A Dual-Planar Microstrip Antenna Design for UHF RFID

advertisement

A Dual-Resonant Planar Microstrip Antenna Design for UHF RFID

Using Paperboard as a Substrate

Mutharasu Sivakumar, Daniel D.Deavours

Information and Telecommunication Technology Center

University of Kansas

email: {muthus, deavours}

Abstract— Passive UHF RFID tags are commonly used in the

supply chain, and generally use dipole antennas. It is well

known that the performance of these tags degrade when placed

near water or metal continents. Thus, it is desirable for tags to

have consistent performance regardless of the contents of

containers. Microstrip antennas offer a potential solution, but

variations in the dielectric properties of corrugated paperboard

with varying moisture content provide unique challenges. In

this paper, we investigate whether microstrip antennas are

appropriate for cardboard containers, and show a novel dualresonant microstrip antenna and matching circuit that

provides good performance over a wide range of dielectric

properties. The antenna design can be realized using low-cost,

commodity “inlay” and “smart label” manufacturing

techniques.

T

I. INTRODUCTION

HE majority of passive UHF RFID tags available in the

market are tuned for optimal performance on free space

or when attached to corrugated paperboard/fiberboard

(commonly called “cardboard”). That is because the great

majority of tags are destined to be integrated into “smart

labels” for tagging paperboard for use in the supply chain

(e.g., Wal-Mart “mandates”). While stripline dipoles offer

good performance and low manufacturing costs (as little as

$0.10 US in high volume as of 2006), their primary

limitation is that the performance is highly dependent on the

materials to which they are attached. In the case of

paperboard containers, the contents of the container can

have a dramatic affect on tag performance. Recent advances

in lower-power IC designs offer some improvements, but

those are being offset by lower interrogator usage in order to

limit the interrogation zones.

The materials of greatest significance are metal and water.

Metal in the form of canned goods are relatively easy to

manage by finding the air gaps between cans. The most

difficult products are those that contain metallic foil in their

packaging, which is common, e.g., in dishwashing

detergent. Water-based products are also difficult if they are

packaged in rectangular-shaped containers so that there is no

predictable air gap.

In principle, these limitations can be overcome by the use

of microstrip antennas [1]. There are a number of microstrip

Manuscript received November 24, 2006.

antenna solutions for UHF RFID [2] [3] [4] and [5], but the

main limitation of those approaches is the complexity in

manufacturing those tags, and thus they are not amenable to

use in the supply chain. Indeed, the cost of some microstrip

tags can exceed the cost of a cardboard container. In

contrast, [1] provides a solution that requires no connection

from the antenna and the ground plane, and thus is

potentially viable for use in the supply chain. The only

modification is that a metal foil needs to be applied to the

inside of the container, and the paperboard becomes the

substrate of the microstrip antenna. We discuss the

particular antenna design below.

The primary technical challenge to this approach is that

the dielectric properties of paperboard can change

substantially with humidity and temperature. If the relative

dielectric constant changes, for example, from 1.3 to 1.6

with increase in relative humidity, the resonant frequency of

the antenna can shift from 915 MHz to under 800 MHz, and

render the narrowband antenna practically unusable.

Furthermore, the loss tangent increases substantially with

the increased water absorption, resulting in poor impedance

match.

The purpose of this paper is to show that we can design

microstrip antennas that take into account the changing

dielectric properties of paperboard under different humidity

conditions. We do this by designing a very simple dualresonant patch antenna and matching circuit. The elements

are designed so that the first antenna and matching circuit

resonates and provides a good match with the lower

dielectric constant and loss tangent, and the second antenna

and matching circuit resonates and provides a good match at

the higher dielectric constant and loss tangent. The

increased complexity of our proposed solution is the

application of a metallic foil to a portion of the interior of

the container.

II. APPROACH

In this section, we review known properties of paperboard

and previous work on planar microstrip antennas.

