IP 69K, IP 67 etc. - an introduction

advertisement

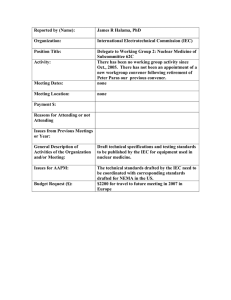

IP 69K, IP 67 etc. - an introduction Product specifications with details such as IP 54, IP 67, etc. have become widely established. For the most part, there is a mention that the latter is a degree of protection. Even amongst specialists, however, many are unable to interpret the abbreviation correctly. Whilst the letter pair “IP” stands for “ingress protection”, the meaning of the numbers is considerably more complicated. Most users do not even know where the definitions of these specifications could be looked up - a problem that frequently causes application failures. The following explanations should contribute to a better understanding of this important specification. IEC 60529 The relevant standard is IEC publication IEC 60529, formerly IEC 529 (IEC stands for International Electrotechnical Commission), first published in 1989. It can be obtained directly from the IEC (address at the end of this article). Originally intended for housings, its scope has been extended during the course of time, and today includes a multitude of devices, including sensors and connecting cables. The standard has been extended, translated and modified several times. Of particular interest is the European, i.e. German equivalent DIN 40050. As a general rule, IEC standards are created by teams of IEC specialists (technical committees), consisting of representatives of manufacturers and end-users from member states. IEC 60529 is the work of Technical Committee 70. However, national standards are not infrequently used as the basis for international standards and their further evolution. direction. This degree Picture 1 of protection primarily concerns the resistance of electrical production equipment to cleaning using high-pressure jets, where there are requirements with respect to pressure, increased temperature (hot water) and highly active chemical cleaning and disinfecting agents (in particular, hydrogen peroxide, but also other alkali IP 68 & IP 69K and chlorine-containing products). Cleaning in the food sector is, as a rule, coupled with disinfection, which requires the use of further, generally aggressive additives. Although cleaning with high-pressure jets is highly effective, this method First digit: Meaning with regard to the protection of electrical equipment against the penetration of solid foreign objects (including dust) 0 not protected 1 with diameter ≥ 50 mm 2 with diameter ≥ 12.5 mm 3 with diameter ≥ 2.5 mm 4 with diameter ≥ 1 mm 5 dust protected 6 dust-tight IP 69K Here, DIN (Deutsches Institut für Normung / German Institute for Standardization), whose standards frequently first become EN standards (with validity in the EU) before then becoming IEC standards, is particularly active. Standardization of the IP degrees of protection followed exactly this path. Encountering great interest, the relatively new degree of protection IP 69K resulted from the demands of the European food industry. Requests from utility vehicle manufacturers tended in the same Second digit: Meaning with regard to the protection of electrical equipment against ingress of water 0 not protected 1 vertically falling drops 2 vertically falling drops (15o inclination of the test piece) 3 spraying water 4 splashing water 4K splashing water with increased pressure 5 water jets 6 powerful water jets 6K powerful water jets with increased pressure 7 temporary immersion 8 continuous immersion 9 not defined 9K high-pressure / steam-jet cleaning An overview of IP degrees of protection according to IEC 60529 / DIN 40050. The table is divided into a number of criteria for the penetration of solid and liquid objects, as well as dust. The abbreviation of an IP degree of protection consists of the recurrent letters “IP”, followed by the first and second digits according to the above table. As a general rule, the higher the digit, the better the protection. The commonly used degree of protection IP 54, for instance, stands for dust protection, which includes protection against the penetration of large and small solid foreign objects, as well as protection against splashing water, but not immersion in water. Inset 1 also aggressively attacks metals and plastics of all kinds. Particularly concerned is the electrical equipment of food-processing installations, worst of all the sensors, which are already particularly exposed. As a result of this situation an appendix (DIN 40050 part 9) was added to DIN 40050, which includes a definition of IP 69K (amongst others), describing an elaborate, standardized test procedure for production equipment. Testing In the IP 69K test, the device to be tested is mounted on a