TBG...PN - Industrial burners Baltur

advertisement

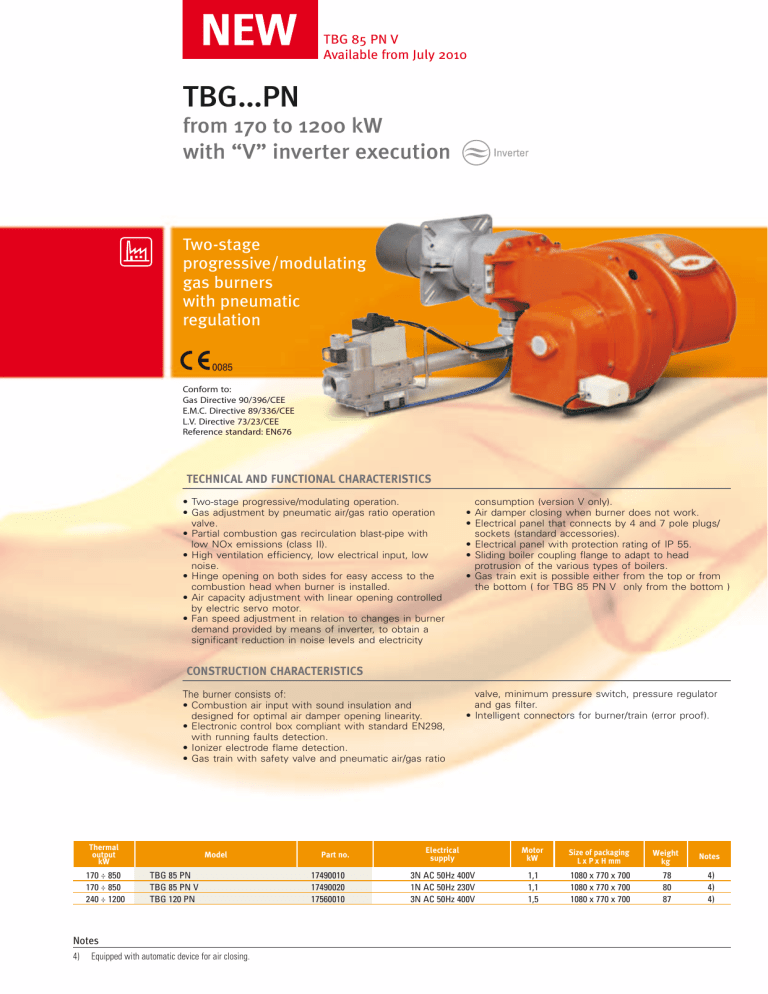

TBG 85 PN V Available from July 2010 TBG...PN from 170 to 1200 kW with “V” inverter execution Two-stage progressive/modulating gas burners with pneumatic regulation 0085 Conform to: Gas Directive 90/396/CEE E.M.C. Directive 89/336/CEE L.V. Directive 73/23/CEE Reference standard: EN676 TECHNICAL AND FUNCTIONAL CHARACTERISTICS • Two-stage progressive/modulating operation. • Gas adjustment by pneumatic air/gas ratio operation valve. • Partial combustion gas recirculation blast-pipe with low NOx emissions (class II). • High ventilation efficiency, low electrical input, low noise. • Hinge opening on both sides for easy access to the combustion head when burner is installed. • Air capacity adjustment with linear opening controlled by electric servo motor. • Fan speed adjustment in relation to changes in burner demand provided by means of inverter, to obtain a significant reduction in noise levels and electricity consumption (version V only). • Air damper closing when burner does not work. • Electrical panel that connects by 4 and 7 pole plugs/ sockets (standard accessories). • Electrical panel with protection rating of IP 55. • Sliding boiler coupling flange to adapt to head protrusion of the various types of boilers. • Gas train exit is possible either from the top or from the bottom ( for TBG 85 PN V only from the bottom ) CONSTRUCTION CHARACTERISTICS The burner consists of: • Combustion air input with sound insulation and designed for optimal air damper opening linearity. • Electronic control box compliant with standard EN298, with running faults detection. • Ionizer electrode flame detection. • Gas train with safety valve and pneumatic air/gas ratio Thermal output kW 170 ÷ 850 170 ÷ 850 240 ÷ 1200 Model TBG 85 PN TBG 85 PN V TBG 120 PN Notes 4) Equipped with automatic device for air closing. valve, minimum pressure switch, pressure regulator and gas filter. • Intelligent connectors for burner/train (error proof). Part no. Electrical supply Motor kW Size of packaging L x P x H mm Weight kg Notes 17490010 17490020 17560010 3N AC 50Hz 400V 1N AC 50Hz 230V 3N AC 50Hz 400V 1,1 1,1 1,5 1080 x 770 x 700 1080 x 770 x 700 1080 x 770 x 700 78 80 87 4) 4) 4) TBG...PN from 170 to 1200 kW TBG 85P-PN-ME-PV TBG 120P-PN-ME TBG 150P-PN-ME TBG 210P-PN-ME 0002922491 mbar 16 14 B1 12 B6 D 10 A 8 C Model A mm B1 mm B6 mm C mm D mm E mm F mm TBG 85 PN TBG 85 PN V TBG 120 PN 645 645 645 380 380 380 160 1230 175 ÷ 400 180 160 1230 175 ÷ 400 180 160 1280 200 ÷ 450 224 178 178 219 6 4 2 0 Burner/gas train match Burner model Gas type Curve on graph P.Max ** Execution mbar 70A TBG 85 PN NATURAL 70B TBG 85 PN V GAS 70C 70D 71A 100 360 100 100 500 100 360 TBG 120 PN NATURAL 71B 100 