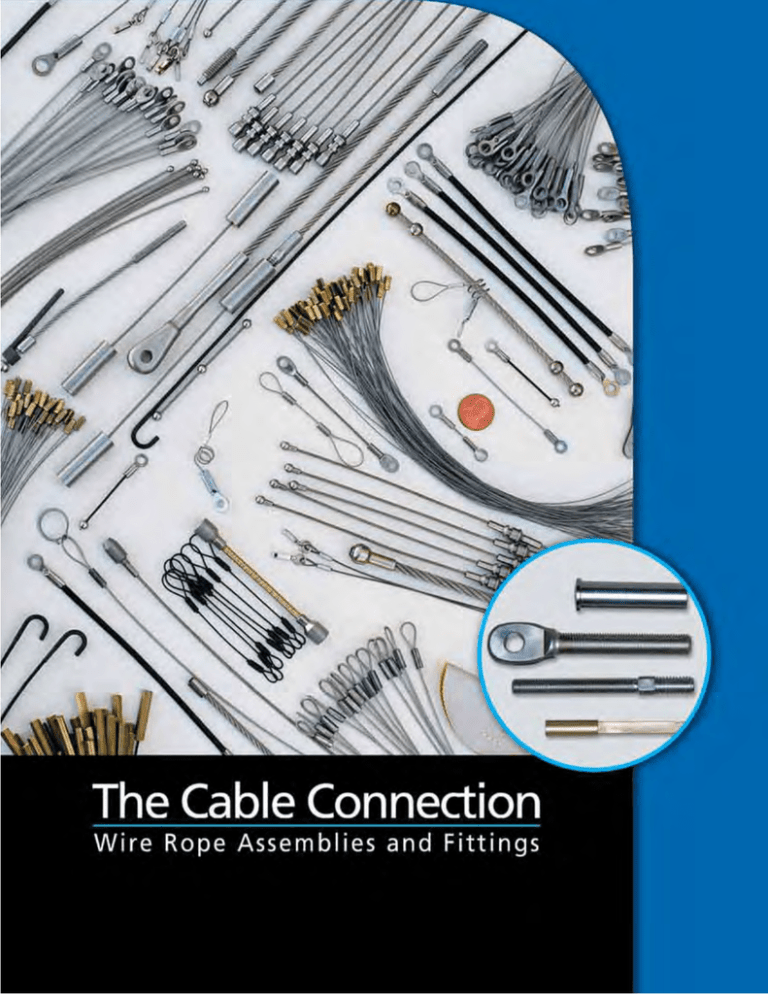

Assemblies

and Fittings

Catalog

Volume 2

52 Heppner Drive • Carson City, Nevada 89706

800.851.2961 • 775.885.1443 • Fax: 775.885.2734

Website: www.thecableconnection.com

E-mail: info@thecableconnection.com

r Drive

52 Heppne

V 89706

N

y,

it

C

Carson

88

) 5-1443

Phone: (775

5-2734

)

Fax: (775 88

rope

n in the wire

als have bee

p

ci

n

ri

p

s

It

under cable

in 1991.

iameter and

established

d

”

as

½

w

n

in

o

ti

ts

ialis

onnec

sses

become spec

many proce

The Cable C

es and have

d developed

ad

an

ec

h

d

it

e

w

re

ar

th

ty

e famili

ur abili to

business for

e result is o

have becom

e

Th

W

e.

s.

liz

g

ti

u

in

tt

d fi

yet to

s.

etitive price

e field have

assemblies an

highly comp

y others in th

g

at

y

lo

it

o

n

al

u

ch

q

te

r

perio

and uses of

roducts of su

in

mers with p

o

st

cu

r

u

tion to assist

o

e

provid

able Connec

C

e

th

le

hin

ab

w

ilities en

supplied it

eering capab

enerally be

g

in

g

n

en

ca

d

es

p

an

esign

Prototy

Innovative d

en needed.

opment wh

el

ev

d

d

an

parts design

art

f drawings.

of receipt o

rve set us ap

a few days

gerness to se

ea

an

d

o

an

w

s

method

stomers h

production

ith many cu

d

w

s

ce

ip

n

sh

va

n

ad

o

ilities,

t relati

joy excellen

endability.

Design capab

proud to en

ice and dep

e

rv

ar

se

e

y,

W

it

al

s.

u

er

on for q

from the oth

le Connecti

on The Cab

ly

re

onnection,

to

e

m

have co

The Cable C

h

it

w

s

es

n

si

w can

doing bu

we ask, “Ho

benefits of

e that when

iscover the

se

d

d

to

an

t

s

ye

u

e

contact

If you hav

y longer to

not wait an

ill

w

u

yo

e

I hop

mean it.

?” we really

we help you

Michaecehl elKy echely

Michael K

President

©2009 The Cable Connection, Carson City, Nevada. All rights reserved

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

Table of Contents

Information

Facilities and Capabilities ..................................................................................................... 2

Custom Design Services ...................................................................................................... 3

Choosing the Right Cable .................................................................................................... 4

Construction and Components of Strand and Cable (Wire Rope) .................. 6

Cable Stretch, Pre-stretching and Proof Testing ..................................................... 8

Wire Rope Jacket Specifications ..................................................................................... 9

Recommended Minimum Pulley Diameters ............................................................ 10

Summarized Military Specifications ............................................................................ 11

Products

Strand and Cable .................................................................................................................. 12

Eyelets ........................................................................................................................................ 16

Thimbles ................................................................................................................................... 18

Oval Swaging Sleeves ......................................................................................................... 19

Balls: Plain ................................................................................................................................ 20

Balls: with Shank and with Double Shank .................................................................. 21

Special Fittings — L and Z Fittings ................................................................................ 21

Cable Hangers ....................................................................................................................... 22

Eyes and Clevises.................................................................................................................. 23

Ferrules: Hex and Round Swaged ................................................................................ 24

Radiused Ferrules: Hex and Round Swaged............................................................ 25

Threaded Studs: Hex Swaged ........................................................................................ 26

Threaded Studs: Round Swaged ................................................................................... 28

259 Studs................................................................................................................................ 30

Round Swivel Sleeves (tapped)....................................................................................... 31

Male-Threaded Swivel Sleeves ....................................................................................... 32

Hex Swivel Sleeves (tapped) ............................................................................................ 33

Threaded Sleeves ................................................................................................................. 34

Special Fittings ....................................................................................................................... 35

Conduit and Conduit Swaged Fittings ......................................................................... 36

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

Facilities and Capabilities

Our production capabilities include the ability to machine

special fittings to meet your particular needs. State-ofthe-art CNC lathes and mills and efficient swaging and

assembly operations assure you high quality products at

the lowest possible cost.

Our ability to machine many of the fittings we

use in our own facilities offers many benefits to

our customers:

It helps us control costs, to provide you with the lowest

price possible.

We are in the process of obtaining ISO 9000/2001

certification, so you can be assured that your standards

and specifications are being met.

Special custom parts to meet your particular needs can

be produced especially for you, so you are not limited in

your product design to using only “off-the-shelf” fittings

provided by others.

Because we do not have to rely on outside sources

for machined parts, we are better able to control

production operations and provide you with reliable

delivery schedules.

Modern, versatile cutting and swaging operations allow

us to efficiently produce cable assemblies in large or

small quantities. You don’t necessarily have to order

large quantities to get a reasonable price.

Many cables can be cut on automated cutting

equipment, to reduce costs and maintain uniformity

in cut lengths.

Punch presses, hydraulic presses and rotary swagers

are available to swage fittings on your cables. The ability

to swage in different ways allows us to use the most

efficient method for your job, so we can keep your costs

to a minimum.

Other machining and assembly capabilities can help you

reduce your costs.

We can supply many other machined and stamped parts

used in conjunction with your cable assemblies.

Complete assembled units where the cables are a

sub-assembly component can be supplied, to reduce

the number of vendors required and eliminate the need

for your own assembly labor to make the complete

assembled unit.

