Oct-Dec 2006

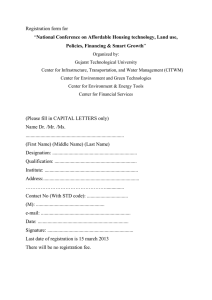

advertisement