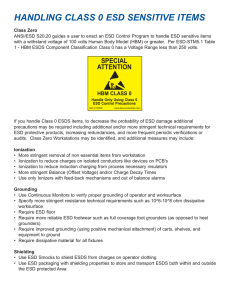

Electrostatic Discharge Sensitive Devices

advertisement

AY P S RIN VE T R CO IF Y PY TO f or C T U ra R in R in EN g T /R R e EV fe IS ren IO ce N O O nl N y SE R Electrostatic Discharge Sensitive Devices (ESD) Handling Procedure STD VE R . ESD Handling Standard Originated By: Scott Fischer Initial Date: 09/01/09 Page: 1 of 8 Brenda Boone APPROVAL: Digitally signed by Brenda Boone DN: cn=Brenda Boone, o=OPS, ou, email=bboone@raydon.com, c=US Date: 2009.09.21 07:43:48 -04'00' Date AL W Director, Production Operations 210 FENTRESS BLVD., DAYTONA BEACH, FL 32114 PHONE (386) 267-2936 FAX (386) 271-2283 www.raydon.com WS AS-4500-4001 Rev: A As of: 09/18/2009 ESD Handling Standard Originated By: Scott Fischer Initial Date: 09/01/09 Page: 2 of 8 VE AY P S RIN VE T R CO IF Y PY TO f or C T U ra R in R in EN g T /R R e EV fe IS ren IO ce N O O nl N y SE R Hardware Quality Personnel/Director Material Control Personnel/Manager Engineering Personnel/Manager Shop Operations Manager/Supervisor Production Test Personnel Final Integration Assy Personnel/Manager Raydon Server R . DISTRIBUTION PURPOSE The purpose of this procedure is to define minimum requirements for effective electrostatic discharge (ESD) control. Adherence to this procedure will provide adequate protection for ESD sensitive devices during handling and storages processes. SCOPE This procedure is written for the handling of any ESD sensitive device. All processing of an ESD sensitive device or of a subassembly or assembly containing an ESD sensitive device must be completed with the intent of providing maximum protection against electrostatic discharge. Even though care must be exercised in the handling of the device, thought must be given to the actual application of the ESD sensitive device. REFERENCES N/A ACRONYMS ESD-Electrostatic Discharge DEFINITIONS AL W Anti Static – Unable to drain a charge within a few minutes. Has low enough resistively (109 to 1014 ohms/sq) to resist formation of static charge when rubbed, but not capable of preventing the build up of a voltage along or across the surface. (blue or pink bags, bubble wrap) Electrostatic Discharge (ESD) – A transient or rapid transfer of charge, between bodies at different electrostatic potentials (voltages), either: a) caused by direct contact, b) by arc-over due to the items being close, or c) induced by an electrostatic field. Electrostatic Discharge Sensitive (ESDS) – Susceptible to damage or destruction by electrostatic discharge, usually from melting of a microscopic segment of semi-conductive material. ESDS Device (component, part) – Any component whose structure incorporates: (a) very thin insulating layers between conductive materials, (b) very small junction areas, or (c) very thin layers of a conductive material or any combination of these structures. This is inclusive of any assembly containing such devices, although once installed in a container (or other appropriate Faraday cage) slightly different handling procedures may be used. ESDS Device Zone – An identified zone where there are exposed ESDS devices present. A high level of static awareness should be maintained. Electrostatic Field – An electric field developed between two items at different voltages. Faraday Cage – A container in which ESDS devices are no longer considered sensitive. 210 FENTRESS BLVD., DAYTONA BEACH, FL 32114 PHONE (386) 267-2936 FAX (386) 271-2283 www.raydon.com WS AS-4500-4001 Rev: A As of: 09/18/2009 AY P S RIN VE T R CO IF Y PY TO f or C T U ra R in R in EN g T /R R e EV fe IS ren IO ce N O O nl N y SE R VE Insulator – Able to generate an electrostatic potential on its surface. Because of its high resistive nature it requires very long periods of time to lose its charge. Resistivity for this material is greater than 1014 ohms/sq. Resistivity (Surface) – A measure of resistance across the surface of a conductive mat, tabletop, floor, etc. The measurement is made in units of ohms/sq. What this means is for every square piece of conductive material the electrical resistance from along one side to the opposite side will measure the same no matter how big the square piece is, this the value of ohms/sq. The lower the value of resistivity, the easier and quicker it is to drain away the static charge. Static Conductive – Able to drain an electrostatic charge very rapidly, the range of resistivity for this material