ADCP-80-526 • Issue 1 • November 2000

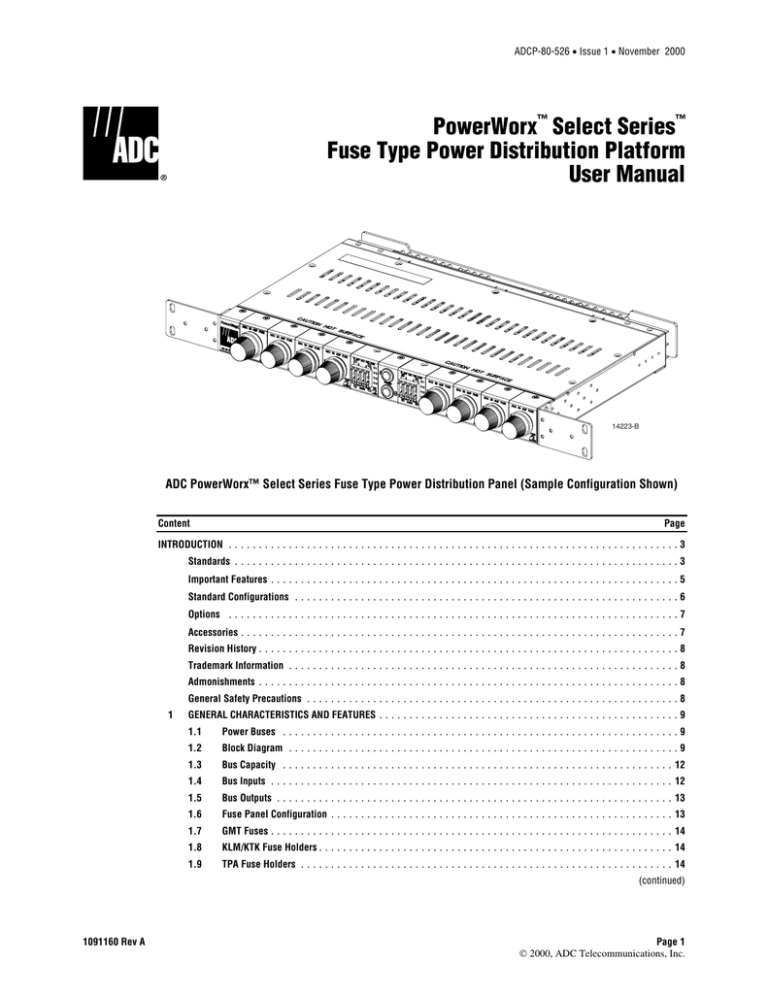

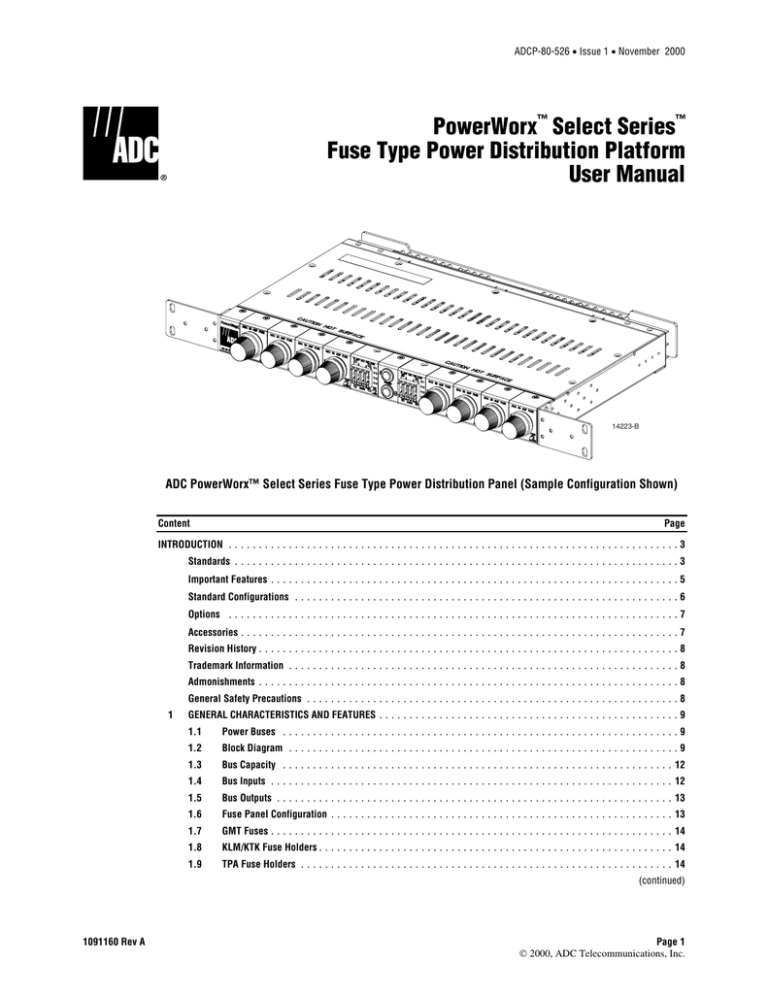

PowerWorx™ Select Series™

Fuse Type Power Distribution Platform

User Manual

14223-B

ADC PowerWorx™ Select Series Fuse Type Power Distribution Panel (Sample Configuration Shown)

Content

Page

INTRODUCTION ........................................................................... 3

Standards .......................................................................... 3

Important Features .................................................................... 5

Standard Configurations ................................................................ 6

Options ........................................................................... 7

Accessories ......................................................................... 7

Revision History...................................................................... 8

Trademark Information ................................................................. 8

Admonishments ...................................................................... 8

General Safety Precautions .............................................................. 8

1

GENERAL CHARACTERISTICS AND FEATURES .................................................. 9

1.1

Power Buses .................................................................. 9

1.2

Block Diagram ................................................................. 9

1.3

Bus Capacity ................................................................. 12

1.4

Bus Inputs ................................................................... 12

1.5

Bus Outputs .................................................................. 13

1.6

Fuse Panel Configuration ......................................................... 13

1.7

GMT Fuses ................................................................... 14

1.8

KLM/KTK Fuse Holders........................................................... 14

1.9

TPA Fuse Holders .............................................................. 14

(continued)

1091160 Rev A

Page 1

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

Content

2

Page

1.10

Dummy Fuses................................................................. 14

1.11

Blank Modules ................................................................ 15

1.12

Chassis Ground Connection ....................................................... 15

1.13

Alarm Contact Closures .......................................................... 15

1.14

Fuse Alarm Indicators ........................................................... 16

1.15

Power-On Indicator ............................................................. 16

1.16

Fuse Designation Card and Holder ................................................... 16

