Thermolatch

advertisement

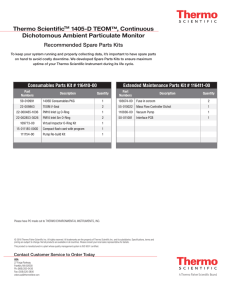

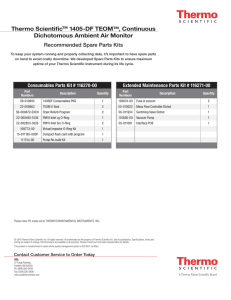

Table of Contents XVIII. Thermolatch and Accessories 1. General Notes 2. Standard Thermolatch 3. 115-24 VAC Electric Thermolatch 4. 24 VDC Electric Thermolatch 5. 24 VDC “Power On” Electric Thermolatch 6. Combination Fire/Explosion Thermolatch 7. ETL Thermolatch 8. Standard Thermolatch II 9. 115 VAC Electric Thermolatch II 10. 24 VAC Electric Thermolatch II 11. 24 VDC Electric Thermolatch II 12. 24 VDC “Power On” Electric Thermolatch II 13. Double Leaf Combination Fire/Explosion Thermolatch 14. Double Leaf ETL Thermolatch 15. Thermolatch Field Modifications 16. Exposion Vent General notes 17. The McCABE Link PROPRIETARY Bilco information for Authorized Personnel Only. Not to be Reproduced. Technical Data Sheet Thermolatches & Accessories Thermolatch The Bilco Thermolatch is a heat-sensitive device used to hold fire vent covers in the closed and secure position and to prevent inadvertent openings of the cover(s) caused by wind, building vibrations or various other factors. In case of fire, the ambient temperature increases to the point that causes the fusible link to fuse, releasing the latch mechanism and allowing the cover(s) to open to full, 90-degree, open position. A frictionless mechanism allows for immediate release of the latch. Manual interior and exterior pull release cables can be used to open the cover(s) without disturbing the fusible link. The fusible link is replaced and the unit is ready to “fight another fire.” Units equipped with a resettable electric actuator (115,24 VAC or 24 VDC) will also release when the latch mechanism is energized (or de-energized – power-on) by electrical signal from a smoke detector system or central fire alarm system. Combination fire and explosion vents will open either when fusible link melts or when cover(s) are subject to 25-30 psf (1.197-1.435 KN/m2) pressure on the underside of the cover(s). Combination fire and explosion vents can also be electrically released using an Electro-Thermal Link (ETL). The power requirements of the ETL are such that it can be released with an electrical impulse from any smoke detector’s power source. It is independent of power failure since it draws power from the stand-by power source of the smoke detector if needed. Note: “Power on” Thermolatches require a continuous, uninterrupted supply of power to keep the cover(s) closed. Any interruption of the power supply will release the covers. This could cause a problem during a power failure if no backup power supply is available. Thermolatch and accesories.doc PROPRIETARY Bilco information for Authorized Personnel Only. Not to be Reproduced. 1/14/02 Technical Data Sheet Thermolatches & Accessories Fusible Links The fusible links are designed to break apart at a predetermined temperature. The standard temperature rating is 1650F (740C). Other temperature ratings that are readily available are 1350F (570C) and 2120F (1000C). The fusible links are UL listed and FM approved. The load rating for these links is 30 lb (13.6 Kg). By using a series of levers in the Thermolatch design, the actual latch load can be reduced by a factor of 25 when it reaches the fusible link. This will ensure that the fusible link is never overstressed and will always release at its rated temperature. Thermolatch material and finish Material: Steel Finish: Zinc-Plated with a yellow Chromate seal. Note: Stainless Steel is not available. PROPRIETARY Bilco information for Authorized Personnel Only. Not to be