PARKING STRUCTURE

PGL

SERIES

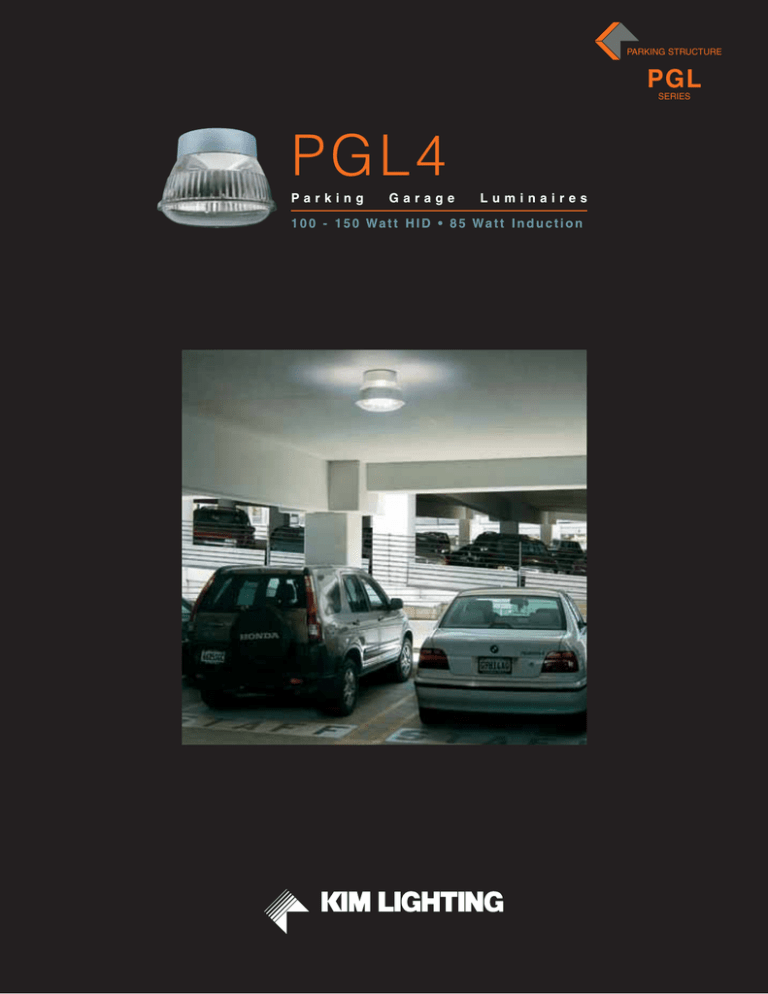

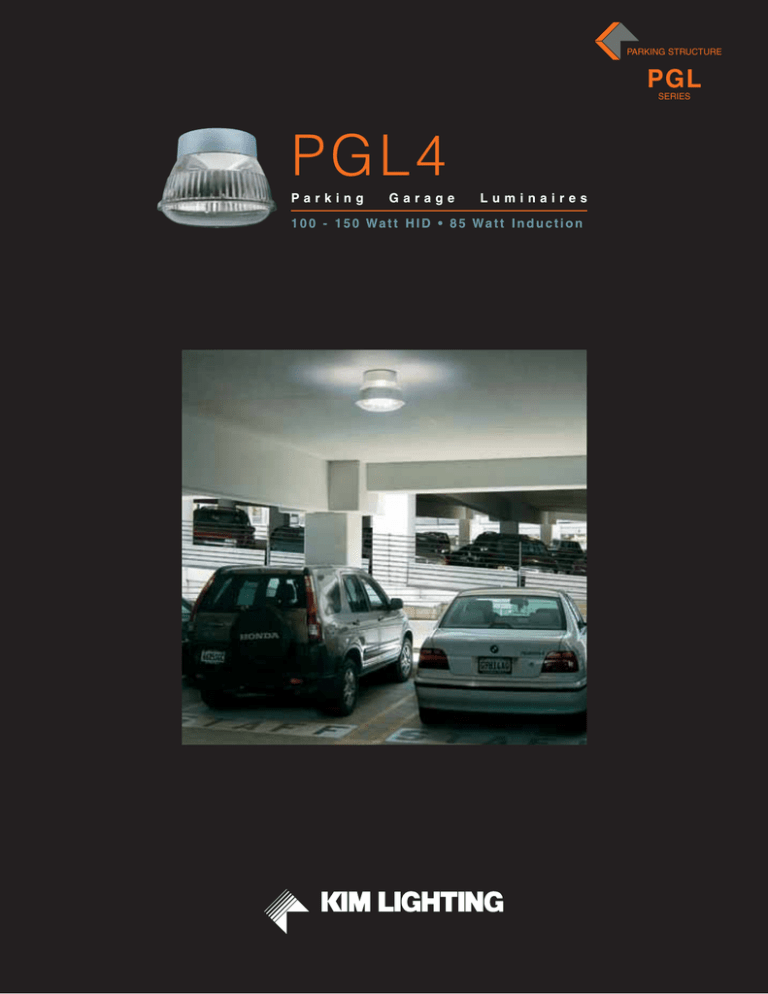

PGL4

Parking

Garage

Luminaires

1 0 0 - 1 5 0 Wa t t H I D • 8 5 Wa t t I n d u c t i o n

PGL4

Proven Success

Over 2 decades ago, Kim took a long hard look at

Parking Garage Lighting and concluded that a great

deal of improvement could be made.

Table of Contents

Design

2-3

Features

4

Installation and Maintenance

5

Luminaire

Ordering Information

6-7

Luminaire Specifications

8

Optical Choices

9

PGL4

10-11

DL-W

Wide Downlight Option

12-13

DL-N

Narrow Downlight Option 14-15

Induction Fluorescent

Lamp Option

16

Related Products

17

Application

Engineering Services

17

SITE / AREA

PARKING STRUCTURE

ROADWAY

ARCHITECTURAL FLOOD

ACCENT

LANDSCAPE

MAILING ADDRESS:

P.O. BOX 60080

CITY OF INDUSTRY, CA

91716-0080

BUSINESS ADDRESS:

16555 EAST GALE AVENUE

CITY OF INDUSTRY, CA 91745

U.S. A.

PHONE 626 / 968 - 5666

FAX 626 / 369 - 2695

ENTIRE CONTENTS

© COPYRIGHT 2012 KIM LIGHTING INC.

ALL RIGHTS RESERVED

REPRODUCTION IN WHOLE OR IN PART

WITHOUT PERMISSION IS STRICTLY PROHIBITED.

www.kimlighting.com

Hubbell

Lighting, Inc.

