Australian Journal of Basic and Applied Sciences, 8(15) Special 2014, Pages: 86-91

AENSI Journals

Australian Journal of Basic and Applied Sciences

ISSN:1991-8178

Journal home page: www.ajbasweb.com

Effectiveness of kapok fibre (Ceibapentandra) as roof insulation for residential buildings

in hot climate

1

Muhd Fadhil Nuruddin, 1NadzhratulHusna Ahmad Puad, 2Azirul Zainal, 1Syed Ahmad Farhan, 3MohdFaris Khamidi

1

Department of Civil Engineering, Faculty of Engineering, UniversitiTeknologi PETRONAS,Bandar Seri Iskandar, 31750 Tronoh,

Perak,Malaysia.

2

Project Management and Delivery Department, Technology and Engineering Division, PETRONAS Holdings Berhad, Level 6,

MenaraDayabumi, Jalan Sultan Hishamuddin, 50050 Kuala Lumpur, Malaysia.

3

School of the Built Environment, Heriot-Watt University Malaysia, Level 2, MenaraPjH, 2 JalanTun Abdul Razak, Precinct 2, 62100

Putrajaya, Malaysia.

ARTICLE INFO

Article history:

Received 15 September 2014

Accepted 5 October 2014

Available online 25 October 2014

Keywords:

Kapok

fibre,

roof

insulation,

residential building, hot climate,

thermal discomfort

ABSTRACT

Background: Occupants in residential buildings experience high levels of thermal

discomfort due to the intense and long hours of solar radiation that causes the indoor

temperature to rise. Absence of insulation in the roof structure of residential buildings

allows more heat to penetrate into the indoor space through the roof. Many building

insulation materials in the market today such as polystyrene, polyurethane and

polyethylene are expensive and not environmentally friendly because they are produced

synthetically and involve numerous processes that emit carbon dioxide to the

environment. Kapok fibre is an organic material that is cheap, environmentally friendly

and easily obtained. Previous researchers have conducted laboratory experiments on

kapok fibre and proved that it has low thermal conductivity. However, there is lack of

research on the performance of kapok fibre as a roof insulation material. This paper

evaluates the effectiveness of kapok fibre as roof insulation for residential buildings in

hot climate. Two scaled-down experimental house models equipped with temperature

data loggers were set up. One house was uninsulated and the other was insulated with

kapok fibre. The thickness of kapok fibre insulation was 5 cm and then increased to 10

cm. Hourly outdoor and indoor temperatures for each house were measured for five hot

days. The highest outdoor-indoor temperature difference was 6.42 °C, which was

obtained by 10-cm kapok fibre insulation at 1000 hours. The results proved that kapok

fibre can reduce indoor temperature of residential buildings. The effectiveness of kapok

fibre insulation can be further validated by conducting experiments in actual houses

with the presence of occupants, appliances and furniture.

© 2014 AENSI Publisher All rights reserved.

ToCite ThisArticle:Nuruddin M.F., Puad, N.H.A., Zainal, A., Farhan, S.A. andKhamidi M.F., Effectiveness of kapok fibre

(ceibapentandra) as roof insulation for residential buildings in hot climate. Aust. J. Basic & Appl. Sci., 8(15): 86-91, 2014

INTRODUCTION

The production of 30% carbon dioxide in 2005 comes from buildings in many developed countries (United

Nations Environment Programme, 2009). McKinsey & Company (2009) stated that greenhouse gases can be

reduced through building insulation. Thermal insulation materials can retard heat from solar radiation from

penetrating into the building. There are many different types of commercialized insulation materials in the

industry. Traditional insulation materials such as mineral wool, cellulose, cork and polyurethane are widely used

because of their high thermal resistance (Jelle, 2011). However, many building insulation materials in the

market are expensive (Al Yacoubyet al., 2011) and some of them are hazardous and not environmentally

friendly. Many of the commercialized products such as expanded polystyrene, cellulose fibre, cork, glass wool

and polyurethane has thermal conductivity ranging between 0.02 to 0.06 W/mK.

Insulation materials can be installed in different parts of the building envelope such as walls, ceiling and

roof. Other than that, insulation materials can also be mixed into the material that is used to construct the

building envelope (Khamidiet al., 2014; Farhanet al., 2012b). Previous research on building insulation focused

more on wall insulation (Farhanet al., 2012a).The effectiveness of installing insulation in the roofing system

must be explored further as most of the heat gain into the building is through the roof(Suehrckeet al., 2008; AlHomoud, 2005).

