Yale University Design Standards Instructions

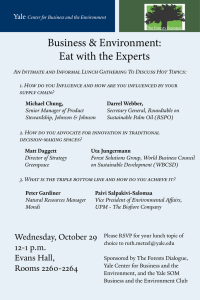

advertisement