Printed in U.S.A.

5502613095

Version 2.4 (4/13)

In 1989, Kim introduced the PGL Parking Garage

Luminaire. This innovative product was the first to offer

an integrated, direct/indirect luminaire, purposely built

for modern parking garage facilities.

Today, the Kim PGL4 remains the choice for parking

garage lighting design. Continuous improvement,

including a regular program of enhancements and

innovations, keeps the PGL4 the leader in garage

illumination.

PGL4

KIM LIGHTING

1

Design

The Dynamics of Parking Garage Lighting Design

E

A

D

B

C

A

Low overall ceiling heights and deep exposed structural

elements combine to create a “cave effect.” This is

overcome by including indirect illumination of the ceiling

surfaces in the lighting system design.

B

For the safety and security of people entering and

leaving their vehicles, and easy identification of open

parking spaces for traffic flow, vertical illumination in the

parking zones is required. This is best approached through

direct high angle illumination, combined with ambient

indirect lighting to reduce harsh shadows and contrast.

Busy traffic in the drive lanes, plus cars backing out of

parking spaces and negotiating within confined space,

requires high visibility. This can only be accomplished by

cutoff optical designs that provide high vertical illuminance

with minimal glare.

C

A

2

B

KIM LIGHTING

C

D

Visibility of the facility must provide an inviting

appearance with no glare to surrounding properties. The

combination of indirect illumination of the garage interior

and cutoff optical control, provides the most attractive

presentation from the exterior of the garage.

E

Fixture row spacings are controlled by the structural

elements of the garage. Luminaire performance must be

designed to accommodate the various combinations of

structural element depths used to construct modern

garage facilities.

Fixture design considerations also include ease of

installation, ease of maintenance, and resistance to

intrusion by insects, dirt, or water. Other considerations in

garages may include controlling bird nesting, vandal

resistance and mounting system flexibility.

D

PGL4 Design

Integrated Approach

Clear uplight window

and diffuse reflector

segment

Diffuse Uplight eliminates the “cave effect”

and provides a secure and inviting

appearance. This ambient light also reduces

contrast between the fixture brightness and

ceiling, which increases visibility.

Drive Lane Direction

Prismatic uplight window

and specular reflector

segment

Up/Downlight produces high vertical

illuminance to reach between parked

vehicles. This improves visibility and

provides a sense of security and safety.

Drive Lane Direction

Cutoff Downlight provides overall

illumination with low glare. A balance of

providing high vertical illuminance and

drive lane comfort is accomplished by

a symmetrical reflector design that

redirects light from unwanted angles to more

useful zones.

Symmetric reflector

Integrated

Design

for

complete

Performance is the approach taken in

the development of the PGL Series.

By providing comfortable illumination,

eliminating the “cave effect,” and producing

excellent visibility, the PGL series continues

to satisfy the strictest of parking garage

lighting design.

KIM LIGHTING

3

Features

Wire Seal

Speed Mount

A molded silicone grommet provides protection

against moisture entry by sealing all three wires

exiting the fixture top.

The Kim “Speed Mount” easily attaches

to mud boxes as well as standard

4" junction boxes.

Hydroformed Uplight Reflector

Die-Cast Housing, Finish

The one-piece hydroformed uplight reflector is

configured to capture and redirect lamp output

to useful angles. It also retains the lamp socket,

and is easily removable for access to the

electrical components.

The electrical housing is die-cast aluminum

finished in Kim’s exclusive “Super TGIC”

powder coat paint. Housing hangs from

the “Speed Mount” for easy wiring, and

locks into place once it is raised to the final

mounting position.

Electrical Components

Housing Gasket

All ballasts and related components are rigidly

mounted inside the die-cast housing and 100%

tested before shipment.

For added longevity, the housing gasket is

a one-piece silicone component.

Uplight

to Parking Stalls

Uplight

Component

A generous amount of

uplight is provided to

illuminate the ceiling

and beams. This

reduces the “cave

effect,” providing a

more inviting parking

garage with a greater

sense of security.

Hydroformed Reflector

The primary reflector is a onepiece hydroformed aluminum

component with an Alzak®

finish. This provides maximum

longevity, maintained light output

and easier care over vacuummetalized reflectors. Vertical

facets prevent reflected light from

passing through the lamp for

high efficiency and long lamp life.

The reflector is retained inside

the one-piece injection molded

polycarbonate optical housing.

See photo below.

Two prism areas in

the uplight window

bend light downward

for extra fill into the

parking stalls. Prism

areas are 180° apart.

Cuto

ff

ff

Cuto

Toward

Driving A

Lane

A stainless steel

hanger hinge allows

easy no-tool removal

of the downlight

window.

Toward

B Parking

Stalls

Wide Throw Downlight

The primary garage illumination is provided

by cutoff downlight in which the lamp is fully

shielded above horizontal. Full coverage of

the garage bay is achieved by the wide

throw and high candlepower.

Gasket and Fasteners

The downlight window gasket is

silicone for maximum recovery

of shape after relamping. The

closure fasteners are stainless

steel captive shoulder screws to

prevent over-tightening and

cracking of the lens.

See detail below.

Hanger Hinge

Downlight Window

The injection molded downlight window has been configured for

greatest performance by optimizing the light transmission at high

angles. The standard material is high temperature UV stabilized

acrylic with optional polycarbonate available.

Top view of luminaire and orientation to parking stalls.

Prisms

B

Prisms

A

Parking Stalls

4

KIM LIGHTING

Installation and Maintenance

Speed Mount and Optional Bird Shroud

Because parking garage luminaires must be installed quickly and

securely, every PGL is supplied with the Kim “Speed Mount.”

The “Speed Mount” attaches to any standard 4" junction box or

mud box, whether recessed, surface or rigid pendant1 mounted.

It serves as a fixture hanger, freeing both hands for connecting field

wires, and locks the fixture to the junction box without tools.

1

See PB2 option on page 8.

Wiring and Locking

With the “Speed Mount” in place, the PGL luminaire can

be removed from its carton and easily installed without tools. The

fixture hangs at an angle so field wire connections can be quickly

and easily made. All wires are tucked into the junction box, and

the fixture is ready for final mounting. Without tools, the fixture

is simply lifted and pushed forward until an audible lock is heard.

At this point, the fixture is locked to the junction box and cannot

be removed without internal access through the ballast

compartment. This feature reduces the possibility of theft,

particularly during the period prior to building occupancy.

