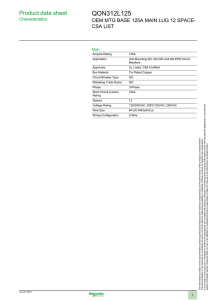

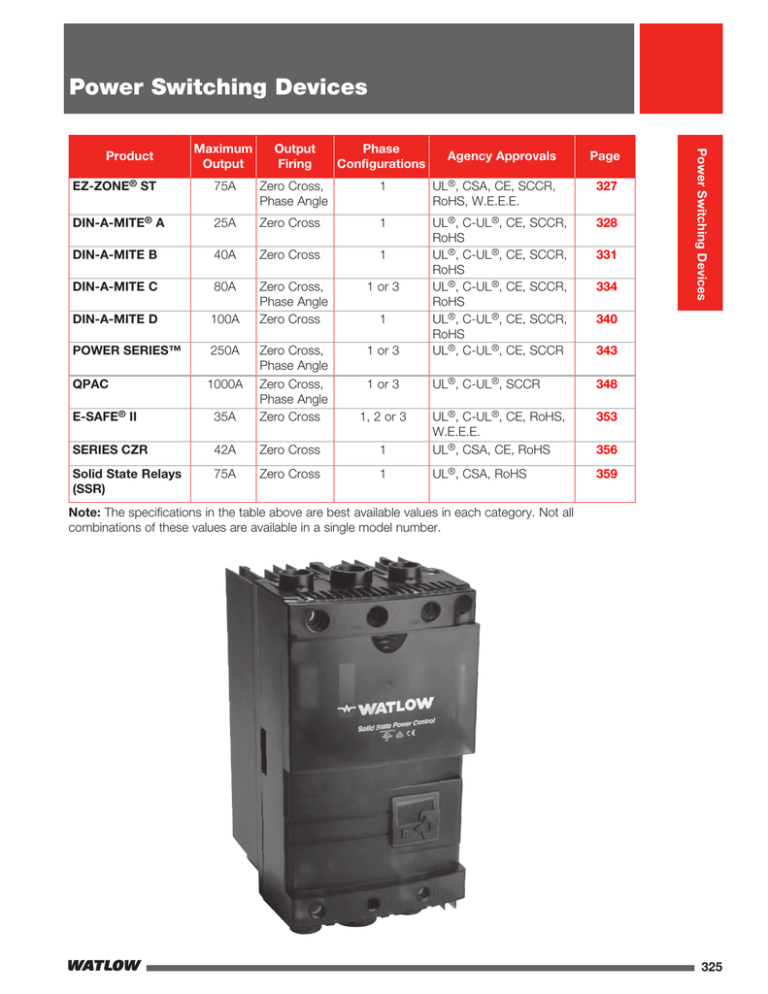

Controller Catalog (Section) - Power Switching Devices

advertisement