Technical Specification for ON-TRACK RAIL GRINDING SERVICE

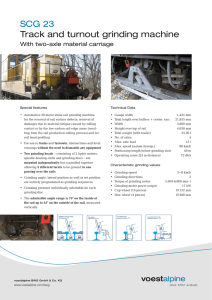

advertisement

ISRAEL RAILWAYS LTD. INFRASTRUCTURE DIVISION Technical Specification for ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 1 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 CONTENTS 1. SCOPE ......................................................................................................................... 3 2. REFERENCE DOCUMENTS ........................................................................ 3 3. DEFINITIONS ............................................................................................. 4 4. RAIL GRINDING SERVICE REQUIREMENTS ............................................. 6 5. RGV REQUIRMENTS .................................................................................. 8 6. GRINDING SYSTEM REQUIREMENTS ..................................................... 11 7. QUALITY CONTROL - ACCEPTANCE OF COMPLETED TRACK GROUND SECTION .................................................................................................. 13 8. PRODUCTION REPORTS .......................................................................... 14 9. RGV APPROVAL ...................................................................................... 15 10. MEASURMENT SYSTEM APPROVAL ...................................................... 15 11. CONTRACTOR TEAM APPROVAL ........................................................... 15 12. RGV PERMIT ............................................................................................ 15 TECHNICAL APPENDIX A - ISRAEL CLIMATE AND ENVIRONMENTAL CONDITIONS ............. 16 TECHNICAL APPENDIX B – ISRAEL RAILWAYS TRACKS DATA ........................................... 17 TECHNICAL APPENDIX C – ISRAEL RAILWAYS LOADING GAUGE ...................................... 18 TECHNICAL APPENDIX D – ISRAEL RAILWAYS RAIL RE-PROFILING TARGET PROFILES ........ 19 TECHNICAL APPENDIX E1 – DETAILS TO BE INCLUDED IN THE 'AFTER WORKING SHIFT REPORT' FORM........................................................................................................................ 25 TECHNICAL APPENDIX E2 – DETAILS TO BE INCLUDED IN THE 'MONTHLY REPORT' FORM . 26 TECHNICAL APPENDIX F - THE TECHNICAL DESCRIPTION OF ISR AXLE COUNTERS ............. 27 TECHNICAL APPENDIX G – ISR TELECOMMUNICATION SYSTEMS AND ANTENNAS ............ 31 2 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 1. 1.1 SCOPE This document described the technical requirements for On-Track Rail Grinding Service ("The Grinding Service"/ "The Service") by Railbound Rail Grinding Vehicle ("RGV") 1.2 The Service shall be carried out during the Service Time, as defined in section 3.12 hereinafter, in four stages as described in section 4.24.2 hereinafter. 1.3 The RGV shall be designed to grind the running surface region, gauge side region and field side region of the rail head on both rails simultaneously or separately in track. 1.4 The RGV shall has the capabilities to perform the following grinding types: a) b) c) 1.5 New Rail Grinding; Corrective/ Re-Profile Grinding; Preventive/ Cycle Grinding. The RGV shall be capable of grind the following rail types: GRADE (*) R350HT R320cr R260 R220 50E6 (U50) - - - + 54E1 (UIC54) + - + - 60E1 (UIC60) - + + - 60E2 + - + - PROFILE (*) (*) in accordance with EN13674-1 2. REFERENCE DOCUMENTS EN 13231-3 Railway applications - Track - Acceptance of works - Part 3 Acceptance of rail grinding milling and planing work in track; EN 13674-1 Track - Rail - Part 1 Vignole railway rails 46 kg/m and above; EN 14033-1 Railway applications - Track - Railbound construction and maintenance machines - Part 1 - Technical requirements for running; 3 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 EN 14033-2 Railway applications – Track – Railbound construction and maintenance machines - Part 2 - Technical requirements for working; EN 14033-3 Railway applications - Track - Railbound construction and maintenance machines - Part 3 - General safety requirements; UIC 712 Rail Defects; Note – the latest edition of the referenced document should be considered 3. DEFINITIONS 3.1. Contractor/ The Contractor The winning bidder in tender 3.2. Contractor Team 3.3. Grinding Supervisor The Contractor team which includes at least two Contractor employees - One of them shall be the Grinding Supervisor and one of them shall be the RGV Driver; An integral employee of The Contractor who is: 1) Suitably qualified and certified by the RGV manufacturer, and at least 3 years experienced in grinding operation with the same or similar type of RGV and maintaining all its systems, 2) Suitably qualified and certified for driving on track by a Railways Authority/ Company, 3) At least 2 years experienced with driving On-Track the RGV or similar vehicle, 4) In charge of grinding and approving the grinding work results, 5) Responsible for the reliability of the grinding work results; 4 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 3.4. 3.5. Grinding System RGV Driver: All the systems which are used in performing the grinding operation: 1) Grinding system, 2) Measurement systems, 3) Grinding dust collector, 4) Fire protection system, 5) Etc.; An employee of The Contractor, who is: 1) Suitably qualified and certified for driving On-Track by a Railways Authority/ Company, 2) at least 2 years experienced with driving On-Track the RGV or similar vehicle, 3) Qualified to maintain the RGV and its systems by the RGV manufacturer; 3.6. IPM ISR project manager; 3.7. ISR Israel Railways Ltd.; 3.8. ISR's Accompanying Employee An employee of ISR who will: 1) Accompany the RGV Driver during the RGV running and working, 2) Be in charge of track positions and communication with ISR dispatcher, 3) Accompany the Test supervisor (and the Contractor Team) on track when one or more of the following procedures will come about: a. b. 5 Visual rail defect, inspection, Grinding performances, visual inspection, ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 c. Roughness measurements, d. Grinding stone replacement; as defined and coded in UIC712; The Contractor's rail grinding On-Track railbound vehicle installed with all the Grinding System and other equipment for carried out The Service; The net period of time the RGV is conducting actual grinding service on track, daily, during Track Time, day and/or night (it starts at the initial measurement and end at final measurement); The Track Time shall include the preparation time (not including maintenance and refilling of water), the Spark Time and time required for the RGV to arrive from the parking track or the previous grinding place to the place where the grinding services shall be performed. 3.9. 3.10. Rail Defect: RGV 3.11. Spark Time: 3.12. Track Time 4. 4.1.1. RAIL GRINDING SERVICE REQUIREMENTS The Service shall be carried out continuously with Grinding System on two rails simultaneously along the place where the grinding services shall be performed. The Works shall be carried out, without adversely affecting the metallurgical structure of the rail and its surface, no gouging or significant bluing of the rail is permitted. 4.2. The daily Shift shall be carried out with four stages by the Contractor Crew: Stage One – before start grinding, Grinding Supervisor shall measure and record longitudinal and transverse rail profiles with dedicated computerized measurement system; Stage Two – grinding operation shall be carried out by the Grinding Supervisor in accordance to IPM instructions, based on Service Work Plan (as defined in the agreement section 10.1) and his professional decision in accordance to 6 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 the actual rail longitudinal and transverse profiles conditions; 4.3. Stage Three – after grinding completion, Grinding Supervisor shall measure and record with dedicated computerized measurement