1.17

Voltage Designation Label ........................................................ 17

PHYSICAL CHARACTERISTICS............................................................ 17

2.1

Material and Finish ............................................................. 17

2.2

Cooling ..................................................................... 17

2.3

Protector Cover ................................................................ 17

2.4

Weight ..................................................................... 17

2.5

Mounting .................................................................... 18

2.6

Environmental Characteristics...................................................... 18

2.7

Dimensions .................................................................. 18

3

ACCESSORIES ...................................................................... 18

4

UNPACKING AND INSPECTION ........................................................... 20

5

6

INSTALLATION ...................................................................... 20

5.1

Cable Management Bar (Optional Accessory) ........................................... 21

5.2

Mounting Brackets.............................................................. 21

5.3

Wiring Connections ............................................................. 22

5.4

Fuse Designation Pins ........................................................... 26

5.5

Fuse Designation Card Holder and Card ............................................... 26

5.6

Voltage Designation Label ........................................................ 27

5.7

Fuse Installation ............................................................... 27

TESTING THE FUSE PANEL .............................................................. 27

6.1

Quality Control ................................................................ 27

6.2

Resistance Test ............................................................... 27

6.3

Connection Polarity Test ......................................................... 27

6.4

Wiring Connections Measurements .................................................. 28

6.5

Power Indication Test ........................................................... 28

6.6

Fuse Alarm Test ............................................................... 28

7

OPERATION ........................................................................ 29

8

MAINTENANCE ...................................................................... 29

9

8.1

Inspection ................................................................... 29

8.2

Cleaning .................................................................... 29

8.3

Adjustments .................................................................. 29

8.4

Fuse Removal................................................................. 29

8.5

LED Replacement .............................................................. 30

CUSTOMER INFORMATION AND ASSISTANCE ................................................. 30

Page 2

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

INTRODUCTION

This manual describes a fuse type power distribution platform that contains one or two buses

(feeds) that accept input power of up to 100 Amps per bus, and provides fuse protected output

power using two different types of fuses as selected from three types by the customer. This

power distribution platform is designated ADC PowerWorx™ Select Series™ Fuse Type

Power Distribution Platform, and is hereafter called “fuse panel.”

This fuse panel is for telecommunications products used in central offices, multimedia headends,

remote sites, and other locations requiring fused dc power.

This fuse panel is available with several configurations of fuse types and fuse position modules.

Two types of fuses, either GMT, KLM, or TPA, may be selected. KTK fuses will also fit in the

KLM/KTK fuse holder, but are not currently rated for dc voltages by Underwriters Laboratories

(UL). In a dual bus configuration, both the A bus and the B bus have the same type and size fuse

holder modules. The maximum current that each type of fuse can provide is as follows

(maximum bus current capacity is 100 Amps):

• TPA type fuse; each fuse in four position module: 50 Amps

• KLM type fuse; each fuse in one, two, three, four, or five position modules: 30 Amps

• GMT type fuse; each fuse in four position module: 15 Amps

• GMT type fuse; each fuse in five or 10 position modules: 10 Amps

Two sample PowerWorx™ Select Series Fuse Type fuse panels are shown in Figures 1, 2, and 3.

A description of this fuse panel, with its available options and accessories, is provided in this

manual. The information necessary to install and operate the fuse panel is also provided herein.

Standards

The fuse panel complies with UL, Telcordia (formerly Bellcore), NEC 1999, CE, IEC, CSA, and

NEBS Level 3 standards. The fuse panel design places emphasis on high reliability and

simplicity of operation.

Page 3

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

UL/CSA/CE

LABEL

VENTS

BUS A KLM/KTK

FUSE HOLDER

(4 PER BUS)

BUS A GMT

FUSE HOLDER

(4 POSITION)

BUS B GMT

FUSE HOLDER

(4 POSITION)

FRONT VIEW

BUS B KLM/KTK

FUSE HOLDER

(4 PER BUS)

UNIVERSAL

MOUNTING

BRACKETS (2),

INSTALLED FOR 23-IN.

(58.42 CM) RACK

MOUNTING

PROTECTIVE COVER PLACED

OVER INPUT AND OUTPUT

POWER, GROUND, AND ALARM

CONTACT CONNECTIONS

REAR VIEW

14224-B

Figure 1. Front and Rear Views of ADC PowerWorx Select Series Fuse Type Fuse Panel with

Protector Cover in Place (Fuse Panel with Dual Power Feed, Four 1-Position KLM/KTK Fuse Holders,

and One 4-Position GMT Fuse Holder on Each Bus Shown)

Page 4

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

BUS A GMT FUSE

VALUE DESIGNATION

PIN HOLDERS

(1 PER POSITION)

GMT FUSE HOLDER

MAXIMUM CURRENT LIMIT

(ON EACH FUSE HOLDER,

BOTH BUSES)

KLM/KTK FUSE HOLDER

MAXIMUM CURRENT LIMIT

(ON EACH FUSE HOLDER,

BOTH BUSES)

BUS B

POWER-ON

INDICATOR

BUS A

POWER-ON

INDICATOR

BUS B GMT FUSE

VALUE DESIGNATION

PIN HOLDERS

(1 PER POSITION)

14225-B

BUS A KLM

FUSE FAILURE

INDICATOR (1 PER

FUSE HOLDER)

BUS A GMT

FUSE FAILURE

INDICATOR (1 PER

FUSE HOLDER)

BUS B KLM

FUSE FAILURE

INDICATOR (1 PER

FUSE HOLDER)

BUS B GMT

FUSE FAILURE

INDICATOR (1 PER

FUSE HOLDER)

Figure 2. Front View of ADC PowerWorx Select Series Fuse Type Fuse Panel

(Fuse Panel with Dual Power Feed, Four 1-Position KLM/KTK Fuse Holders,

and One 4-Position GMT Fuse Holder on Each Bus Shown)

Important Features

The fuse panel provides several important features:

• Self-configuring voltage capabilities to simplify installation and allow one panel to fit

most dc voltage applications.

• “Upside down” GMT fuse holders to make blown fuses more easily visible.

• Optimally-positioned, high-brilliance fuse alarm red LED indicators that enable quick

identification of blown GMT, KLM, and TPA type fuses.

• Field-replaceable high-brilliance Power-On green LED indicator(s).

• Easily-removable clear polycarbonate, protector cover over connectors to enhance safety

and panel accessibility.

• Two-post grounding to ensure robust and reliable ground connectivity.

• Recess-mountable, universal mounting ears accommodate EIA or WECO 19-inch

(48.26-cm) or 23-inch (58.42-cm) racks.

