Brochure EN pag

advertisement

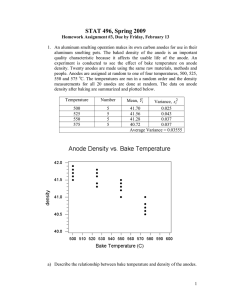

Drieluik ENGELS 2051184 20-12-2005 15:06 Pagina 1 Applications A Cathodic Protection In modern ICCP-systems, Titanium and Niobium anodes are used. To realise a continuous current electrical conductivity and a long lifetime, the anodes are applied with a thin layer of Platinum or Keramox® coating. Frequently seen applications are: ◆ Internal protection of storage tanks, condensers, tank bottoms, pipes, pipelines, heat exchangers and boilers ◆ External protection of pipelines, ship hulls, platforms and other offshore constructions, piers, dams and cooling water inlet parts of power stations. Seawater Electrolysis (anti bio-fouling) The invention of the Titanium anode has been of paramount importance for the electrolysis of seawater. Well known applications are the prevention of algae growth on ship hulls and oil platforms and in cooling water installations of, for instance, power plants. Electroplating In the electroplating industry our oxygen evolving anodes are used for: ◆ Electro galvanising (zinc plating), including steel strip plating ◆ Precious metal plating (gold, silver, palladium, etc.) ◆ (Hard) chromium plating, nickel plating, tin plating ◆ Copper plating, copper foil production and copper foil treatment ◆ Reverse Pulse Plating ◆ Aluminium anodising in liquid-contact-cells. The principle of metal plating is almost identical for all applications. The metal to be plated is dissolved in the electrolyte and the object to be plated is cathodically polarised. With the anodically polarised anodes, the electrical loop is closed. The counter reaction in the plating bath is oxygen evolution at the anode surface. Water treatment Our anodes are used in processes such as potable water treatment, treatment of process water and wastewater, but also for recovery and MAGNETO special anodes B.V. Calandstraat 109 separation of valuable or environmentally hazardous materials. For instance: 3125 BA Schiedam ◆ Electrochemical recovery of metals (Ni, Cd, Cu, Zn, Sn, Ag, Au, etc.) The Netherlands ◆ Direct or indirect oxidation and break-down of organic contamination or cyanide ◆ Removal of small solid particles by means of electroflocculation ◆ Electrodialysis, desalination of process water and electroflotation ◆ Softening of water, de-scaling Phone +31(0)10 - 262 07 88 Fax +31(0)10 - 262 02 01 E-mail info@magneto.nl ◆ Membrane processes. Please visit our website Hypo chlorite & Disinfection The availability of Titanium anodes has been a major break-through for the on-site production of hypo chlorite for potable water treatment and for both private and public swimming pools. The use of Titanium anodes for on-site generation of hypo chlorite is both safer and more environment friendly than the alternative storage and use of chlorine gas or bulk hypo chlorite. By using Titanium anodes, the use of highly corrosive and dangerous chemicals, such as hydro chloric acid can be avoided. Synthesis Reactions MAGNETO special anodes B.V. started to do research years ago, to search for the possibilities of using special anodes for several electrochemical synthesis reactions. At present, anodes are available for several inorganic conversions and oxidation reactions. Some new applications are: ◆ The production of chromic acid ◆ The oxidation of Ce3+ in Ce4+ ◆ Hydrogen production by water electrolysis. www.magneto.nl The original manufacturer of Titanium Anodes Drieluik ENGELS 2051184 20-12-2005 15:06 Pagina 2 COMPANY PRODUCTS Models & Designs Because of a very flexible production facility, we are able to manufacture anodes of all types: sheet, plate, mesh, wire, rod, tubular or combinations and/or assemblies of these materials. Their size and number vary from several cm2 to 2 m2 and from 1 to 10,000 pieces. The process in which the anodes are used determines size, shape and coating specification of an anode. Important parameters determining the anode design are: Profile MAGNETO special anodes B.V. is a technology driven, customer orientated company. The majority of our products consist of tailor made anodes, based on specific needs of our customers. Each of our sales engineers is specialised in specific segments of the inert anode market and is in close contact with our customers. Through these close contacts we are able to optimise the anodes we produce for their specific application and needs. Introduction ◆ The Theelectrochemical electrochemicalcell cellor orinstallation installationwherein whereinthe theanodes anodesare areused used ◆ The process conditions, such