systems the longitudinal and transverse rail profiles, in addition he shall measure and record the rail roughness with electronically roughness tester; Stage Four – after every daily shift, 'After Working Shift Report' (see section 8.1.1) shall be submitted to the IPM signed by the Grinding Supervisor. The Grinding Service shall include the following grinding types: a) New Rail Grinding – for elimination of mill scale or decarburized (decarbonized) layer from new rail and defects up to 0.1 mm; b) Corrective/ Re-Profile Grinding – for fitting of rail head profile to the profiles in Technical Appendix D, for rails which has never been ground or ground of rails with surface defects depth equal or greater than 0.25 [mm]. c) Preventive/ Cycle Grinding - Periodically grinding of ReProfiled rails. Grinding of rails with defect depth of up to 0.25 [mm]. 4.4. The RGV shall be operated by the Grinding Supervisor. 4.5. The RGV shall not be operated or driven at any time unless it is accompanied by ISR's Accompanying Employee, appointed by the IPM. 4.6. The grinding operation and the longitudinal and transverse rail profile measurement shall be done by a computerized system. Full data record shall be saved and submitted to the IPM. 4.7. Rail roughness measurements shall be taken with electronically roughness tester in accordance to the requirements of EN13231-3, section 7. Data record shall be saved and submitted to the IPM. 4.8. The Contractor's grinding services shall guarantee working output capacity of not less than: New Rail Grinding - minimum 1.0 KM of track per hour; 7 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 Preventive Grinding – minimum 350 meter of track per hour; Corrective/Re-profile Grinding – minimum 200 meter of track per hour; 5. RGV REQUIRMENTS 5.1. The RGV shall be designed to carried out grinding on all track types of track found on ISR to include: a. Main lines b. Station tracks c. Level crossings d. Guarded track to include track with guard or check rails e. Jointed track to include track with standard or insulated joints. f. Tracks with axle counters (if needed the axle counters shall be disassembled before grinding and shall be reassembled after finishing grinding), g. Tracks with lubricators systems (if needed the lubricators systems shall be disassembled before grinding and shall be reassembled after finishing grinding). 5.2. The RGV and all of its systems shall be designed for full continuously operation in accordance with Israel railways track superstructure, specified in Technical Appendix B. And Israel climate with hot and dusty environmental conditions, specified in Technical Appendix A. 5.3. The RGV clearance envelope shall fit in to ISR loading gauge, specified in Technical Appendix D. Documents approving compliance with the requirements shall be submitted. 5.4. The RGV shall be designed to travel and operate in tunnels. Documents approving compliance with the requirements shall be submitted. 5.5. The RGV will have the following basic operating characteristics: Operation Characteristics 5.4.1 5.4.2 5.4.3 5.4.4 5.4.5 Track gauge nominal Track gauge maximum Track gauge minimum Travel speed – self propelled Travel speed – towed 8 Up to 1435 [mm] 1470 [mm] 1426[mm] 60 [Km/h] 100 [Km/h] ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 5.4.6 5.4.7 5.4.8 5.6. 30 ‰ 140 [m] 160 [mm] Max gradient Min curve radius Max superelevation The RGV frame, suspension, propelling system and braking system shall be designed to enable safe operation with maximum traveling speed and at gradient of up to 30‰. As a single vehicle as well as in train formation. Documents approving compliance with requirements shall be submitted. (Maximum braking distance - 800 meters at 60 km/h). 5.7. The RGV propulsion and brake systems must be available at both ends to enable bi-directional travelling and operation. 