A. Properties of paperboard

Corrugated cardboard or corrugated paperboard (hereafter

paperboard) can be classified based on the number of paper

walls. Cardboard commonly comes in three forms: single

faced, in which flutes have paper on one side, single walled,

in which flutes are sandwiched between paper walls, and

double walled, in which two layers of flutes are contained

by three paper walls. Single-walled paperboard is the type

most commonly used in the supply chain.

Paperboard can also be classified in the type of flutes and

number of flutes per unit length. The “C” flute is the most

common, and the flute density of 42 flutes every 12 inches,

i.e., approximately one flute per 2/7th of an inch. For this

paper, we use a sample of “C” flute, 42 flutes per 12 inches,

and 150 mils (0.150 inches, 3.81 mm) thick.

Table I: Sorption / desorption of paperboard [2].

40% RH

90% RH

8 g/100g (Sorption)

16 g/100g (Sorption)

1° C

10 g/100g (Desorption)

18 g/100g (Desorption)

6 g/100g (Sorption)

14 g/100g (Sorption)

40° C

10 g/100g (Desorption)

18 g/100g (Desorption)

Temp.

The main limitation of using paperboard as a substrate for

a microstrip “patch” antenna is the fact that dielectric

properties of the paperboard can change over time

depending on the water content in the cardboard. Water

content in cardboard is typically measured in grams of water

per 100 grams of solid substance. Water content follows a

sorption / desorption isotherm based on the relative humidity

and temperature [6]. When the relative humidity increases,

the sorption rate is used to calculate the moisture content,

and when the relative humidity decreases, the desorption

rate is used. Table 1 illustrates a typical sorption /

desorption isotherm. As Table I indicates, water content can

vary between 6 and 18 g/100g.

Equilibrium moisture content of single walled paperboard

at 20 degree Celsius and 54.4% relative humidity

(approximately room temperature conditions) is 9.34 grams

per 100 grams of solid substance [4], although we measured

a lower rate for our paperboard sample (see Section 3).

Considering temperatures between 1 and 40 degree Celsius

and RH between 40 and 90 percent, the range of water

contents we are looking for would be from 6 to 18 grams per

100 grams of solid paper substance. To be conservative, we

consider water content rates between 5 and 25 g/100g. In

Section 3, we measure the dielectric properties for

paperboard with varying moisture content.

B. Microstrip Antennas

Traditional microstrip antennas for RFID tags (e.g., [3]),

require some direct electrical connection between the

antenna or matching circuit and the ground plane. For lowcost packaging, introducing a via is simply not cost

effective. A completely planar microstrip antenna design in

which the antenna, matching circuit, and RFID IC are all on

the same plane (e.g., [1]) is ideally suited for such an

application.

Using this method, the only additional step is to include a

ground plane in the paperboard, which can be performed

relatively easily at manufacturing time, either by integrating

a metal foil into the paper wall, or by applying a metal foil

tape to the interior of the box before it is formed. The

microstrip inlay (antenna and IC on a PET substrate) can be

converted to a “smart label” (label with inlay affixed) and

applied using the usual label-application method.

To exercise this approach, what is necessary is to design a

planar microstrip tag for the paperboard substrate. The

primary difficulty of this approach is that the dielectric

properties of paperboard can change substantially with

changes in relative humidity. What we will show is that a

simple, rectangular antenna and matching circuit that is

designed for relatively low water content becomes

practically unreadable at higher moisture contents. Thus, we

need to develop a microstrip antenna and matching circuit

that is able to match to the range of different dielectric

properties of the paperboard.

III. DIELECTRIC PROPERTIES OF PAPERBOARD

If we can find the percentage of water by volume for

various values of water content then we will be able to

obtain a theoretical bound on the dielectric constants we

need to operate over, provided we know the dielectric

properties of water over the range of temperatures and water

behaves the same way electrically when bonded with the

paper molecules and at free state.

Dielectric properties of water have been evaluated

extensively and available in literature [7]. Values of relative

permittivity and loss tangent for water at different

temperatures are tabulated in Table II.

