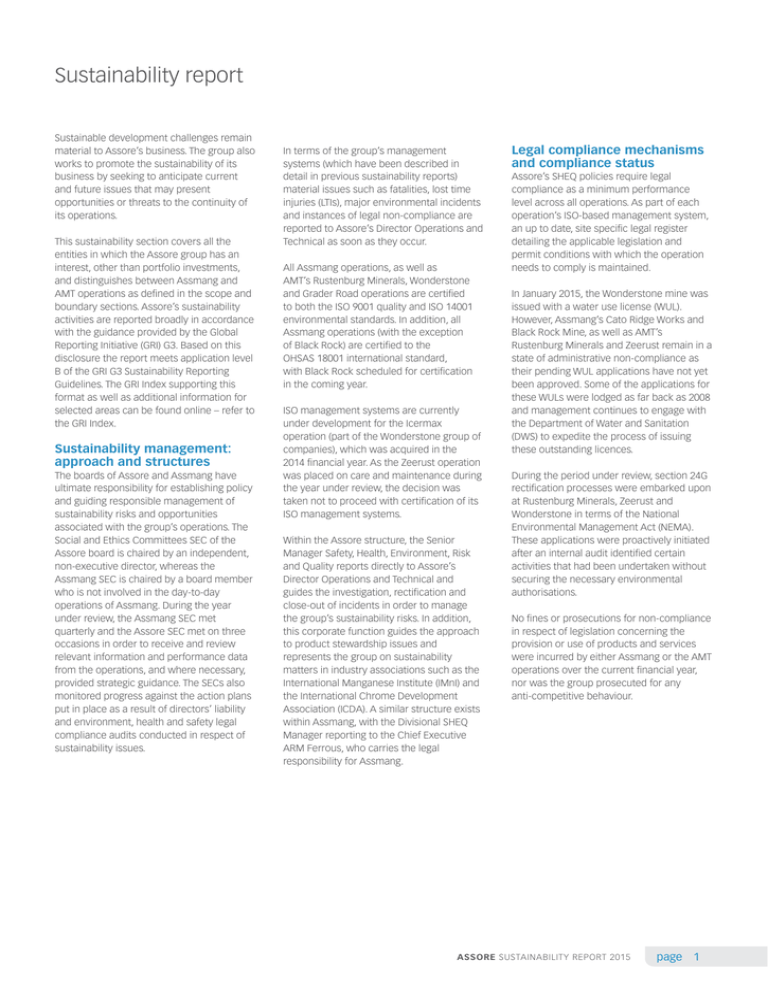

View Sustainability report

advertisement