5.8. The RGV shall be designed to keep the environment protection of: noise; pollution; etc. in accordance with the relevant regulation. Documents approving compliance with requirements shall be submitted. 5.9. The RGV shall be designed to operate continuously On-Track with electric system and electronic signaling. Certificate approving it shall be submitted. 5.10. The RGV shall be design to operate efficiently near high voltage electrical wire line, on electrified track with 25k VAC and on non-electrified track with CWR and jointed track. The relevant technical documents and certificates approving it shall be submitted. 5.11. The RGV must be fully recognized at any speed by the axle counters installed in ISR track network (See Technical Appendix E). Certificate approving it shall be submitted. 5.12. The RGV shall be designed and shall have efficient capacity of water to operate continuously and safety during at least 10 hours net (not including break time). 5.13. The RGV shall have buffers at height of 1060 mm, draw gear, pneumatic system all in accordance with UIC and EN standards to enable towing it by ISR locomotives (when needed). 5.13.1. The RGV shall be equipped with Coupling and Buffers as follows - Each headstock shall be fitted with UIC type coupling system and buffers, namely: 9 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 1 central Draw Gear to UIC 520 with an elastic draw system; 1 Draw Hook to UIC 520 OR with a breaking force of 1,000KN; 1 Screw coupler to UIC 520 OR with a breaking force of 850KN; 2 side buffers with a stroke of 105 mm to UIC 526-1; at height of 1060 mm; 1 brake hose with valve. To enable towing it by ISR locomotives (when needed). The relevant technical details shall be submitted. 5.14. The RGV shall be equipped with at least the following safety accessories: 5.14.1. 2 Rotating beacons (one to each driving direction); 5.14.2. 2 Electro-pneumatic warning horns (one to each direction); 5.14.3. 5 Fire extinguishers containing dry powder; 5.15. The RGV shall be equipped with adequate interior and exterior lighting to enable it effectively and safely travel and carried out service at night time and in tunnels. 5.16. The RGV shall be equipped with proper devices to enable reliable continuous communication, when the Grinding Supervisor and the Driver are not in the same cabin. 5.17. The RGV shall be equipped with wheels enable it to be driven safe, comfort and without damaging ISR rail profiles (see Technical appendix B). The wheel drawing and wheel rail interface drawings shall be submitted. 5.18. In accordance to ISR regulations each vehicle driven on-track has to be equipped with 2 different telecommunication systems and antennas. The 2 different telecommunication systems and antennas, will be supplied by ISR and installed by its sub-contractor on ISR expense. 01 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 6. GRINDING SYSTEM REQUIREMENTS 6.1. The RGV shall be equipped with sufficient number grinding stones with sufficient power capacity to guaranty its capability to grind with equal or better output capacity than the mention in section 4.8. 6.2. The Grinding System shall be design to carry out grinding works productively in curves down to 140 meters radius and gradient of up to 30 ‰. 6.3. The Grinding System shall have the abilities to carried out rails grinding eliminate of rail surface defects (defects codes in accordance to UIC 712): 6.3.1. Corrugation - defect codes 2201, 2202; 6.3.2. Crushing – defect codes 123, 223; 6.3.3. Abnormal vertical wear – defect codes 2204; 6.3.4. Surface defects – defect codes 121, 221; 6.3.5. Batter of running surface – defects codes 124, 224; 6.3.6. Wheel burns – defect codes 125, 2251, 2252; 6.3.7. Squats - defect code 227; 6.3.8. Head checking - defect code 2223; 6.3.9. Shelling - defect codes 2221, 2222; 6.3.10. High welds. 6.4. The Grinding System equipment shall be designed to conform to the noise, vibration while working or traveling requirements specified in 14033-3. A special attention must to be focused on vacuum maximum grinding dust to eliminate of environmental damage. 