Corresponding Author: Dr. Muhd Fadhil Nuruddin, Department of Civil Engineering, Faculty of Engineering,

UniversitiTeknologi PETRONAS, Bandar Seri Iskandar, 31750 Tronoh, Perak, Malaysia.

E-mail: fadhilnuruddin@petronas.com.my

87

Muhd Fadhil Nuruddin et al, 2014

Australian Journal of Basic and Applied Sciences, 8(15) Special 2014, Pages: 86-91

Kapok fibre is an organic material extracted from kapok trees and it has a low thermal conductivity (0.034

to 0.035 W/mK) (Louppeet al., 2008). Kapok fibre has a low density and is seven times less dense compared to

cotton because it contains unicellular fibres (Chaiarrekijet al., 2011; Manohar et al., 2006). Kapok fibre shows

better performance in thermal properties compared to other natural fibres and allows it to challenge other

synthetic fibres (Voumbo, 2010). However, Nuruddinet al.(2014) reports that based on previous literature, there

is presently no research that explores the adoption of kapokfibre as a roof insulation material.

Herein, this paper determines the effectiveness of kapok fibre as an insulation roofing material in residential

buildings in hot climate. Also, the effect of thickness on its insulation effectiveness is also determined.

Experimentation:

Measurements of outdoor and indoor temperatures were conducted using two scaled-down experimental

house models equipped with temperature data loggers. The house models were built with reference to the

minimum dimensions of a room as mentioned in Uniform Building By-Laws (UBBL) 1984 (Legal Research

Board, 2012a; Legal Research Board, 2012b) Dark grey coloured roof tiles were employed to allow maximum

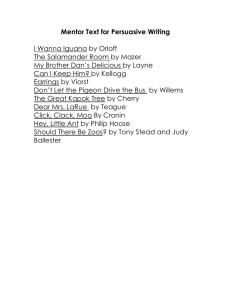

absorption of heat from solar radiation. Table 1 presents the insulations installed in the house model variations.

Table 1: Insulations installed in the house model variations

House Model

Insulation

A

Uninsulated (Figure 1)

B

5-cm kapok fibre (Figure 2)

C

10-cm kapok fibre (Figure 2)

D

Radiant barrier (Figure 3)

Fig. 1: Top view of attic of uninsulated house model

Fig. 2: Top view of attic of insulated house model

88

Muhd Fadhil Nuruddin et al, 2014

Australian Journal of Basic and Applied Sciences, 8(15) Special 2014, Pages: 86-91

Fig. 3: Top view of attic of radiant barrier house model

Kapok fibre used in this study was obtained from Bota, Perak. Impurities were removed from the kapok

fibre before it was placed in the model. Brown paper was selected as the ceiling board material to hold the

kapok fibre in place because it is very thin and will not influence the indoor temperature. Radiant barrier used in

this study was obtained from a local manufacturer. The radiant barrier is a pure aluminium foil bonded to a layer

of woven fabric.

Indoor and outdoor temperatures were recorded simultaneously for all models using temperature data

loggers with built-in thermometers. Hourly temperatures were taken for five hot days. The climate of Malaysia

is hot throughout the year and therefore, five hot days is sufficient. Then, hourly outdoor-indoor temperature

differences were calculated.

RESULTS AND DISCUSSION

40

35

30

25

20

0900

1400

1900

0000

0500

1000

1500

2000

0100

0600

1100

1600

2100

0200

0700

1200

1700

2200

0300

0800

1300

1800

2300

0400

0900

Temperature for

uninsulated house model

(Model A) (°C)

Figure 4 shows the indoor and outdoor temperature profiles of Model A. In general, daily outdoor

temperatures peak in between 1000 to 1600 hours due to the position of the sun that leads to maximum solar

radiation. The highest outdoor-indoor temperature difference recorded was 4.82°C, which was obtained at 1100

hours in Day 4.

Hours

Indoor

Outdoor

Fig. 4: Indoor and outdoor temperature profiles for uninsulated house model (Model A)

Figure 5 shows the indoor and outdoor temperature profiles for Model B. The highest outdoor-indoor

temperature difference recorded was 5.26 °C, which was obtained at 1000 hours in Day 3. The outdoor-indoor

temperature difference for Model A at this time was 4.63 °C, which is 0.63 °C lower compared to Model B.

Therefore, Model B is effective in retarding heat into the house model.