Page 5

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

BUS B GMT FUSE

VALUE DESIGNATION

PIN HOLDERS

(1 PER POSITION)

BUS A TPA

4-POSITION

FUSE HOLDER

BUS A GMT

4-POSITION

FUSE HOLDER

BUS B GMT

4-POSITION

FUSE HOLDER

BUS B TPA

4-POSITION

FUSE HOLDER

MAXIMUM CURRENT LIMIT

INDICATION FOR EACH

GMT FUSE (ON EACH GMT

FUSE HOLDER)

BUS A GMT FUSE

VALUE DESIGNATION

PIN HOLDERS

(1 PER POSITION)

15981-A

BUS A GMT

FUSE FAILURE

INDICATOR (1 PER

FUSE HOLDER)

BUS A TPA

FUSE FAILURE

INDICATOR(1 PER

FUSE HOLDER)

MAXIMUM CURRENT LIMIT

INDICATION FOR EACH TPA FUSE

(ON EACH TPA FUSE HOLDER)

BUS B TPA

FUSE FAILURE

INDICATOR (1 PER

FUSE HOLDER)

BUS B GMT

FUSE FAILURE

INDICATOR (1 PER

FUSE HOLDER)

BLANK PANEL

(NO POWER-ON

INDICATORS)

Figure 3. Front View of ADC PowerWorx Select Series Fuse Type Fuse Panel

(Fuse Panel with Dual Power Feed, One 4-Position TPA Fuse Holder,

and One 4-Position GMT Fuse Holder on Each Bus Shown)

Standard Configurations

The standard configuration fuse panel has one or two power buses (feeds), with each power bus

having multiple fuse holder modules with multiple fuse positions. In a two (dual) bus fuse panel,

the second bus (Bus B) is a “mirror” image of the first bus (Bus A), having the same types of

fuses and the same size fuse holder modules. Two different fuse types, selected from the GMT,

KLM, or TPA fuse types may be used on each bus. The number of fuse positions on each bus is

dependent upon the bus maximum limit of 100 Amps, the type and current value of fuses, and

the width of the fuse holders.

The dimensions of the fuse panel are 1.75 inches (4.45 centimeters) high, 17.12 inches (43.48

centimeters) wide, and 10.00 inches (25.41 centimeters) deep (does not include depth of

protective covers, connectors, fuse holders, fuses, and visual indicators).

The current capacity of each bus is 100 Amps maximum, which is marked on the fuse panel.

The power dissipation of the fuse panel is 40 watts maximum at 100 A per bus.

The fuse panel is capable of sensing the input voltage level and can be used with either –24 Vdc

or –48 Vdc input voltages.

Page 6

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

Using the universal mounting brackets included with the fuse panel, the fuse panel can be

flush or recess mounted in 19-inch (48.26-cm) or 23-inch (58.42-cm) racks with WECO or

EIA mounting options available.

Options

The fuse panel is available with the following options:

• One bus or two buses

• Two types of alarm contact connectors, either screw-down terminal strip connectors or

wire-wrap pin block connectors

• Power-On LEDs on the front of the fuse panel or no Power-On LEDs

Other options are available by special order.

Accessories

Several accessories for the fuse panels are available (see Section 3):

• Standard value GMT, KLM, and TPA fuses within the value limits in Table 1

• GMT colored fuse value designation pins (rivets)

• Cable management bar kits

• GMT fuse pullers

• Three sizes of two-hole compression connector lugs for input power connections

• Lug terminals to connect #10 AWG wire to earth ground.

• Spare GMT Series type fuse value designation pin holders

• Spare fuse value designation card holder kits

Table 1. PowerWorx Select Series Fuse Panel Fuse Holders, Fuse Types, and Fuse Values

FUSE

TYPE

FUSES PER AVAILABLE

FUSE HOLDER MODULE

FUSE HOLDER

MODULE WIDTH

TPA

1 to 4 in 4 position module

4.5 in. (11.43 cm)

KLM

1 in 1 position module

1 or 2 in 2 position module

1 to 3 in 3 position module

1 to 4 in 4 position module

1 to 5 in 5 position module

1 to 4 in 4 position module

1.5 in. (3.81 cm)

3.0 in. (7.62 cm)

4.5 in. (11.43 cm)

6.0 in. (15.24 cm)

7.5 in. (19.05 cm)

1.5 in. (3.81 cm)

1 to 5 in 5 position module

1 to 10 in 10 position

module

3.0 in. (7.62 cm)

3.0 in. (7.62 cm)

GMT

GMT

FUSE VALUE RANGE

Standard values, 3.0 Amps

minimum, 50.0 Amps maximum

Standard values, 5.0 Amp minimum,

30.0 Amps maximum

Standard values, 0.2 Amp

minimum, 15.0 Amps maximum (see

1.7)

Standard values, 0.2 Amp minimum,

10.0 Amps maximum

Page 7

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

Revision History

ISSUE

DATE

Issue 1

11/2000

REASON FOR CHANGE

Original

Trademark Information

ADC is a registered trademark of ADC Telecommunications, Inc.

PowerWorx and Select Series are trademarks of ADC Telecommunications, Inc.

Admonishments

Important safety admonishments are used throughout this manual to warn of possible hazards

to persons or equipment. An admonishment identifies a possible hazard and then explains

what may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times. These warnings are flagged by use

of the triangular alert icon (seen below), and are listed in descending order of severity of

injury or damage and likelihood of occurrence.

Danger: Danger is used to indicate the presence of a hazard that will cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Warning: Warning is used to indicate the presence of a hazard that can cause severe

personal injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

General Safety Precautions

Caution: The fuse panel uses electrical voltage and amperage levels which, per GR-1089,

may be considered an electrical hazard. Care should be exercised to assure that only qualified

personnel are allowed to install, operate, maintain, or otherwise come in contact with this

equipment when the fuse panel is energized. Only insulated tools should be used on energized

elements of the fuse panel.

Caution: All fuse panel wiring and cabling should be connected with the system office battery

input off or disconnected at the office distribution panel.

Caution: A replacement fuse must have exactly the same current rating as the fuse being

replaced.

Page 8

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

1

GENERAL CHARACTERISTICS AND FEATURES

The fuse panel has the general characteristics and features defined in the following paragraphs. The

rear view of the fuse panel, with the protective cover removed to show the external connectors is

shown in Figures 4 and 5. Available accessories for the fuse panel are defined in Section 3.

1.1 Power Buses

The fuse panel has one or two separate power buses. Each bus provides normal distribution of

the input power to multiple fused output circuits using two different types of fuses, selected

from GMT, KLM, or TPA types. In each bus circuit, current flows from the input to the fuse

bus. When a fuse is installed in a fuse holder, the circuit is completed to the output connector.