6.5. The Grinding System shall be designed with the ability to lift the stones with minimize work disruption near obstacles, while grinding within the full grinding speed range. 6.6. The Grinding System shall be designed to enable the Grinding Supervisor manage and control Computerized pattern control to include automatic pattern change sequencing capability, to select grinding patterns from the operator’s cab. 00 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 6.7. The Grinding System shall be designed to enable computer controlled constant power application to each grinding stone. 6.8. The Grinding System shall be capable of grinding either rail or both rails simultaneously. 6.9. The Grinding System shall remove metal from the rail surface in consistent and uniform manner. 6.10. The grinding stones angle and power settings shall be all computer-controlled while grinding and pre-set within the patterns. 6.11. The Grinding System shall have the capabilities of grinding rail head in angles from 45 degrees gauge to 32 degrees field or wider. 6.12. The Grinding System shall be equipped with a gauge referencing system to provide a positive reference point for grinding modules to insure that grinding facets are accurately placed, and remain consistent on the rail head regardless of curve elevation or changes in track gauge. 6.13. An adequate fire protection system shall be part of the Grinding System and shall include the following features: a. Minimum of one day’s work water capacity. b. Separately controlled sleeper and ditch sprays front and rear. c. Water cannon or hoses with reach of 30 meters and throughput sufficient to extinguish any fire that will be encountered. d. Grinding stones and spark guards must be of sufficient size and strength to contain broken stones and sparks. 6.14. The Grinding System shall include computerized longitudinal and transverse rail profile measurement system. It shall have the capability of full data recording and storing. 6.15. The longitudinal rail profile measuring system shall have four recording channels as follows: - Short waves, left rail. - Short waves, right rail. - Long waves, left rail. 02 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 - Long waves, right rail. 6.16. The measurement systems shall be integrated with the RGV odometer or other equivalent system to ensure the continuous RGV longitudinal coordinate in reference to the track km-posts, with longitudinal location accuracy of up to ±1 meter. 7. QUALITY CONTROL - ACCEPTANCE OF COMPLETED TRACK GROUND SECTION 7.1. Acceptance criteria for longitudinal profile 7.1.1. Acceptance criteria for longitudinal profile shall be in accordance with EN 13231-3, section 4.3. 7.1.2. The number of irregularities shall not exceed the limits given in EN 13231-3, Table 1 – Class 1; and Table 2. 7.1.3. After grinding, high welds should be less than 0.1 mm. 7.2. Acceptance criteria for transverse profile 7.2.1. Acceptance criteria for transverse profile shall be in accordance with EN 13231-3, section 5.3. 7.2.2. The percentage of measurements for which the deviation exceeds the stated range of 0.6 [mm] shall not exceed the value given in EN 13231-3, Table 3 – Class Q. The maximum positive and negative permitted deviations shall not exceed the limits of ±0.1 [mm]. Other Acceptance criteria 7.3. The grinding works shall be carried out, without adversely affecting the metallurgical structure of the rail and its surface, no gouging or significant bluing of the rail is permitted. 7.4. Surface roughness shall be carried out in accordance with EN 13231-3, section 7. Roughness measurement results - Ra shall not exceed 10 [μm]. 