Muhd Fadhil Nuruddin et al, 2014

Australian Journal of Basic and Applied Sciences, 8(15) Special 2014, Pages: 86-91

45

40

35

30

25

20

0900

1400

1900

0000

0500

1000

1500

2000

0100

0600

1100

1600

2100

0200

0700

1200

1700

2200

0300

0800

1300

1800

2300

0400

0900

Temperature for 5-cm

kapok fibre insulated house

model (Model B) (°C)

89

Hours

Indoor

Outdoor

Fig. 5: Indoor and outdoor temperature profiles for 5-cm kapok fibre insulated house model (Model B)

45

40

35

30

25

20

0900

1400

1900

0000

0500

1000

1500

2000

0100

0600

1100

1600

2100

0200

0700

1200

1700

2200

Temperature for 10-cm

kapok fibre insulated house

model (Model C) (°C)

Figure 6 shows indoor and outdoor temperature profiles for Model C. The highest outdoor-indoor

temperature difference recorded was 8.4°C, which was obtained at 1000 hours in Day 3. Model B recorded a

5.26 °C difference during this time. This proves that the outdoor-indoor temperature difference for Model C is

3.14°C higher than Model B. Therefore, Model C provides better thermal performance than Model B. In

addition, the outdoor-indoor temperature difference for Model A is 4.63 °C, which is 3.77 °C lower than Model

C.

Hours

Indoor

Outdoor

Fig. 6: Indoor and outdoor temperature profiles for 10-cm kapok fibre insulated house model (Model C)

Figure 7 shows indoor and outdoor temperature profiles for Model D. The highest outdoor-indoor

temperature difference recorded is 7.05°C, which was obtained at 1100 hours in Day 4. Model C recorded a 2.79

°C difference during this time. This proves that the outdoor-indoor temperature difference for Model D insulated

house model is 4.26°C higher than Model C. Therefore, Model D provides better thermal performance than

Model C. In addition, the outdoor-indoor temperature differences for Model A and Model B are 4.82 and 2.79

°C, which are 2.23 and 2.11 °C lower than Model D respectively. Table 2compares the outdoor-indoor

temperature differencesof all house models from 1000 to 1400 hours. The highest average temperature

difference is 5.09 °C, which was obtained by Model C.

Muhd Fadhil Nuruddin et al, 2014

Australian Journal of Basic and Applied Sciences, 8(15) Special 2014, Pages: 86-91

45

40

35

30

25

20

0900

1400

1900

0000

0500

1000

1500

2000

0100

0600

1100

1600

2100

0200

0700

1200

1700

2200

0300

0800

1300

1800

2300

0400

0900

Temperature for 10-cm

kapok fibre insulated

house model (Model D)

(°C)

90

Hours

Indoor

Outdoor

Fig. 7: Indoor and outdoor temperature profiles for radiant barrier insulated house model (Model D)

Table 2: Outdoor-indoor temperature differences of insulated and uninsulated house models

Outdoor-Indoor Temperature Difference (°C)

Time (hours)

Model A

Model B

Model C

1000

3.60

4.61

6.42

1100

3.98

4.29

5.11

1200

2.79

3.28

4.56

1300

2.86

2.33

5.18

1400

2.21

2.71

4.19

Average

2.72

3.44

5.09

Model D

5.45

5.13

5.23

3.61

4.06

4.69

Analysis of Variance (ANOVA):

Analysis of variance (ANOVA) was used to determine the significant differences between uninsulated and

insulated house model. A one-way analysis was performed to compare the means of subgroups. The analysis

included standard deviations, variances and 95% of confidence interval means. The results are considered

significant when the P-value is lower than 0.05. However, it is considered marginally significant if the P-value

is lower than 0.1. The ANOVA results are shown in Table 3. Results showed a marginally significant preference

for Model A (M = 3.087, SD = 1.137, p = 0.089) and Model B (M = 3.446, SD = 1.539, p = 0.068). The

outdoor-indoor temperature difference for Model A is marginally significant at 1100 and 1400 (p = 0.084).

However, there are no statistically significant differences for Model C (M = 5.090, SD = 1.579, p = 0.221) and

Model D (M = 4.697, SD = 1.395, p = 0.139).

Table 3: Results of ANOVA on insulated and uninsulated house models

House Model

Mean (M)

Standard Deviation (SD)

Model A

3.087

1.137

Model B

3.446

1.539

Model C

5.090

1.579

Model D

4.697

1.395

P-Value (p)

0.089

0.068

0.221

0.139

Conclusion:

Findings suggest that kapok fibre is effective as a roof insulation material in residential buildings in hot

climate. In addition, thicker kapok fibre improves its effectiveness. The highest outdoor-indoor temperature

difference was 5.09 °C for 10-cm kapok fibre insulated house model, which is 2.37°C higher than the

uninsulated house model. For future research, it is recommended that higher thicknesses of kapok fibre are used

for evaluation. Also, the evaluation can be conducted in actual houses with the presence of occupants,

appliances and furniture.

