University of Houston Telecommunication Infrastructure Standards

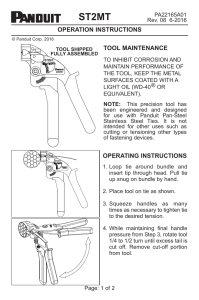

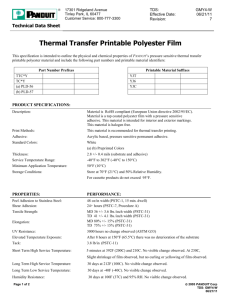

advertisement