7.5. Ridges left by grinding facets must not be so sharp as to result in the development of “flow lines” or spalling at the end of the contact bands. Maximum facet widths should be as follows: i. ii. Gauge corner 5 to 7 mm; Crown of rail 10 mm. 03 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 7.6. The IPM shall accept completed grinding sections on the basis of the compliance of the Contractor’s computerized records, in accordance with this technical specifications, as well as on the basis of visual inspection. 8. PRODUCTION REPORTS 8.1. The Contractor shall responsible to generate and submit the following reports: 8.1.1. i. After Working Shift Report; ii. Monthly Report; After Working Shift Report The Grinding Supervisor shall generate and submit daily after each working shift 'After Working Shift Report' which will include: Daily Shift Form (see hereinafter in Technical Appendix F1 details which need to be included in the form) filled in and signed by the Grinding Supervisor; Computer data file of longitudinal rail profile of the entire length of the ground track, carried out before the grinding work; Computer data file of longitudinal rail profile of the entire length of the ground track, carried out after the grinding work; Computer data files of Transverse profile of the entire length of the ground track, carried out before the grinding work and are including a compare of initial profile and with ISR desired profile (template)); Computer data files of Transverse profile of the entire length of the ground track, carried out after the grinding works and are including a compare of final ground rail profile and with ISR desired profile (template)); Computer data files of roughness measurement results carried out after the grinding works and are including minimum of six roughness measurements per rail; The Contractor shall report to the IPM regarding sections that weren't fully grinded. The report shall include the Form of Track Section Final Acceptance Certificate (see agreement Annex C1) signed. 8.1.2. Monthly Report 04 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 The Contractor shall generate and submit monthly (on the first week of every following month) 'Monthly Report' which will include: Monthly Report Form (see hereinafter in Technical Appendix F2 details to be included in the form) filled up and signed by the Grinding Supervisor and the Contractor; Invoices in accordance to the grinding work capacity in the previous month. 8.2. The contractor must deliver viewer software (s) or other relevant software(s) with at least 7 unlimited time licenses (for each software) to enable ISR employees access to all of the reported data. 9. RGV APPROVAL 9.1. As detailed in the General Terms and Conditions, appendix E. 10. MEASURMENT SYSTEM APPROVAL 10.1. As detailed in the Agreement, section xx. 11. CONTRACTOR TEAM APPROVAL 11.1. As detailed in the Agreement, section 11. 12. RGV PERMIT 12.1. As detailed in the Agreement, section 6.5. 05 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 A.1 A.2 TECHNICAL APPENDIX A - ISRAEL CLIMATE AND ENVIRONMENTAL CONDITIONS Climate and Environmental Conditions Max. ambient temperature 50 °C (shade) Min. ambient temperature -5 °C Relative humidity 10 to 90 % Altitude -400 to +800 meter Sunny 3300 hours per year UV Radiation 360 to 600 MJ/m² per year Rainfall 400 to 800 mm/year Dust Conditions in the atmosphere Maximum Half Hour Maximum Daily Average Value* Value* NOx 1064 560 71 SO2 780 260 21 O3 312 143 84 Suspended 350 100 Dust *(Microgram per m³ atmosphere) A.3 Suspended Particulate Matter (SPM) Particle size to 0.5-1 micron A.4 Sea Salt Concentrations in the Atmosphere Salt Element Na* Cl* Position Dry Wet Dry Sea Air at Coast Line 7.3 16.0 12.0 600 m from Shore 3.1 4.8 4.2 6000 m from Shore 1.1 1.4 1.5 * (Micrograms per m³ atmosphere) 06 Wet 22.0 7.9 1.7 SO4* Dry 5.3 1.9 1.3 Wet 7.0 2.0 1.4 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 TECHNICAL APPENDIX B – ISRAEL RAILWAYS TRACKS DATA B.1. B.2. B.3. B.4. B.5. B.6. B.7. B.8. B.9. B.10 B.11 B.12 B.13 ISRAEL RAILWAYS TRACK SUPERSTRUCTURE ISR railway network has CWR track with flash-butt and aluminothermic