2

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

Custom Design Services

There are several different ways we can help you design

a cable assembly to meet your particular requirements.

Chances are, we have manufactured cable assemblies

similar to yours in the past, so we can offer you the

benefit of this experience in the design of your product.

For instance, often our sales people are familiar with

a special fitting we have made for a similar use or

application in the past. Or, perhaps we can modify an

existing design or manufacture a new fitting to meet

your needs. Because we machine most of our own

fittings, we are not limited in design to off-the-shelf

terminals made by others.

We can make suggestions regarding the construction of

the strand or cable for your application. You can draw

on our experience to determine the right material for

your terminals. Prototypes can be made at modest cost,

and tests can be performed in our factory to verify that

your design meets necessary load requirements.

Let us put our experience and expertise to work for you.

To get started, you can request design assistance on

our website; or call us at 800-851-2961,

fax us at 775-885-2734, or e-mail us at

info@thecableconnection.com.

3

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

Choosing the Right Cable

1.

2.

The first thing to consider in choosing the right cable is

the kind of load to which the cable might be subjected.

Once this is determined, it is time to make an evaluation

of what kind of safety factor will be desired. In some

extreme cases the suggested safety factors are as high

as 10:1. Normally, the safety factors are 4:1 or 5:1 of the

minimum breaking strength of the cable being used.

The next step is to select a construction of cable.

EXAMPLE: Let’s say that you are going to hang

something that weighs 55 pounds from the ceiling of a

public building. If this item were to fall onto someone

below, it would certainly cause harm, or worse. The

minimum safety factor that you would want to consider

would be 5:1. Therefore 55 x 5 = 275. The minimum

breaking strength of the cable that you would select

would be in excess of 275 pounds.

You must also consider other factors to which the cable

might be subjected, such as the possibility of a shock

load in an earthquake or exposure to winds or blowing

air from ventilation systems. Cable is not recommended,

nor is it rated for shock loads. Unknown loads must

be determined by testing prior to determining which

cable to use. Determining the load that the cable will be

exposed to, and under what conditions, will enable us to

choose an appropriate diameter of cable.

Is the cable going to go over pulleys? If so, consult

the table regarding minimum recommended pulley

groove diameters (see page 10) to determine the

construction of cable most compatible to the pulley

diameter being used.

If the cable is not going over pulleys, it may still need

to be somewhat flexible. If moderate flexibility is

required (such as with a door retaining lanyard) a

7 x 7 construction will probably be adequate.

Maybe the cable is for guying purposes or being used

on a railing. In such cases a 1 x 19 construction is

normally preferred.

Our sales staff will be happy to help you determine

the proper construction of cable for your applications.

Sample assemblies are available at a nominal or no cost

in many cases.

The tables in the “Strand and Cable” section (pages

12-15) show breaking strengths for readily available

types of strand and cable.

4

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

3.

4.

The third step is choosing the correct cable composition.

The primary considerations in choosing the composition

of the cable are service life, environment, and cost.

The final consideration will be whether or not the cable

needs to be coated. Some of the most common reasons

to choose coated cable are:

Just because the cable is going to be exposed to the

elements outdoors does not mean that it should

necessarily be galvanized—such as wire rope used on

tow trucks. The service life of the cable is probably a year

or two at best. Unless you are in a severe environment,

the cable will not have an opportunity to significantly

deteriorate within the cable’s service life. There is no

need to use galvanized in this circumstance. Also, most

special purpose hoisting ropes, such as compacted ropes

and spin resistant ropes, are not available in galvanized.

(Although some sizes of spin resistant wire rope are

available in stainless steel.)

to increase the appearance of the size of the cable

to protect the cable from undesired substances

to offer the cable in a certain color for

aesthetic reasons

to protect the cable and/or the pulleys that the

cables are running over from abrasion

to reduce friction

If the answer is yes, it should be coated, please refer

to the few paragraphs concerning different types of

coatings in the “Construction and Components of

Strand and Cable” section (pages 6-7).

Non-galvanized wire rope is referred to as “bright”

and is usually coated with a petroleum based lube.

Galvanized aircraft cable is almost always used in smaller

diameter assemblies when stainless steel is not specified

(smaller being under 1/4” diameter).

Galvanized cable is normally adequate corrosion

protection for most conditions. Exceptions to this

statement include the following conditions or situations:

Applications close to a salt water or salt air

environment. This would include applications that

are exposed to winter salting of roads.

Environments of corrosive chemical exposure.

Applications such as food preparation and medical

products or any application that has a frequent

wash down.

Applications where an aesthetic consideration with

a preference for shine exists.

Stainless steel is the preferred choice when the

exceptions listed above apply.

5

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

Construction, Components of Strand and Cable (wire rope)

1 x 19

Non-Flexible

7x7

Flexible

7 x 19

Flexible

6 x 37 PFC

6 x 37 IWRC

6 x 19 IWRC

Strand

Construction

Strand is two or more wires wound concentrically in

a helix. They are usually wound around a center wire.

Strand is normally referred to as 1 by the total number

of wires in the given strand. Such as 1 x 7 (one group of

seven wires) or 1 x 19 (one group of nineteen wires).

Construction of strand, wire rope or cable is the

nomenclature for describing the number of wires

contained in, and their relationships to each other in the

particular product being described. 1 x 19 describes one

group of nineteen wires; 7 x 19 describes seven groups

of nineteen wires (or seven groups of 1 x 19); 6 x 37

IWRC describes six groups of thirty-seven wires wound

around a core that might actually be 7 x 7 construction

itself. Thus the term Independent Wire Rope Core, since

the core of 7 x 7 is actually a piece of wire rope. The

construction of the core is partially determined by the

diameter of the wire rope being described.

Cable / Wire Rope

CABLE is the generic term that refers to constructions of

wire rope that fall into the category of “aircraft” cable.

These constructions include 7 x 7 (seven groups of

1 x 7 strand) and 7 x 19 (seven groups of 1 x 19

strand) respectively. Aircraft cable ranges in size from

1/32” to 3/8”.

WIRE ROPE is technically the correct term for groups of

strand wrapped in a uniform helix around a core. Sizes

over 3/8” are not considered aircraft cable, they are

wire rope. The constructions included in wire rope are

numerous, but the most common are 6 x 19 and 6 x 37

class wire ropes. These descriptions of the construction

fail to include the core as a part of the primary number.

Part of the reason for this is that the composition and

the construction of the cores in these wire ropes is

so numerous, that it is necessary to call out the outer

construction of the wire rope and then describe the core.

Such as 6 x 19 fiber core, or 6 x 37 IWRC (Independent

Wire Rope Core). The terms CABLE and WIRE ROPE are

synonymous for all intents and purposes.

Core

The core can be a variety of things, including strand in

many constructions or even a cable or wire rope. The

core can also be of a composition other than metal, such

as polypropylene rope. Whatever the construction or the

composition of the core, it is the center member of the

cable or wire rope.

Composition

Composition of the wire rope or strand refers to the

material used to manufacture the product being

described. Strand, wire rope and cable are made from

various grades of both stainless steel and carbon steel.

The STAINLESS STEEL grades that are the most

common are Type 302/304, Type 305 (nonmagnetic),

and Type 316.

Type 302/304 is 18-8 (18 parts chromium and 8 parts

nickel) stainless steel and is most commonly used in the

manufacture of wire rope. This type of stainless steel

is commonly used in applications that require more

corrosion protection than is available from galvanized

carbon steel cable. Contrary to popular belief, stainless

steel is not stronger than galvanized carbon steel cable.

The fact is, it usually has a lower breaking strength than

galvanized cable of the same diameter and construction.

Type 305 S/S cable (nonmagnetic) is also commonly

available in 1/16” and 3/32” diameters. This type of

S/S is generally used in applications where sensitive

instrumentation or other systems might be affected

by magnetism.

