Sustainability Report 2013/2014

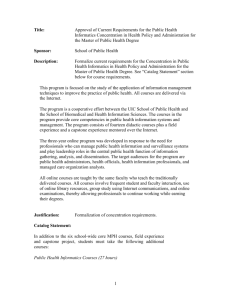

advertisement