Reproduced. Thermolatch and accesories.doc 1/14/02 MODEL TECHNICAL DATA SHEET STD THERMO THERMOLATCHES AND ACCESSORIES SINGLE LEAF UNIT STANDARD THERMOLATCH WITH 165° FUSIBLE LINK PROPRIETARY Bilco information for Authorized Personnel Only. Not to be Reproduced. STD THERMO.doc 1/30/02 MODEL TECHNICAL DATA SHEET 115/24 VAC THERMO THERMOLATCHES AND ACCESSORIES SINGLE LEAF UNIT 115 AND 24 VAC ELECTRIC THERMOLATCH WITH 165° FUSIBLE LINK NOTE: “POWER-ON” DETAIL VERY SIMILAR – SEE ENGINEERING FOR MORE INFORMATION PROPRIETARY Bilco information for Authorized Personnel Only. Not to be Reproduced. 115-24VAC THERMO.doc 1/4/02 MODEL TECHNICAL DATA SHEET 24 VDC THERMO THERMOLATCHES AND ACCESSORIES SINGLE LEAF UNITS 24 VDC ELECTRIC THERMOLATCH PROPRIETARY Bilco information for Authorized Personnel Only. Not to be Reproduced. 24VDC THERMO 6/13/2001 MODEL TECHNICAL DATA SHEET THERMOLATCHES AND ACCESSORIES SINGLE LEAF UNIT 24 VDC POWER ON THERMO 24 VDC ELECTRIC THERMOLATCH “POWER ON” “POWER ON” LATCH WILL RELEASE AND COVER (S) WILL OPEN UPON INTERRUPTION OF POWER SUPPLY PROPRIETARY Bilco information for Authorized Personnel Only. Not to be Reproduced. 24VDC_PO_THERMO 6/13/2001 MODEL STD SV/EX THERMO TECHNICAL DATA SHEET THERMOLATCHES AND ACCESSORIES SINGLE LEAF UNIT COMBINATION FIRE AND EXPLOSION VENT WITH STANDARD 165°F FUSIBLE LINK PROPRIETARY Bilco information for Authorized Personnel Only. Not to be Reproduced. STD SVEX THERMO.doc 1/4/02 MODEL ETL THERMO TECHNICAL DATA SHEET THERMOLATCHES AND ACCESSORIES SINGLE LEAF UNIT COMBINATION FIRE AND EXPLOSION VENT WITH STANDARD 165°F ELECTRO THERMO LINK PROPRIETARY Bilco information for Authorized Personnel Only. Not to be Reproduced. ETL THERMO.doc 1/4/02 MODEL TECHNICAL DATA SHEET DETAIL OF THERMOLATCH II CURB-MOUNTED RESET STANDARD STD THERMO II STANDARD THERMOLATCH –II WITH FUSIBLE LINK NOTE: Shown on standard curb with cap flashing. Installation on other types is the same PROPRIETARY Bilco information for Authorized Personnel Only. Not to be Reproduced. STD THERMO II 6/21/2001 MODEL 115 VAC THERMO II TECHNICAL DATA SHEET DETAIL OF THERMOLATCH II CURB-MOUNTED RESET 115 VAC Cable To Release Mechanism 1. Thermolatch II Mechanism – Covers Will Open Only When Activated A. Manually B. By Heat At Fusible Link C. Electrically By Signal 2. Each Unit Is Equipped With Electrically Operated Thermolatch 115 VAC, 60 Cycles, 0.25 AMPS. 3. Electric Thermolatch, When Energized, Releases Vent Covers To Open. Note: Shown on standard curb with capflashing. Installation on other curb types is the same. PROPRIETARY Bilco information for Authorized Personnel Only. Not to be Reproduced. 115VAC THERMO II 6/20/2001 MODEL TECHNICAL DATA SHEET DETAIL OF THERMOLATCH II CURB-MOUNTED RESET 24VAC THERMO II 24 VAC Cable To Release Mechanism 1. Thermolatch II Mechanism – Covers Will Open Only When Activated A. Manually B. By Heat At Fusible Link C. Electrically By Signal 2. Each Unit Is Equipped With Electrically Operated Thermolatch 24 VAC, 60 Cycles, 1.2 AMPS. 3. Electric Thermolatch, When Energized, Releases Vent Covers To Open. Note: Shown on standard curb with capflashing. Installation on other curb types is the same. PROPRIETARY Bilco information for Authorized Personnel Only. Not to be Reproduced. 24VAC THERMO II 6/20/2001 MODEL 24 VDC THERMO II TECHNICAL DATA SHEET DETAIL OF THERMOLATCH II CURB-MOUNTED RESET 24 VDC Cable To Release Mechanism 1. Thermolatch II Mechanism – Covers Will Open Only When Activated A. Manually B. By Heat At Fusible Link C. Electrically By Signal 2. Each Unit Is Equipped With Electrically Operated Thermolatch 24 Volt DC, 60 Cycles, 1.8 AMPS. 3. Electric Thermolatch, When Energized, Releases Vent Covers To Open. Note: Shown on standard curb with capflashing. Installation on other curb types is the same. PROPRIETARY Bilco information for Authorized Personnel Only. Not to be Reproduced. 