6

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

Type 316 S/S is increasingly popular in many outdoor salt

air environments. It has excellent corrosion protection

and is the preferred choice of the marine industry. The

increase in popularity of Type 316 S/S has spurred the

availability of many wire rope terminals also becoming

available in Type 316 S/S.

Monel is an uncommon grade of stainless and is used

in applications where added resistance to corrosive

substances and liquids are required. The main drawbacks

to Monel are that its minimum breaking strength is

about 30% less than that of Type 302/304 S/S, and that

it is not readily available.

CARBON STEEL WIRE is available in different grades,

sometimes referred to as Plow Steel, Improved Plow

Steel, or even Extra Improved Plow Steel. Wire rope

manufactured from uncoated wire is commonly referred

to as “Bright.” Bright wire rope is available in sizes 1/4”

and over.

GALVANIZED carbon steel wire is frequently used to

manufacture wire rope. Galvanized wire rope provides

good corrosion protection in mild environments. In

smaller sizes (less than 1/4”) it is almost automatically

used when stainless steel is not specified.

Lay

The lay of the strand, wire rope or cable, is the direction

in which the helix of the wires orbit the core. An easy

way to determine the lay is to hold the specimen

vertically in front of you and observe whether the

strands or wires travel up and to the right or up and

to the left. Just as you might visually determine the

direction of a thread on a bolt. There are other types of

lay or wire rope, such as Lang and Herringbone. These

types of lays in wire rope are for special purposes, so we

will not go into them here.

Preforming

Preforming of the wires refers to the forming of the

individual wires of a strand into a helix so as to enable

them to all be “closed” into a uniform cylinder, capable

of retaining its shape when cut. Furthermore, when

wire rope or cable is made (using preformed strand), the

strand (groups of preformed wires) is also preformed

into a helix so that the six or seven groups of strand all

lay together in a cylindrical form and remain that way

when cut. Miniature diameters (smaller than 3/64“)

often are not preformed and must be specified to be

“stress relieved” at the time of ordering. Without

preforming or stress relieving, cable will typically

“broom” or fray when cut or disturbed. Miniature cable

not withstanding, it is not usually necessary to specify

preforming when ordering cable or wire rope since

almost all wire rope and cable is preformed.

Coating

The coating of a cable is optional, but can serve many

useful purposes. The most common types of coatings are

Polyvinyl chloride (PVC), various nylon compounds, and

Teflon®. These materials are referred to as compounds.

These compounds are applied to the cable via the use of

a plastic extrusion machine.

PVC

PVC is relatively inexpensive and is available in almost

any color. PVC lends itself well to applications that are

going to be exposed to sunlight. PVC would also be a

good choice for an application that requires an increase

in mass, or a particular color. PVC is relatively soft and

does not have good abrasion resistance.

Nylon and Thermoplastic

Elastomers

Nylon and thermoplastic elastomers are numerous

in types of compounds, each with its own special

properties that may be more or less suitable for a

particular application. Most are suitable for cycling over

pulleys. The differences vary from high temperature

environments to specific chemical exposures. This

is one reason to discuss your application with a

KNOWLEDGEABLE salesperson.

Teflon®

Teflon is used in certain applications that may include

high temperature, chemical exposure, or applications

that require a low coefficient of friction. Teflon is

relatively expensive, but commonly used and available.

Teflon is a registered trademark of E. I. du Pont de Nemours and Company.

7

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

Cable Stretch, Pre-stretching and Proof Testing

Cable

Measuring

Cable stretches as a load is applied. The amount of

stretch will increase as the load is increased. There

are two types of stretch occurring here. The first type

of stretch is called CONSTRUCTIONAL STRETCH. The

second type is referred to as ELASTIC STRETCH.

Measuring strand, cable and wire rope properly is done

using a pair of calipers or micrometers. Move the anvils

into contact with the peaks of two opposing strands (see

illustration below). DO NOT HAVE THE ANVILS MAKE

CONTACT WITH FOUR STRANDS SIMULTANEOUSLY as

this will give a false reading. All cable is manufactured

to a plus tolerance. Please see the charts on pages

12-15 for bare cable tolerances and page 9 for coated

(jacketed) cable diameters.

Constructional Stretch

Constructional Stretch occurs as the outer wires of a

strand close around its core and as the outer strands

of the cable close around its core under tension. This

closing action is the filling up of the spaces between

the individual wires and the spaces between the

strands. Unfortunately, this type of stretch is not

consistent (because of all of the variables involved in

the manufacture of the cable) and cannot be quantified

into a formula. Constructional stretch can be removed

by pre-stretching or pre-stressing (whichever term you

prefer). We accomplish this in accordance with

MIL-DTL-5688. This specification can be downloaded

from our website at www.thecableconnection.com.

Elastic Stretch

Elastic Stretch occurs as the individual wires elongate

under load. This is a quantifiable factor until the

yield point of the cable is exceeded. The factor varies

according to load applied and the construction of the

cable or strand. In short; the fewer wires and strands

in a given diameter, the lower the stretch factor. If you

require a calculation for elastic stretch for a particular

cable, contact us at 1-800-851-2961 and one of our

sales staff will acquire this information for you.

Overhead view of lanyard being proof tested.

8

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

Wire Rope Jacket Specifications

Type II Wire Rope

Construction and Dimensional Properties

Jacket Tolerance per specification MIL-DTL-83420M

Nominal Diameter

of Wire Rope

(inches)

Outside

Tolerance on

Jacket Wall

Construction

Diameter of

Jacket OD Thickness (inches)

Jacket (inches) Plus Only (inches) Reference (inches)

Approx.

Weight

per 100 ft.

1/32

3x7

3/64

0.008

0.008

0.022

3/64

7x7

1/16

0.010

0.008

0.049

3/64

7x7

5/64

0.012

0.016

0.076

1/16

7x7

3/32

0.012

0.016

0.093

1/16

7x7

1/8

0.014

0.031

1.18

1/16

7 x 19

3/32

0.012

0.016

0.093

1/16

7 x 19

1/8

0.014

0.031

1.18

3/32

7x7

1/8

0.014

0.016

1.85

3/32

7x7

5/32

0.016

0.016

2.18

3/32

7 x 19

1/8

0.014

0.031

1.99

3/32

7 x 19

5/32

0.016

0.031

2.32

1/8

7 x 19

3/16

0.018

0.031

3.62

5/32

7 x 19

7/32

0.018

0.031

6.10

5/32

7 x 19

9/32

0.022

0.063

7.51

3/16

7 x 19

1/4

0.018

0.031

7.75

3/16

7 x 19

5/16

0.022

0.063

9.20

7/32

7 x 19

9/32

0.020

0.031

9.76

7/32

7 x 19

11/32

0.024

0.063

11.55

1/4

7 x 19

5/16

0.020

0.031

12.30

1/4

7 x 19

3/8

0.024

0.063

14.42

9/32

7 x 19

13/32

0.024

0.063

16.18

5/16

7 x 19

7/16

0.024

0.063

19.8

3/8

7 x 19

1/2

0.027

0.063

27.20

9

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

Recommended Minimum Pulley Diameters

to maximize cable life

Cable

Construction

Tread or Groove

Diameter

3x7—

50 times cable

(uncoated) diameter

7x7—

40 times cable

(uncoated) diameter

7 x 19 —

25 times cable

(uncoated) diameter

6 x 37 —

17 times cable

(uncoated) diameter

10

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

Summarized Military Specifications

Common specifications for wire rope, strand and wire rope assemblies.

These specifications can be downloaded from our

website: www.thecableconnection.com

RR-W-410

Federal specification for wire rope and strand. This

specification covers wire ropes and wire seizing strands,

and is intended to cover the more common types,

classes and categories suitable for federal government

and commercial uses. This specification is not applicable

to wire ropes specified for aircraft control uses.