When a fuse fails, depending on the type of fuse, the following occurs:

• KLM fuses: If a KLM fuse output is connected to a load, the fuse failure is sensed by a

sensor, causing the alarm monitor to light a red LED indicator on the front of the fuse

holder and close normally open contact closures (Form C contacts) at the alarm output

connection.

If a KLM fuse output is connected to a load, with no fuse installed, the corresponding

sensor remains active and indicates a failure. If a KLM fuse output is not connected to a

load, the corresponding sensor is inactive and no failure is indicated. Therefore, unused

KLM/KTK fuse positions should not be connected to a load.

• TPA fuses: The failure causes the alarm monitor to light a red LED indicator on the front

of the fuse holder and close normally open contact closures (Form C contacts) at the alarm

output connection.

If a TPA fuse output is connected to a load, and no fuse is installed, the corresponding

sensor remains inactive and no failure is indicated.

• GMT fuses: The failure causes the alarm monitor to light a red LED indicator on the front

of the fuse holder and close normally open contact closures (Form C contacts) at the alarm

output connection.

If a GMT fuse output is connected to a load, and no fuse is installed, the corresponding

sensor remains inactive and no failure is indicated.

1.2 Block Diagram

A block diagram of the fuse panel is shown in Figure 6.

Page 9

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

BUS A AND BUS B

ALARM CONTACT CONNECTOR

(SCREW-DOWN BARRIER

TERMINAL STRIP TYPE SHOWN)

FEED B INPUT CONNECTORS

(TWO HOLE COMPRESSION

LUG STUD TYPE)

PROTECTIVE COVER

MOUNTING STANDOFFS

(2 SETS)

FEED A INPUT CONNECTORS

(TWO HOLE COMPRESSION

LUG STUD TYPE)

14226-B

FEED B KLM FUSE

OUTPUT CONNECTORS

(SCREW-DOWN BARRIER

TERMINAL STRIP)

CHASSIS

FEED A KLM FUSE

GROUND

OUTPUT CONNECTORS

TERMINALS

(SCREW-DOWN BARRIER

FEED A GMT FUSE

FEED B GMT FUSE

TERMINAL STRIP)

OUTPUT CONNECTORS

OUTPUT CONNECTORS

(SCREW-DOWN BARRIER

(SCREW-DOWN BARRIER

TERMINAL STRIP)

TERMINAL STRIP)

Figure 4. Rear View of Fuse Panel with Protector Cover Removed to Show Connectors

(Fuse Panel with Dual Power Feed, One 4-Position KLM Output Connector Module Per Bus,

One-4 Position GMT Output Connector Module Per Bus, and Screw-down Barrier

Terminal Strip Alarm Contact Connector Shown)

BUS A AND BUS B

ALARM CONTACT CONNECTOR

(WIRE-WRAP PIN BLOCK

TYPE SHOWN)

FEED B INPUT CONNECTORS

(TWO HOLE COMPRESSION

LUG STUD TYPE)

FEED A INPUT CONNECTORS

(TWO HOLE COMPRESSION

LUG STUD TYPE)

PROTECTIVE COVER

MOUNTING STANDOFFS

(2 SETS)

15982-A

FEED B GMT FUSE

OUTPUT CONNECTORS

(SCREW-DOWN BARRIER

TERMINAL STRIP)

CHASSIS

GROUND

TERMINALS

FEED B TPA FUSE

OUTPUT CONNECTORS

(SCREW-DOWN BARRIER

TERMINAL STRIP)

FEED A TPA FUSE

OUTPUT CONNECTORS

(SCREW-DOWN BARRIER

TERMINAL STRIP)

FEED A GMT FUSE

OUTPUT CONNECTORS

(SCREW-DOWN BARRIER

TERMINAL STRIP)

Figure 5. Rear View of Fuse Panel with Protector Cover Removed to Show Connectors

(Fuse Panel with Dual Power Feed, One 4-Position TPA Output Connector Module Per Bus,

One 4-Position GMT Output Connector Module Per Bus, and Screw-down Barrier

Terminal Strip Alarm Contact Connector Shown)

Page 10

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

BATTERY A

RETURN A

FEED A

KLM FUSE

ARRAY

FEED A

KLM SENSOR

FEED A

ALARM MONITOR

FEED A POWER

INDICATOR

FEED B

ALARM MONITOR

FEED B POWER

INDICATOR

BATT

1

2

3

4

RTN

1

2

3

4

FEED A

KLM FUSE

ALARM INDICATOR

FEED B KLM FUSE

ALARM INDICATOR

FEED B

KLM SENSOR

RETURN B

BATTERY B

FEED B

KLM

FUSE

ARRAY

BATT

1

2

3

4

FEED A

GMT/TPA

FUSE

ARRAY

BATT RTN

1

1

2

2

3

3

4

4

FEED A

GMT/TPA FUSE

ALARM INDICATOR

FEED B

GMT/TPA FUSE

ALARM INDICATOR

RTN

1

2

3

4

FEED B

GMT/TPA

FUSE

ARRAY

BATT

1

2

3

4

RTN

1

2

3

4

14227-B

Figure 6. PowerWorx Select Series Fuse Panel Block Diagram (Dual Power Feed, Four-1 Position

KLM/KTK Fuse Holders and One-4 Position GMT/TPA Fuse Holder on Each Bus Shown)

Page 11

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

1.3 Bus Capacity

The current capacity of each bus is 100 Amps maximum, which is marked above the input

connectors on the rear of the fuse panel. The total current of a fuse panel with two buses is

200 Amps maximum. The power dissipation of the fuse panel is 40 watts maximum. The

maximum current that each type of fuse can provide is:

• TPA type fuse; each fuse in four position module: 50 Amps

• KLM type fuse; each fuse in one, two, three, four, or five position modules: 30 Amps

• GMT type fuse; each fuse in four position module: 15 Amps

• GMT type fuse; each fuse in five or 10 position modules: 10 Amps

1.4 Bus Inputs

1.4.1

Input Voltage

The fuse panel can accommodate –24 Vdc input power on both busses or –48 Vdc input

power on both busses.

The voltage is sensed by the fuse panel circuitry.

The input voltage used with the fuse panel is required to have the following voltage

characteristics:

• –24 Vdc nominal, within a range of –21 Vdc to –30 Vdc

• –48 Vdc nominal, within a range of –42 Vdc to –56 Vdc

Fuse panels for use with other input voltage values and polarity may be available by special order.

1.4.2

Input Connectors

Each bus has two (2) input connectors on the rear of the fuse panel through which input power

is applied. The two input power connectors are labeled “BATT” (battery) and “RTN” (return).