welds, and tracks with insulated joint rails and fishplates. Rail profiles: 50E6, 54E1, 60E1, 60E2 and 50E6 in accordance with EN13674-1:2011. Rail grades: R220, R260, R350HT. Switches: 1/8, 1/9, 1/12, 1/20, scissor-crossovers, double slips and expansion joints. Standard track gauge: 1435 mm (-2, +5). Rails inclination: 1/30. Type of sleepers: Universal monoblock concrete sleepers, Frankvagon sleepers, wooden sleepers, steel sleepers. Minimum number of sleepers of one km of track: 1667. Minimum horizontal curve radius: Main line: 141 m. Secondary line: 120 m. S-Curve: In some lines there are S-curves with short tangent section (6 m) and there are some without tangent. Minimum vertical curve: 3000 m. Vertical geometry: Maximum gradient 30‰. Maximum cant (superelevation): 150 mm. ISRAEL RAILWAYS TRACK LOAD B.14. Maximum axle load: 22.5 ton. B.15. Maximum traffic speed: 160 km/h. B.16. Potential Traffic load: 20 MGT per year. 07 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 TECHNICAL APPENDIX C – ISRAEL RAILWAYS LOADING GAUGE 08 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 TECHNICAL APPENDIX D – ISRAEL RAILWAYS RAIL REPROFILING TARGET PROFILES D.1 - Target profile Tangent Track for 54E1 profiles Tangent Track G x -3.55 -3.45 -3.25 -3.05 -2.85 -2.65 -2.45 -2.25 -2.05 -1.85 -1.65 -1.45 -1.25 -1.05 -0.85 -0.65 -0.45 -0.25 -0.05 0.15 0.35 0.55 0.75 0.95 1.15 1.35 1.55 1.75 1.95 2.15 2.35 2.55 2.75 2.95 3.15 3.35 3.55 y 0.051808 0.19274 0.43128 0.621717 0.773841 0.895611 0.993417 1.072305 1.1362 1.188098 1.230249 1.264316 1.291515 1.312743 1.328679 1.339874 1.346816 1.349984 1.349877 1.347026 1.341991 1.335336 1.327588 1.319173 1.310342 1.301069 1.290936 1.279001 1.263643 1.24239 1.211733 1.166913 1.101698 1.008136 0.876294 0.693972 0.446408 09 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 D.2 - Target profile Curved Track for 54E1 profiles – High Rail Curved Track – High Rail Gauge x -3.55 -3.45 -3.25 -3.05 -2.85 -2.65 -2.45 -2.25 -2.05 -1.85 -1.65 -1.45 -1.25 -1.05 -0.85 -0.65 -0.45 -0.25 -0.05 0.15 0.35 0.55 0.75 0.95 1.15 1.35 1.55 1.75 1.95 2.15 2.35 2.55 2.75 2.95 3.15 3.35 3.55 y -0.27025 -0.04007 0.33649 0.621535 0.835702 0.995941 1.115967 1.20667 1.27651 1.331882 1.377446 1.416443 1.450967 1.482222 1.510748 1.536615 1.559596 1.579306 1.595321 1.607257 1.61484 1.617926 1.616513 1.610715 1.600708 1.586654 1.568594 1.546312 1.519173 1.485935 1.444531 1.391822 1.323328 1.232925 1.112517 0.951683 0.73729 21 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 D.3 - Target profile Curved Track for 54E1 profiles – Low Rail Curved Track – Low Rail Gauge x -3.55 -3.45 -3.25 -3.05 -2.85 -2.65 -2.45 -2.25 -2.05 -1.85 -1.65 -1.45 -1.25 -1.05 -0.85 -0.65 -0.45 -0.25 -0.05 0.15 0.35 0.55 0.75 0.95 1.15 1.35 1.55 1.75 1.95 2.15 2.35 2.55 2.75 2.95 3.15 3.35 3.55 y -0.33571 -0.09523 0.284494 0.556297 0.747419 0.879765 0.970609 1.033243 1.077586 1.110741 1.137516 1.160886 1.182419 1.202653 1.221422 1.238145 1.252061 1.262422 1.268639 1.270381 1.267633 1.260694 1.25015 1.236783 1.22144 1.204859 1.187446 1.169006 1.148426 1.123316 1.089604 1.041077 0.968888 0.861007 0.701631 0.470547 0.142446 20 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 D.4 - Target profile Tangent Track for 60E profiles Tangent Track Gauge x -3.55 -3.45 -3.25 -3.05 -2.85 -2.65 -2.45 -2.25 -2.05 -1.85 -1.65 -1.45 -1.25 -1.05 -0.85 -0.65 -0.45 -0.25 -0.05 0.15 0.35 0.55 0.75 0.95 1.15 1.35 1.55 1.75 1.95 2.15 2.35 2.55 2.75 2.95 3.15 3.35 3.55 y -0.29221 -0.05105 0.324903 0.589333 0.772464 0.898303 0.98547 1.047987 1.095992 1.136418 1.173598 1.209829 1.245874 1.281406 1.315407 1.346497 1.373226 1.394289 1.408708 1.41594 1.415942 1.409176 1.396557 1.37935 1.359007 1.336954 1.314319 1.291604 1.268305 1.242476 1.210233 1.16521 1.097954 0.995268 0.839497 0.607761 0.271126 22 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 D.5 - Target profile Curved Track for 54E1 profiles – High Rail Moderate Curves – High Rail Gauge