MIL-DTL-87161 (supersedes MIL-W-87161,

MIL-W-5693 and MIL-W-6940)

Military specification for wire strand, stainless steel and

zinc coated, non flexible, for aircraft control. Generally

1x19 construction for aircraft controls.

MIL-DTL-87218

MIL-DTL-83140 (supersedes MIL-W-83140)

Military specification for cable, lock clad,

for aircraft control.

Military specification for wire rope, steel, (stainless

steel) preformed, non-rotating, for aircraft rescue hoist

and cargo handling (winching).

MIL-DTL-781

MIL-DTL-18375 (supersedes MIL-W-18375)

Military specification for flexible ( 7x7 and 7x19

constructions) wire rope, corrosion resistant,

nonmagnetic, for aircraft control. Generally referred

to as type 305 S/S. The wire rope covered by this

specification is intended for use in aircraft control

system applications where low magnetic permeability

and high resistance is needed against corrosion,

abrasion and fatigue wear. Wire rope conforming to

composition B of MIL-DTL-83420 has a higher strength

and magnetic permeability than wire rope conforming

to this specification.

MIL-DTL-83420 (supersedes MIL-W-83420)

Military specification for wire rope, flexible (3x7, 7x7

and 7x19 constructions) stainless steel and galvanized,

for aircraft control. The wire rope covered by this

specification is intended for aircraft control system

applications where high resistance is needed against

corrosion, abrasion and fatigue wear.

Military specification for terminal, wire rope swaging.

The corrosion resistant steel terminals covered by this

specification are intended for swaging to corrosion

resistant steel and galvanized cable conforming to

MIL-DTL-83420 or RR-W-410, as applicable.

(The ratings do not apply to strand. Terminals will not

develop full breaking strength on strand; not intended

for use with MIL-DTL-87161.) These terminals can also

be used in applications involving corrosive conditions or

where nonmagnetic properties are essential.

MIL-DTL-6117

Military specification for terminal, cable assemblies

swaged type. This specification covers swaging

terminals (conforming to MIL-DTL-781) to cables to

make up terminal cable assemblies.

MIL-DTL-5688

Military specification for cable assemblies, aircraft, proof

testing and pre-stretching. This specification presents

the standard method for proof testing and pre-stretching

of aircraft cable assemblies.

11

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

Strand and Cable

Strand and cable are manufactured in various materials

and constructions. These charts contain only those

most commonly used in cable assemblies and are not

representative of all the types of strand and cable that

are available.

1 x 19 Strand

Non-Flexible

1 x 19 Stainless Steel Strand Type 302/304

Nominal Dia.

of Strand or

Cable

Tolerance on

Diameter

Plus Only

Lbs.

Breaking

Strength

1/32"

.006"

185

3/64"

.008"

375

1/16"

.010"

3/32"

.012"

1/8"

.014"

5/32"

3/16"

Approx.

Weight

Lbs./100 ft.

1 x 19 Galvanized Strand

Our

Part

Number

Nominal Dia.

of Strand or

Cable

Tolerance on

Diameter

Plus Only

.20

1AS1

1/32"

.006"

185

.25

1AG

.55

1.5AS1

3/64"

.008"

375

.55

1.5AG

500

.85

2AS1

1/16"

.010"

500

.85

2AG

1,200

2.00

3AS1

3/32"

.012"

1,200

2.00

3AG

2,100

3.50

4AS1

1/8"

.014"

2,100

3.50

4AG

.016"

3,300

5.50

5AS1

5/32"

.016"

3,300

5.50

5AG

.018"

4,700

7.70

6AS1

3/16"

.018"

4,700

7.70

6AG

7/32"

.018"

6,300

10.20

7AS1

7/32"

.018"

6,300

10.20

7AG

1/4"

.018"

8,200

13.50

8AS1

1/4"

.018"

8,200

13.50

8AG

9/32"

.020"

10,300

17.00

9AS1

9/32"

.020"

10,300

17.00

9AG

5/16"

.022"

12,500

21.00

10AS1

5/16"

.022"

12,500

21.00

10AG

3/8"

.026"

17,500

29.40

12AS1

3/8"

.026"

17,500

30.10

12AG

Lbs.

Breaking

Strength

Approx.

Weight

Lbs./100 ft.

Our

Part

Number

7/16"

--

22,500

41.00

14AS1

7/16"

--

22,500

41.00

14AG

1/2"

--

30,000

52.10

16AS1

1/2"

--

30,000

52.10

16AG

1 x 19 Stainless Steel Strand Type 316

Extra Corrosion Resistant

12

Nominal Dia.

of Strand or

Cable

Tolerance on

Diameter

Plus Only

Lbs.

Breaking

Strength

Approx.

Weight

Lbs./100 ft.

Our

Part

Number

1/8"

.014"

1,780

3.50

4AS2

5/32"

.016"

2,800

5.50

5AS2

3/16"

.018"

4,000

7.70

6AS2

7/32"

.018"

5,350

10.20

7AS2

1/4"

.018"

6,900

13.50

8AS2

5/16"

.022"

10,600

21.00

10AS2

3/8"

.026"

14,800

30.00

12AS2

7/16"

--

20,000

41.00

14AS2

1/2"

--

27,000

52.10

16AS2

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

7 x 7 Wire Rope

Flexible

7 x 7 Galvanized Wire Rope

7 x 7 Stainless Steel Wire Rope Type 302/304

Our

Part

Number

Nominal Dia.

of Strand or

Cable

Tolerance on

Diameter

Plus Only

.20

1BS1

3/64"

.008"

270

270

.42

1.5BS1

1/16"

.010"

480

.75

2BS1

3/32"

.012"

.012"

920

1.60

3BS1

1/8"

Nominal Dia.

of Strand or

Cable

Tolerance on

Diameter

Plus Only

Lbs.

Breaking

Strength

1/32"

.006"

115

3/64"

.008"

1/16"

.010"

3/32"

Approx.

Weight

Lbs./100 ft.

Lbs.

Breaking

Strength

Approx.

Weight

Lbs./100 ft.

Our

Part

Number

.36

1.5BG

480

.75

2BG

920

1.60

3BG

.014"

1,700

2.80

4BG

1/8"

.014"

1,700

2.80

4BS1

5/32"

.016"

2,600

4.30

5BG

5/32"

.016"

2,400

4.30

5BS1

3/16"

.018"

3,700

6.20

6BG

3/16"

.018"

3,700

6.20

6BS1

7/32"

.018"

4,800

8.30

7BG

7/32"

.018"

4,800

8.30

7BS1

1/4"

.018"

6,100

10.60

8BG

1/4"

.018"

6,100

10.60

8BS1

9/32"

.020"

10,300

17.00

9BG

9/32"

.020"

7,400

13.40

9BS1

5/16"

.022"

12,500

21.00

10BG

5/16"

.022"

9,000

16.70

10BS1

3/8"

.026"

17,500

30.10

12BG

3/8"

.026"

12,000

23.60

12BS1

7/16"

--

15,600

34.20

14BS1

1/2"

--

23,300

44.00

16BS1

7 x 7 Stainless Steel Wire Rope Type 316

Extra Corrosion Resistant

Nominal Dia.

of Strand or

Cable

Tolerance on

Diameter

Plus Only

Lbs.

Breaking

Strength

Approx.

Weight

Lbs./100 ft.

Our

Part

Number

1/8"

.014"

1,360

2.85

4BS2

3/16"

.018"

3,300

6.20

6BS2

1/4"

.018"

5,500

10.60

8BS2

5/16"

.022"

7,600

16.00

10BS2

3/8"

.026"

11,700

24.00

12BS2

13

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

Strand and Cable continued

7 x 19 Wire Rope

Flexible

7 x 19 Galvanized Wire Rope

7 x 19 Stainless Steel Wire Rope Type 302/304

Our

Part

Number

Nominal Dia.

of Strand or

Cable

Tolerance on

Diameter

Plus Only

.20

1CS1

1/16"

.010"

270

.42

1.5CS1

3/32"

.012"

480

.75

2CS1

1/8"

.014"

.012"

920

1.70

3CS1

5/32"

.016"

.014"

1,760

2.90

4CS1

3/16"

.018"

5/32"

.016"

2,400

4.50

5CS1

7/32"

3/16"

.018"

3,700

6.50

6CS1

7/32"

.018"

5,000

8.60

7CS1

Nominal Dia.

of Strand or

Cable

Tolerance on

Diameter

Plus Only

Lbs.