as electrolyte composition, temperature, current density, design life, etc. ◆ Mechanical load of the anode ◆ Capacity of electrical conductivity of the base material. special anodes B.V. “Reliability” and “fit for use” are the keywords when it comes to quality at All anodes are produced according to customer specifications. When these specifications are not yet completely determined, MAGNETO special anodes B.V. distinguishes itself from its main competitors by focussing We are focussed on checks and verifications in all stages that are necessary to produce anodes with on only one product: the inert anode. This results in highly advanced anodes, especially anodes B.V. was founded custom developed and produced for applications specified by our customers. in 1957 under the name of an optimum quality. This starts during the first contact with the customer, when the specifications Main application areas Cathodic Protection MAGNETO-CHEMIE B.V. and is the original inventor and Seawater electrolysis manufacturer of Titanium anodes with Platinum and Ruthenium coatings. Policy Statement Under the responsibility of director-owner Ir. P.J.F.M. Hack, Magneto The steady growth of the production and the continuous development of inert anodes special anodes B.V. has developed and implemented a policy of Anodes and coatings KERAMOX® Titanium anode Platinised Titanium Anodes based on Niobium or Tantalum position in the market for Titanium anodes. Titanium with an Iridium Mixed Metal Oxide coating ◆ To maintain a good and responsible position in the market of inert anodes, to guarantee continuity to MAGNETO special anodes B.V., which combines the Water treatment customers, in accordance with the agreed well-known name of MAGNETO and our specialisation: the production of special anodes. Platinised Titanium our customers, our suppliers and our employees. ◆ To satisfy the needs and demands of our specifications and/or standards. ◆ To enterprise within the legal frame in all her aspects We are located in Schiedam, in the industrial heart of the Netherlands, close to important access by road, air and water. Even though Western Europe is our main market, and also in an ethical responsible way. ◆ To strive to working conditions as optimal as possible and thus securing the safety, health and wellbeing of the employees. ◆ To strive to a minimal impact on the environment. Not just looking at our own production process, but also looking at our products. Platinised Titanium Titanium with an Iridium Mixed Metal Oxide coating Boron-Doped-Diamond anodes In highly acidic environments such as: ◆ Electro galvanising (zinc plating) ◆ Anodising of Aluminium ◆ Chromium, Nickel, Tin, etc. plating ◆ Precious metal plating ◆ Reverse pulse Copper plating Hard Chromium plating Precious metal plating Electro dialysis with polarity reversal Recovery of metals Oxidation and break-down of organic contaminations Higher overpotentials,amongst others for disinfection Hypo chlorite & Disinfection Titanium with a Ruthenium Mixed Metal Oxide Depending on salinity, polarity reversal and current coating density Titanium with an Iridium Mixed Metal Oxide coating Titanium with a Platinum-Iridium Oxide coating Synthesis reactions Most of our clients are either producers of complete electrochemical cells and Platinised Titanium Titanium with an Iridium Mixed Metal Oxide coating Boron-Doped-Diamond anodes Depending on the particular reaction At higher overpotentials production systems (Original Equipment Manufacturers) or end-users. In several countries we work in close co-operation with local agents or specialised distributors. are determined. In the following steps, all parts of the production process are looked at to make sure the specifications will be met. Determination and the performance of Research & Development and all our supporting and administrative activities are within our Management System Already in the early 90’s we had started formalising and implementing unequivocal production methods and other procedures. By 1998 our Electroplating which the most important items are: In the middle of 2002, the name was changed to Details All round applicable At high current densities, for example in sea water High voltages or strongly corrosive electrolytes KERAMOX® Titanium anode Depending on amongst others temperature and Titanium with a Ruthenium Mixed Metal Oxide salinity coating Titanium with a Platinum-Iridium Oxide coating have given MAGNETO-CHEMIE B.V. a prominent exported and used all over the world. MAGNETO special anodes B.V. our engineers are pleased