REFERENCES

Al-Homoud, M.S., 2005. Performance characteristics and practical applications of common building

thermal insulation materials, Building and Environment, 40(3): 353-366, DOI: 10.1016/j.buildenv.2004.05.013.

Al Yacouby, A.M., M.F. Khamidi, Y.W. Teo, M.F. Nuruddin, S.A. Farhan, S.A. Sulaiman, A.E. Razali,

2011. Housing developers and home owners awareness on implementation of building insulation in Malaysia.

WIT Transactions on Ecology and the Environment, 148: 219-230, doi: 10.2495/RAV110211.

Chaiarrekij, S., A. Apirakchaiskul, K. Suvarnakich and S. Kiatkamjornwong, 2011. Kapok 1:

Characteristics of kapok fibre as a potential pulp source for paper making. Bioresources, 7(1): 475-488.

Farhan, S.A., M.F. Khamidi, A.M. Al Yacouby, A. Idrus, M.F. Nuruddin, 2012a. Critical review of

published research on building insulation: Focus on building components and climate. BEIAC 2012-2012 IEEE

91

Muhd Fadhil Nuruddin et al, 2014

Australian Journal of Basic and Applied Sciences, 8(15) Special 2014, Pages: 86-91

Business, Engineering and Industrial Applications Colloquium.article number 6226046, 172-177, doi:

10.1109/BEIAC.2012.6226046.

Farhan, S.A., M.F. Khamidi, M.H. Murni, M.F. Nuruddin, A. Idrus, A.M. Al Yacouby, 2012b. Effect of

silica fume and MIRHA on thermal conductivity of cement paste.WIT Transactions on the Built Environment,

124: 331-339, doi: 10.2495/HPSM120291.

Jelle, B.P., 2011. Traditional, state-of-the-art and future thermal building insulation materials and solutions–

Properties, requirements and possibilities. Energy and Buildings, 43: 2549-2563.

Legal Research Board, 2012a. Space, Light and Ventilation in "Uniform Building By-Laws 1984," rule no.

42, Selangor, Malaysia: International Law Book Services, 30.

Legal Research Board, 2012b. Space, Light and Ventilation in "Uniform Building By-Laws 1984," rule no.

44, Selangor, Malaysia: International Law Book Services, 30.

Louppe, D., A.A. Oteng-Amoako, M. Brink, 2008. Plant Resources of Tropical Africa 7: timbers 1.

PROTA Foundation. Leiden, the Netherlands. Backhuys Publishers.

Khamidi, M.F., C. Glover, S.A. Farhan, N.H.A. Puad and M.F. Nuruddin, 2014. Effect of silica aerogel on

the thermal conductivity of cement paste for the construction of concrete buildings in sustainable cities. WIT

Transactions on the Built Environment, 137: 665-674, doi: 10.2495/HPSM140601.

Manohar, K., D. Ramlakhan, G. Kochhar and S. Haldar, 2006. Biodegradable fibrous thermal insulation. J.

Braz. Soc. Mech. Sci. Eng., 28(1): 45-47.

McKinsey and Company, 2009. Pathways to a Low-Carbon Economy – Version 2 of the Global

Greenhouse Gas Abatement Cost Curve.

Nuruddin, M.F., N.H.A. Puad, K.A.M. Azizli, S.A. Farhan and A. Zainal, 2014. Prospect of adopting

kapok fibre as roof insulation, Applied Mechanics and Materials, 567: 482-487, doi:

10.4028/www.scientific.net/AMM.567.482

Suehrcke, H., E.L. Peterson, N. Selby, 2008. Effect of roof solar reflectance on the building heat gain in a

hot climate, Energy and Buildings, 40(12): 2224-2235, doi: 10.1016/j.enbuild.2008.06.015.

United Nations Environment Programme (UNEP), 2009. Buildings and Climate Change Summary for

Decision Makers, UNEP DTIE Sustainable Consumption & Production Branch, Paris, France.

Voumbo, M.L., 2010. Characterization of the Thermal Properties of Kapok. Ecole Nationale Supérieure

Polytechnique, UniversitéMarienNgouabi, Congo Brazzaville. 2, s.l. : Maxwell Scientific Organization, Vol. 2.

ISSN: 2040-7467.