is less than 105 ohms/sq. Because of its low resistivity it has a high current carrying capacity. Static Dissipative – Able to drain a charge in a few seconds to a few minutes. The range of resistivity for this material is 105 ohms to 1015 ohms/sq. (i.e., most ESD mats) Static Protective – Materials characterized by static-conductive and antistatic properties, provides shielding from electrostatic fields, electrostatic discharge, and from frictional charge generation. Static Safe – This is any material with resistivity less than 1014 ohms/sq. characterized by its ability to not generate a charge, and (except for antistatic, above) can remove static charge from conductive items (including employees). It creates an environment that has a lower risk of charge build up within a Static Safe Perimeter. This is a general term including antistatic, static dissipative, static conductive, static shielding, and static protective. Static Safe Perimeter – A radius of 12 inches around an ESDS device that shall not have an electric field that exceeds + 100 volts, as measured with an ESD field meter. Static Shielding – Able to shield the product from direct contact with electrostatic discharge, and from breakdowns caused by a near electrostatic field. Shields are conductive or have a conductive layer buried inside. Static Table Mat – A flexible work surface composed of vinyl or rubber with an added component to allow static to drain from its surface to ground via a connected ground cord. There are 2 styles of mats used at Static Safeguarded Work Stations: a) Multi layered – with conductive middle layer, a dissipating top layer, and an insulating (or dissipating in some models) bottom layer. b) Single layered – Homogeneous – No conductive middle layer, rather the entire mat is uniformly resistive. R . ESD Handling Standard Originated By: Scott Fischer Initial Date: 09/01/09 Page: 3 of 8 RECORDS N/A ATTACHMENTS N/A RESPONSIBILITIES AL W All personnel who handle ESD sensitive parts and assemblies must be trained and certified in ESDS handling techniques. Training and certification should be updated on an ‘as needed’ basis. Each person should handle and protect the components according to this procedure. Each person is responsible for the testing and maintenance of their Static Safe Work station. This will include actual operation by testing to insure specification compliance. Application of this procedure begins by receiving and ESDS item and is inclusive of all handling and storage operations involving ESDS components through shipment of the assembly. All lead operators, supervisors, or other personnel who directly oversee or manage individuals who handle ESD sensitive parts and/or assemblies shall have ESD training. They will also 210 FENTRESS BLVD., DAYTONA BEACH, FL 32114 PHONE (386) 267-2936 FAX (386) 271-2283 www.raydon.com WS AS-4500-4001 Rev: A As of: 09/18/2009 VE ensure that ESD training is provided (for employees) and that a system is established for proper handling and storage of ESD sensitive components. This is inclusive of maintaining a proper workstation environment (i.e., handling equipment, tooling, etc.) to ensure minimum ESD exposure. R . ESD Handling Standard Originated By: Scott Fischer Initial Date: 09/01/09 Page: 4 of 8 AY P S RIN VE T R CO IF Y PY TO f or C T U ra R in R in EN g T /R R e EV fe IS ren IO ce N O O nl N y SE R Customers, Government representatives, or other non-Company personnel who have access to any area within Raydon where ESD type components or assemblies may be present shall have ESD training. PROCEDURES ESDS Identification ESDS ID Requirements All known ESDS devices or assemblies containing ESDS components shall be readily identified and easily recognizable at every location. The following provisions need to be reviewed for applicability and addressed as necessary: a) identification of special packaging and labeling requirements for ESDS devices for incorporation into purchase orders b) assurance of vendor compliance with handling, packaging, and labeling requirements for procured ESDS parts c) necessary precautions to guarantee customer specifications are met (as a minimum) for any customer supplied ESDS device d) assurance of ESDS labeling and protective packaging for both stored and issued ESDS devices within Raydon e) flagging of special handling requirements for ESDS devices and assemblies on manufacturing instructions (drawings/BOM). This shall include reference to this document and at what point such designation (ESDS) can be removed. AL W ESDS Device Designation An ESDS device or component may reach a point during production where the assembled components are no longer considered ESD sensitive. This is true when the device is enclosed in a ‘Faraday Cage’ such as a sheet metal container. Once the device has reached this point, the responsible individual may decide to change the ESDS designation or the handling procedures as long as they do not violate contractual requirements. Once the device is installed in a Faraday Cage, the container may be treated the same as any other container with the following exceptions: 1-Whenever possible during the handling, testing, and storage of containers, the cover will remain on the container to keep the device completely enclosed. 2-If a container has an ESDS device or component installed, no work will be completed on the inside of the container without following standard ESD handling procedures, including the workstation. Once it becomes an assembly the container may be treated as normal. ESDS Device Handling Procedures ESDS Device Handling The handling procedures for ESDS devices have 2 basic requirements: 210 FENTRESS BLVD., DAYTONA BEACH, FL 32114 PHONE (386) 267-2936 FAX (386) 271-2283 www.raydon.com WS AS-4500-4001 Rev: A As of: 09/18/2009 ESD Handling Standard Originated By: Scott Fischer Initial Date: 09/01/09 Page: 5 of 8 AY P S RIN VE T R CO IF Y PY TO f or C T U ra R in R in EN g T /R R e EV fe IS ren IO ce N O O nl N y SE R These requirements are met with periodic checks and monitoring of static safeguarded workstations. VE R . 1 – Limiting electrostatic voltage near or between any parts of an ESDS device to +100 volts 2 – Dissipating charge on surfaces within the Static Safe Perimeter to a level of +100 volts or less within 1 second. ESDS devices include both discrete components (individual parts) and assemblies having these components. Special handling procedures shall apply to: - placement into and removal from the device package or container - assembly, inspection, test, and rework - preparation for transport between storage, handling, and working stations Receiving Inspection Handling When any item is received that indicates an ESDS device may be present, it shall have the outside packing container inspected for damage or penetration. If any damage exists, notify the shipping company, the shipment originator, and purchasing. The outside package will not be unsealed unless the entire package is moved to the ESD Workstation and proper ESDS precautions are observed. The sealed package may be kept in Material Control until needed for testing or production. ESDS Device Transportation ESDS devices or assemblies shall be transported to the ESD Workstation using the unopened container that the device was received in. If the device needs to be transported outside the ESD Workstation area the device will be protected by either a full enclosure in a static shielding bag or by being placed inside a container with a cover in place, the connector shall be protected. Shipment of ESDS Device When packaging an ESDS device for return shipment, keep it in the static shielding bag that it was received in, unless the bag was damaged. Close the bag using staples or other suitable method. The outside shipping container shall show that an ESDS device is contained within. For ESDS devices or assemblies that are built into a container, the container will keep the device properly protected, but care shall be taken to protect connector(s) pins and the container shall be identified as containing an ESDS device. Specific Handling Procedures ESDS devices should be kept in contact with a grounded surface. Where grounded surface contact cannot be maintained, keep the device’s contacts shorted together with static conductive or dissipative material until ready for test, installation, etc. Once ESDS devices have been installed, avoid touching exposed connector pins. AL W Before handling ESDS devices, an individual shall remove static charge by first touching the station’s ESD mat or other grounded point. Secondly, use a grounded wrist strap to maintain the path of discharge. While handling an ESDS device, always maintain static dissipation path for the device and operator by continuous contact to ground using a grounded wrist strap. Although there are other methods for grounding (i.e., heel straps, coat straps, etc.), the grounded wrist strap is the preferred method for the processing of ESDS cards. 