRIPTION: GLASS AHERA MATERIAL NUMBER: M-05 CONTAINS ASBESTOS ?: NO MATERIAL DISTURBANCE INSTRUCTIONS: OK TO DISTURB. ITEM #6 MATERIAL DESCRIPTION: WINDOW PUTTY AHERA MATERIAL NUMBER: M-07 KNOWN TO CONTAIN ASBESTOS ?: YES MATERIAL DISTURBANCE INSTRUCTIONS: DO NOT DISTURB, KNOWN TO CONTAIN ASBESTOS. IF THIS MATERIAL MUST BE DISTURBED AN UPDATED, A SPECIFIC DISTURBANCE PERMIT MUST BE REQUESTED AND RECEIVED PRIOR TO ANY DISTURBANCE TO THIS MATERIAL. ITEM #7 MATERIAL DESCRIPTION: WOOD BUILDING PRODUCTS AHERA MATERIAL NUMBER: M-06 CONTAINS ASBESTOS ?: NO MATERIAL DISTURBANCE INSTRUCTIONS: OK TO DISTURB. ITEM #8 MATERIAL DESCRIPTION: WOOD/METAL DOOR AHERA MATERIAL NUMBER: M-08 KNOWN TO CONTAIN ASBESTOS ?: YES MATERIAL DISTURBANCE INSTRUCTIONS: DO NOT DISTURB, ALL DOORS SUSPECTED FIRE DOORS. DO NOT DISTURB THE INTERNAL SECTION OF THE DOOR. OK TO DISCONNECT/INSTALL HARDWARE ON WOOD/METAL PORTIONS OF THE DOOR. IF ANY MATERIAL OTHER THAN WOOD OR METAL IS OBSERVED IMMEDIATELY DISCONTINUE DISTURBANCE, AND REPORT THIS TO THE FACILITIES ANALYST/PROJECT MANAGER. ITEM #9 MATERIAL DESCRIPTION: CEILING TILE AHERA MATERIAL NUMBER: M-10 KNOWN TO CONTAIN ASBESTOS ?: YES MATERIAL DISTURBANCE INSTRUCTIONS: DO NOT DISTURB, KNOWN TO CONTAIN ASBESTOS. IF THIS MATERIAL MUST BE DISTURBED AN UPDATED, A SPECIFIC DISTURBANCE PERMIT MUST BE REQUESTED AND RECEIVED PRIOR TO ANY DISTURBANCE TO THIS MATERIAL. PAGE #2 OF 11 WASHOE COUNTY SCHOOL DISTRICT MATERIAL, WATER, AND LEAD DISTURBANCE PERMIT CONTINUATION PAGE ITEM #10 MATERIAL DESCRIPTION: FLOOR TILE AND MASTIC AHERA MATERIAL NUMBER: M-12 KNOWN TO CONTAIN ASBESTOS ?: YES MATERIAL DISTURBANCE INSTRUCTIONS: DO NOT DISTURB, KNOWN TO CONTAIN ASBESTOS. IF THIS MATERIAL MUST BE DISTURBED AN UPDATED, A SPECIFIC DISTURBANCE PERMIT MUST BE REQUESTED AND RECEIVED PRIOR TO ANY DISTURBANCE TO THIS MATERIAL. ITEM #11 MATERIAL DESCRIPTION: SHEET VINYL AND MASTIC AHERA MATERIAL NUMBER: M-14 KNOWN TO CONTAIN ASBESTOS ?: YES MATERIAL DISTURBANCE INSTRUCTIONS: DO NOT DISTURB, KNOWN TO CONTAIN ASBESTOS. IF THIS MATERIAL MUST BE DISTURBED AN UPDATED, A SPECIFIC DISTURBANCE PERMIT MUST BE REQUESTED AND RECEIVED PRIOR TO ANY DISTURBANCE TO THIS MATERIAL. ITEM #12 MATERIAL DESCRIPTION: CARPET AND MASTIC AHERA MATERIAL NUMBER: M-15 KNOWN TO CONTAIN ASBESTOS ?: YES MATERIAL DISTURBANCE INSTRUCTIONS: DO NOT DISTURB, KNOWN TO CONTAIN ASBESTOS. IF THIS MATERIAL MUST BE DISTURBED AN UPDATED, A SPECIFIC DISTURBANCE PERMIT MUST BE REQUESTED AND RECEIVED PRIOR TO ANY DISTURBANCE TO THIS MATERIAL. ITEM #13 MATERIAL DESCRIPTION: ASBESTOS PIPE INSULATION AHERA MATERIAL NUMBER: T-40 KNOWN TO CONTAIN ASBESTOS ?: YES MATERIAL DISTURBANCE INSTRUCTIONS: ABSOLUTELY NO DISTURBANCE. EXTREME CARE MUST BE TAKEN WHEN WORKING AROUND ASBESTOS PIPE INSULATION TO ENSURE THAT NO DAMAGE TO THIS MATERIAL RESULTS. ITEM #14 MATERIAL DESCRIPTION: FIBERGLASS PIPE INSULATION AHERA MATERIAL NUMBER: T-41 CONTAINS ASBESTOS ?: NO MATERIAL DISTURBANCE INSTRUCTIONS: OK TO DISTURB HOWEVER IF HARD ELBOWS ARE ENCOUNTERED THESE CANNOT BE DISTURBED. HARD ELBOW CONTAIN ASBESTOS. PAGE #3 OF 11 WASHOE COUNTY SCHOOL DISTRICT MATERIAL, WATER, AND LEAD DISTURBANCE PERMIT CONTINUATION PAGE ITEM #15 MATERIAL DESCRIPTION: BOILER TANK INSULATION AHERA MATERIAL NUMBER: T-42 KNOWN TO CONTAIN ASBESTOS ?: YES MATERIAL DISTURBANCE INSTRUCTIONS: ABSOLUTELY NO DISTURBANCE. EXTREME CARE MUST BE TAKEN WHEN WORKING AROUND ASBESTOS PIPE INSULATION TO ENSURE THAT NO DAMAGE TO THIS MATERIAL RESULTS. ITEM #16 MATERIAL DESCRIPTION: PLUMBING/MECHANICAL GASKETS AHERA MATERIAL NUMBER: N/A CONTAINS ASBESTOS ?: YES MATERIAL DISTURBANCE INSTRUCTIONS: DO NOT DISTURB, KNOWN TO CONTAIN ASBESTOS. IF THIS MATERIAL MUST BE DISTURBED AN UPDATED, A SPECIFIC DISTURBANCE PERMIT MUST BE REQUESTED AND RECEIVED PRIOR TO ANY DISTURBANCE TO THIS MATERIAL. ITEM #17 MATERIAL DESCRIPTION: ROOFING MATERIALS AHERA MATERIAL NUMBER: N/A KNOWN TO CONTAIN ASBESTOS ?: YES MATERIAL DISTURBANCE INSTRUCTIONS: DO NOT DISTURB, KNOWN TO CONTAIN ASBESTOS. IF THIS MATERIAL MUST BE