Sustainability Report

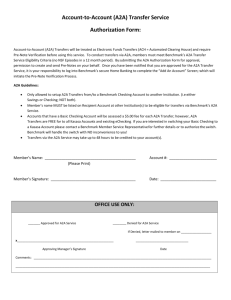

advertisement