210 FENTRESS BLVD., DAYTONA BEACH, FL 32114 PHONE (386) 267-2936 FAX (386) 271-2283 www.raydon.com WS AS-4500-4001 Rev: A As of: 09/18/2009 ESD Handling Standard Originated By: Scott Fischer Initial Date: 09/01/09 Page: 6 of 8 VE R . Minimize physical handling of an ESDS device. Hold the device by its body without touching its leads or contacts. Don’t slide the device against another surface. An ESDS device that has its leads shorted in black foam or other shunting material shall be held until processing or testing requires removal of the shunting material. AY P S RIN VE T R CO IF Y PY TO f or C T U ra R in R in EN g T /R R e EV fe IS ren IO ce N O O nl N y SE R Before installing or removing an ESDS device in the next higher assembly or test circuit, be sure power to the circuit is off. ***WARNING: When working where 120 volts or more may be present, always remove your wrist strap grounding cord and ESD coat before applying power. After turning off the power, reattach to your grounding strap and coat before handling the ESDS assembly. Low Humidity Operation When the relative humidity drops below 30%, the following precautions must be taken: Stop handling the device until precautions are in place. If at any time the ground alarm sounds, the wrist straps will be checked. The wrist strap must be rechecked if it is removed for any reason. If only the cord is removed, rechecking is not necessary. Apply moisturizing lotion to wrists and hands as often as necessary. This will insure proper grounding of wrist straps. Avoid static generating clothing such as polyesters, acrylics and wool. Cotton clothing is the best choice. Maintain an awareness of proper ESD practices. Static Safeguarded Work Station/Zone Requirements Static Safeguarded Work Stations Static Safeguarded Work Stations shall include: Resistive ground path(s) for electrostatic charge on conductive and dissipative objects, including personnel; Static inhibiting surfaces for prevention of charge build up (i.e., anti static coatings or materials); The ability to neutralize any charge build up from insulating materials or from normal movement. Basically, a properly grounded ESD mat with the connections for operator wrist straps along with an isolated work are all that is required to set up a proper ESD work station. All Static Safeguarded Work Stations shall be identified. AL W ESDS Device Work Zone Requirement Work zones that will be used for ESDS device processing will consist of the workstation described above along with the immediate surrounding area. The immediate surrounding area is defined as the table and shelf where the ESD mat is laying, the aisle normally used by the operator when working at that table. The work zone shall include the following requirements: 1) Conspicuous identification to include an electrostatic sensitivity symbol. 2) Whenever there are unprotected ESDS device present (outside the original protective bag and not within a Faraday cage), all personnel who will be in the work zone shall wear properly connected wrist straps. 210 FENTRESS BLVD., DAYTONA BEACH, FL 32114 PHONE (386) 267-2936 FAX (386) 271-2283 www.raydon.com WS AS-4500-4001 Rev: A As of: 09/18/2009 ESD Handling Standard Originated By: Scott Fischer Initial Date: 09/01/09 Page: 7 of 8 AY P S RIN VE T R CO IF Y PY TO f or C T U ra R in R in EN g T /R R e EV fe IS ren IO ce N O O nl N y SE R VE ESDS Work Zone Operations Personnel Grounding For processes in which an operator stays at a fixed location and handles an ESDS device, an electrical connection from operator to work surface (wrist strap to mat ground connection) is required at all times. The resistance from the operator’s body surface to ground shall be between 1 megohm and 10 megohms. All personnel working within an ESDS Device Zone shall test their R . 