Breaking

Strength

1/32"

.006"

110

3/64"

.008"

1/16"

.010"

3/32"

1/8"

Approx.

Weight

Lbs./100 ft.

Lbs.

Breaking

Strength

480

Approx.

Weight

Lbs./100 ft.

Our

Part

Number

.75

2CG

1,000

1.70

3CG

2,000

2.90

4CG

2,800

4.50

5CG

4,200

6.50

6CG

.018"

5,600

8.60

7CG

1/4"

.018"

7,000

11.00

8CG

9/32"

.020"

8,000

13.90

9CG

1/4"

.018"

6,400

11.00

8CS1

5/16"

.022"

9,800

17.30

10CG

9/32"

.020"

7,800

13.90

9CS1

3/8"

.026"

14,400

24.30

12CG

5/16"

.022"

9,000

17.30

10CS1

3/8"

.026"

12,000

24.30

12CS1

7 x 19 Stainless Steel Strand Type 316

Extra Corrosion Resistant

Nominal Dia.

of Strand or

Cable

Tolerance on

Diameter

Plus Only

Lbs.

Breaking

Strength

Approx.

Weight

Lbs./100 ft.

Our

Part

Number

1/8"

.014"

1,300

2.90

4CS2

5/32"

.016"

2,000

4.50

5CS2

3/16"

.018"

2,900

6.50

6CS2

1/4"

.018"

4,900

11.00

8CS2

5/16"

.022"

7,600

17.30

10CS2

3/8"

.026"

11,000

24.30

12CS2

14

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

6 x 19 IWRC

Wire Rope

6 x 37 IWRC

Wire Rope

6 x 19 IWRC Stainless Steel Wire Rope

Type 302/304

6 x 37 IWRC Stainless Steel Strand Type 316

Extra Corrosion Resistant

Nominal Dia.

of Strand or

Cable

Lbs.

Breaking

Strength

Approx.

Weight

Lbs./100 ft.

Our

Part

Number

Nominal Dia.

of Strand or

Cable

Tolerance on

Diameter

Plus Only

7/16"

16,300

35.60

14ES1

3/16"

.018"

2,500

6.50

1/2"

22,800

45.80

16ES1

6 x 19 IWRC Stainless Steel Wire Rope

Type 316 Extra Corrosion Resistant

Nominal Dia.

of Strand or

Cable

Lbs.

Breaking

Strength

Approx.

Weight

Lbs./100 ft.

Our

Part

Number

7/16"

15,000

35.60

14ES2

1/2"

19,300

45.80

16ES2

Lbs.

Breaking

Strength

Approx.

Weight

Lbs./100 ft.

Our

Part

Number

6FS2

1/4"

.018"

4,860

10.00

8FS2

5/16"

.022"

7,470

18.00

10FS2

3/8"

.026"

10,530

24.00

12FS2

7/16"

--

14,200

33.00

14FS2

1/2"

--

18,360

43.00

16FS2

15

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

Eyelets

.28‘’

.53‘’

16

Note: The dotted line on the fitting illustrations denotes the measuring point for that terminal when used on a cable assembly.

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

Order

Part Number *

General Description

GBG Part

Number

Loos & Co.

Part Number

Sava

Part Number

Dimensions (Inches)

"H"

"W"

"T"

"X"

"L"

302

0.100

0.190

0.032

0.120

0.280

N.A.

N.A.

0.127

0.190

0.032

0.120

0.280

N.A.

N.A.

305-S-142

0.142

0.264

0.040

0.150

0.460

N.A.

N.A.

305-S-171

0.168

0.264

0.040

0.150

0.460

2083-01.5

EY8-160-1.5P

310-P-156

0.160

0.330

0.048

0.260

0.730

2023-01.5

EY8-190-1.5P

310-P-190

0.190

0.330

0.048

0.260

0.730

2081-01.5

EY8-160-1.5

310-S-156

0.160

0.330

0.048

0.260

0.730

520-S-190

2021-01.5

EY8-190-1.5

310-S-190

0.190

0.330

0.048

0.260

0.730

530-P-129

2313-02

EY8-129-2P

N.A.

0.129

0.420

0.058

0.325

0.950

530-P-165

N.A.

N.A.

N.A.

0.165

0.420

0.058

0.325

0.950

2003-02

EY8-190-2P

315-P-190

0.190

0.420

0.058

0.325

0.950

505-S-100

505-S-125

510-S-142

510-S-168

520-P-160

520-P-190

520-S-160

530-P-190

.030” Material Thickness

.190” Wide Head

.010” - .030” Cable

N.A.

N.A.

N.A.

.040” Material Thickness

.265” Wide Head

.018” - .038” Cable

.040” Material Thickness

.330” Wide Head

1/32” - 3/64” Cable

.060” Material Thickness

530-P-260

.420” Wide Head

2013-02

EY8-260-2P

315-P-260

0.260

0.420

0.058

0.325

0.950

530-S-129

3/64” - 1/16” Cable

N.A.

N.A.

N.A.

0.129

0.420

0.058

0.325

0.950

530-S-190

2001-002

EY8-190-2

315-S-190

0.190

0.420

0.058

0.325

0.950

530-S-219

N.A.

N.A.

315-S-218

0.219

0.420

0.058

0.325

0.950

530-S-260

2011-002

EY8-260-2

315-S-260

0.260

0.420

0.058

0.325

0.950

2303-03

EY8-204-3P

320-P-203

0.203

0.500

0.093

0.520

1.440

2343-03

EY8-251-3P

320-P-250

0.260

0.500

0.093

0.520

1.440

2301-03

EY8-204-3

320-S-203

0.203

0.500

0.093

0.520

1.440

540-S-260

2341-03

EY8-251-3

320-S-250

0.260

0.500

0.093

0.520

1.440

550-P-203

N.A.

N.A.

N.A.

0.203

0.750

0.088

0.530

1.320

540-P-203

540-P-260

540-S-203

.090” Material Thickness

.500” Wide Head

3/32” Cable

550-P-260

N.A.

N.A.

N.A.

0.260

0.750

0.088

0.530

1.320

550-P-320

090” Material Thickness

N.A.

N.A.

N.A.

0.320

0.750

0.088

0.530

1.320

550-P-380

.750” Wide Head

2323-03

EY8-376-3P

321-P-375

0.380

0.750

0.088

0.530

1.320

550-S-203

3/32” Cable

N.A.

N.A.

N.A.

0.203

0.750

0.088

0.530

1.320

550-S-260

N.A.

N.A.

N.A.

0.260

0.750

0.088

0.530

1.320

550-S-320

N.A.

N.A.

N.A.