to use their knowledge and experience to finalise the design together with the customer. MAGNETO special we are proud to say that our anodes are The supply of the most suitable anodes possible is paramount for our customers and for MAGNETO Hydrogen production Nickel electrodes with a precious metal coating Coating process by means of exchange plating The purpose is to decrease the overpotentials Management System had been operational for a long time and had been optimised in such a way that getting our Product Development A significant part of our turnover is dedicated to research and product first ISO certificate NEN-EN-ISO 9002 (1994 standard) was only a formality. development, both in our own laboratory as well as at universities and international research institutes with whom we work in close co-operation. In 2001 we were one of the first Dutch companies to be Our research & development includes the continuous and extensive awarded certification according to the new standard: search for new anode coatings. It also includes the applicability and NEN-EN-ISO 9001:2000. Our ISO certificate is awarded by one behaviour of existing and new anode coatings for different applications and under specific conditions. In case that none of our existing coating specifications meet the specific needs of a customer’s application or special conditions, our objective is always to develop a coating specification in co-operation with our customer that will fully satisfy the customer or end-user. of the world’s best known organisations in this field: Lloyd’s Register Assurance. Drieluik ENGELS 2051184 20-12-2005 15:06 Pagina 2 COMPANY PRODUCTS Models & Designs Because of a very flexible production facility, we are able to manufacture anodes of all types: sheet, plate, mesh, wire, rod, tubular or combinations and/or assemblies of these materials. Their size and number vary from several cm2 to 2 m2 and from 1 to 10,000 pieces. The process in which the anodes are used determines size, shape and coating specification of an anode. Important parameters determining the anode design are: Profile MAGNETO special anodes B.V. is a technology driven, customer orientated company. The majority of our products consist of tailor made anodes, based on specific needs of our customers. Each of our sales engineers is specialised in specific segments of the inert anode market and is in close contact with our customers. Through these close contacts we are able to optimise the anodes we produce for their specific application and needs. Introduction ◆ The Theelectrochemical electrochemicalcell cellor orinstallation installationwherein whereinthe theanodes anodesare areused used ◆ The process conditions, such as electrolyte composition, temperature, current density, design life, etc. ◆ Mechanical load of the anode ◆ Capacity of electrical conductivity of the base material. special anodes B.V. “Reliability” and “fit for use” are the keywords when it comes to quality at All anodes are produced according to customer specifications. When these specifications are not yet completely determined, MAGNETO special anodes B.V. distinguishes itself from its main competitors by focussing We are focussed on checks and verifications in all stages that are necessary to produce anodes with on only one product: the inert anode. This results in highly advanced anodes, especially anodes B.V. was founded custom developed and produced for applications specified by our customers. in 1957 under the name of an optimum quality. This starts during the first contact with the customer, when the specifications Main application areas Cathodic Protection MAGNETO-CHEMIE B.V. and is the original inventor and Seawater electrolysis manufacturer of Titanium anodes with Platinum and Ruthenium coatings. Policy Statement Under the responsibility of director-owner Ir. P.J.F.M. Hack, Magneto The steady growth of the production and the continuous development of inert anodes special anodes B.V. has developed and implemented a policy of Anodes and coatings KERAMOX® Titanium anode Platinised Titanium Anodes based on Niobium or Tantalum position in the market for Titanium anodes. Titanium with an Iridium Mixed Metal Oxide coating ◆ To maintain a good and responsible position in the market of inert anodes, to guarantee continuity to MAGNETO special anodes B.V., which combines the Water treatment customers, in accordance with the agreed well-known name of MAGNETO and our specialisation: the production of special anodes. Platinised Titanium our customers, our suppliers and our employees. ◆ To