24VDC THERMO II 1/4/02 MODEL TECHNICAL DATA SHEET DETAIL OF THERMOLATCH II CURB-MOUNTED RESET 24VDC POWER ON THERMO II 24 VDC “POWER ON” 1. Thermolatch II Mechanism – Covers Will Open Only When Activated A. Manually B. By Heat At Fusible Link C. Termination of Electrical Signal 2. Each Unit Is Equipped With Electrically Operated Thermolatch 24 VAC, 60 Cycles, 1.2 AMPS. 3. Electric Thermolatch, When De-Energized, Releases Vent Covers To Open. Note: Shown on standard curb with capflashing. Installation on other curb types is the same. PROPRIETARY Bilco information for Authorized Personnel Only. Not to be Reproduced. 24VDC_PO_THERMO II 1/4/02 MODEL TECHNICAL DATA SHEET THERMOLATCHES AND ACCESSORIES COMBINATION FIRE AND EXPLOSION THERMO AND ACCESSORIESCOMBO FIRE/EX PROPRIETARY Bilco information for Authorized Personnel Only. Not to be Reproduced. THERMO AND ACCESSORIES- COMBO FIRE/EX 7/25/2001 MODEL TECHNICAL DATA SHEET THERMOLATCHES AND ACCESSORIES COMBINATION FIRE AND EXLOSION WITH ELECTRO THERMO LINK THERMO AND ACCESSORIESCOMBO F/EX THERMO LINK PROPRIETARY Bilco information for Authorized Personnel Only. Not to be Reproduced. THERMO AND ACCESSORIES- COMBO F/EX THERMO LINK 01/04/02 Technical Data Sheet Smoke Vents Thermolatch Field Modification Field Modification To The Electric Operation Of A Thermolatch The customer can modify our standard single or double leaf smoke vents for electrical operation as follows. Single leaf: 1. Remove standard Thermolatch mechanism. This is accomplished by removing (3) bolts and cutting the exterior pull release cable. 2. Install the new electric Thermolatch mechanism just like the old one was installed. 3. Run exterior pull release cable through the frame, then use cable clamps (provided) to secure the handle to the cable. 4. Connect wires to electrical source. Double leaf: 1. Line up electric release mechanism with the fusible link on the unit and mark the holes on the curb. 2. Drill marked holes. 3. Bolt in place the electric release mechanism. 4. Connect wires to electrical source. Note: See electric Thermolatch details to better picture how these procedures are accomplished. PROPRIETARY Bilco information for Authorized Personnel Only. Not to be Reproduced. STD_THERMO_13 3/6/09 Technical Data Sheet Explosion Vents General Notes Explosion Vent The BILCO explosion vent is designed to open by the force of the explosion acting directly on the underside of the covers. It is the explosive force pushing on the underside of the covers that causes the latch to release and move the covers upward, thereby releasing the pressure to the atmosphere. Our latching mechanism incorporates a constant force spring which causes the latch to release when a predetermined pressure is applied through the cover as a result of the explosion. Prior to shipment, all BILCO vents are carefully inspected and all are tested for proper explosion release pressure. This is performed by applying pressure directly to the underside of each cover through the use of an air cylinder. The line air pressure required for release of the latch is determined by calculations and each latch is factory set to release at the required pressure. PROPRIETARY Bilco information for Authorized Personnel Only. Not to be Reproduced. EX-THERMO-NOTE 1/4/02