0.320

0.750

0.088

0.530

1.320

550-S-380

2321-03

EY8-376-3

321-S-375

0.380

0.750

0.088

0.530

1.320

560-P-380**

.120” Material Thickness

2423-04

EY8-376-4P

331-P-375

0.380

0.870

0.115

0.680

1.850

560-P-510**

.875” Wide Head

2433-04

EY8-501-4P

331-P-500

0.510

0.870

0.115

0.680

1.850

560-S-380

1/8” Cable

2421-04

EY8-376-4

331-S-375

0.380

0.870

0.115

0.680

1.850

2431-04

EY8-501-4

331-S-500

0.510

0.870

0.115

0.680

1.850

2403-04

EY8-260-4P

330-P-250

0.260

0.580

0.115

0.680

1.970

2413-04

EY8-328-4P

330-P-312

0.320

0.580

0.115

0.680

1.970

2401-04

EY8-260-4

330-S-250

0.260

0.580

0.115

0.680

1.970

2411-04

EY8-328-4

330-S-312

0.320

0.580

0.115

0.680

1.970

560-S-510

570-P-260

570-P-320***

570-S-260

570-S-320

.120” Material Thickness

.580” Wide Head

1/8” Cable

* P = Zinc Plated Carbon Steel S = Stainless Steel

** 560-P-380 & 560-P-510 have a max. holding power of 1,850 Lbs.

*** 570-P-320 has a max. holding power of 1,600 Lbs.

Unless otherwise noted, the fittings shown on this page are designed to

hold at least the minimum cable breaking strength for 7x7 and 7x19

construction. For other fittings swaged onto cables of other constructions,

please consult our sales and customer service department.

17

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

Thimbles

Part No.

Pa t/ No

Material

Ma

Sta

Stainless

Steel

“C”

Cable Size

Cab

“A”

eWidth

T-2C

T-2P

3/64-1/1

3/6

T-4C

T-4P

3/32-1/8

3/

T-5C

T-5P

Part No. / Material

“B”

Length

Stainless

Steel

.35

.67

T-MD-4C

.35

.70

5/32

.40

.80

T-6C

T-6P

3/16

.50

1.00

T-8C

T-8P

7/32-1/4

7/

.70

1.41

Part No.

Pa t/ No

Material

Ma

Stainless

Sta

Steel

Galvanized

s

Galv

Steel

T-HD-8C

T

“C”

Cable Size

1/8

.75

1.30

T-MD-4G

1/8

.60

1.37

3/16

.75

1.40

3/16

.67

1.37

T-MD-6C

T-MD-6G

HeavyHeavy

P ttern

Pattern

(inches)

(in

Medium Pattern (inches)

Galvanized

Steel

“A”

Width

“A”

eWidth

“B”

Length

Part

Number

“C”

Cable Size

“A”

Width

“B”

Length

1/4

.95

1.58

T-4M

1/8

.39

.63

1/4

.85

1.62

T-5M

5/32

.47

.71

1.10

1.90

T-6M

3/16

.51

.83

T-HD-10G

TH

5/16

1.08

1.87

T-8M

1/4

.59

1.02

3/8

1.13

2.10

T-HD-12G

T-H

3/8

1.13

2.10

7/16-1/2

7/

1.53

2.65

T-HD-16G

TH

G

7/16-1/2

7/

1.53

2.90

T-HD-12C

T-H

T-HD-16C

TH

“B”

Length

Marine Pattern (inches)

“C”

Cab

Cable Size

5/16

T-HD-8G

TH

T-HD-10C

TH

18

AN Pattern

AN Pattern

(inches)

(in

s Plated

Zinc

Zinc

Steel

Note: The dotted line on the fitting illustrations denotes the measuring point for that terminal when used on a cable assembly.

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

Oval Swaging Sleeves

Part Number / Material

Dimensions (inches)

Aluminum

Plain

Copper

Zinc Plated

Copper

Nickel Plated

Copper

Stainless

Steel

Cable

Size

“D”

Diameter*

“L”

Length*

844-70

844-40

844-20

--

--

1/32

.10

.26

844-71

844-41

844-21

844-81

--

3/64

.15

.49

844-72

844-42

844-22

844-82

--

1/16

.19

.42

844-73

844-43

844-23

844-83

--

3/32

.27

.44

844-74

844-44

844-24

844-84

--

1/8

.36

.67

844-75

844-45

844-25

844-85

--

5/32

.41

.78

844-76

844-46

844-26

844-86

--

3/16

.48

1.25

844-77

844-47

844-27

844-87

--

7/32

.51

1.11

844-78

844-48

844-28

844-88

--

1/4

.60

1.33

--

844-49

844-29

844-89

--

5/16

.73

1.40

--

844-50

844-30

844-90

--

3/8

.80

1.66

--

844-51

844-31

844-91

--

7/16

.92

2.14

--

844-52

844-32

844-92

--

1/2

1.00

2.52

--

--

--

--

844-60

1/32

.10

.41

--

--

--

--

844-61

3/64

.15

.44

--

--

--

--

844-62

1/16

.15

.44

--

--

--

--

844-63

3/32

.19

.44

--

--

--

--

844-64

1/8

.27

.44

--

--

--

--

844-65

5/32

.35

.84

--

--

--

--

844-66

3/16

.39

.88

--

--

--

--

844-67

7/32

.48

1.03

--

--

--

--

844-68

1/4

.51

1.28

*Dimensions after swage

Unless otherwise noted, the fittings shown are designed to hold at least the minimum cable breaking strength for 7x7 and 7x19 constructions.

For fittings swaged onto cables of other constructions, please consult our sales and customer service department.

Note: The dotted line on the fitting illustrations denotes the measuring point for that terminal when used on a cable assembly.

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

19

Balls

Plain Balls

Part Number / Material

Dimensions (inches)

Brass

Stainless

Steel

Carbon Steel

Plated

“C”

Cable Size

“B”

Ball Size

B1-B125

B1-C125

B1-F125

1/32

.125

B1-B156

B1-C156

B1-F156

1/32

.156

B1-B190

B1-C190

B1-F190

1/32

.190

B1.5-B125

B1.5-C125

B1.5-F125

3/64

.125

B1.5-B156

B1.5-C156

B1.5-F156

3/64

.156

B1.5-B190

B1.5-C190

B1.5-F190

3/64

.190

B2-B190

B2-C190

B2-F190

1/16

.190

--

B2-C250

B2-F250

1/16

.250

--

B3-C250

B3-F250

3/32

.250

--

B3-C312

B3-F312

3/32

.312

--

B4-C312

B4-F312

1/8

.312

--

B4-C375

B4-F375

1/8

.375

--

B5-C375

B5-F375

5/32

.375

--

B5-C437

B5-F437

5/32

.437

--

B6-C437

B6-F437

3/16

.437

--

B6-C500

B6-F500

3/16

.500

--

B7-C500

B7-F500

7/32

.500

--

B8-C562

B8-F562

1/4

.562

--

B8-C813

B8-F813

1/4

.813

--

B10-C694

B10-F694

5/16

.694

--

B12-C812

B12-F812

3/8

.812

Note: Ultimate breaking strength, plain ball sizes:

3/32" and smaller — 80% of Catalog Nominal Strength,

1/8" and larger — 60% of Catalog Nominal Strength,

applies to 7x7 and 7x19 cable construction only;

for 1x19 construction, consult our engineering department.

20

Unless otherwise noted, the fittings shown are designed to hold at least the minimum cable breaking strength for 7x7 and 7x19 constructions.

For fittings swaged onto cables of other constructions, please consult our sales and customer service department.

Note: The dotted line on the fitting illustrations denotes the measuring point for that terminal when used on a cable assembly.

