S 90 C

advertisement

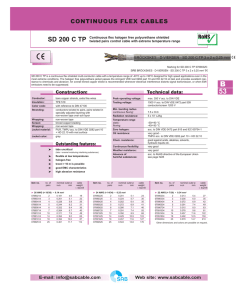

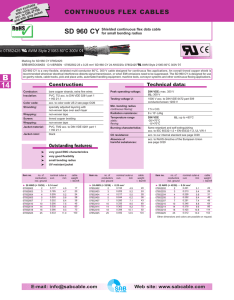

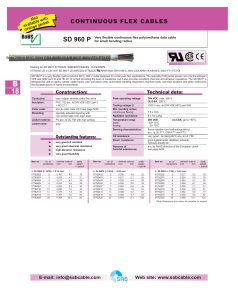

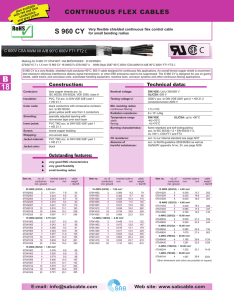

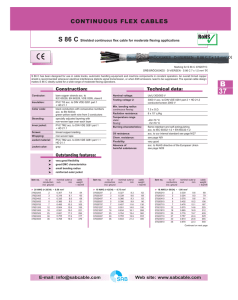

CONTINUOUS FLEX CABLES S 90 C Continuous flex shielded polyurethane cable C S BRÖCKSKES · D-VIERSEN · S 90 C 5 x 1,5 mm2 C Marking for S 90 C 07880515: S BRÖCKSKES · D-VIERSEN · S 90 C 5 x 1,5 mm2 C S 90 C is a continuous flex cable with a polyurethane outer jacket that provides cost effective operation of machine tools requiring long service life in harsh environments. An overall tinned copper shield is recommended whenever electrical interference distorts signal transmission, or when EMI emissions need to be suppressed. The polyurethane outer jacket provides excellent resistance to abrasion and mineral oils in continuous flex applications. Passes the stringent VDE test 0282 part 10 and HD 22.10 oil test. Construction: Conductor: Technical data: bare copper strands acc. to. IEC 60228, EN 60228, VDE 0295, class 6 Insulation: PVC, TI2 acc. to DIN VDE 0281 part 1 + HD 21.1 Color code: black conductors with consecutive numbers acc. to EN 50334; green-yellow earth wire from 3 conductors Nominal voltage: Uo/U 300/500 V Testing voltage U: 3000 V acc. to DIN VDE 0281 part 2 + HD 21.2 conductor/screen 2000 V Min. bending radius continuous flexing: 7.5 x O.D. Radiation resistance: 5 x 107 cJ/kg -40/+70 °C +5/+70 °C Stranding: specially adjusted layering with non-woven tape over each layer Temperature range static: flexing: Inner jacket: PVC, TM2 acc. to DIN VDE 0281 part 1 + HD 21.1 Oil resistance: very good TMPU acc. to DIN VDE 0282 part 10 + HD 22.10 Screen: tinned copper braiding Chem. resistance: Wrapping: non-woven tape good against acids, alkalines, solvents, hydraulic liquids etc. Jacket material: TMPU acc. to DIN VDE 0282 part 10 + HD 22.10 with mat surface Flexibility: very good Absence of harmful substances: acc. to RoHS directive of the European Union see page N/28 Jacket color: gray Outstanding features: item no. ä very good EMC characteristics ä improved abrasion resistance ä high tear resistance ä good chemical resistance ä increased efficiency no. of conductors incl. ground nominal outer-ø mm inch ® 20 AWG (≈ 28/34) • 0.50 mm2 07880205 2 0.299 07880305 3 0.311 07880405 4 0.327 07880505 5 0.350 07880705 7 0.406 07881205 12 0.476 07881805 18 0.535 0.642 07882505 25 0.724 07883605 36 0.795 07884405 44 0.823 07885205 52 0.925 07886505 65 7.6 7.9 8.3 8.9 10.3 12.1 13.6 16.3 18.4 20.2 20.9 23.5 cable weight ≈ lbs/mft 57 61 69 79 106 139 184 183 341 392 437 541 item no. no. of conductors incl. ground nominal outer-ø mm inch ® 19 AWG (≈ 42/34) • 0.75 mm2 07880207 2 0.319 07880307 3 0.331 07880407 4 0.350 07880507 5 0.374 07880707 7 0.441 07881207 12 0.516 07881807 18 0.587 0.724 07882507 25 0.795 07883607 36 0.874 07884407 44 0.921 07885207 52 1.028 07886507 65 8.1 8.4 8.9 9.5 11.2 13.1 14.9 18.4 20.2 22.2 23.4 26.1 cable weight ≈ lbs/mft 68 73 81 93 126 169 228 327 425 491 568 694 item no. no. of conductors incl. ground nominal outer-ø mm inch ® 18 AWG (≈ 56/34) • 1.00 mm2 07880210 2 0.319 07880310 3 0.339 07880410 4 0.362 07880510 5 0.402 07880710 7 0.453 07881210 12 0.531 07881810 18 0.622 0.748 07882510 25 0.823 07883610 36 0.921 07884410 44 0.965 07885210 52 1.039 07886510 65 cable weight ≈ lbs/mft 8.1 8.6 9.2 10.2 11.5 13.5 15.8 19.0 20.9 23.4 24.5 26.4 73 79 91 112 140 196 269 374 491 583 671 817 Continued on next page E-mail: info@sabcable.com Web site: www.sabcable.com