x -3.55 -3.45 -3.25 -3.05 -2.85 -2.65 -2.45 -2.25 -2.05 -1.85 -1.65 -1.45 -1.25 -1.05 -0.85 -0.65 -0.45 -0.25 -0.05 0.15 0.35 0.55 0.75 0.95 1.15 1.35 1.55 1.75 1.95 2.15 2.35 2.55 2.75 2.95 3.15 3.35 3.55 y -0.44636 -0.16651 0.276661 0.595705 0.822096 0.981176 1.092944 1.172796 1.232214 1.279402 1.319877 1.357001 1.39247 1.426748 1.45945 1.489678 1.516303 1.538197 1.554415 1.564325 1.567691 1.564699 1.555939 1.54233 1.525001 1.505115 1.483647 1.461108 1.43722 1.410542 1.378041 1.334615 1.272566 1.181022 1.045304 0.84625 0.559483 23 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 D.6 - Target profile Curved Track for 60E profiles – Low Rail Moderate Curves – Low Rail Gauge x -3.55 -3.45 -3.25 -3.05 -2.85 -2.65 -2.45 -2.25 -2.05 -1.85 -1.65 -1.45 -1.25 -1.05 -0.85 -0.65 -0.45 -0.25 -0.05 0.15 0.35 0.55 0.75 0.95 1.15 1.35 1.55 1.75 1.95 2.15 2.35 2.55 2.75 2.95 3.15 3.35 3.55 y -0.4394 -0.21966 0.132306 0.390494 0.578023 0.713564 0.811914 0.884531 0.940026 0.984627 1.022602 1.056643 1.088218 1.117882 1.145553 1.170751 1.192799 1.210992 1.22472 1.233562 1.23734 1.236137 1.23028 1.220278 1.206735 1.190218 1.171089 1.149304 1.124171 1.094073 1.056154 1.005968 0.937091 0.840698 0.705097 0.515237 0.252167 24 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 TECHNICAL APPENDIX E1 – DETAILS TO BE INCLUDED IN THE 'AFTER WORKING SHIFT REPORT' FORM The following information will be detailed in the 'After Working Shift Report' Form: a. ISR Grinding Plan to include: i. Condition of the rail prior to grinding (see pre-grind inspection below); ii. Grinding objective; iii. Recommended grinding program: 1. Patterns 2. Number of passes 3. Speed iv. Preliminary schedule. b. Grinding performed on a curve by curve (and tangent basis) to include: i. Date of grinding; ii. Names of Grinding Supervisor; iii. Name of Driver; iv. Name of ISR's accompanying employee ; v. Names of the persons present in the RGV; vi. Patterns used; vii. Track Time; viii. Spark Time; ix. From Km/ To Km ground; x. Grinding length; xi. Type of grinding; xii. Grinding speed; xiii. Number of passes; xiv. Number of replaced stones; xv. Condition of the rail; xvi. Roughness measurement results values; c. Other information i. Exceptional problems targeted during the grinding on the rails (e.g. corrugations, rail defects, dipped welds, transposed rail, etc.); ii. Track and field conditions that may interfere with standard grinding (crossings, turnouts, axle counters, etc.) iii. Exceptional problems during the grinding with the RGV; iv. Exceptional problems during the grinding with the ISR (e.g. problems with the ISR's accompanying employee, problems with Spark Time, etc.) 25 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 TECHNICAL APPENDIX E2 – DETAILS TO BE INCLUDED IN THE 'MONTHLY REPORT' FORM The following information will be detailed in the 'Monthly Report' Form: i. Dates of grinding; ii. Type of grinding; iii. Km of grinding on each date; iv. Measurement results File names of each date; v. Total Track Time (in a month); vi. Total Spark Time (in a month); 26 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 TECHNICAL APPENDIX F - THE TECHNICAL DESCRIPTION OF ISR AXLE COUNTERS F1 - Axle counter Zp30C-NT 27 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 28 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 F2- Axle counter AZL70 29 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 31 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 TECHNICAL APPENDIX G – ISR TELECOMMUNICATION SYSTEMS AND ANTENNAS G1 - TELECOMMUNICATION SYSTEM – APX7500 30 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 32 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 33 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 34 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 G2 - TELECOMMUNICATION SYSTEM – M710 35 ISRAEL RAILWAYS LTD ON-TRACK RAIL GRINDING SERVICE by Railbound Vehicle No. E-06-0004 December 2015 G3 – Antenna 36