satisfy the needs and demands of our specifications and/or standards. ◆ To enterprise within the legal frame in all her aspects We are located in Schiedam, in the industrial heart of the Netherlands, close to important access by road, air and water. Even though Western Europe is our main market, and also in an ethical responsible way. ◆ To strive to working conditions as optimal as possible and thus securing the safety, health and wellbeing of the employees. ◆ To strive to a minimal impact on the environment. Not just looking at our own production process, but also looking at our products. Platinised Titanium Titanium with an Iridium Mixed Metal Oxide coating Boron-Doped-Diamond anodes In highly acidic environments such as: ◆ Electro galvanising (zinc plating) ◆ Anodising of Aluminium ◆ Chromium, Nickel, Tin, etc. plating ◆ Precious metal plating ◆ Reverse pulse Copper plating Hard Chromium plating Precious metal plating Electro dialysis with polarity reversal Recovery of metals Oxidation and break-down of organic contaminations Higher overpotentials,amongst others for disinfection Hypo chlorite & Disinfection Titanium with a Ruthenium Mixed Metal Oxide Depending on salinity, polarity reversal and current coating density Titanium with an Iridium Mixed Metal Oxide coating Titanium with a Platinum-Iridium Oxide coating Synthesis reactions Most of our clients are either producers of complete electrochemical cells and Platinised Titanium Titanium with an Iridium Mixed Metal Oxide coating Boron-Doped-Diamond anodes Depending on the particular reaction At higher overpotentials production systems (Original Equipment Manufacturers) or end-users. In several countries we work in close co-operation with local agents or specialised distributors. are determined. In the following steps, all parts of the production process are looked at to make sure the specifications will be met. Determination and the performance of Research & Development and all our supporting and administrative activities are within our Management System Already in the early 90’s we had started formalising and implementing unequivocal production methods and other procedures. By 1998 our Electroplating which the most important items are: In the middle of 2002, the name was changed to Details All round applicable At high current densities, for example in sea water High voltages or strongly corrosive electrolytes KERAMOX® Titanium anode Depending on amongst others temperature and Titanium with a Ruthenium Mixed Metal Oxide salinity coating Titanium with a Platinum-Iridium Oxide coating have given MAGNETO-CHEMIE B.V. a prominent exported and used all over the world. MAGNETO special anodes B.V. our engineers are pleased to use their knowledge and experience to finalise the design together with the customer. MAGNETO special we are proud to say that our anodes are The supply of the most suitable anodes possible is paramount for our customers and for MAGNETO Hydrogen production Nickel electrodes with a precious metal coating Coating process by means of exchange plating The purpose is to decrease the overpotentials Management System had been operational for a long time and had been optimised in such a way that getting our Product Development A significant part of our turnover is dedicated to research and product first ISO certificate NEN-EN-ISO 9002 (1994 standard) was only a formality. development, both in our own laboratory as well as at universities and international research institutes with whom we work in close co-operation. In 2001 we were one of the first Dutch companies to be Our research & development includes the continuous and extensive awarded certification according to the new standard: search for new anode coatings. It also includes the applicability and NEN-EN-ISO 9001:2000. Our ISO certificate is awarded by one behaviour of existing and new anode coatings for different applications and under specific conditions. In case that none of our existing coating specifications meet the specific needs of a customer’s application or special conditions, our objective is always to develop a coating specification in co-operation with our customer that will fully satisfy the customer or end-user. of the world’s best known organisations in this field: Lloyd’s Register Assurance. Drieluik ENGELS 2051184 21-12-2005 12:20 Pagina 2 COMPANY PRODUCTS Models & Designs Because of a very flexible production facility, we are able to manufacture anodes of all types: sheet, plate, mesh, wire, rod, tubular or combinations and/or assemblies of these materials. Their size and