The input connectors are two-hole compression lugs (stud type). Each input connector has two

(2) screws (studs) with nuts mounted on a tin plated copper plate(see Figures 4 and 5). Each

set of two screws can accept different size 2-hole lugs which can be used with a range of wire

sizes up to #2 AWG copper wire.

Two 2-hole lugs per bus and one spare lug for use with #2 AWG wire (five total) are included

with the fuse panel.

Page 12

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

1.5 Bus Outputs

1.5.1

Output Voltage

The output voltages will be the same voltage as the applied input voltage when the fuses do

not fail.

1.5.2

Output Connectors

Each bus has two sets of output connectors for each different type of fuses on the rear of the

fuse panel through which the output power of the bus is available for connection to

telecommunications equipment.

The sets of output connectors are screw-down barrier terminal strips. Terminals are mounted

in two barrier type terminal blocks per fuse type (see Figures 4 and 5). One of the strips is for

output power; the other strip is for the power return. On the terminal strip, the terminal screw

size, terminal barrier distance (width of ring or spade lug terminal) and the size of bare copper

wire (insulation stripped back) to be used is dependent upon the fuse type as follows:

TPA Fuse: Terminal screw size is 8-32. Maximum distance between barriers (maximum

connecting terminal width) is 0.378 inch (9.601 mm). Bare wire size is #10 to #22 AWG.

KLM Fuse: Terminal screw size is 8-32. Maximum distance between barriers (maximum

connecting terminal width) is 0.320 inch (8.128 mm). Bare wire size is #12 to #22 AWG.

GMT Fuse, four and five position module: Terminal screw size is 6-32. Maximum

distance between barriers (maximum connecting terminal width) is 0.325 inch (8.255

mm). Bare wire size is #12 to #22 AWG.

GMT Fuse, ten position module: Terminal screw size is 6-32. Maximum distance

between barriers (maximum connecting terminal width) is 0.260 inch (6.604 mm). Bare

wire size is #14 to #22 AWG. Bare wire size is #14 to #22 AWG.

Combination of four TPA Fuses and 10 GMT fuses: Terminal screw size is 3-48.

Maximum distance between barriers (maximum connecting terminal width) is 0.200 inch

(5.080 mm). Bare wire size is #16 to #30 AWG.

1.6 Fuse Panel Configuration

Two different fuse types, either GMT, KLM, or TPA, may be used on each bus. The number of

fuse positions can be configured with a combination of standard size fuses of each of the two

types by determining the types and number of fuses required, the size of the fuse holders, the

width of the fuse panel available for mounting fuse holder modules, and the fuse values as

shown in Table 1. The maximum mounting width available for mounting fuse holder modules in

the single bus fuse panel is 7.50 inches (19.05 cm). The maximum mounting width available for

mounting fuse holder modules in the dual bus fuse panel is 15.0 inches (38.1 cm).

Page 13

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

1.7 GMT Fuses

Using four position GMT fuse holder modules, up to four 15 Amp fuses can be installed sideby-side. If more than four 15 Amp fuses are installed, a space (one empty fuse position) must

be placed between the four 15 Amp fuses and other 15 Amp fuses.

Using five position and ten position fuse holder modules, 10 Amp fuses can be installed sideby-side without the need to have space between the fuses. Fifteen Amp fuses can be used in

five position and ten position fuse holder modules, but a space (one empty fuse position) must

be placed between each fuse.

Each GMT fuse has a small color-coded fuse identification flag that identifies the value of the

fuse that is installed. When the fuse fails, the flag moves away from the fuse to indicate the

fuse failure.

1.7.1

GMT Fuse Holders

GMT fuse holders are mounted on the fuse panel such that the GMT fuses install with the fuse

identification flags located at the bottom of the fuse holder (upside-down position). When the

flags are located at the bottom of the fuse holder, they are more visible from below when the

fuse panel is installed in a location at or near the top of the rack. A fuse alarm red LED is

mounted on the GMT module to allow quick identification of blown GMT fuses (see

Figures 2 and 3).

1.7.2

GMT Fuse Value Designation Pin Holder

The GMT fuse holder has numbered holes in the front of the fuse holder that corresponds to

fuse positions in the fuse holder. The holes can be used to place color-coded pins (rivets) that

identify the values of the GMT fuses (see Figures 2 and 3).

1.8 KLM/KTK Fuse Holders

The KLM/KTK fuse holder modules will accept both KLM and KTK fuses. A fuse alarm red

LED is mounted on the KLM/KTK fuse holder to allow quick identification of blown KLM

fuses (see Figure 2).

1.9 TPA Fuse Holders

The TPA fuse holder modules will accept four TPA fuses. A fuse alarm red LED is mounted

on each TPA fuse holder to allow quick identification of blown TPA fuses (see Figure 3).

1.10 Dummy Fuses

The fuse panel is shipped with dummy GMT fuses installed in all positions of the GMT type

fuse holders and with dummy KLM fuses in all positions of the KLM/KTK fuse holders.

Page 14

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

1.11 Blank Modules

Space in the fuse panel that is not filled with fuse holder modules will be filled with blank modules.

1.12 Chassis Ground Connection

Two #10 screws and nuts for grounding the fuse panel chassis are mounted on 0.625 inch

(15.875 mm) centers (see Figures 5 and 6). This chassis ground connection can be used to

attach a separate grounding conductor when mounting the fuse panel in non-grounded or nonconducting material or when required by local practice. Two crimp ring lug terminals for two

#10 AWG wires are enclosed with the fuse panel. The fuse panel can be grounded using only

one (1) screw.

1.13 Alarm Contact Closures

The fuse panel contains circuitry that will provide three contact closures when any fuse on the

bus fails or when input power to the bus is lost. These contact closures may be used as loop

closures in alarm systems.

The circuitry consists of alarm relays with Form C contacts that are terminated at a screwdown barrier terminal strip connector or wire-wrap pin block on the outside rear of the fuse

panel. During normal operation, the normally open (NO) contacts remain open, and the

normally closed (NC) contacts remain closed. When a fuse fails or power is lost, the NO

contacts close, creating a connection from NO to common (C), and the NC contacts open.

The current for each fuse alarm relay (set of three contacts) is 1.0 Amp maximum.

1.13.1

Alarm Contact Connection

The fuse panel is available with either of two types of alarm contact connections. The two

types of alarm contact connections are:

• Screw-down barrier terminal strip: Six terminals with 3-48 screws are mounted in a

barrier type terminal block (see Figure 4). The terminals are on 0.250 inch (6.350 mm)

centers with a maximum distance between barriers (maximum connecting terminal

width) of 0.200 inch (5.080 mm). The alarm terminal strip has two sets of three

terminals labeled NO, C, and NC. Each set of terminals is for use with one alarm system.