Lamping and Relamping

For initial lamping or future relamping, the downlight window

is hinged and retained by three captive screws. Access to the

lamp is quick, and the entire lamping task can be rapidly

accomplished. Relamping schedules should always be combined

with basic cleaning to maintain optimum light output. Since the

PGL optical chamber is totally sealed, exterior dusting is all that

is normally required.

For additional installation labor cost savings and convenience,

fixtures can be ordered with lamp included and factory installed,

allowing fixture to be installed without opening the optical chamber.

Control of Light Pollution

Parking garages are notorious for light pollution because they

have traditionally been illuminated with non-cutoff prismed refractor

luminaires. The PGL now allows parking garages to be fully

illuminated without significant light spill into the surrounding

neighborhood.

PGL test installation

Non-Cutoff prismed

refractor luminaires,

175 watt Metal Halide

Kim PGL, 150 watt

High Pressure Sodium

KIM LIGHTING

5

Luminaire Ordering Information

PGL4

Fixture

Ordering Example:

Electrical Module

Options

PGL4 / 175MH277 / DL-N / LS / PB2 / QS / TS / SF

1

2

1 Fixture:

3-10

PGL4

Contemporary garage luminaire. Die-cast, low copper (<0.6% CU)

aluminum alloy ballast housing with Platinum Silver Super TGIC powder

coat paint over titanated zirconium conversion coating, one-piece clear

optical housing. Downlight optical reflector visible through optical housing

material.

2 Electrical Module:

PMH = Pulse Start Metal Halide

HPS = High Pressure Sodium

IF = Induction Fluorescent

Lamp Lamp Line

Watts Type Volts

150

PMH

277

CAUTION: All manufacturers of

metal halide lamps recommend

turning them off for 15 minutes once

per week when under continuous

operation. This will reduce the risk of

arc tube rupture at end of life.

Also, color temperature may

differ between manufacturers of

metal halide lamps. See lamp

manufacturer’s specification sheets.

All fixtures are available pre-lamped

by Kim. Consult representative for

pricing.

Electrical

Module

Cat. No.

100PMH120

100PMH208

100PMH240

100PMH277

100PMH347

100PMH480

150 Watt Clear

150PMH120

Pulse Start Metal Halide

150PMH208

ED-17 Medium Base

150PMH240

ANSI Ballast Type M-102

150PMH277

150PMH347

150PMH480

100 Watt Clear

100HPS120

High Pressure Sodium

100HPS208

E-17 Medium Base

100HPS240

ANSI Ballast Type S-54

100HPS277

100HPS347

100HPS480

150 Watt Clear

150HPS120

High Pressure Sodium

150HPS208

E-17 Medium Base

150HPS240

ANSI Ballast Type S-55

150HPS277

150HPS347

150HPS480

85 Watt

85IF120

Induction Fluorescent

85IF208

85IF240

85IF277

2

Max. Amps reflect open circuit current load.

3

480 volt with medium base sockets may require approval

Lamp Mode

(Lamps by others)

100 Watt Clear

Pulse Start Metal Halide

ED-17 Medium Base

ANSI Ballast Type M-90

Line

Volts

120

208

240

277

347

4803

120

208

240

277

347

4803

120

208

240

277

347

4803

120

208

240

277

347

4803

120

208

240

277

Input

Watts

129

129

129

129

129

129

185

185

185

185

185

185

130

130

130

130

130

130

188

188

188

188

188

188

86

86

86

90

Max. Input

Amps2

2.30

1.40

1.15

1.00

1.00

0.55

3.65

2.10

1.80

1.58

1.25

0.81

2.20

1.40

1.10

0.95

0.70

0.34

3.00

1.65

1.45

1.25

0.92

0.70

0.73

0.38

0.36

0.38

of local building code authority.

NOTE: Due to the Energy Independence and Security Act (EISA) of 2007, Kim Lighting can no longer supply probe

start metal halide ballasts with its luminaires, effective January 1, 2009. Contact Kim Lighting for availability of

replacement ballasts for warranty service claims.

(Visit www.aboutlightingcontrols.org or the Library of Congress website for more details.)

6

KIM LIGHTING

3 Optional Narrow

Cat. No.: DL-N

Two-piece hydroformed aluminum reflector with Alzak® finish.

Reflector fills optical housing and provides minimal uplight

distribution. Symmetric downlight distribution is narrower

than standard symmetric pattern, with increased intensity.

Cat. No.: DL-W

Two-piece hydroformed aluminum reflector with Alzak® finish.

Reflector fills optical housing and provides minimal uplight

distribution. Symmetric downlight distribution is similar to

standard symmetric pattern, with increased intensity.

Cat. No.: LS

One-piece clear injection molded UV stabilized

polycarbonate downlight lens in place of standard acrylic.

Downlight Optics:

4 Optional Wide

Downlight Optics:

5 Optional Polycarbonate

Downlight Lens:

Polycarbonate

Downlight Lens

6 Optional Balanced

Cat. No.: PB2

Pendant Junction Box

and Bird Shroud:

Balanced Pendant

Junction Box and

Bird Shroud

7 Optional Quartz

Cat. No.: QS

Standby:

Quartz Standby

CAUTION: Use only when fixture vandalism is anticipated

within the parking garage. Service life is reduced by UV

discoloration from metal halide lamps. High Pressure

Sodium lamps are recommended to promote full service life.

Cast aluminum, finished to match fixture body. Offset

L" NPT pendant entry to balance fixture in free-swinging

installation. For fixture mounting, Kim Speed Mount attaches

directly to Balanced Pendant Junction Box (PB2).

Integral current sensing relay energizes a T-4 mini-can

socket during lamp warm-up and after power interruption.

Socket de-energizes prior to the HID lamp reaching

full brightness. T-4 mini-can halogen lamp by others;

100 watt maximum.

NOTE: Input amps will increase by .80 with this option.

Not available on 85IF.

8 Optional TamperResistant Lens Screws:

9 Optional Fusing:

Cat. No.: TS

Captive hex socket (allen) shoulder screws provided for downlight window instead of standard

phillips-head screws.

Line Volts:

120V

208V

240V

277V

347V

480V

Cat. No.:

SF

DF

DF

SF

SF

DF

Single Fuse

10 Lamp Included:

To order fixtures with lamp included and installed, add “lamp included” suffix to catalog number. Will also include

QS option lamp (when specified).