3) No ESDS device(s) shall be left unattended without first placing them within a protective environment (i.e., return to protective bag, or as a minimum, completely cover the ESDS device and any attached components with ESD wrap or bags). wrist straps and grounding cords on a daily basis unless they are working with a continuous monitoring ESD workstation. The first verification will be done at the beginning of the work period within the ESD work zone. If the wrist strap is removed, it shall be rechecked before continuing work. All personnel who will be in the work zone while work on an ESDS device is being performed must have a properly functioning wrist strap (verified by testing or checking) and be properly grounded to the ESD work mat prior to exposing any ESDS device(s). Visitors must not borrow or use another person’s wrist strap without testing it at a wrist strap checker. Prohibited Materials High static generating materials must not be allowed in the ESD Work Zone when ESDS devices are exposed. In general, this means that the following items shall be removed from the work zone prior to removal of any ESD protection from ESDS device(s). -remove all items that are not necessary to the specific ongoing process, -items prohibited from the area during ESDS device exposure are: a) untreated Styrofoam (cups, containers, sheets, packing and shipping materials) b) regular bubble pack c) cellophane or other food and snack wrappers -certain parts necessary for production may need treatment with a topical anti static solution to prevent (neutralize) their static generating potential including tooling, materials, part holders, etc. Equipment Grounding (Electrical) All electrical equipment used in the processing of ESDS devices must have a connection directly to ground unless the test setup needs a floating ground for proper measurement. Soldering irons, test fixtures, or meters are some examples of this type of equipment. AL W ESD Shielding Bags The standard bag for all ESD protection shall be the ESD shielding bag. This bag is dark or silver tinted, and is slightly see through. Any shielding bag shall be discarded if found to be damaged, has holes larger than the diameter of a paper clip, or is determined to be worn or aged. The presence of staples or staple holes does not necessarily degrade the bag, unless they are present in quantities or the holes are large enough for component leads to easily penetrate. When in doubt, replace. Work Station and Equipment Calibration Calibration of Work Station Work stations that are equipped with monitored ESD stations do not require daily calibration as they are constantly being monitored for ground continuity. The Manufacturing assembly and test 210 FENTRESS BLVD., DAYTONA BEACH, FL 32114 PHONE (386) 267-2936 FAX (386) 271-2283 www.raydon.com WS AS-4500-4001 Rev: A As of: 09/18/2009 ESD Handling Standard Originated By: Scott Fischer Initial Date: 09/01/09 Page: 8 of 8 VE AY P S RIN VE T R CO IF Y PY TO f or C T U ra R in R in EN g T /R R e EV fe IS ren IO ce N O O nl N y SE R Equipment Checks Using the ohmmeter or DMM, measure the resistance from the tip of the soldering iron to the ground prong of the power plug. The value must be less than 5 ohms. Check the resistance from any other electrical device that will come close (within 2 inches) to ESDS devices, to the ground prong of the power plug. The value must be less than 5 ohms. If any electrical equipment has the ground prong removed, notify the supervisor for immediate replacement. R . areas are equipped with these style ESD stations. Traditional ESD workstations can be tested using a DMM following the manufacturers’ instructions. AL W Potential Damage If an ESDS device is exposed to a significant field or discharge, the device might fail immediately or have a latent failure. In the latter case, the device may function normally but for a shorter lifetime. If an ESDS device is handled by an ungrounded person, that person will hold the device in one hand and place the other hand on a conductive mat for 5 seconds to drain any built up charge. The device will then be placed on the mat and the person will put on and test a wrist strap before handling any ESDS device. The incident shall be brought to the attention of the area supervisor. If an ESDS item has been exposed to a possibly damaging ESD field or environment, bring it to the attention of the area supervisor or lead. Devices exposed to ESD threats need to be evaluated for extent of damage and potential damage. Unless no possible threat exists, the device shall not be used without customer approval or retesting, or the event must be clearly documented to provide clear traceability for that particular device. 210 FENTRESS BLVD., DAYTONA BEACH, FL 32114 PHONE (386) 267-2936 FAX (386) 271-2283 www.raydon.com WS AS-4500-4001 Rev: A As of: 09/18/2009