The terminals can also accept #16 to #30 AWG copper wire (with insulation stripped

back). Wires are inserted in the terminal strip, and the screws are screwed down on the

wires.

• Wire-wrap terminal block: Wire-wrap pins are mounted in a terminal block for both

buses (see Figure 5). The alarm terminal block has three sets of three wire-wrap pins

(NO, C, NC), for use with three alarm systems. The wire-wrap pins can accept #22 to

#26 AWG copper wire with insulation stripped back.

Page 15

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

1.14 Fuse Alarm Indicators

A visual fuse alarm indicator (red LED) mounted on the front of each fuse holder module

lights when any fuse in that fuse holder module fails. The LED is not lighted when all fuses in

the fuse holder module do not fail.

Loss of power to a bus will cause all fuse alarm indicators corresponding to that bus to remain

not lighted.

1.15 Power-On Indicator

An optional power-on indicator (green LED) for each power bus mounts near the center of the

front panel on the fuse panel (see Figure 2). A lighted LED indicates that power is applied to

the bus input connectors. An unlighted LED indicates that power is not applied to the bus

input connectors.

The power-on indicator LED can easily be replaced in the field (see 8.5).

The fuse panel can also be optionally configured without the power-on indicator(see Figure 3).

1.16 Fuse Designation Card and Holder

Two types of fuse designation cards (see Figure 7) and a card holder are provided with the

fuse panel. The card holder is intended to be attached to the fuse panel, to one of the fuse

panel mounting brackets, to a part of the rack, or at a location close to the fuse panel, as

desired. One of the cards should be filled out with circuit information for each of the fuses that

are installed in the fuse holder and inserted in the card holder. The card holder has a pressure

sensitive adhesive backing for attachment.

1.60 IN.

(4.06 CM)

1.60 IN.

(4.06 CM)

2.36 IN.

(5.99 CM)

2.36 IN.

(5.99 CM)

18 POSITION CARD

10 POSITION A AND B CARD

15983-A

Figure 7. Fuse Designation Cards

Page 16

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

1.17 Voltage Designation Label

A voltage designation label (see Figure 8) is provided with the fuse panel. The label is

intended to be filled out with the actual voltage present on the buses and placed on the fuse

panel. The voltage designation label has a pressure sensitive adhesive backing for attachment.

0.38 IN.

(0.96 CM)

1.00 IN.

(2.54 CM)

14228-A

Figure 8. Voltage Designation Label

2

2.1

PHYSICAL CHARACTERISTICS

Material and Finish

The fuse panel chassis and brackets are made of 16 gauge cold rolled steel. The fuse panel and

brackets are finished with powder paint that is putty white color.

2.2

Cooling

The fuse panel is well ventilated to allow efficient convection cooling of all components

without the use of fans or blowers. A minimum of 1.75 inches (4.45 cm) of air space (one rack

space) for cooling shall be provided between the top of the fuse panel and the item in the rack

above the fuse panel, and between the bottom of the fuse panel and the item in the rack below

the fuse panel.

2.3

Protector Cover

A clear, polycarbonate protector cover is mounted on the rear of the fuse panel, over the input

power connectors, the output power connectors, the chassis ground terminals, and the external

alarm contact connections.

To gain access to these connections and terminals, the cover is easily removed with the twist

of a screw. To remove a cover, loosen the screws that attach the cover to the chassis, and pull

the cover sideways and over the screws (holes are keyed for easy access). Screws do not need

to be completely removed to remove the protector cover.

2.4

Weight

The weight of the fuse panel is approximately 12.5 pounds (5.675 kilograms).

Page 17

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

2.5 Mounting

The standard (front and rear access) fuse panel can be mounted in a 19-inch (48.26-cm) rack

or a 23-inch (58.42-cm) rack, using the universal fuse panel mounting brackets shipped with

the panel. The mounting brackets can be flush mounted or recessed 1 inch (25.4 mm), 2 inches

(50.8 mm), 3 inches (76.2 mm) or 4 inches (101.6 mm) from the front of the panel. The

mounting brackets allow mounting with WECO 1.00-inch (2.54 cm) hole spacing or EIA

1.25-inch (3.18 cm) hole spacing.

Two mounting brackets, eight (8) 1/4-inch (6.350 mm) 6-32 screws for attaching the brackets

to the fuse panel, and four (4) 3/8-inch (9.525 mm) 12-24 screws with washers for attaching

the brackets to the rack, are included with the fuse panel.

2.6 Environmental Characteristics

Table 2 lists the environmental characteristics of the fuse panel.

Table 2. Fuse Panel Environmental Characteristics

PARAMETER

Operating temperature

Storage temperature

Humidity range (operating)

Altitude range

Fire rating

Earthquake design

Acoustic noise

Heat dissipation (fully loaded)

Heat dissipation (no load)

DESCRIPTION

–5° C to +50° C

–45° C to +85° C

0% to 95% humidity (non-condensing)

–197 ft. (0.06 km) to 13,000 ft. (3.96 km) above sea level

All components UL94-V1.

NEBS Level 3; Zone 4

0 dBA above ambient

40watts maximum @ 100 A per bus

1 watt per bus

2.7 Dimensions

The dimensions of the fuse panels are shown in Figure 9.

3

ACCESSORIES

The following accessories for the PowerWorx fuse panel are available:

• TPA fuses. Standard sizes from 3.0 Amp to 50.0 Amps

• KLM fuses. Standard sizes from 5.0 Amp to 40.0 Amps

• GMT fuses. Standard sizes from 0.2 Amp to 15.0 Amps

• GMT colored, standard value, fuse value designation pins (rivets)

• GMT Series type fuse value designation pin holder

Page 18

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

• Cable management bar with mounting screws. Provides cable tie points. Installed at rear

of fuse panel by fastening ends of bar to both sides of fuse panel.

• GMT fuse puller

• Three sizes of two-hole compression connector lugs for #2, #4, and #6, AWG wire for

input power connections

• Lug terminals to connect #10 AWG wire to earth ground.

• Fuse value designation card holder kit

17.13 IN.

(43.51 CM)

10.98 IN.

(27.90 CM)

10.00 IN.

(25.41 CM)

1.75 IN.

(4.44 CM)

23.00 IN.

(58.42 CM)

22.31 IN.

(56.67 CM)

1.13 IN.

(2.87 CM)

14229-B

Figure 9. Dimensions of PowerWorx Select Series Fuse Type Fuse Panel with

Protector Cover in Place and Mounting Bracket Attached for Mounting in

23 Inch (58.42 cm) Rack (Top and Front Views Shown

Page 19

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

4

UNPACKING AND INSPECTION

Unpack and inspect the various components as follows:

1. Inspect the exterior of the shipping container for evidence of handling that may have

damaged the components in the container.