KIM LIGHTING

7

Luminaire Specifications

PGL4

Speed Mount: Formed steel, electro-zinc plated for mounting

to standard 4" junction box or mud box. Hooks are designed to hang

fixture, freeing both hands for field wire connections. Allows tool-free

fixture mounting to junction box, with integral anti-theft locking device.

Dimensions

Electrical

Housing

11" DIA.

(279.4 mm)

Ballast Housing: Die-cast, low copper (<0.6% Cu) aluminum alloy

for direct mounting to the Kim Speed Mount. Wire entry is sealed with

a silicone grommet.

3B"

Optical

Housing

(79.4 mm)

6D"

11L"

(298.5 mm)

(168.3 mm)

Downlight

Window

16" DIA.

(406.4 mm)

2"

(50.8 mm)

Hinge

Speed Mount

Toward

Parking

Stalls

Toward

Parking

Stalls

Mounting

holes for

standard

mud box or

4" J-box

Pendant Installations

Rigid conduit

pendant

Standard

4" J-box

or optional

PB2 J-box

Free-swinging

pendant

PB2 Balanced

Pendant J-box

Optical Housing: One-piece injection molded UV stabilized

polycarbonate (minimum wall thickness .125") with hydroformed

Alzak® aluminum reflector insert. Reflector has vertical facets to

prevent reflected light from passing through the lamp envelope.

Uplight window contains two prismed sections to spread additional

light downward in the direction of parking stalls. Optical Housing is

secured to Electrical Housing with full silicone gasketing around the

perimeter.

Uplight Reflector and Socket: One-piece hydroformed aluminum

with Alzak® surface facing prisms and diffuse white surface facing

uplight window areas. Socket is 4KV pulse rated medium base.

Reflector is removed by loosening three screws allowing access

to the electrical components.

Downlight Window: One-piece clear injection molded UV stabilized

high temperature acrylic (polycarbonate optional). Attached

to Optical Housing with a “no-tool” quick release spring hinge and

three captive phillips-head “shoulder” type screws to prevent

overtightening (tamper-resistant hex socket screws optional).

Perimeter is fully gasketed with silicone. Convex shape yields

maximum light transmission.

HID Electrical Components: High power factor ballasts for

-20°F. starting, rigidly mounted inside electrical housing and prewired

with leads extended out top of housing.

Induction Fluorescent Lamp Electrical Components: Complete

HF generator and induction lamp system is furnished. Induction lamp

system is high power factor, rated for -4° starting.

Optical Configuration: In the direction of the driving lanes, luminaire

downlight is of the “cutoff” classification with uplight provided for

illuminating ceiling and beams. In the direction of parking stalls,

luminaire is a “semi-direct” type with partial uplight refracted

downward for additional fill-light in the parking stalls. In all directions,

lamp is shielded from normal viewing angles by the opaque reflector

section of the luminaire.

Finish: Platinum Silver color on ballast housing only. Super TGIC

thermoset polyester powder coat paint over titanated zirconium

conversion coating. Clear optical housing.

CAUTION: Fixtures must be grounded in accordance with national,

state and/or local codes. Failure to do so may result in serious

personal injury.

• For rigid conduit pendant mount, use a standard

4" junction box with a centered pendant entry.

• For Free-swing pendant mount, use the optional

PB2 Balanced Pendant Junction Box (page 7).

Listings and Ratings

• For all pendant installations where bird shroud

protection is desired, use the optional PB2 Balanced

Pendant Junction Box (page 7).

UL cUL 15981

IP66 Rated

Suitable for wet locations.

1

8

KIM LIGHTING

40C Ambient

ISO 9001:2000

Optical Choices

Candlepower

Distribution

Toward

Driving Lane

120°

Candlepower

Distribution

Toward

Parking Stalls

150°

180°

150°

120°

PGL4

Standard Distribution

Innovated by Kim in 1989, the PGL system of garage luminaires has

revolutionized how parking structures are illuminated. Designed

to provide uniform vertical and horizontal illumination when installed

in regular garage areas, the PGL4’s uplighting reduces the “cave

effect” by illuminating the ceiling surfaces.

The PGL4 offers the following features:

• Wide distribution for optimum fixture spacing and economy

90°

90°

• Asymmetric uplight reduces “cave effect” and maximizes visibility

• Cutoff optics controls glare

60°

30°

0°

30°

Candlepower

Distribution

Toward

Driving Lane

120°

60°

Candlepower

Distribution

Toward

Parking Stalls

150°

180°

150°

120°

DL-N

Optional Narrow Downlight Distribution (Minimum Uplight)

Modern parking structures include areas where ceiling heights are

higher for access by emergency vehicles, or other similar

construction. The DL-N option provides increased downlight intensity

in a narrower distribution, for increased mounting heights. This option

can also be used where focused horizontal illumination levels

are desired, such as entries and ticket dispenser locations.

• Narrow distribution for higher mounting heights

90°

90°

• Cutoff optics and minimum uplight control glare and luminaire

brightness

• Retains aesthetic continuity with standard distribution luminaires

60°

30°

0°

30°

Candlepower

Distribution

Toward

Driving Lane

120°

60°

Candlepower

Distribution

Toward

Parking Stalls

150°

180°

150°

120°

DL-W

Optional Wide Downlight Distribution (Minimum Uplight)

The DL-W option is offered for applications where restricted uplight

distribution is desired. The downlight distribution is essentially the

same as the standard PGL4, maintaining full cutoff optical control,

with an increase in output, from redirection of uplight illumination into

the direct illumination zone.

• Wide distribution with increased intensity

90°

90°

• Cutoff optics and minimum uplight control glare and luminaire

brightness

• Retains aesthetic continuity with standard distribution luminaires

60°

30°

0°

30°

60°

KIM LIGHTING

9

PGL4

Maintained Illumination

Single Row Per Bay

NOTE: Contributions from adjacent bays included in

areas shown.

Includes 32% effective ceiling reflectance (40% surface

reflectance, with 24" D structural beams).

PLAN VIEW

F

E

F

D

C

D

A

B

A

D

C

D

F

E

F

S

Bay

Width

150 Watt HPS

E-17 clear

medium base

16,000 initial lumens

I.T.L. Test No. 48443

Light Loss Factor: 0.81

Bay

Width

Fixture

Fixture

Mounting Spacing

Height

H

8'

55'

9'

10'

H

8'

Not to scale

60'

9'

10'

S

Maintained Horizontal

Footcandles on Deck

A

B

C

D

E

F

Maintained Uniformity

Avg. fc

Avg./Min. Max./Min.