B 43 CONTINUOUS FLEX CABLES S 90 C Continuous flex shielded polyurethane cable C S BRÖCKSKES · D-VIERSEN · S 90 C 5 x 1,5 mm2 C Marking for S 90 C 07880515: S BRÖCKSKES · D-VIERSEN · S 90 C 5 x 1,5 mm2 C B 44 S 90 C is a continuous flex cable with a polyurethane outer jacket that provides cost effective operation of machine tools requiring long service life in harsh environments. An overall tinned copper shield is recommended whenever electrical interference distorts signal transmission, or when EMI emissions need to be suppressed. The polyurethane outer jacket provides excellent resistance to abrasion and mineral oils in continuous flex applications. Passes the stringent VDE test 0282 part 10 and HD 22.10 oil test. Construction: Conductor: Technical data: bare copper strands acc. to. IEC 60228, EN 60228, VDE 0295, class 6 Insulation: PVC, TI2 acc. to DIN VDE 0281 part 1 + HD 21.1 Color code: black conductors with consecutive numbers acc. to EN 50334; green-yellow earth wire from 3 conductors Nominal voltage: Uo/U 300/500 V Testing voltage U: 3000 V acc. to DIN VDE 0281 part 2 + HD 21.2 conductor/screen 2000 V Min. bending radius continuous flexing: 7.5 x O.D. Radiation resistance: 5 x 107 cJ/kg -40/+70 °C +5/+70 °C Stranding: specially adjusted layering with non-woven tape over each layer Temperature range static: flexing: Inner jacket: PVC, TM2 acc. to DIN VDE 0281 part 1 + HD 21.1 Oil resistance: very good TMPU acc. to DIN VDE 0282 part 10 + HD 22.10 Screen: tinned copper braiding Chem. resistance: Wrapping: non-woven tape good against acids, alkalines, solvents, hydraulic liquids etc. Jacket material: TMPU acc. to DIN VDE 0282 part 10 + HD 22.10 with mat surface Flexibility: very good Absence of harmful substances: acc. to RoHS directive of the European Union see page N/28 Jacket color: gray Outstanding features: item no. ä very good EMC characteristics ä improved abrasion resistance ä high tear resistance ä good chemical resistance ä increased efficiency no. of conductors incl. ground nominal outer-ø mm inch ® 16 AWG (≈ 84/34) • 1.50 mm2 07880215 2 0.350 07880315 3 0.366 07880415 4 0.406 07880515 5 0.433 07880715 7 0.500 07881215 12 0.583 07881815 18 0.705 0.823 07882515 25 0.921 07883615 36 1.024 07884415 44 1.063 07885215 52 1.201 07886515 65 8.9 9.3 10.3 11.0 12.7 14.8 17.9 20.9 23.4 26.0 27.0 30.5 cable weight ≈ lbs/mft 87 97 119 136 179 247 368 483 656 784 889 1100 item no. no. of conductors incl. ground nominal outer-ø mm inch cable weight ≈ lbs/mft ® 14 AWG (≈ 140/34) • 2.50 mm2 07880225 2 0.437 07880325 3 0.457 07880425 4 0.496 07880525 5 0.535 07880725 7 0.642 07881225 12 0.791 07881825 18 0.890 1.063 07882525 25 1.201 07883625 36 11.1 11.6 12.6 13.6 16.3 20.1 22.6 27.0 30.5 134 150 175 208 294 430 573 767 1046 ® 12 AWG (≈ 224/34) • 4.00 mm2 07880240 2 0.500 07880340 3 0.524 0.559 07880440 4 0.606 07880540 5 0.728 07880740 7 12.7 13.3 14.2 15.4 18.5 163 194 232 288 412 item no. no. of conductors incl. ground nominal outer-ø mm inch cable weight ≈ lbs/mft ® 10 AWG (≈ 186/32) • 6.00 mm2 07880260 2 0.614 07880360 3 0.618 07880460 4 0.673 07880560 5 0.740 07880760 7 0.850 15.6 15.7 17.1 18.8 21.6 228 274 340 432 571 ® 8 AWG (≈ 320/32) • 10.00 mm2 07880461 4 0.795 07880561 5 0.866 20.2 22.0 508 637 ® 6 AWG (≈ 504/32) • 16.00 mm2 07880462 4 0.913 07880562 5 1.008 23.2 25.6 716 925 ® 4 AWG (≈ 760/32) • 25.00 mm2 07880463 4 1.071 27.2 1031 ® 2 AWG (≈ 1083/32) • 35.00 mm2 07880464 4 30.8 1.213 1348 Other dimensions and colors are possible on request. E-mail: info@sabcable.com Web site: www.sabcable.com