rotating table turning at 5 revolutions per minute. During the course of the test, the test piece is splashed for 30 seconds from each of the angles of 0, 30, 60 and 90o. The jet comes from a flat nozzle at a distance of 100 to 150 mm and has a temperature of 80 ± 5 oC, a delivery rate of 14 to 16 l/min and a pressure of 8,000 to 10,000 kPa (80 - 100 bar) (fig. 1). These conditions may seem extreme, but are, however, typical for applications in the food-processing industry. It only remains to be said that the really tricky part is actually satisfying all three requirements simultaneously. Seals Elastic materials are generally chosen for the sealing, as well as for eventual connecting cables. However, elastic materials are rather unsatisfactory when exposed to mechanical forces, which is precisely the case with high-pressure jets. The standard solution consists of mechanically pretensioning the sealing materials to such an extent that the forces created by the jet are guaranteed to be inferior, even at increased temperatures and over a long period of time. Choice of material Water jet from a distance of 100 to 150 mm Jet for 30 seconds from every angle Delivery rate: 14 – 16 l/min Water pressure: 80 - 100 bar (8,000 – 10,000 kPa) Rotation at 5 rpm The ultimate material for metal parts is stainless steel. From the wide range of available types on the market, there are some that have the necessary chemical resistance (V4A, i.e. AISI 316L). With regard to plastics, although Teflon could fulfil all the requirements without problem, its price and complicated processing requirements are an obstacle. As an alternative, the ubiquitous PVC can do the job, since its chemical resistance is perfectly sufficient. However, not all countries permit the use of PVC in the food industry, since its raw materials are strongly carcinogenic. However, in the wide range of plastics available, there are sufficient alternatives. Resistance to temperature change Temperature-change resistance is a complex matter. Since it is not specified in IP 69K, its great importance for the long-term reliability of sensors is merely pointed out here. Fig. 1 Product development for IP 69K applications To pass this test, what do products have to be like? First and foremost, the following 3 problem areas must be tackled: - The seals must prevent the damaging penetration of liquids, even under pressure - The materials must be able to resist the chemicals and the temperature. - The electronics must be able to withstand the temperature changes. The real objective of IP standardization should not be lost from sight. Operators of manufacturing facilities want their installations to be in use as much as possible, which requires as low a rate of component failures as possible. Failures during operation, with the corresponding downtimes, are extremely costly, and thus totally unacceptable. But even “plannable” failures, such as the preventive replacement of components, are problematic. The costs of such preventive maintenance, after a few cycles already, nearly always bear no relation to the actual component prices. The only valid alternative is obvious: The components of an installation must outlive the latter’s planned operating life, with no ifs or buts. Other IP degrees of protection Although other more commonly encountered degrees of protection, such as IP 67 and IP 68 are, at first sight, less problematic, quite the opposite is, in fact, found in practice. With IP 67, users often mistakenly assume that devices so specified can be operated in any liquid for any length of time. Both assumptions are false, since the standard is unambiguous in this respect. The liquid must be water, and the test piece immersed to a depth of 1 meter for 30 minutes. In the case of IP 68, on the other hand, the standard itself is ambiguous. Although operation under water for an unlimited time is required (or rather suggested), the small print is, however, exceedingly non-committal. As for IP 67, the liquid is water, but the immersion depth and the guaranteed immersion duration, however, have to be negotiated on a case-by-case basis by the “users of the standard”, i.e. in practice the manufacturers and end-users. In addition, it has to be pointed out that the higher degree of protection IP 69K in no way also implies IP 67 or IP 68. Quite the opposite is true, so that these must be stated additionally and independently, i.e. “IP 68 & IP 69K”, for instance. Products There is a huge demand for products, particularly sensors, that conform to IP 69K. The corresponding offer is, at present however, still limited. The new Contrinex series 700L inductive proximity switches can be regarded as a particularly successful realization of