15'

34.3 25.0 12.5 12.3 4.46 4.36

12.95

2.97

7.87

30'

23.5 10.5 5.97 6.27 2.04 2.25

7.18

3.52

11.52

15'

28.1 23.2 12.3 12.3 6.19 6.11

12.67

2.07

4.6

30'

19.0 8.73 6.5

5.75 2.95 3.12

6.72

2.28

6.44

15'

24.0 22.0 11.9 12.4 8.02 7.81

12.7

1.63

3.07

30'

16.3 7.49 6.53 5.78 3.79 3.92

6.63

1.75

4.3

15'

34.2 25.0 11.2 11.1 3.12 3.08

11.92

3.87

11.1

30'

23.5 10.4 5.20 5.82 1.44 1.57

6.69

4.65

16.32

15'

27.8 23.0 11.4 11.4 4.54 4.47

11.59

2.59

6.22

30'

19.2 8.77 5.88 5.40 2.15 2.28

6.26

2.91

8.93

15'

23.7 21.8 11.0 11.4 6.07 5.98

11.53

1.93

3.96

30'

16.4 7.45 6.00 5.21 2.92 2.98

6.05

2.07

5.62

150 Watt PMH

E-17 clear

medium base

13,300 initial lumens

I.T.L. Test No. 48440

Light Loss Factor: 0.72

Bay

Width

Fixture

Fixture

Mounting Spacing

Height

H

8'

55'

9'

10'

H

8'

Not to scale

60'

9'

10'

10

KIM LIGHTING

S

Maintained Horizontal

Footcandles on Deck

A

B

C

D

E

F

Maintained Uniformity

Avg. fc

Avg./Min. Max./Min.

15'

31.3 21.5 10.2 10.2 2.93 2.85

10.84

3.8

10.98

30'

22.5 8.46 5.02 5.09 1.24 1.52

6.17

4.98

18.15

15'

25.2 19.9 9.78 10.3 4.35 4.35

10.46

2.4

5.79

30'

17.9 6.86 5.56 4.56 2.00 2.26

5.66

2.83

8.95

15'

21.6 19.0 9.61 10.1 6.22 5.98

10.52

1.76

3.61

30'

15.3 5.99 5.29 4.56 2.82 3.03

5.54

1.96

5.43

15'

31.2 21.4 9.39 9.15 1.97 1.97

10.07

5.11

15.84

30'

22.5 8.44 4.29 4.78 0.88 1.00

5.8

6.59

25.57

15'

24.9 19.7 9.13 9.50 3.00 2.98

9.58

3.21

8.56

30'

18.2 6.93 5.11 4.28 1.38 1.54

5.3

3.84

13.19

15'

21.3 18.8 8.92 9.30 4.40 4.30

9.49

2.21

4.95

30'

15.5 5.98 5.03 4.14 2.01 2.15

5.06

2.52

7.71

PGL4

Maintained Illumination

Includes 32% effective ceiling reflectance (40% surface

reflectance, with 24" D structural beams).

NOTE: Contributions from adjacent bays included in

areas shown.

Double Row Per Bay

150 Watt HPS

E-17 clear

medium base

16,000 initial lumens

I.T.L. Test No. 48443

Light Loss Factor: 0.81

Bay

Width

Fixture

Fixture

Mounting Spacing

Height

H

8'

55'

9'

10'

H

8'

Not to scale

60'

9'

10'

Maintained Horizontal

Footcandles on Deck

A

B

C

D

E

F

Maintained Uniformity

Avg. fc

Avg./Min. Max./Min.

L

S

27.5'

15'

38.7 29.5 25.0 24.6 25.1 24.6

29.07

1.18

1.57

27.5'

30'

25.8 12.6 12.0 12.6 12.0 12.6

16

1.33

2.15

27.5'

15'

31.0 26.4 22.0 22.1 21.9 22.1

24.99

1.14

1.42

27.5'

30'

22.6 11.9 13.1 11.7 13.0 11.5

14.83

1.29

1.97

27.5'

15'

28.6 27.0 21.2 22.3 21.1 22.2

24.32

1.15

1.36

27.5'

30'

20.4 11.4 13.2 11.7 13.2 11.7

14.26

1.25

1.79

30'

15'

37.5 28.2 22.3 22.3 22.3 22.2

27.07

1.22

1.69

30'

30'

25.2 12.0 10.5 11.7 10.5 11.7

15.08

1.44

2.4

30'

15'

32.5 27.7 22.8 22.7 22.7 22.7

25.99

1.14

1.43

30'

30'

21.7 11.0 11.9 10.9 11.9 10.8

13.91

1.29

2.01

30'

15'

29.8 27.9 22.1 22.7 22.1 22.7

25.13

1.14

1.35

30'

30'

19.3 10.4 12.1 10.5 12.1 10.6

13.13

1.26

1.86

150 Watt PMH

E-17 clear

medium base

13,300 initial lumens

I.T.L. Test No. 48440

Light Loss Factor: 0.72

Bay

Width

Fixture

Fixture

Mounting Spacing

Height

H

8'

55'

9'

10'

H

8'

Not to scale

60'

9'

10'

Maintained Horizontal

Footcandles on Deck

A

B

C

D

E

F

Maintained Uniformity

Avg. fc

Avg./Min. Max./Min.

L

S

27.5'

15'

34.2 24.5 20.4 20.4 20.4 20.4

24.61

1.21

1.68

27.5'

30'

24.1 9.78 10.1 10.3 10.1 10.3

13.86

1.42

2.46

27.5'

15'

26.8 21.8 17.5 18.4 17.4 18.4

20.88

1.2

1.54

27.5'

30'

20.5 9.05 11.3 9.30 11.3 9.23

12.64

1.4

2.27

27.5'

15'

24.8 22.6 17.0 17.9 17.0 17.9

20.17

1.19

1.46

27.5'

30'

18.6 8.95 10.8 9.30 10.8 9.34

12.03

1.34

2.08

30'

15'

33.4 23.5 18.8 18.4 18.7 18.3

23.06

1.26

1.83

30'

30'

23.6 9.43 8.69 9.67 8.70 9.68

13.15

1.51

2.72

30'

15'

28.1 22.9 18.3 19.0 18.3 19.0

21.81

1.19

1.54

30'

30'

20.0 8.35 10.3 8.71 10.3 8.68

11.92

1.43

2.4

30'

15'

25.8 23.3 17.8 18.6 17.8 18.6

20.95

1.18

1.45

30'

30'

17.6 8.11 10.2 8.35 10.2 8.39

11.1

1.38

2.18

KIM LIGHTING

11

DL-W Wide Downlight Option

Maintained Illumination

Single Row Per Bay

NOTE: Contributions from adjacent bays included in

areas shown.