DISTURBED AN UPDATED, A SPECIFIC DISTURBANCE PERMIT MUST BE REQUESTED AND RECEIVED PRIOR TO ANY DISTURBANCE TO THIS MATERIAL. NOTE: THE MATERIAL DISTURBANCE INSTRUCTIONS LISTED ABOVE ARE BASED ON THE AHERA REGULATION. THERE MAY EXIST OTHER REGULATIONS THAT MAY BE MORE STRINGENT THEN THESE RECOMMENDATIONS. IT IS THE RESPONSIBILITY OF THE CONTRACTOR TO ENSURE COMPLIANCE WITH ALL REGULATIONS THAT ARE APPLICABLE TO THE DISTURBANCE OF ASBESTOS CONTAINING MATERIALS. ASBESTOS IS A MICROSCOPIC FIBER AND THE CLEANING OF ASBESTOS DEBRIS MUST BE CONDUCTED TO A MICROSCOPIC LEVEL. IN THE EVENT THAT ANY VISIBLE DEBRIS IS DISCOVERED FROM A DISTURBANCE OR AIR SAMPLING RESULTS ARE NOT PROVIDED TO THE DISTRICT, THE DISTRICT WILL IMMEDIATELY HIRE A THIRD PARTY ASBESTOS CONSULTANT TO INVESTIGATE POSSIBLE ASBESTOS CONTAMINATION AND AN ASBESTOS ABATEMENT CONTRACTOR TO PERFORM ANY RECOMMENDED CLEAN-UP. THE CONTRACTOR WILL BE REQUIRED TO REIMBURSE THE DISTRICT FOR ALL COSTS INCURRED. IF AIR MONITORING IS REQUIRED, AIR MONITORING MUST BE CONDUCTED THROUGHOUT THE PROJECT. DATE ISSUED: January 20, 2016 MANAGEMENT PLANNER: JOHN NOLAN SIGNATURE: PAGE #4 OF 11 WASHOE COUNTY SCHOOL DISTRICT MATERIAL, WATER, AND LEAD DISTURBANCE PERMIT CONTINUATION PAGE RS&A Department Disturbance Permit, Water System Disturbance Permit Appendix – Page #1 Contractors, their sub-contractors or workers are responsible in completing all work without impacting the water quality of District facilities and the domestic water supplies which feed district facilities. This Water System Disturbance Permit identifies the minimum requirements that Contractors, their sub-contractors and all workers will utilize to perform disturbance to the Districts water systems. The following general requirements shall apply to any person who will be disturbing a District water system. In addition, they must contact the Regulated Systems and Assessment Department (RS&A Dept) prior to any disturbance at 851-5675. This phone number has an answering machine and can be accessed 24 hours a day. These disturbances will be logged in and documented by the RS&A department. All requirements for isolation are designed to protect the facility's potable water source from existing as well as potential cross-connections and to prevent any backflow occurrences in the form of backpressure or backsiphonage. The Water Disturbance Procedures listed are not site or incident specific and great care must be taken by technicians during all valving and isolation activities within a facility to prevent a potential backflow occurrence. There may be additional requirements that must be utilized to prevent any cross-connection or backflow occurrence, and each entity performing the disturbance is responsible for ensuring none occur and utilizing any additional steps as necessary to ensure none result from the completion of this project. Any costs to correct any cross-connections and/or any backflow occurrences that result from the performance of this project are solely the responsibility of the Contractor, their sub-contractor and workers and the signing of this RS&A Department Disturbance Permit on acknowledges and agrees to this requirement. FACILITY ISOLATION MINIMUM REQUIREMENTS MECHANICAL ROOMS: When turning off or disrupting the water service to a mechanical room all applicable requirements below must be conducted per this permit 1. 2. 3. 4. 5. 6. 7. Remove all hoses from custodial faucets and bibs in location to be effected. Shut down all boiler and chiller circulating pumps. Heating, Cooling and Domestic. Shut down boiler, chiller and cooling tower if present. Isolate boiler, cooling tower, chiller and relieve pressure from boiler. Shut down hot water return pump, isolate any hot water heaters and turn off heating source. Isolate domestic service to mechanical room. Re-establish service to mechanical room in reverse order. BASIC WING: When turning off or disrupting the water service to a facility wing all applicable requirements below must be conducted per this permit 1. 