Table II: Dielectric properties of water at 915 MHz.

tan δ

T (°C)

εr

0

87.0

0.095

25

78.2

0.044

40

73.1

0.031

We found that the density of our dry cardboard sample

has a density of 0.14 g/cc. It is well known that water has a

density of 1 g/cc. A simple calculation shows that water

content between 6 and 18 g/100g yields 0.84% to 2.52%

water by volume respectively. Assuming a simplistic model

of proportionality, and assuming that the dielectric constant

of cardboard is 1 (air), we could estimate that the dielectric

constant of cardboard varies between 1.66 and 2.97,

respectively. Based on measurements we show below later,

this simplistic model is not valid, and clearly the water is not

behaving electrically the same way as it does in liquid form.

Thus, we must obtain direct measurement of the dielectric

constant of the cardboard in order to design to that material.

We found the dielectric properties of different materials

by constructing a resonant rectangular microstrip antenna

and measuring the S-parameters using a network analyzer.

We start by estimating a value for dielectric constant and

loss tangent of the paperboard. Using the assumed dielectric

properties, we constructed a microstrip patch antenna,

measured the impedance characteristics over a broad

frequency range, then used data fitting and a method of

moments simulation package to estimate the dielectric

properties of the paperboard. The antenna design was

fabricated using the paperboard as substrate as shown in

Figure 1.

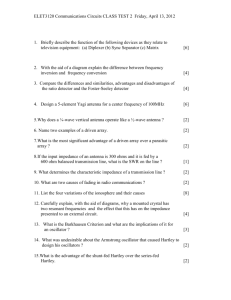

Figure 1: Microstrip test apparatus for paperboard. The

reverse side is laminated with a metal foil.

Table III: Measured dielectric properties of paperboard.

Water content

εr

tan δ

(g/100g)

~0

1.2

0.01

6.5

1.24

0.014

10

1.3

0.02

25

1.45

0.05

moisture content at room temperature and approximately

55% relative humidity was 6.5 g/100g, which differs from

[8]. We can conclude that different paperboard behaves

differently, and thus results from this paper should not be

overly generalized.

IV.

SINGLE RESONANT ANTENNA DESIGN

Once we know the dielectric properties of the substrate,

we first investigated whether a single-resonant patch

antenna such as [1] can be used to give the required

performance.

A. Design

We began by attempting to design the antenna with roomtemperature conditions (i.e., εr = 1.24 and tan δ = 0.014).

We chose the patch antenna to have a width of 40 mm,

which can safely fit in a 2-inch label. As illustrated in

Figure 2, we shaped the antenna so that the matching circuit

could safely fit within the 40 mm width. We determined the

length to be 128 mm. The matching circuit was constructed

with 3 mm transmission lines with 3 mm spacing, and the

matching circuit is placed in a 32 mm by 12 mm cavity.

This yields a resonant frequency of about 932 MHz with a

resonant impedance of 89 + j111 for 6.5g/100g paperboard.

The resonant frequency was intentionally high and the

impedance intentionally too large in order to obtain good

performance over the range of dielectric constants.

5

0

Dry

6.5

10

25

For accuracy, we repeated the procedure a number of

times until we were satisfied with the accuracy. Relative

permittivity and loss tangent of paperboard at room

temperatures conditions found using the above procedure

were 1.24 and 0.014 respectively. Note that the measured

-10

-15

960

950

940

930

920

910

900

890

-20

880

Five samples of paperboard of same dimensions were

taken. The samples were dried completely, weighed, and

stored in an air tight bag. After about 24 hours, they were

weighed again to make sure there was no change in water

content. Then we added water to obtain a 10g, and 25g of

water per 100g of dry paperboard. The samples were kept

for about 24 hours in an air tight bag to reach uniform

moisture content throughout the paperboard. Finally, the

dielectric constants of all the samples were measured using

the microstrip method. The dielectric constant and loss

tangent that we obtained are tabulated in Table III.

Dielectric constant and loss tangent of paperboard with

25g/100g water content was 1.45 and 0.05 respectively.

Dielectric constant and loss tangent of paperboard with no

water content was 1.2 and 0.01 respectively. These specify

the upper and lower bound of the dielectric properties of the

paperboard respectively.

Gain (dBi)

-5

Frequency (MHz)

Figure 2: Simulated antenna gain of single patch for various

moisture levels.