2. Unpack each container while carefully checking the contents for damage and verify with

the packing slip.

3. File a claim with the commercial carrier and notify ADC Customer Service if damage is

detected or if parts are missing. Save damaged cartons for inspection by the carrier.

4. Refer to the Customer Service section at the back of this manual for repair, replacement,

and warranty information.

5. Save all shipping containers for use if the equipment requires return shipment at a future date.

5

INSTALLATION

The following guidelines should be used when mounting the fuse panel in a rack.

• Mount the fuse panel in the upper area of the rack or cabinet to reduce exposure of the power

wiring. A minimum of 1.75 inches (4.45 cm) of air space (one rack space) between the top of the

fuse panel and the item above the fuse panel, and between the bottom of the fuse panel and the

item below the fuse panel shall be provided for cooling.

• Adding a fuse panel to a rack may displace a device which may require relocation.

• Use common hand tools to install the fuse panel. The use of a power screwdriver to install

the self-tapping screws that attach the mounting brackets to the rack is recommended.

Caution: This equipment employs electrical voltage and amperage levels which may be

considered an electrical hazard. Care should be exercised to assure that only qualified

personnel are allowed to install, operate, maintain, or otherwise come in contact with this

equipment when the fuse panel is energized. Only insulated tools should be used on energized

elements of the fuse panel.

Warning: Never install telephone equipment in a wet location or during a lightning storm.

When installing or modifying telephone lines, disconnect lines at the network interface before

working with uninsulated lines or terminals to prevent electrical shock.

Warning: Do not install fuses in fuse panel or power source until you have completed the

power wiring connections.

Page 20

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

5.1 Cable Management Bar (Optional Accessory)

Before installing the fuse panel in the rack, mount the cable management bar (not supplied

with fuse panel) on the rear of the fuse panel as shown in Figure 10.

Caution: When attaching the cable management bar to the fuse panel, use only the 1/4-inch

(6.350 mm) long 4-40 screws that are supplied with the cable management bar. Use of any other

hardware could cause contact with internal parts of the fuse panel.

The cable management bar can be recess mounted by using the mounting holes closest to the

front of the fuse panel.

Note: A fuse panel with the cable management bar attached may exceed the 12 inch (305

mm overall depth objective described in GR-63 COORE, 02-14.

MOUNTING BRACKET

INSTALLED FOR

23-IN. (58.42 CM)

RACK MOUNTING

ATTACH TO

EITHER SET

OF 3 HOLES

CABLE

MANAGEMENT

BAR

14230-B

Figure 10. Cable Management Bar Installation (Dual Power Feed Fuse Panel Shown), Rear View

5.2 Mounting Brackets

Two 1-3/4-inch (4.45-cm) high universal mounting brackets are used to mount the

PowerWorx Select Series fuse type fuse panel in either a 19-inch (48.26-cm) rack or a 23-inch

(58.42-cm) rack. The brackets, mounting screws, and washers are provided with the fuse panel

(see 2.5). See Figure 11.

Caution: When attaching the mounting brackets to the fuse panel, use only the hardware

supplied with the fuse panel. The flathead screws are for attaching the mounting brackets to the

fuse panel. Use of any other hardware could cause contact with internal parts of the fuse panel.

The slotted mounting hole pattern in the mounting brackets compensates for vertical rack

differences and allows mounting the standard (front and rear access) 1-3/4-inch (4.45-cm)

high fuse panel in either 1-3/4-inch (4.45 cm) high or 2-inch (5.08-cm) high rack spaces and

allows mounting the 21.25-inch (53.97-cm) wide fuse panel in either 3-1/2-inch (8.89-cm)

high or 3-3/4-inch (9.53 cm) high rack spaces.

Page 21

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

19-IN. (48.26 CM) RACK,

MOUNT ON FRAME,

USE 3/8-IN. (9.525 MM) LONG

SCREWS AND WASHERS (2)

23-IN. (58.42 CM) RACK,

MOUNT ON FRAME,

USE 3/8-IN. (9.525 MM) LONG

SCREWS AND WASHERS (2)

23-IN. (58.42 CM) RACK,

MOUNT ON FUSE PANEL,

USE 1/4-IN. (6.350 MM) LONG

FLATHEAD SCREWS (3)

19-IN. (48.26 CM) RACK,

MOUNT ON FUSE PANEL,

USE 1/4-IN. (6.350 MM) LONG

FLATHEAD SCREWS (4)

15984-A

Figure 11. Universal Mounting Brackets for Mounting PowerWorx Select Series

Fuse Type Fuse Panel in 19-Inch (48.26-cm) Rack or 23-Inch (58.42-cm) Rack

Install the fuse panel in the rack as shown in Figure 12 and as follows:

1. Mount the brackets to the fuse panel chassis using the eight (8) 1/4-inch (6.350 mm) 6-32

flathead screws.

2. Secure the fuse panel to the rack using the four (4)3/8-inch (9.525 mm) 12-24 screws

and washers supplied with the fuse panel.

Caution: Do not use any hardware other than the hardware supplied with the fuse panel by ADC.

5.3 Wiring Connections

Note: Before connecting the input and output power wires, measure the resistance as

defined in 6.2.

Remove the protective cover from the fuse panel by loosening the four screws that attach the

cover, sliding the cover to the right, and pulling it over the screws.

Route and connect ground cables, power cables, and alarm cables to the fuse panel connectors

according to local practice and the following subparagraphs. An example of the connections to

the fuse panel is shown in Figure 13. After routing the cables, tie them to the cable

management bar (if optional accessory ordered).

Caution: Connect only the input voltage wire (wire labeled “BATTERY” or “BATT,” or

labeled with the negative voltage polarity and/or the voltage value) – the “hot wire” – to the

connector on the fuse panel labeled “BATT” (battery). Connect only the input return wire

(wire labeled “RTN,” “RETURN,” or “BATTERY GROUND”) – the “ground wire” – to

the connector on the fuse panel labeled “RTN” (return). If the wires are reversed, voltage

could be present on the fuse panel chassis and current could flow through the unfused return

wiring in the fuse panel. This condition causes damage to equipment in the rack in which the

fuse panel is installed and to equipment in adjacent frames!

Replace the protector cover on the fuse panel after all the wiring connections are made and

before power is applied to the fuse panel.