2. 3. 4. 5. Remove all hoses from custodial, art and science faucets along with bibs in location to be effected. Isolate all water utilizing chemical dispensers in location to be effected. Shut down and isolate any water using equipment if applicable. Hot water heaters, domestic make ups for heat exchangers, photo labs, etc. Isolate domestic cold water main to wing. Re-establish service to wing in reverse order. Flush system at the end of each lateral to remove any and all foreign material and air. PAGE #5 OF 11 WASHOE COUNTY SCHOOL DISTRICT MATERIAL, WATER, AND LEAD DISTURBANCE PERMIT CONTINUATION PAGE RS&A Department Disturbance Permit, Water System Disturbance Permit Appendix – Page #2 FACILITY: When turning off or disrupting the water service to a facility all applicable requirements below must be conducted per this permit. Turning off or disturbing the waters services to a facility should only be done as a last resort. If it is possible to isolate the area of disturbance without disrupting facilities entire water service that is the way the project is to be accomplished. This will also keep the contractor, his sub-contractors or workers from having to perform all the listed requirements. 1. 2. 3. 4. 5. 6. Remove all hoses from custodial, art and science faucets along with bibs in entire facility. Isolate mechanical room. See above requirements. Isolate each individual wing where possible. See above requirements. Isolate all irrigation laterals connected to the domestic potable water supply. Isolate domestic cold water main at all locations present to allow as little drain back as possible. Re-establish service to facility in reverse order. Flush system at the end of each lateral to remove any foreign material and air. PAGE #6 OF 11 WASHOE COUNTY SCHOOL DISTRICT MATERIAL, WATER, AND LEAD DISTURBANCE PERMIT CONTINUATION PAGE PAINTS AND COATINGS – Material Disturbance Permit Appendix - Lead in Paints and Coatings in WCSD Facilities Lead containing paints and coating are present in WCSD facilities. Bidders/Contractors that disturb lead containing or potentially lead containing paints or coatings, by law, are required to know all applicable regulations applicable and comply with all state and federal regulations that apply to the disturbances to lead paints and coating they are conducting. The regulations that it is recommended by the District for a contractor to be properly trained and knowledgeable, related to lead disturbance includes, but is not limited to the following: OSHA Regulation CFR 1926.62 – Lead & Appendix A, B, C, & D – Lead Construction Standard. OSHA Regulation CFR 1910. 1025 - Lead & Appendix A, B, C, & D – General Industry Standard. EPA, 40 CFR Part 745 – Lead; Renovation, Repair, and Painting Regulation. Bidders/Contractors accept and acknowledge by signing this Material Disturbance Permit, the existence of lead related regulations, and accept all liability related to the disturbance of lead containing materials, citation resulting from, or any other costs the District may incur by the action of all parties of the bidders company or companies hired by the successful bidder to complete this project. Construction Age of buildings at this facility Since this permit is being issued district-wide the year of construction is not know so the contractor must comply with the requirements for lead category #1 listed below. Included is an overview of some of the known lead regulation requirements. While WCSD had done its best to identify, what we believe to be some of the most important requirements, Bidders/Contractors are expected to be fully familiar with the applicable regulations. Omission of other requirements, not listed, in no way relieves the successful bidder from his responsibility to comply with all applicable regulations. LEAD CATEGORY #1 CATEGORY DESCRIPTION: PAINTS AND COATINGS – BUILDINGS CONSTRUCTED PRIOR TO 1978 CONTAINS LEAD?: YES/NO THE FOLLOWING BUILDINGS AT THIS FACILITY WERE CONSTRUCTED PRIOR TO 1978: Performing projects using this permit