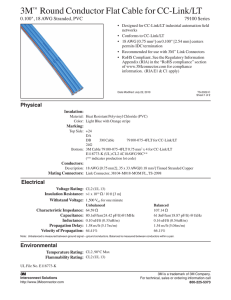

Cables according to Overseas standards

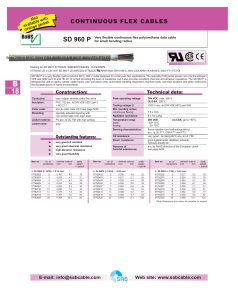

advertisement