One novel aspect of the design in Figure 5 over [1] is that

that [1] forces relatively high current densities through 1 mm

transmission lines, while Figure 2 uses 3 mm transmission

lines. Using wider lines yielded a measurable increase in

performance. The matching circuit was designed to provide

a good match to 65 –j110 Ohms. For the performance

criterion, we chose a gain of -5 dBi, which should be

readable reliably to about 16 feet (about 5 meters), and

found that this design gives about 44 MHz of bandwidth

with that criterion. The simulated gain values are shown in

Figure 3.

When we varied the dielectric properties of the material,

the simulation results showed the gain curves in Figure 2.

While 10g/100g still gives acceptable performance,

25g/100g is completely unacceptable. Experimentation with

simulation indicates that about 15g/100g is enough to reduce

the gain to unacceptable levels. Thus, the change in

dielectric constant due to 90% relative humidity is sufficient

to render this tag as below-adequate performance.

120

Figure 5: Image of single patch design for paperboard.

100

Dry

Real Impedance (Ohm)

6.5

10

80

25

60

40

20

960

950

940

930

920

910

900

890

880

0

Frequency (MHz)

Figure 3: Simulated input resistance of single patch for

various moisture levels.

Assuming minimum transmit power obtained provides the

minimum turn on power for the chip (a known quantity), we

can find gain of the tag antenna using Friss’ transmission

equation. What we obtain is a result that includes the

product of the tag antenna gain (Gt) and the power

transmission coefficient (τ). We call this product the

realized gain. The results for the realized gain are shown in

Figure 6 for 6.5g/100g. Note that for 25g/100g, we were not

able to achieve a single read at any frequency at 1 meter.

0

-0.5

160

Dry

-1

10

25

-1.5

Gain (dBi)

Imaginary Impedance (Ohm)

6.5

80

-2

-2.5

-3

-3.5

Also, it was found that for higher values of loss tangent the

port impedance reduced drastically which lead to poor

impedance matching. Figures 3 and 4 show the simulated

real and imaginary input impedance for the tag, which we

found to have good agreement with measured impedance

values. Note that the 6.5g/100g and 10g/100g show a good

impedance match over a portion of the band, but 25g/100g

has unacceptably low real impedance over the FCC band.

B. Measurements

Next, we constructed a rectangular tag, attached the RFID

IC, and measured its performance. An image of the

constructed tag is shown in Figure 5. Note that a metal foil

was attached to the reverse side. We used an instrumented

RFID reader in which we varied the frequency and power

settings from 903 to 927 MHz in order to find the minimum

power setting required to stimulate the tag. The tag was

placed a fixed distance (1 meter) from the reader antenna.

Note that the “turn-on power” measures both gain and

impedance match.

927

924

921

918

915

912

909

Figure 4: Simulated input reactance of single patch for

various moisture levels.

-4

906

Frequency (MHz)

903

960

950

940

930

920

910

900

890

880

0

Frequency (MHz)

Figure 6: Measured antenna gain of single patch antenna at

6.5g/100g. At 25g/100g, the tag was unreadable.

C. Interpretations

The tag shows excellent performance at 6.5g/100g, and

we would expect similar performance at 10g/100g. This tag

should be readable well over 20 feet away. However, with

higher moisture contents, the tag becomes completely

unreadable. The tag experiences very poor performance at

the higher moisture levels both because the antenna is not

resonant at the higher dielectric constants and because it

experiences poor impedance matching that happens when

the antenna is non-resonant and because there is a

significant reduction in the resonant resistance due to the

higher tan δ.

From these results, we conclude that a suitable microstrip

patch antenna is not suitable to address the variance in

dielectric constant for paperboard. Traditional methods of

making the antenna more broadband, such as making the tag

wider or thicker, are not practical for this problem.

If we are to achieve good performance over a considerable

variation in the dielectric constant of the paperboard, we

must develop new techniques to address this unique

challenge.

V.