requires that the contractor must at all locations in the district, comply with the following requirements unless a site specific permit is received from the RS&A department. If lead issues impact this project then this permit is not the proper permit to use and a site specific material disturbance permit must be requested and received prior to conducting this project unless complying with all listed lead requirements. A large amount of paints and coatings contain some levels of lead. Due to the potential that there may be lead paints and coating in this facility, the contractor is required to treat all paints and coating in facilities constructed prior to 1978 as lead containing unless the suspect paints and coating has been found to be lead free. The process to determine a paint or coating is lead free must be done by laboratory analysis of a bulk sample, performed by a District approved lead professional. Wipe samples or XRF sampling alone, without the bulk samples to confirm a paint or coating does not contain lead, will not be allowed so as to be in compliance with OSHA lead regulations. Sampling costs are to be paid for by the successful Bidder/Contractor unless available sampling data is listed below. No additional District paid sampling will be conducted. – CONTINUED SEE NEXT PAGE #5 PAGE #7 OF 11 WASHOE COUNTY SCHOOL DISTRICT MATERIAL, WATER, AND LEAD DISTURBANCE PERMIT CONTINUATION PAGE LEAD CATEGORY #1 CATEGORY DESCRIPTION: PAINTS AND COATINGS – BUILDINGS CONSTRUCTED PRIOR TO 1978 CONTAINS LEAD?: YES/NO – CONTINUED FROM PAGE #6: Lead Containing or Assumed Lead Containing Paints and Coatings Disturbance Instructions: OSHA Requirements All persons performing any disturbance to coatings or paints to paints and coating in and on the buildings listed above must have taken an OSHA lead action level training class from a WCSD, RS&A department approved training provider, and utilize lead safe work practices. In addition, all work must be completed, as a minimum, utilizing the lead safe work practices identified in the EPA guidance document titled “steps to lead safe renovation, repair and painting”, pages 12 thru 23. This document is available electronically at the following link: HTTP://WWW.EPA.GOV/LEAD/PUBS/STEPS.PDF. EPA Renovation, Repair and Painting Regulation Requirements In general, all firms that disturb 6 square feet of painted surface in a room or 20 square feet on the exterior within a 30 day period in this facility must comply with the EPA’s Renovation, Remodel and Repair (RR&P) regulation and must be registered with the federal EPA. Per the Regulation, the area of disturbance is calculated, by adding up the entire surface areas being removed/disturbed, which then determines the amount of painted surface area disturbed. Work that involves window replacement or demolition of a painted surface, the RR&P regulation applies regardless of size. This regulation also requires that the contractor must assign a RR&P trained supervisor that is responsible for ensuring and documenting all work is conducted in compliance with the RR&P regulation and there are extensive record keeping and notification requirements that the Contractor must perform. In addition, This is a general overview of the regulation and the contractor must refer to regulation for additional requirements and information. Fines are expensive and the compliance with this regulation rests solely on the Contractor so it is very important that Bidders/Contractors are well versed in this regulation. WCSD Requirements In addition to regulatory requirements, the WCSD has requirements that must be met by the Contractor/Bidder. The contractor is responsible for submitting to the RS&A department lead disturbance procedures that outline the lead safe work practices to be utilized and that procedure must comply with the Districts minimum lead disturbance requirements. The current minimum lead disturbance requirements, which will apply to this project, follow these tables. OSHA action level training and RR&P