Includes 32% effective ceiling reflectance (40% surface

reflectance, with 24" D structural beams).

PLAN VIEW

F

E

F

D

C

D

A

B

A

D

C

D

F

E

F

S

Bay

Width

150 Watt HPS

E-17 clear

medium base

16,000 initial lumens

I.T.L. Test No. 49266

Light Loss Factor: 0.81

Bay

Width

Fixture

Fixture

Mounting Spacing

Height

H

8'

55'

9'

10'

H

8'

Not to scale

60'

9'

10'

S

Maintained Horizontal

Footcandles on Deck

A

B

C

D

E

F

Maintained Uniformity

Avg. fc

Avg./Min. Max./Min.

15'

32.1 31.7 12.9 12.8 4.16 4.10

13.8

3.21

7.83

30'

21.3 10.7 5.63 7.13 1.87 2.19

7.04

3.76

11.39

15'

27.1 26.7 13.3 13.5 5.87 5.91

13.13

2.24

4.63

30'

17.2 9.94 6.29 7.12 2.80 3.06

6.87

2.45

6.14

15'

24.2 23.9 13.7 14.2 7.79 7.71

13.52

1.75

3.14

30'

14.4 9.68 6.63 7.41 3.70 3.90

6.96

1.88

3.89

15'

32.0 31.6 11.3 11.3 2.88 2.88

12.05

4.18

11.1

30'

21.3 10.7 4.88 6.34 1.34 1.48

6.47

4.83

15.9

15'

27.1 26.6 12.0 11.9 4.25 4.29

11.87

2.79

6.38

30'

17.1 9.89 5.63 6.21 2.01 2.20

6.2

3.08

8.51

15'

24.1 23.7 12.3 12.5 5.77 5.82

12.09

2.1

4.18

30'

14.3 9.60 5.97 6.40 2.81 2.93

6.2

2.21

5.09

150 Watt PMH

E-17 clear

medium base

13,300 initial lumens

I.T.L. Test No. 49263

Light Loss Factor: 0.72

Bay

Width

Fixture

Fixture

Mounting Spacing

Height

H

8'

55'

9'

10'

H

8'

Not to scale

60'

9'

10'

12

KIM LIGHTING

S

Maintained Horizontal

Footcandles on Deck

A

B

C

D

E

F

Maintained Uniformity

Avg. fc

Avg./Min. Max./Min.

15'

32.0 28.7 10.4 10.4 2.54 2.46

11.33

4.61

13.01

30'

22.7 9.20 4.35 5.94 1.06 1.34

6.3

5.94

21.42

15'

26.6 24.3 10.8 11.0 3.79 3.85

11.07

2.92

7.02

30'

17.9 8.54 5.11 5.80 1.74 2.04

5.96

3.43

10.29

15'

23.4 21.9 11.1 11.6 5.44 5.37

11.31

2.11

4.36

30'

14.9 8.36 5.40 6.01 2.49 2.75

5.93

2.38

5.98

15'

31.9 2.87 9.00 9.01 1.68 1.68

10.45

6.22

18.99

30'

22.7 9.18 3.66 5.28 0.75 0.85

5.86

7.81

30.27

15'

26.5 24.2 9.73 9.75 2.60 2.64

10.09

3.88

10.19

30'

17.9 8.53 4.56 5.06 1.18 1.35

5.43

4.6

15.17

15'

23.3 21.8 9.96 10.2 3.81 3.81

10.13

2.66

6.12

30'

14.8 8.32 4.85 5.14 1.77 1.93

5.3

2.99

8.36

Maintained Illumination

DL-W Wide Downlight Option

Includes 32% effective ceiling reflectance (40% surface

reflectance, with 24" D structural beams).

NOTE: Contributions from adjacent bays included in

areas shown.

Double Row Per Bay

150 Watt HPS

E-17 clear

medium base

16,000 initial lumens

I.T.L. Test No. 49266

Light Loss Factor: 0.81

Bay

Width

Fixture

Fixture

Mounting Spacing

Height

H

8'

55'

9'

10'

H

8'

Not to scale

60'

9'

10'

Maintained Horizontal

Footcandles on Deck

A

B

C

D

E

F

Maintained Uniformity

Avg. fc

Avg./Min. Max./Min.

L

S

27.5'

15'

36.2 35.8 25.9 25.6 25.9 25.6

29.85

1.17

1.41

27.5'

30'

23.7 12.6 11.3 14.3 11.3 14.4

15.97

1.41

2.09

27.5'

15'

30.8 30.3 24.4 24.7 24.4 24.7

26.98

1.11

1.26

27.5'

30'

20.3 12.8 12.7 14.3 12.6 14.3

15.35

1.22

1.61

27.5'

15'

29.6 29.3 25.2 26.0 25.1 26.0

27.22

1.08

1.18

27.5'

30'

18.4 13.5 13.3 14.9 13.3 14.9

15.33

1.15

1.38

30'

15'

34.9 34.5 22.6 22.7 22.6 22.7

27.51

1.22

1.54

30'

30'

22.9 12.1 9.87 12.8 9.87 12.8

14.81

1.5

2.32

30'

15'

31.4 30.9 24.1 23.9 24.1 23.9

26.87

1.12

1.31

30'

30'

19.3 12.0 11.4 12.5 11.4 12.5

14.03

1.23

1.69

30'

15'

29.9 29.5 24.6 25.0 24.6 25.0

26.83

1.09

1.22

30'

30'

17.4 12.5 12.1 12.9 12.1 12.9

13.87

1.15

1.44

150 Watt PMH

E-17 clear

medium base

13,300 initial lumens

I.T.L. Test No. 49263

Light Loss Factor: 0.72

Bay

Width

Fixture

Fixture

Mounting Spacing

Height

H

8'

55'

9'

10'

H

8'

Not to scale

60'

9'

10'

Maintained Horizontal

Footcandles on Deck

A

B

C

D

E

F

Maintained Uniformity

Avg. fc

Avg./Min. Max./Min.