GAS 71C 100 71D 500 Burner model Gas type P.Min * Execution mbar TBG 85 PN TBG 85 PN V LPG 30 CTV TBG 120 PN LPG 30 CTV CTV CTV CTV CTV CTV CTV CTV CTV CTV CTV 200 300 Part no. 19990441 19990441 19990448 19990448 19990442 19990442 19990443 19990443 19990530 19990530 19990441 19990441 19990448 19990448 19990442 19990442 19990443 19990443 19990530 19990530 Part no. 400 500 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 kW Burner/gas train adapter Part no. Included Included Included Included Notes D3 D3 D3 D3 D3 D3 D3 D3 D3 D3 D3 D3 D3 D3 D3 D3 D3 D3 D3 D3 LPG nozzles kit Part no. – 98000101 – 98000101 Pic. 98000357 98000357 98000358 98000358 Notes D3 D3 D3 D3 Natural gas HI 35,8MJ/m3 = 8550 kcal/m3 LPG HI 92MJ/m3 = 22000 kcal/m3 **) Maximum gas inlet pressure at pressure regulator in CE version, at gas train for EXP version. Net calorific value at reference conditions of 0°C, 1013mbar: gas + regolatore di pressione) Pic. – 98000101 – 98000101 – 98000101 – 98000101 – 98000102 – 98000101 – 98000101 – 98000101 – 98000101 – 98000102 Valve tightness control kit Part no. 96000032 96000032 96000007 96000007 Pressure drop (combustion head + Perdite di carico (testatrain di combustione + rampa gas + pressure regulator) Valve tightness control kit Part no. 96000032 96000032 96000032 96000032 96000007 96000007 – – – – 96000032 96000032 96000032 96000032 96000007 96000007 – – – – Burner/gas train adapter Part no. Regulator with incorporated filter Part no. 19990441 19990441 19990442 19990442 600 Regulator with incorporated filter Part no. Included Included Included Included Included Included Included Included Included Included Included Included Included Included Included Included Included Included Included Included Gas train Gas train CTV) Gas train with Valve Tightness Control. *) Minimum gas train inlet pressure needed to obtain maximum burner power with a combustion chamber backpressure of zero. 100 Perdite di carico Pressure drop (combustion head + TBG 120PN Natural gas metano (testatrain di combustione + rampa gas + pressure regulator) CE gas + regolatore di pressione) TBG 85PN Natural metanogas CE 90 45 85 80 40 75 35 Baltur S.p.A. Quality System Certified UNI-EN ISO 9001 I.C.I.M. n° 202 Data reported in this brochure shall be considered as indicative; Baltur reserves the right to change them without previous notice. 71A 65 60 30 70B 20 70C 15 mb a r 25 Pressure P R E S S IO NE mb a r 55 P R E S S IO NE Pressure Via Ferrarese, 10 44042 Cento (Fe) - Italy Tel. +39 051-6843711 Fax: +39 051-6857527/28 www.baltur.it info@baltur.it 70 70A 50 45 40 71B 35 30 70D 71C 25 20 10 71D 15 5 10 5 0 0 0 ediz.03/2006 10 20 30 40 50 ThermalPORTATA output 60 Kw x10 70 80 90 100 10 ediz.03/2006 20 30 40 50 60 70 80 Thermal output PORTATA kW x10 90 100 110 120 130