training certification and RR&P firm certification must be submitted to the project manager and they are to submit a copy to the RS&A department. The RS&A department must review, verify, and approve all required documentation prior to the contractor being able to perform any disturbance, so time for review must be taken into account when developing schedules. Once the RS&A department has approved the procedures and training and firm certification, the contractor may proceed but they must notify the RS&A department at 851-5675 of any paint/coating disturbance immediately disturbance prior to the disturbance. RS&A department personnel, project managers and assistant project managers and other district personnel will spot check in the field, to ensure compliance with the contractors submitted and approved procedures. Lead Samples Available: Refer to section listed below regarding lead sampling that may be available. Lead Samples Available: The school district has a limited number of lead surveys that have been done of our facilities. A site specific permit will take the site specific age of construction and sampling to clarify lead issues but cannot be addressed on this District wide permit. If lead issues impact this project then this permit is not the proper permit to use and a site specific material disturbance permit must be requested and received prior to conducting this project unless complying with all listed lead requirements. PAGE #8 OF 11 WASHOE COUNTY SCHOOL DISTRICT MATERIAL, WATER, AND LEAD DISTURBANCE PERMIT CONTINUATION PAGE Replacement Paints and Coating The Contractor shall not reinstall any lead containing paints/coatings in any detectable levels during the process of completing this project. “lead containing” is defined as any paint or coating that has ANY detectable lead level when paint chip sampling is conducted and chip is analyzed by atomic absorption spectroscopy EPA 3050B digestion / EPA 7420 Analysis methods. The District may perform sampling of replacement materials and if analysis finds any detectable levels of lead, the Contractor will be liable for all costs to properly remove that material and re-apply paints and coatings with no detectable levels of lead. Contractors are encouraged to pre-sample paints they may be using to determine the actual amount in paint/coatings used. PAGE #9 OF 11 WASHOE COUNTY SCHOOL DISTRICT MATERIAL, WATER, AND LEAD DISTURBANCE PERMIT CONTINUATION PAGE Minimum Requirements to Perform an Asbestos/Lead Paint or Assumed Asbestos/Lead Paint Disturbance in the Washoe County School District – No Exceptions Below are the minimum requirements required to perform any disturbance to asbestos/lead-containing or assumed asbestos/leadcontaining paint or coating within the WCSD. Additional steps beyond the minimum requirements may be necessary to comply with all applicable regulations. Each contractor is required to develop a procedure that complies with all applicable regulations as well as developing a procedure that includes all items listed below. To simplify the procedure development process, electronic copies of these requirements are available upon request by calling 851-5675. Contractors may utilize the electronic template provided to make company specific modifications and print it out on their company letterhead, sign, and date the procedure. 1. Contractors must have a copy of their approved asbestos/lead paint or assumed asbestos/lead paint disturbance procedure and a copy of the material disturbance permit on site at all times. The Contractor must submit their procedures for review to the Regulated Systems and Assessment Department (RS&A) and the RS&A department must approve all asbestos/lead paint or assumed asbestos/lead paint disturbance procedures prior to performing any disturbance. A procedure will be submitted for asbestos materials and a separate procedure will be submitted for lead. Procedures must be approved by the RS&A department prior to starting any disturbance. A minimum of one work day will required by the RS&A department for the review and approval process. 