L

S

27.5'

15'

34.5 31.3 20.9 20.8 20.9 20.7

25.85

1.25

1.67

27.5'

30'

24.2 10.3 8.81 12.0 8.81 12.0

14.38

1.63

2.75

27.5'

15'

28.5 26.2 19.7 20.2 19.6 20.2

23.1

1.18

1.45

27.5'

30'

20.1 10.4 10.3 11.7 10.3 11.7

13.49

1.31

1.95

27.5'

15'

26.8 25.4 20.4 21.2 20.4 21.2

23.1

1.13

1.31

27.5'

30'

17.7 11.0 11.0 12.2 10.9 12.1

13.23

1.21

1.62

30'

15'

33.7 30.4 18.0 18.1 18.1 18.1

23.88

1.33

1.87

30'

30'

23.6 10.0 7.42 10.7 7.43 10.7

13.39

1.8

3.18

30'

15'

29.2 26.9 19.5 19.6 19.5 19.5

23.09

1.18

1.5

30'

30'

19.4 9.81 9.26 10.3 9.25 10.3

12.45

1.35

2.1

30'

15'

27.2 25.7 20.0 20.4 19.9 20.4

22.83

1.15

1.37

30'

30'

16.9 10.2 9.92 10.5 9.90 10.5

12.05

1.22

1.71

KIM LIGHTING

13

DL-N Narrow Downlight Option

Maintained Illumination

Single Row Per Bay

NOTE: Contributions from adjacent bays included in

areas shown.

Includes 32% effective ceiling reflectance (40% surface

reflectance, with 24" D structural beams).

PLAN VIEW

F

E

F

D

C

D

A

B

A

D

C

D

F

E

F

S

Bay

Width

150 Watt HPS

E-17 clear

medium base

16,000 initial lumens

I.T.L. Test No. 49260

Light Loss Factor: 0.81

Bay

Width

Fixture

Fixture

Mounting Spacing

Height

H

10'

55'

12'

14'

H

10'

Not to scale

60'

12'

14'

S

Maintained Horizontal

Footcandles on Deck

A

B

C

D

E

F

Maintained Uniformity

Avg. fc

Avg./Min. Max./Min.

15'

27.1 37.9 13.2 12.8 2.58 2.48

12.31

4.96

15.28

30'

13.7 13.3 4.30 8.39 1.13 1.23

6

5.31

12.12

15'

23.2 29.3 14.5 14.7 3.90 3.94

12.48

3.2

7.51

30'

10.1 12.9 6.57 7.94 1.69 2.04

5.97

3.53

7.63

15'

20.4 23.7 15.0 15.7 6.11 6.10

12.93

2.12

3.89

30'

8.33 11.6 7.52 7.76 2.60 3.10

6.13

2.36

4.46

15'

27.0 37.8 10.7 10.5 1.91 1.89

11.11

5.88

20

30'

13.7 13.3 3.39 6.94 0.86 0.90

5.37

6.24

15.93

15'

23.1 29.2 12.9 12.8 2.81 2.76

11.27

4.08

10.58

30'

10.1 12.8 5.56 6.93 1.15 1.35

5.3

4.61

11.13

15'

20.2 23.4 13.5 13.8 4.24 4.24

11.44

2.7

5.52

30'

8.26 11.6 6.67 6.74 1.78 2.04

5.34

3

6.52

150 Watt PMH

E-17 clear

medium base

13,300 initial lumens

I.T.L. Test No. 49257

Light Loss Factor: 0.72

Bay

Width

Fixture

Fixture

Mounting Spacing

Height

H

10'

55'

12'

14'

H

10'

Not to scale

60'

12'

14'

14

KIM LIGHTING

S

Maintained Horizontal

Footcandles on Deck

A

B

C

D

E

F

Maintained Uniformity

Avg. fc

Avg./Min. Max./Min.

15'

24.0 24.1 10.1 9.58 1.91 1.85

10.12

5.47

18.43

30'

13.5 10.4 2.63 6.77 0.83 0.88

4.99

6.01

16.27

15'

20.6 25.3 11.9 11.3 2.57 2.60

10.07

3.92

9.84

30'

9.71 10.8 4.55 6.42 1.10 1.22

4.81

4.37

9.82

15'

17.7 20.1 12.1 12.7 3.92 3.83

10.25

2.68

5.25

30'

7.54 9.74 6.04 6.24 1.49 1.92

4.83

3.24

6.54

15'

23.9 34.1 7.72 7.43 1.44 1.41

9.04

6.41

24.18

30'

13.5 10.4 2.00 5.31 0.62 0.65

4.43

7.15

21.77

15'

20.6 25.2 10.4 9.69 1.97 1.93

9.18

4.76

13.06

30'

9.66 10.7 3.72 5.65 0.79 0.82

4.33

5.48

13.54

15'

17.5 20.0 10.9 10.9 2.67 2.60

9.08

3.49

7.69

30'

7.50 9.70 5.13 5.29 1.01 1.11

4.17

4.13

9.6

Maintained Illumination

DL-N Narrow Downlight Option

Includes 32% effective ceiling reflectance (40% surface

reflectance, with 24" D structural beams).

NOTE: Contributions from adjacent bays included in

areas shown.

Double Row Per Bay

150 Watt HPS

E-17 clear

medium base

16,000 initial lumens

I.T.L. Test No. 49260

Light Loss Factor: 0.81

Bay

Width

Fixture

Fixture

Mounting Spacing

Height

H

10'

55'

12'

14'

H

10'

Not to scale

60'

12'

14'

Maintained Horizontal

Footcandles on Deck

A

B

C

D

E

F

Maintained Uniformity

Avg. fc

Avg./Min. Max./Min.

L

S

27.5'

15'

29.7 40.5 26.5 25.7 26.5 25.7

28.91

1.12

1.58

27.5'

30'

15.1 14.6 8.80 17.0 8.78 17.0

14.53

1.65

1.94

27.5'

15'

27.3 33.4 29.3 29.7 29.2 29.6

29.43

1.08

1.22

27.5'

30'

12.4 14.8 13.4 16.1 13.4 16.1

14.4

1.16

1.3

27.5'

15'

26.6 29.9 30.2 31.5 30.1 31.4

29.67

1.12

1.18

27.5'

30'

11.9 14.7 15.5 16.0 15.4 15.9

14.59

1.23

1.34

30'

15'

29.1 39.8 21.5 21.1 21.5 21.1

25.81

1.22

1.89

30'

30'

14.8 14.3 7.03 14.1 7.03 14.1

12.9

1.83

2.11

30'

15'

26.1 32.1 25.9 25.8 25.9 25.8

26.73

1.04

1.24

30'

30'

11.8 14.3 11.5 14.3 11.5 14.3

13.07

1.14

1.24

30'

15'

20.2 23.4 13.5 13.8 4.25 4.24

11.44

2.7

5.52

30'

30'

10.7 13.8 13.8 14.0 13.8 13.9

13.04

1.22

1.31

150 Watt PMH

E-17 clear

medium base

13,300 initial lumens

I.T.L. Test No. 49257

Light Loss Factor: 0.72

Bay

Width

Fixture

Fixture

Mounting Spacing

Height

H

10'

55'

12'

14'

H

10'

Not to scale

60'

12'

14'

Maintained Horizontal

Footcandles on Deck

A

B

C

D

E

F

Maintained Uniformity

Avg. fc

Avg./Min. Max./Min.