number vary from several cm2 to 2 m2 and from 1 to 10,000 pieces. The process in which the anodes are used determines size, shape and coating specification of an anode. Important parameters determining the anode design are: Profile MAGNETO special anodes B.V. is a technology driven, customer orientated company. The majority of our products consist of tailor made anodes, based on specific needs of our customers. Each of our sales engineers is specialised in specific segments of the inert anode market and is in close contact with our customers. Through these close contacts we are able to optimise the anodes we produce for their specific application and needs. Introduction ◆ The electrochemical cell or installation wherein the anodes are used ◆ The process conditions, such as electrolyte composition, temperature, current density, design life, etc. ◆ Mechanical load of the anode ◆ Capacity of electrical conductivity of the base material. special anodes B.V. “Reliability” and “fit for use” are the keywords when it comes to quality at All anodes are produced according to customer specifications. When these specifications are not yet completely determined, MAGNETO special anodes B.V. distinguishes itself from its main competitors by focussing We are focussed on checks and verifications in all stages that are necessary to produce anodes with on only one product: the inert anode. This results in highly advanced anodes, especially anodes B.V. was founded custom developed and produced for applications specified by our customers. in 1957 under the name of an optimum quality. This starts during the first contact with the customer, when the specifications Main application areas Cathodic Protection MAGNETO-CHEMIE B.V. and is the original inventor and Seawater electrolysis manufacturer of Titanium anodes with Platinum and Ruthenium coatings. Policy Statement Under the responsibility of director-owner Ir. P.J.F.M. Hack, Magneto The steady growth of the production and the continuous development of inert anodes special anodes B.V. has developed and implemented a policy of Anodes and coatings KERAMOX® Titanium anode Platinised Titanium Anodes based on Niobium or Tantalum position in the market for Titanium anodes. Electroplating Titanium with an Iridium Mixed Metal Oxide coating ◆ To maintain a good and responsible position in the market of inert anodes, to guarantee continuity to MAGNETO special anodes B.V., which combines the Water treatment specifications and/or standards. ◆ To enterprise within the legal frame in all her aspects We are located in Schiedam, in the industrial heart of the Netherlands, close to important access by road, air and water. Even though Western Europe is our main market, and also in an ethical responsible way. ◆ To strive to working conditions as optimal as possible and thus securing the safety, health and wellbeing of the employees. ◆ To strive to a minimal impact on the environment. Not just looking at our own production process, but also looking at our products. In highly acidic environments such as: ◆ Electro galvanising (zinc plating) ◆ Anodising of Aluminium ◆ Chromium, Nickel, Tin, etc. plating ◆ Precious metal plating ◆ Reverse pulse Copper plating Hard Chromium plating Precious metal plating Platinised Titanium Titanium with an Iridium Mixed Metal Oxide coating Boron-Doped-Diamond anodes Electro dialysis with polarity reversal Recovery of metals Oxidation and break-down of organic contaminations Higher overpotentials,amongst others for disinfection Hypo chlorite & Disinfection Titanium with a Ruthenium Mixed Metal Oxide Depending on salinity, polarity reversal and current coating density Titanium with an Iridium Mixed Metal Oxide coating Titanium with a Platinum-Iridium Oxide coating Synthesis reactions complete electrochemical cells and Platinised Titanium Titanium with an Iridium Mixed Metal Oxide coating Boron-Doped-Diamond anodes Depending on the particular reaction At higher overpotentials production systems (Original end-users. In several countries we work in close co-operation with local agents or specialised distributors. Determination and the performance of Research & Development and all our supporting and Management System administrative activities are within our Already in the early 90’s we had started formalising and implementing unequivocal production methods and other procedures. By 1998 our Management System had been operational for a long time and Product Development Quality System. had been optimised in such a way that getting our A significant part of our turnover is