2. A site-specific asbestos/lead paint or assumed asbestos/lead paint disturbance procedure may be submitted to the RS&A Department or a blanket procedure may be submitted. A blanket procedure will apply at all future sites where a contractor will be performing disturbances and a site specific procedure will apply to just one site or project. Each procedure will identify clearly if it is a blanket or site-specific procedure. If a site specific procedure is submitted, that procedure will expire at the end of the identified project and a new procedure must be submitted for any future project. Procedures will be filed and maintained at the RS&A Department. Contractors are also required to provide a copy of their procedures to their assigned WCSD Construction Department Project managers and assistant Project managers. Contractors must ensure that their procedure has been approved, and is on file prior to any disturbance. 3. Technicians performing disturbances will be required to have a minimum of AHERA 16 Hour O&M training and OSHA action level training per 29 CFR 1926.62 (i) (2) lead training. In addition, as applicable, contractors must comply with the EPA RR&P training and certifications requirements listed in the RR&P section of this appendix. Copies of training certifications, including a refresher within the last 12 months, will be provided to the RS&A Department prior to the start of any project. Only personnel with the proper minimum training will be authorized to perform any disturbance to asbestos/lead paint or assumed asbestos/lead paint containing materials, or be in the adjacent area of a disturbance. 4. Notify the RS&A Department at 851-5675 with the time, name of the technician doing the work, date and exact locations in the school where they will be performing any disturbance. This call should take place immediately prior to disturbance and this phone number (851-5675) has an answering machine and contractors will provide notifications with above identified information, 24 hours a day. The Contractor is also required to notify their assigned WCSD Construction Department Project Managers and Assistant Project Managers of scheduled disturbances so they can also verify compliance with the contractors approved disturbance procedures. 5. Contractors must refer to the Material disturbance permit to determine what materials contain asbestos or lead and utilize the applicable lead/asbestos procedures. Some materials cannot be disturbed and each specific material disturbance permit will identify what can be disturbed and provided material disturbance instructions. The minimum disturbance permits in this section of the material permit are in addition to requirements listed in the material disturbance instructions. Any instance where 100% of the minimum asbestos/lead requirements are not followed the contractor will immediately hire an environmental remediation contractor as well as an environmental consultant to properly clean up the contamination and perform air sampling. The contractor will be responsible for reimbursing the District for all costs due to any improper or unauthorized disturbances. 6. Contractors or technicians who are new to performing asbestos/lead paint or assumed asbestos/lead paint disturbances for the District must contact the RS&A Department and schedule a disturbance. A RS&A employee will be scheduled to review the technician’s compliance with disturbance procedures in the field. Once a technician has demonstrated to the RS&A Department that he has an understanding of the District disturbance requirements and proper equipment, the RS&A Department will then authorize that technician to perform disturbances without prior approval of the RS&A Department. Notifications prior to starting all disturbances as listed above will still be required and technicians should expect unannounced random compliance inspections. PAGE #10 OF 11 WASHOE COUNTY SCHOOL DISTRICT MATERIAL, WATER, AND LEAD DISTURBANCE PERMIT CONTINUATION PAGE 7. Post the appropriate “Danger Lead - Keep Out” or “Danger Asbestos Keep Out” signs on the entry side of all doors leading into classroom, hallway, bathroom, office or mechanical room where drilling is to occur. It is the contractor’s/technician’s responsibility to take adequate means to keep the public or school staff out of the disturbance area. 8. Large rooms, such as multipurpose rooms, will have yellow caution tape placed across all entries to the room in addition to signage. 