L

S

27.5'

15'

26.0 36.2 20.3 19.3 20.2 19.2

23.5

1.22

1.89

27.5'

30'

14.6 11.4 5.53 13.8 5.51 13.8

12.04

2.19

2.65

27.5'

15'

23.5 28.1 24.1 22.8 24.1 22.7

23.91

1.05

1.24

27.5'

30'

11.2 12.2 9.49 13.2 9.48 13.2

11.79

1.24

1.39

27.5'

15'

21.7 24.2 24.4 25.6 24.4 25.6

24.13

1.11

1.18

27.5'

30'

9.91 11.7 12.5 13.0 12.5 12.9

11.88

1.2

1.31

30'

15'

25.5 35.7 15.6 15.0 15.6 15.0

20.69

1.38

2.38

30'

30'

14.4 11.2 4.24 10.9 4.24 10.9

10.54

2.49

3.4

30'

15'

22.7 27.4 21.0 19.6 21.0 19.6

21.75

1.11

1.4

30'

30'

10.9 11.9 7.92 11.7 7.89 11.7

10.75

1.36

1.51

30'

15'

20.4 22.9 22.0 22.1 22.0 22.0

21.71

1.06

1.12

30'

30'

9.06 11.1 10.8 11.1 10.7 11.1

10.48

1.16

1.23

KIM LIGHTING

15

Induction Fluorescent Lamp Option

Maintained Illumination

Double Row Per Bay

NOTE: Contributions from adjacent bays included in

areas shown.

Includes 32% effective ceiling reflectance (40% surface

reflectance, with 24" D structural beams).

85 Watt Induction Fluorescent

6,000 initial lumens

I.T.L. Test No. 46569

Light Loss Factor: 0.85

Bay

Width

Fixture

Fixture

Mounting Spacing

Height

H

8'

55'

9'

10'

H

8'

Not to scale

60'

9'

10'

Maintained Horizontal

Footcandles on Deck

A

B

C

D

E

F

Maintained Uniformity

Avg. fc

Avg./Min. Max./Min.

L

S

27.5'

15'

21.7 12.7 7.81 7.89 7.85 7.94

12.2

1.56

2.78

27.5'

30'

17.1 4.10 3.25 4.48 3.23 4.49

7.54

2.33

5.29

27.5'

15'

17.2 11.2 7.44 7.49 7.39 7.45

10.53

1.42

2.33

27.5'

30'

14.0 4.45 3.69 4.75 3.64 4.68

6.94

1.91

3.85

27.5'

15'

15.1 10.9 7.81 7.78 7.77 7.73

10.14

1.31

1.95

27.5'

30'

11.7 4.55 3.92 4.73 3.89 4.72

6.38

1.64

3.01

30'

15'

21.3 12.3 6.75 6.79 6.74 6.76

11.36

1.69

3.16

30'

30'

16.8 3.90 2.85 3.77 2.84 3.76

7.08

2.49

5.92

30'

15'

17.9 11.8 7.32 7.34 7.28 7.33

10.72

1.47

2.46

30'

30'

13.7 4.17 3.23 4.04 3.22 3.99

6.43

2

4.25

30'

15'

15.8 11.6 7.78 7.79 7.74 7.77

10.42

1.35

2.04

30'

30'

11.3 4.29 3.5 4.15 3.47 4.12

5.94

1.71

3.26

The 100,000 Hour Induction Fluorescent Lamp

Features & Benefits

• Ultra-long lamp life; <20% failure at 60,000 hours, and <50%

failure at 100,000 hours.

Ferrite Core

Antenna

{ (inside)

Coil

Fluorescent Coating

• Excellent lumen maintenance; over 70% of initial light output is

maintained after 60,000 hours.

• Good efficiency; 85 Watt lamp rated at 6000 lumens or 70 lumens

per watt. Comparable output to 70 Watt High Pressure Sodium.

_ 80, no color deviation.

• Excellent color; 4000°K. white light, CRI >

Heat Conduction Rod

HF Generator

Mounting Flange

Coaxial Cable

• Electronic control; fluctuations in supply voltage have a negligible

effect on light output, >0.9 power factor, -20°C. (-4°F.) starting.

• Fast run-up time; >80% light output in 10 seconds.

• Instant restart; <0.1 seconds.

• High frequency operation; no flickering, noise or stroboscopic

effect.

Induction Lamp Concept

The induction fluorescent lamp is a state-of-the-art source, utilizing no electrodes or filament as in conventional discharge or incandescent

sources. In this lamp, light is generated by means of induction – the transmission of energy via a magnetic field – combined with gas

discharge. This produces a highly efficient, extremely long-lived source that starts very quickly with little deterioration over its rated life.

16

KIM LIGHTING

Related Products

Top Deck Lighting

Stairway, Ramp, and Perimeter Lighting

AR/SAR

STL

LLF

AFL

ET

AC

WF

WD

Application Engineering Services

Applications Assistance

Kim Lighting utilizes the latest computer technology and software

to provide specifiers with reliable evaluations of lighting system

performance.

Kim can analyze a proposed luminaire layout or provide

recommendations based on performance criteria.

Hard copies of plans can be sent directly to the Kim Applications

Department via fax, express or regular mail. Any .dwg or .dxf file

can be e-mailed (kim.apps@kimlighting.com), or placed on

CD and forwarded to Kim Lighting, c/o Applications Dept.

Photometric Files

Kim Lighting electronic photometric files include .pdf file format

pages for printing and .ies files for use in lighting calculation

software. The complete .ies / .pdf library is available on the

internet at www.kimlighting.com.

KIM LIGHTING

17

PGL4

Parking Garage Luminaires

Because of a continuing product improvement

program, Kim Lighting reserves the right to

change specifications without notice.

How may we serve you better?

Let us know by visiting our web site at:

www.kimlighting.com

Your input is valuable to us.

www.kimlighting.com

Hubbell

Lighting, Inc.