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

Ball with

Shank

Ball with

Double Shank

Part Number/Material

Dimensions after Swage (inches)

Part Number/Material

Dimensions after Swage (inches)

Stainless

Steel

Plated

Steel

Cable

Size

“A”

“B”

“L”

Stainless

Steel

Plated

Steel

Cable

Size

“A”

“B”

“L”

664C2

664-2

1/16

.112

.190

.16

663C2

663-2

1/16

.112

.190

.39

664C3

664-3

3/32

.143

.253

.24

663C3

663-3

3/32

.143

.253

.58

664C4

664-4

1/8

.190

.315

.32

663C4

663-4

1/8

.190

.315

.77

664C5

664-5

5/32

.222

.379

.40

663C5

663-5

5/32

.222

.379

.95

664C6

664-6

3/16

.255

.442

.47

663C6

663-6

3/16

.255

.442

1.14

664C7

664-7

7/32

.302

.505

.55

663C7

663-7

7/32

.302

.505

1.33

664C8

664-8

1/4

.348

.567

.63

663C8

663-8

1/4

.348

.567

1.52

664C9

664-9

9/32

.382

.632

.76

663C9

663-9

9/32

.382

.632

1.72

664C10

664-10

5/16

.413

.694

.82

663C10

663-10

5/16

.413

.694

1.88

664C12

664-12

3/8

.468

.812

.94

663C12

663-12

3/8

.468

.812

2.25

664C14

664-14

7/16

.562

.937

1.13

663C14

663-14

7/16

.562

.937

2.62

664C16

664-16

1/2

.625

1.060

1.26

663C16

663-16

1/2

.625

1.060

2.97

Special Fittings

L Fitting

Zinc Plated Steel

Z Fitting

Part No. / Material

Part

Number

“C”

Cable Size

Plated

Steel

Stainless

Steel

“C”

Cable Size

L-1.5*

3/64

Z-2

Z-2 C1

1/16

L-2*

1/16

Z-3

--

3/32

*Add “L” for left-hand;

“R” for right-hand

Left-hand clip shown; right-hand is opposite direction.

Unless otherwise noted, the fittings shown are designed to hold at least the minimum cable breaking strength for 7x7 and 7x19 constructions.

For fittings swaged onto cables of other constructions, please consult our sales and customer service department.

Note: The dotted line on the fitting illustrations denotes the measuring point for that terminal when used on a cable assembly.

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

21

Cable Hangers

Tapered

Cable Hanger

“J” Hook and

3-Hole

Cable

Adjuster

Hang from rod or tube

3-HOLE CABLE

ADJUSTER

PART NO. 3HCA

Material:

Zinc Die Cast

(Due to a wide

range of mounting

configurations,

no load rating is

attributed to this part).

.188”

1/4-20 Male Thread

(not included)

Mounting surface

.907”

For use with cable

coated to

1/16” diameter.

7/16 SAE F.W.

(not included)

.500”

.098”

1.21”

“J” HOOK

PART NO. 1.5J

Material:

Black Oxide Brass

(100 lb. min.

breaking strength).

Ferrule —

order separately:

Cable Size

TAPERED

CABLE HANGER

PART NO. TCH

Cylindrical

Cable Hanger

After swage

.080” hex X

.300” long.

Ferrule

1/32

F-1R3F

3/64

F-1.5R3F

1/16

F-2R3F

.83”

.34”

For use with

3/64” bare cable

or cable coated

to 1/16” diameter.

UR

YO N

SIG E

R

HE

.326”

1/4-20 Male Thread

(not included)

Mounting surface

7/16 SAE F.W.

(not included)

CYLINDRICAL

CABLE HANGER

PART NO. LJ01-004

1.00”

Type 303 Stainless Steel

1.25”

Ferrule —

order separately:

Cable Size

.38”

.375” dia.

1/4-20-2B x .75” min. depth

22

Ferrule

1/32

F-1R3F

3/64

F-1.5R3F

1/16

F-2R3F

Unless otherwise noted, the fittings shown are designed to hold at least the minimum cable breaking strength for 7x7 and 7x19 constructions.

For fittings swaged onto cables of other constructions, please consult our sales and customer service department.

Note: The dotted line on the fitting illustrations denotes the measuring point for that terminal when used on a cable assembly.

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

Eyes and Clevises

Eyes

Part Number / Material

Stainless

Steel

Plated

Steel

*Indicates After-Swage Dimensions (inches)

Cable

Size

“A”

“A”*

Before Swage After Swage

“C”

“D”

“J”*

“Ls”*

“R”

.24

668-2

668F2

1/16

.160

.138

.43

.190

.088

1.81

668-3

668F3

3/32

.218

.190

.59

.190

.103

2.16

.28

668-4

668F4

1/8

.250

.219

.61

.190

.190

2.59

.31

668-5

668F5

5/32

.297

.250

.68

.250

.197

3.03

.38

668-6

668F6

3/16

.359

.313

.72

.313

.255

3.19

.47

668-7

668F7

7/32

.427

.375

.80

.313

.291

3.68

.48

668-8

668F8

1/4

.494

.438

.89

.375

.307

4.06

.56

668-9

668F9

9/32

.563

.500

.98

.438

.322

4.51

.65

668-10

668F10

5/16

.635

.563

1.07

.438

.343

4.97

.70

668-12

668F12

3/8

.703

.625

1.34

.500

.375

5.97

.84

668-14

668F14

7/16

.781

.688

1.59

.562

.375

6.87

.97

668-16

668F16

1/2

.844

.750

1.68

.625

.468

7.89

1.03

Clevises

Part Number / Material

Stainless

Steel

Plated

Steel

*Indicates After-Swage Dimensions (inches)

Cable

Size

“A”

“A”*

Before Swage After Swage

“D”

“F”

“G”

“C”

“Ls”*

“R”

.21

667-2

667F2

1/16

.160

.138

.190

.218

.093

.500

1.75

667-3

667F3

3/32

.218

.190

.190

.254

.108

.670

2.06

.26

667-4

667F4

1/8

.250

.219

.190

.383

.195

.735

2.61

.30

667-5

667F5

5/32

.297

.250

.250

.406

.202

.800

3.00

.37

667-6

667F6

3/16

.359

.313

.313

.543

.260

.880

3.24

.43

667-7

667F7

7/32

.427

.375

.313

.625

.296

.970

3.74

.49

667-8

667F8

1/4

.494

.438

.375

.688

.313

1.070

4.10

.52

667-9

667F9

9/32

.563

.500

.438

.719

.327

1.170

4.48

.63

667-10

667F10

5/16

.635

.563

.438

.765

.348

1.268

4.86

.69

667-12

667F12

3/8

.703

.625

.500

.830

.380

1.525

5.74

.80

667-14

667F14

7/16

.781

.688

.562

.830

.380

1.776

6.57

.93

667-16

667F16

1/2

.844

.750

.625

1.035

.473

1.903

7.50

.98

Unless otherwise noted, the fittings shown are designed to hold at least the minimum cable breaking strength for 7x7 and 7x19 constructions.

For fittings swaged onto cables of other constructions, please consult our sales and customer service department.

Note: The dotted line on the fitting illustrations denotes the measuring point for that terminal when used on a cable assembly.

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

23

Ferrules: Hex and Round Swaged

Part Number/Material

Stainless

Steel

Brass

“C”

Carbon Steel Cable

Size

Plated

Dimensions after Swaging

(inches)

Part Number/Material

Brass

Stainless

Steel

“C”

Carbon Steel Cable

Size

Plated

Dimensions after Swaging

(inches)