DUAL-RESONANT ANTENNA DESIGN

In Section 4, we concluded that a single-resonant patch

antenna with a single, balanced feed structure is not suitable

to work suitably over the range of dielectric properties of

paperboard. We noted two factors that caused problems:

poor antenna efficiency due to non-resonant behavior, and

poor impedance matching. Any solution will need to

adequate address both of those challenges.

Here, we propose the use of two resonant patch antennas.

Unlike previous work of [1], we use a single, edge feed off

of the non-radiating edge of each antenna. Each antenna is

designed to resonate at a significantly different frequency.

We note that the non-resonant impedance of a patch antenna

is small in magnitude, and we use that small-magnitude

impedance as an approximation for a reference to ground. A

simple transmission line length is used to increase the

reactive component of the impedance in order to provide

good impedance matching.

maintains a good match and reasonable gain for higher

values of relative permittivity and loss tangent.

A dual patch antenna was designed taking all these factors

into consideration. The design with dimensions is shown in

Figure 7.

Figure 7: Dual-resonant antenna design with measurements.

Next, we present simulation results for the antenna.

Figure 8 shows the simulated antenna gain for varying

moisture rates. We note that the -5 dBi gain bandwidth at

6.5g/100g is approximately 81 MHz, almost twice as large

as the single rectangular patch.

5

0

Dry

6.5

10

25

-5

Gain (dBi)

By using this approach, we are able to not only match to

two different frequencies, but to two different impedances as

well.

-10

-15

1000

985

970

955

940

925

910

895

-20

880

A. The Design

For comparison purposes, we choose width of the antenna

form factor to be the same 40 mm as in section 4. The two

patches are offset in terms of resonant frequency, one has a

resonant frequency of about 925 MHz and the other patch

has a resonant frequency of about 973 MHz. The lengths of

these patches were 148 mm and 136 mm respectively. The

patches were 15mm wide and were placed 10mm apart.

Frequency (M Hz)

Figure 8: Simulated antenna gain of dual patch for various

moisture levels.

350

300

Dry

6.5

Real Impedance (Ohm)

250

10

25

200

150

100

50

1000

985

970

955

940

925

910

895

0

880

A rectangular patch antenna fed offset from center of the

non-radiating edge has a small reactive impedance. This

reactive impedance can be increased as required for

matching by changing length and width of the transmission

line. Again, we make use of the fact that at frequencies in

which one patch is resonating; the other patch has very low

impedance and acts as a virtual ground, eliminating the need

for any via.

Frequency (MHz)

Adjusting lengths and offsets of transmission lines

feeding the two patches, we can control the impedance for

both the resonances separately. This proves to be a great

advantage because for higher values of water content, both

the relative permittivity and loss tangent goes up resulting in

the lower resonant frequencies and a decrease in Q. Hence

we can adjust the impedance of the resonances so that one

resonance maintains a good match and a good gain for lower

values of relative permittivity and the other resonance

Figure 9: Simulated input resistance of dual patch for

various moisture levels.

Next, we show the simulated real and imaginary input

impedance for varying moisture contents in Figures 9 and

10. Note how the tag is able to maintain excellent

impedance matching (to 65 –j110Ω) over the entire band for

all the tested moisture contents. The second, large peak at

988 MHz for dry paperboard is the same peak that gives an

almost ideal peak of 83Ω at 919 MHz with 25g/100g. The

reactive impedance gives excellent results except for the

higher frequencies at 25g/100g, which will begin to degrade

performance significantly.

240

Dry

Imaginary Impedance (Ohm)

160

C. Interpretations

The measured results show generally good matching with

simulated results, and validate this approach. At 6.5g/100g,

the tag showed better-than-expected effective gain. It is

possible that the moisture content was not fixed for the

duration of the experiment, for example, and the tag took on

excess moisture. It is also very possible that the paperboard

samples were not uniform.

6.5

10

25

80

0

1000

985

970

955

940

925

910

895

880

-80

At 25g/100g, the measured effective gain matches closely

with simulation results. We expected to see a peak gain of

about -8 dBi at lower frequencies with a decrease in

performance at the higher frequencies due to poor

impedance matching. The measured results show exactly

this.