dedicated to research and product first ISO certificate NEN-EN-ISO 9002 (1994 standard) development, both in our own laboratory as well as at universities and was only a formality. Our research & development includes the continuous and extensive In 2001 we were one of the first Dutch companies to be search for new anode coatings. It also includes the applicability and awarded certification according to the new standard: behaviour of existing and new anode coatings for different applications and under specific conditions. Most of our clients are either producers of Equipment Manufacturers) or sure the specifications will be met. international research institutes with whom we work in close co-operation. customers, in accordance with the agreed well-known name of MAGNETO and our specialisation: the production of special anodes. Platinised Titanium our customers, our suppliers and our employees. ◆ To satisfy the needs and demands of our are determined. In the following steps, all parts of the production process are looked at to make Quality System. which the most important items are: In the middle of 2002, the name was changed to Details All round applicable At high current densities, for example in sea water High voltages or strongly corrosive electrolytes KERAMOX® Titanium anode Depending on amongst others temperature and Titanium with a Ruthenium Mixed Metal Oxide salinity coating Titanium with a Platinum-Iridium Oxide coating have given MAGNETO-CHEMIE B.V. a prominent exported and used all over the world. MAGNETO special anodes B.V. our engineers are pleased to use their knowledge and experience to finalise the design together with the customer. MAGNETO special we are proud to say that our anodes are The supply of the most suitable anodes possible is paramount for our customers and for MAGNETO Hydrogen production Nickel electrodes with a precious metal coating Coating process by means of exchange plating The purpose is to decrease the overpotentials NEN-EN-ISO 9001:2000. Our ISO certificate is awarded by one of the world’s best known organisations in this field: Lloyd’s Register In case that none of our existing coating specifications meet the specific needs of a customer’s application or special conditions, our objective is always to develop a coating specification in co-operation with our customer that will fully satisfy the customer or end-user. Assurance. Drieluik ENGELS 2051184 20-12-2005 15:06 Pagina 1 Applications A Cathodic Protection In modern ICCP-systems, Titanium and Niobium anodes are used. To realise a continuous current electrical conductivity and a long lifetime, the anodes are applied with a thin layer of Platinum or Keramox® coating. Frequently seen applications are: ◆ Internal protection of storage tanks, condensers, tank bottoms, pipes, pipelines, heat exchangers and boilers ◆ External protection of pipelines, ship hulls, platforms and other offshore constructions, piers, dams and cooling water inlet parts of power stations. Seawater Electrolysis (anti bio-fouling) The invention of the Titanium anode has been of paramount importance for the electrolysis of seawater. Well known applications are the prevention of algae growth on ship hulls and oil platforms and in cooling water installations of, for instance, power plants. Electroplating In the electroplating industry our oxygen evolving anodes are used for: ◆ Electro galvanising (zinc plating), including steel strip plating ◆ Precious metal plating (gold, silver, palladium, etc.) ◆ (Hard) chromium plating, nickel plating, tin plating ◆ Copper plating, copper foil production and copper foil treatment ◆ Reverse Pulse Plating ◆ Aluminium anodising in liquid-contact-cells. The principle of metal plating is almost identical for all applications. The metal to be plated is dissolved in the electrolyte and the object to be plated is cathodically polarised. With the anodically polarised anodes, the electrical loop is closed. The counter reaction in the plating bath is oxygen evolution at the anode surface. Water treatment Our anodes are used in processes such as potable water treatment, treatment of process water and wastewater, but also for recovery and MAGNETO special anodes B.V. Calandstraat 109 separation of valuable or environmentally hazardous materials. For instance: 3125 BA Schiedam ◆ Electrochemical recovery of metals (Ni, Cd, Cu, Zn, Sn, Ag, Au, etc.) The Netherlands ◆ Direct or indirect oxidation and break-down of organic contamination or cyanide ◆ Removal of small solid particles by means of electroflocculation ◆ Electrodialysis, desalination