the requirement profile. Of particular interest is that, at the all-important place, i.e. the sensing face, a radical solution has been implemented. The device housings are turned from solid metal, with no plastic joints, which means that the most important weak point of conventional devices is eliminated (picture 2). In all other aspects too, this product range is completely optimized for the intended application location. With special stainless steel (V4A / AISI 316L), special cable (TPE-S), special plastics, a particularly resistant cable entrance point, increased operating temperature range and, last but not least, laser engraving instead of labels or printing, the product leaves virtually nothing to be desired (picture 3). The well-known advantages of the standard series 700 range are retained, in particular the long operating disPicture 2 tance, achieved also on non-ferrous metals. The switches are thus ideal for use in the food and pharmaceutical industries, where IP 69K is frequently a prerequisite. Picture 3 Historical facts DIN - Deutsches Institut für Normung e.V. (German Institute for Standardization) No industrial society without standards. Alongside patents and licenses, they provide a reliable system for the organization of innovations, new products and even services. The main activity of DIN is the writing of technical rules. The objective of DIN is to create standards for the benefit of the economy and of society as a whole. DIN offers a forum where representatives of the manufacturing industries, commerce, trade and science, service industries and end-users meet, where anyone with an interest in standardization may discuss the latest state-of-the art technology and record the results in German Standards. DIN was established on 22 December 1917 as the “Normenausschuss der deutschen Industrie (NADI)”, the Standards Association of German Industry. In March 1918, the first German Standard was published (DIN 1 Surfacing pins). In 1920, the DIN mark was registered as a trademark with the patent office. In 1922, DIN 476 Paper sizes (DIN A 4 etc.) was published. Today, DIN, Deutsches Institut für Normung e.V. (company trademark DIN), with its headquarters in Berlin, is Germany’s national standardization organization. In collaboration with commerce, industry, science, end-users and government offices, the association promotes technical standards for rationalization and quality assurance. DIN also represents German interests in international standard committees, such as, for instance, ISO, IEC and CEN. Already in 1904, the farsighted International Electrical Congress, which at the time hosted a large number of delegates in St. Louis, drafted a report that said “… steps should be taken to secure the co-operation of the technical societies of the world, by the appointment of a representative commission to consider the question of the standardization of the nomenclature and ratings of electrical apparatus and machinery”. In less than two years, in June 1906, the International Electrotechnical Commission (IEC), with headquarters in London, was officially founded. In 1948, the IEC moved its permanent headquarters from England to Switzerland, where it remains to this day. In 1914, the IEC could already boast the foundation of four technical committees that developed standards, nomenclatures, definitions and ratings. By 1980, this number had climbed to 80. In 2005, the Commission published the most recent edition of its IEC Multilingual Dictionary, which contains 19,400 electrotechnical definitions in French and English and equivalent terms in 13 languages. Consolidated indexes are available in English and French, as well as in German and Spanish. Today, the IEC considers itself the leading global organization for the preparation and publication of international standards for all electrical, electronic and related technologies. Contact for IEC standards: Contact for DIN standards: International Electrotechnical Commission 3, rue de Varembé CH-1211 Geneva 20 Tel.: +41 22 919 02 11 Fax: +41 22 919 03 00 E-mail: info@iec.ch Internet: www.iec.ch Beuth Verlag GmbH D-10772 Berlin Tel.: +49 30 2601-0 Fax: +49 30 2601-1260 E-mail: postmaster@beuth.de Internet: www.beuth.de Contrinex AG Industrial Electronics route André Piller 50 - CH-1762 Givisiez - Switzerland Tel: +41 26 460 46 46 - Fax: +41 26 460 46 40 Internet: www.contrinex.com - E-mail: info@contrinex.com Contrinex AG 2009 Dipl.-Ing. Peter Heimlicher studied electronics at the ETH in Zurich. In 1972, immediately after his studies, he founded Contrinex AG, of which he has been CEO ever since. His company has specialized in the manufacture of high-performance sensing devices for industrial applications.