9. A 6 ml plastic drop will be placed under the disturbance in a manner that extends 6’ out in all directions from the disturbance area. This poly drop can be reused if properly wet-wiped or HEPA-vacuumed off after use. 10. Worker will don the respiratory protection and a protective suit and initiate personal air monitoring procedures. Air monitoring, respiratory protection and protective suits is required throughout all asbestos/lead paint or assumed asbestos/lead paint disturbances in WCSD. 11. Drill hole or holes as required using HEPA VAC and PVC attachments encasing drill bit. The drill bit will pass through PVC fitting during drilling (or Bit Buddy), and then be removed from the hole and still remain in the PVC fittings. A HEPA VAC is to remain running during this whole process to ensure all debris is cleared from hole and PVC. All clean-up must be conducted the HEPA Vacuum. If a contractor fails to properly control the asbestos/lead containing dust, the District will then hire an environmental remediation contractor as well as an environmental consultant to properly clean up the contamination. The contractor will be responsible for reimbursing the District for all costs due to improper disturbances that result in debris exiting the area of disturbance. 12. If required, to be determined by the technician, an encapsulant material may be sprayed or brushed on to the area of the holes. 13. A device, backing, box or raceway or other equipment will then be mounted using anchors installed per #11 above with the HEPA VAC running and properly directed at the area of the disturbance. 14. A HEPA VAC or wet methods will be used to clean up any debris on 6ml poly drop, around device box, technician’s suit, and any surfaces below holes, such as tops of chalkboards and base board. 15. The poly drop, if utilized, will be folded into itself in such a manner as to not spread any debris, the HEPA vacuum hose sealed, and personal air monitoring time logged appropriately. This poly drop can be reused if it is properly wet-wiped or HEPA-vacuumed off after use. 16. All signs and equipment are to be removed, and technician is to move to the next location. The contaminated suit should be removed and a new suit utilized at the new disturbance location, unless the suit can be properly decontaminated. 17. Upon completion of a shift, air samples will be dated and sent in to a properly accredited lab to be analyzed. Results will be forwarded to WCSD. Lab results will be faxed directly from the lab to the RS&A Department at 851-5695 within 48 hours of the disturbance. All lab results will reference the disturbance log tracking number. Results without a number will be returned to the lab for clarification and the addition of the tracking number. 18. All debris, waste, poly drop, suits, etc. will be disposed of properly. THE UNDERSIGNED AGREES TO COMPLY WITH THE CONDITIONS OF THIS MATERIAL, WATER & LEAD DISTURBANCE PERMIT, APPENDIXES, & ALL APPLICABLE REGULATIONS. UNDERSIGNED ACKNOWLEDGES LIABILITY FOR ANY COSTS THE DISTRICT MAY INCUR TO INVESTIGATE & CLEAN UP ANY DISCOVERY OF IMPROPER AND/OR UNAUTHORIZED DISTURBANCES DONE BY UNDERSIGNED’S EMPLOYEE(S) OR SUBCONTRACTOR(S) TO MATERIALS LISTED AS LEAD/ASBESTOS-CONTAINING BY THE DISTRICT. IN ADDITION THE UNDERSIGNED AGREES TO ALL REQUIREMENTS OF THE WATER & LEAD APPENDIX. SIGNED BY (PRINT): ______________________________SIGNATURE:______________________________ COMPANY (PRINT):_______________________________ DATE RECEIVED:_____________ PAGE #11 OF 11