of process water and electroflotation ◆ Softening of water, de-scaling Phone +31(0)10 - 262 07 88 Fax +31(0)10 - 262 02 01 E-mail info@magneto.nl ◆ Membrane processes. Please visit our website Hypo chlorite & Disinfection The availability of Titanium anodes has been a major break-through for the on-site production of hypo chlorite for potable water treatment and for both private and public swimming pools. The use of Titanium anodes for on-site generation of hypo chlorite is both safer and more environment friendly than the alternative storage and use of chlorine gas or bulk hypo chlorite. By using Titanium anodes, the use of highly corrosive and dangerous chemicals, such as hydro chloric acid can be avoided. Synthesis Reactions MAGNETO special anodes B.V. started to do research years ago, to search for the possibilities of using special anodes for several electrochemical synthesis reactions. At present, anodes are available for several inorganic conversions and oxidation reactions. Some new applications are: ◆ The production of chromic acid ◆ The oxidation of Ce3+ in Ce4+ ◆ Hydrogen production by water electrolysis. www.magneto.nl The original manufacturer of Titanium Anodes Drieluik ENGELS 2051184 20-12-2005 15:06 Pagina 1 Applications A Cathodic Protection In modern ICCP-systems, Titanium and Niobium anodes are used. To realise a continuous current electrical conductivity and a long lifetime, the anodes are applied with a thin layer of Platinum or Keramox® coating. Frequently seen applications are: ◆ Internal protection of storage tanks, condensers, tank bottoms, pipes, pipelines, heat exchangers and boilers ◆ External protection of pipelines, ship hulls, platforms and other offshore constructions, piers, dams and cooling water inlet parts of power stations. Seawater Electrolysis (anti bio-fouling) The invention of the Titanium anode has been of paramount importance for the electrolysis of seawater. Well known applications are the prevention of algae growth on ship hulls and oil platforms and in cooling water installations of, for instance, power plants. Electroplating In the electroplating industry our oxygen evolving anodes are used for: ◆ Electro galvanising (zinc plating), including steel strip plating ◆ Precious metal plating (gold, silver, palladium, etc.) ◆ (Hard) chromium plating, nickel plating, tin plating ◆ Copper plating, copper foil production and copper foil treatment ◆ Reverse Pulse Plating ◆ Aluminium anodising in liquid-contact-cells. The principle of metal plating is almost identical for all applications. The metal to be plated is dissolved in the electrolyte and the object to be plated is cathodically polarised. With the anodically polarised anodes, the electrical loop is closed. The counter reaction in the plating bath is oxygen evolution at the anode surface. Water treatment Our anodes are used in processes such as potable water treatment, treatment of process water and wastewater, but also for recovery and MAGNETO special anodes B.V. Calandstraat 109 separation of valuable or environmentally hazardous materials. For instance: 3125 BA Schiedam ◆ Electrochemical recovery of metals (Ni, Cd, Cu, Zn, Sn, Ag, Au, etc.) The Netherlands ◆ Direct or indirect oxidation and break-down of organic contamination or cyanide ◆ Removal of small solid particles by means of electroflocculation ◆ Electrodialysis, desalination of process water and electroflotation ◆ Softening of water, de-scaling Phone +31(0)10 - 262 07 88 Fax +31(0)10 - 262 02 01 E-mail info@magneto.nl ◆ Membrane processes. Please visit our website Hypo chlorite & Disinfection The availability of Titanium anodes has been a major break-through for the on-site production of hypo chlorite for potable water treatment and for both private and public swimming pools. The use of Titanium anodes for on-site generation of hypo chlorite is both safer and more environment friendly than the alternative storage and use of chlorine gas or bulk hypo chlorite. By using Titanium anodes, the use of highly corrosive and dangerous chemicals, such as hydro chloric acid can be avoided. Synthesis Reactions MAGNETO special anodes B.V. started to do research years ago, to search for the possibilities of using special anodes for several electrochemical synthesis reactions. At present, anodes are available for several inorganic conversions and oxidation reactions. Some new applications are: ◆ The production of chromic acid ◆ The oxidation of Ce3+ in Ce4+ ◆ Hydrogen production by water electrolysis. www.magneto.nl The original manufacturer of Titanium Anodes