Frequency (MHz)

Figure 10: Simulated input reactance of dual patch for

various moisture levels.

From the above graph we observe that up to a water

content of 25 g/100g the antenna maintains a gain over -8

dBi over all dielectric conditions.

B. Measurement

As before, the design was etched into inlays on copper

clad polyester. Figure 11 illustrates one of the tags used for

testing. The inlays were then fabricated into tags using

paperboard at room temperature and humidity conditions

(6.5g/100g) and with 25g/100g. The tag was tested using

the same process described in Section 4.2. The performance

results are shown in Figure 12.

As a basis for comparison, a tag designed for optimal

performance at 6.5g/100g with a similar form factor as the

tag in Section 4 will give a gain of about -6 dBi. This poor

performance is primarily due the large loss component of the

dielectric constant.

VI. CONCLUSION

In this paper, we considered the applicability of a

microstrip “patch” antenna and its suitability for providing a

consistently high level of performance regardless of the

contents of the container, and with minimal impact on

current processes. The proposed approach requires (1) the

addition of a foil ground plane to the inside of the

paperboard container, and replacing commodity RFID

antennas (typically dipoles) with a planar microstrip

antenna.

We first characterized the dielectric properties of

paperboard under different moisture conditions. We found

that the dielectric constant may vary between 1.2 and 1.45,

and the loss tangent between .01 and .05.

Figure 11: Image of dual-patch design for paperboard.

0

-2

-4

Gain (dBi)

-6

25

-8

6.5

-10

-12

Our first attempt of using a single microstrip patch

antenna based on [1] performed well at the lower moisture

contents, but completely fails at higher moisture contents.

We developed a novel, dual-resonant structure that

provides both frequency and impedance diversity so that we

are able to achieve both good gain and good impedance over

the range of dielectric constants. We present extensive

simulation data as well as experimental results that show

good consistency between the two.

-14

REFERENCES

927

924

921

918

915

912

909

906

903

-16

Frequency (MHz)

[1]

Figure 12: Measured antenna gain of dual-patch antenna.

[2]

M. Eunni, M. Sivakumar, D. Deavours; ‘A Novel Planar Microstrip

UHF RFID’. The 4th International Conference on Computing,

Communications and Control Technologies, CCCT 2006.

Ukkonen, L., Engles, D., Sydanheimo, L., and Kivikoski, M.; ‘Planar

Wire-Type Inverted-F RFID Tag Antenna Mountable on Metallic

[3]

[4]

[5]

[6]

[7]

[8]

Objects’. Antennas and Propagation Society International Symposium

2004 IEEE, vol.1, pp 101-104.

Kwon, H., and Lee, B.; 'Compact Slotted Inverted-F RFID Tag

Mountable on Metallic Objects'. IEE Electrinic Letters, November

2005 Vol.1 pp 1308-1310.

Son, H.W., Yeo, J., Choi, G.Y., and Pyo, C.S.; ‘A Low Cost,

Wideband Antenna for Passive RFID Tags Mountable on Metallic

Surfaces’. Antennas and Propagation Society International

Symposium 2006, IEEE, pp 1019-1022.

Byunggil Yu; Sung-Joo Kim; Byungwoon Jung; Harackiewicz, F.J.;

Myun-Joo Park; Byungje Lee : ‘Balanced RFID Tag Antenna

Mountable on Metallic Plates’. Antennas and Propagation Society

International Symposium 2006, IEEE, pp 3237-3240.

J. Marcondes: “Corrugated Fiberboard in Modified Atmospheres:

Moisture Sorption/ Desorption and Shock Cushioning”. Packaging

Technology and Science, Volume 9, Issue 2, Pg 55-120, December

1998.

K. Kupfer (Ed.): “Electromagnetic Aquametry: Electromagnetic Wave

Interaction with Water and Moist Substances”. Springer Berlin

Heidelberg New York, 2005.

J. Marcondes: “Cushioning Properties of Corrugated Fibreboard and

Effects of Moisture Content”. Transactions of ASAE 1992; 35(6):

1949-1953.