“Hs”*

“Ls”*

“Ds”*

5/32

--

13/16

.250

5/32

--

13/16

.375

F-5R3F

5/32

--

13/16

.500

F-6H1C

F-6H1F

3/16

5/16

15/16

--

F-6H2C

F-6H2F

3/16

7/16

15/16

--

--

F-6H3C

F-6H3F

3/16

1/2

15/16

--

--

F-6R1C

F-6R1F

3/16

--

15/16

.313

--

--

F-6R2C

F-6R2F

3/16

--

15/16

.437

--

--

F-6R3C

F-6R3F

3/16

--

15/16

.500

1/4

.112

--

F-7H1C

F-7H1F

7/32

3/8

1 1/8

--

1/4

.138

--

F-7H2C

F-7H2F

7/32

1/2

1 1/8

--

--

1/4

.190

--

F-7R1C

F-7R1F

7/32

--

1 1/8

.375

9/64

5/16

--

--

F-7R2C

F-7R2F

7/32

--

1 1/8

.500

5/32

5/16

--

--

F-7R3C

F-7R3F

7/32

--

1 1/8

.625

3/16

5/16

--

--

F-8H1C

F-8H1F

1/4

7/16

1 1/4

--

1/16

--

5/16

.138

--

F-8H2C

F-8H2F

1/4

1/2

1 1/4

--

1/16

--

5/16

.156

--

F-8R1C

F-8R1F

1/4

--

1 1/4

.437

1/16

--

5/16

.190

--

F-8R2C

F-8R2F

1/4

--

1 1/4

.500

3/32

3/16

1/2

--

--

F-8R3C

F-8R3F

1/4

--

1 1/4

.688

3/32

1/4

1/2

--

--

F-10R1C

F-10R1F

5/16

--

1 9/16

.562

3/32

5/16

1/2

--

--

F-10R2C

F-10R2F

5/16

--

1 9/16

.688

F-3R1F

3/32

--

1/2

.190

--

F-10R3C

F-10R3F

5/16

--

1 9/16

.875

F-3R2F

3/32

--

1/2

.250

--

F-12R1C

F-12R1F

3/8

--

1 7/8

.625

F-3R3C

F-3R3F

3/32

--

1/2

.313

--

F-12R2C

F-12R2F

3/8

--

1 7/8

.750

F-4H1B

F-4H1C

F-4H1F

1/8

7/32

5/8

--

--

F-12R3C

F-12R3F

3/8

--

1 7/8

1.000

F-4H2B

F-4H2C

F-4H2F

1/8

1/4

5/8

--

--

F-14R1C

F-14R1F

7/16

--

2 3/16

.688

F-4H3B

F-4H3C

F-4H3F

1/8

3/8

5/8

--

--

F-14R2C

F-14R2F

7/16

--

2 3/16

.750

F-4R1B

F-4R1C

F-4R1F

1/8

--

5/8

.219

--

F-14R3C

F-14R3F

7/16

--

2 3/16

1.000

F-4R2B

F-4R2C

F-4R2F

1/8

--

5/8

.250

--

F-16R1C

F-16R1F

1/2

--

2 1/2

.750

F-4R3B

F-4R3C

F-4R3F

1/8

--

5/8

.375

--

F-16R2C

F-16R2F

1/2

--

2 1/2

.875

--

F-16R3C

F-16R3F

1/2

--

2 1/2

1.000

“Hs”*

“Ls”*

“Ds”*

F-1H1B

F-1H1C

F-1H1F

1/32

3/32

5/32

--

--

F-5R1C

F-5R1F

F-1H2B

F-1H2C

F-1H2F

1/32

1/8

5/32

--

--

F-5R2C

F-5R2F

F-1H3B

F-1H3C

F-1H3F

1/32

5/32

5/32

--

--

F-5R3C

F-1R1B

F-1R1C

F-1R1F

1/32

--

5/32

.095

--

F-1R2B

F-1R2C

F-1R2F

1/32

--

5/32

.138

--

F-1R3B

F-1R3C

F-1R3F

1/32

--

5/32

.156

F-1.5H1B

F-1.5H1C

F-1.5H1F

3/64

1/8

1/4

--

F-1.5H2B

F-1.5H2C

F-1.5H2F

3/64

5/32

1/4

F-1.5H3B

F-1.5H3C

F-1.5H3F

3/64

3/16

1/4

F-1.5R1B

F-1.5R1C

F-1.5R1F

3/64

--

F-1.5R2B

F-1.5R2C

F-1.5R2F

3/64

--

F-1.5R3B

F-1.5R3C

F-1.5R3F

3/64

F-2H1B

F-2H1C

F-2H1F

1/16

F-2H2B

F-2H2C

F-2H2F

1/16

F-2H3B

F-2H3C

F-2H3F

1/16

F-2R1B

F-2R1C

F-2R1F

F-2R2B

F-2R2C

F-2R2F

F-2R3B

F-2R3C

F-2R3F

F-3H1B

F-3H1C

F-3H1F

F-3H2B

F-3H2C

F-3H2F

F-3H3B

F-3H3C

F-3H3F

F-3R1B

F-3R1C

F-3R2B

F-3R2C

F-3R3B

*Special hex sizes, diameters and shank lengths are available on request.

Contact us with your special requirements.

24

*Special hex sizes, diameters and shank lengths are available on request.

Contact us with your special requirements.

Unless otherwise noted, the fittings shown are designed to hold at least the minimum cable breaking strength for 7x7 and 7x19 constructions.

For fittings swaged onto cables of other constructions, please consult our sales and customer service department.

Note: The dotted line on the fitting illustrations denotes the measuring point for that terminal when used on a cable assembly.

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

Radiused Ferrules: Hex and Round Swaged

Part Number/Material

Brass

Stainless

Steel

“C”

Carbon Steel Cable

Size

Plated

Dimensions after Swaging

(inches)

“Hs”*

“Ls”*

“Ds”*

RF-1HB

RF-1HC

RF-1HF

1/32

3/32

5/32

--

RF-1RB

RF-1RC

RF-1RF

1/32

--

5/32

3/32

RF-1.5HB

RF-1.5HC

RF-1.5HF

3/64

9/64

1/4

--

RF-1.5RB

RF-1.5RC

RF-1.5RF

3/64

--

1/4

9/64

RF-2HB

RF-2HC

RF-2HF

1/16

5/32

5/16

--

RF-2RB

RF-2RC

RF-2RF

1/16

--

5/16

5/32

RF-3HB

RF-3HC

RF-3HF

3/32

3/16

1/2

--

RF-3RB

RF-3RC

RF-3RF

3/32

--

1/2

3/16

RF-4HB

RF-4HC

RF-4HF

1/8

1/4

5/8

--

RF-4RB

RF-4RC

RF-4RF

1/8

--

5/8

1/4

--

RF-5HC

RF-5HF

5/32

5/16

13/16

--

--

RF-5RC

RF-5RF

5/32

--

13/16

5/16

--

RF-6HC

RF-6HF

3/16

3/8

15/16

--

--

RF-6RC

RF-6RF

3/16

--

15/16

3/8

--

RF-7HC

RF-7HF

7/32

7/16

1 1/8

--

--

RF-7RC

RF-7RF

7/32

--

1 1/8

7/16

--

RF-8HC

RF-8HF

1/4

1/2

1 1/4

--

--

RF-8RC

RF-8RF

1/4

--

1 1/4

1/2

*Special hex sizes, diameters and shank lengths are available on request.

Contact us with your special requirements.

Unless otherwise noted, the fittings shown are designed to hold at least the minimum cable breaking strength for 7x7 and 7x19 constructions.

For fittings swaged onto cables of other constructions, please consult our sales and customer service department.

Note: The dotted line on the fitting illustrations denotes the measuring point for that terminal when used on a cable assembly.

52 Heppner Drive • Carson City, Nevada 89706

800-851-2961 • 775-885-1443 • Fax 775-885-2734

E-mail: info@thecableconnection.com • Website: www.thecableconnection.com

25

Threaded Studs: Hex Swaged

Part Number / Material

Brass

Stainless

Steel

Dimensions (inches)

Carbon Steel

Plated

“C”

Cable

Size

“T”

Thread Size

“S”

Thread Length

After Swage

“Hs”

“Ls”*

HS1-12CSB

HS1-12CSC

--

1/32

5-40

.375

.093

.70

HS1-12CLB

HS1-12CLC

--

1/32

5-40

.75

.093

1.06

HS1-13CSB

HS1-13CSC

--

1/32

6-32

.44

.125

.75

HS1-13CLB

HS1-13CLC

--

1/32

6-32

.87

.125

1.18

HS1.5-13CSB

HS1.5-13CSC

--

3/64

6-32

.44

.125

.87

HS1.5-13CLB

HS1.5-13CLC

--

3/64

6-32

.87

.125

1.31

HS1.5-16CSB

HS1.5-16CSC

--

3/64

8-32

.50

.141

.93

HS1.5-16CLB

HS1.5-16CLC

--

3/64

8-32

1.00

.141

1.44

HS2-16CSB

HS2-16CSC

--

1/16

8-32