Daikin Rebel Rooftop Systems Catalog

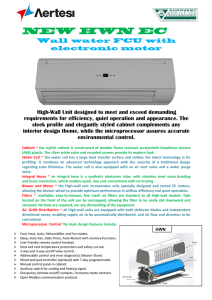

advertisement