Page 22

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

14231-B

Figure 12. Typical PowerWorx Select Series Fuse Type Fuse Panel Installation in

Equipment Rack (With Optional Cable Management Bar), Rear View

Page 23

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

FEED B, ONE TYPE

OUTPUT CONNECTOR

(SCREW-DOWN BARRIER

TERMINAL STRIPS FOR

4 KLM FUSES SHOWN)

CONNECT TO BUS B KLM

FUSE OUTPUT POWER

CONNECT TO BUS B

KLM FUSE RETURN

CHASSIS GROUND

(2 CONNECTORS)

COMBINED ALARM

CONTACT CONNECTORS

(SCREW-DOWN BARRIER

TERMINAL STRIP SHOWN)

CONNECT

TO BATTERY

BUS B*

CONNECT TO

RETURN

BUS B**

CONNECT

CONNECT

TO BATTERY

TO RETURN

BUS A*

BUS A**

FEED B, ONE TYPE

OUTPUT CONNECTOR,

(SCREW-DOWN BARRIER

TERMINAL STRIPS FOR

4 GMT FUSES SHOWN)

CONNECT TO

T

BUS B GMT FUSE

OUTPUT POWER

CONNECT TO BUS B

GMT FUSE RETURN

BUS A OUTPUT CONNECTORS

ARE MIRROR IMAGE OF BUS B

CONNECTORS

*NOTE: CONNECT INPUT VOLTAGE WIRE LABELED "BATTERY" OR "BATT," OR LABELED WITH THE VOLTAGE

POLARITY AND/OR THE VOLTAGE VALUE ("HOT" WIRE) TO THE "BATT" CONNECTOR ON THE FUSE PANEL.

**NOTE: CONNECT INPUT RETURN WIRE LABELED "RTN," "RETURN," OR "BATTERY GROUND" (GROUND WIRE)

TO THE "RTN" CONNECTOR ON THE FUSE PANEL.

Figure 13. Fuse Panel Cabling; Select Series Fuse Type Fuse Panel, Rear View

(Fuse Panel with Dual Power Feed, One 4-Position KLM/KTK Output Module and

One Position GMT Output Module on Each Bus, and Screw-Down Barrier Strip

Alarm Contact Connection Shown)

Page 24

2000, ADC Telecommunications, Inc.

14232-B

ADCP-80-526 • Issue 1 • November 2000

5.3.1

Chassis Ground Connection

Mounting the fuse panel on a metal equipment rack using metal mounting brackets as

described in 5.2 provides a sufficient return path to meet equipment grounding requirements.

However, often a separate grounding conductor is required by local practice or local

inspectors. A separate chassis grounding conductor is always needed when the fuse panel is

mounted to non-grounded or non-conducting material, e.g., a plastic rack or cabinet. When the

fuse panel requires separate chassis grounding, the chassis grounding conductor is sized to

match the upstream protection device feeding the fuse panel. This provides an adequate return

path capable of allowing the fuse to fail in the unlikely event of a battery wire to chassis fault.

Connect one or both of the chassis ground connectors (labeled “C. GND”) to the equipment

rack ground using the following chassis grounding recommendations:

• Chassis ground conductor: Use two #10 AWG wires if using both chassis ground

connectors or one #6 AWG wire if using one chassis ground.

• Chassis grounding conductor connection point: Use provided #10 screws and nuts on

0.625 inch (15.875 mm) centers. Two #10 crimp ring terminals, for use with #10 AWG

wires, are provided.

5.3.2

Output Power Connectors

Connect the output BATT and RTN terminals for each fused circuit on each set of terminal strips.

• Use wireleads with appropriate size crimp-on spade lugs or ring connectors, or use the

size wire with insulation stripped back on the leads as follows (see 1.5.2):

TPA Fuse: Terminal screw size is 8-32. Maximum connecting terminal width is 0.378

inch (9.601 mm). Use #10 to #22 AWG wire without lugs.

KLM Fuse: Terminal screw size is 8-32. Maximum connecting terminal width is 0.320

inch (8.128 mm). Use #12 to #22 AWG wire without lugs.

GMT Fuse, four and five position module: Terminal screw size is 6-32. Maximum

connecting terminal width is 0.325 inch (8.255 mm). Use #12 to #22 AWG wire without

lugs.

GMT Fuse, ten position module: Terminal screw size is 6-32. Maximum connecting

terminal width is 0.260 inch (6.604 mm). Use #14 to #22 AWG wire without lugs.

Combination of four TPA Fuses and 10 GMT fuses: Terminal screw size is 3-48.

Maximum connecting terminal width is 0.200 inch (5.080 mm). Use #16 to #30 AWG

without lugs.

• Torque the screws to approximately 9 pound-inches (1 Newton-meter).

Page 25

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

5.3.3

External Alarm Contact Connections

Connect each set of external alarm contacts to a system alarm as follows (see 1.13):

• Screw-down barrier terminal strip: Terminal screw size is 3-48. Use wire leads with

crimp-on spade lug or ring connectors that have a maximum width of 0.200 (5.080 mm)

or use #16 to #30 AWG copper wire without lugs (insulation stripped back).

Torque the screws to approximately 9 pound-inches (1 Newton-meter).

• Wire-wrap terminal block: Wrap terminal block pins using #22 to #26 AWG copper wire

with insulation stripped back.

5.3.4

Input Power Connectors

Connect input power wires to the input power connectors labeled “BATT” and connect return

wires to the return connectors labeled “RTN” for both buses in the fuse panel. Connect input

power to the appropriate power sources in accordance with applicable local electrical codes

and/or National Electrical Codes.

Caution: Connect only the input voltage wire (wire labeled “BATTERY” or “BATT,” or

labeled with the negative voltage polarity and/or the voltage value) – the “hot wire” – to the

connector on the fuse panel labeled “BATT” (battery). Connect only the input return wire (wire

labeled “RTN,” “RETURN,” or “BATTERY GROUND”) – the “ground wire” – to the

connector on the fuse panel labeled “RTN” (return).

Caution: Caution should be taken to not reverse input wires to the fuse panel. In the fuse

panel, the internal battery (positive or negative voltage) wiring is fused, and the internal

return wiring is not fused.

Use the included 2-hole lugs with #2 AWG copper wire (insulation stripped back) or

appropriate optional 2-hole lugs available as accessories (see Section 3) with appropriate

AWG copper wire. Tighten the nuts to approximately 16 pound-inches (2 Newton-meters).

5.4 Fuse Designation Pins

Insert the appropriate color-coded pins (accessory item, not supplied) in the corresponding

holes in the GMT fuse holder as required.

5.5 Fuse Designation Card Holder and Card

Attach the fuse designation card holder to the fuse panel, to one of the fuse panel mounting

brackets, or to a part of the rack as desired by removing the backing from the back of the card

holder and pressing the card holder against the mounting surface. Fill out one of the cards (see

Figure 7) with circuit information as desired and insert it in the card holder.

Page 26

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

5.6 Voltage Designation Label

Write the voltage used in the fuse panel on the voltage designation label (see Figure 8) and

attach the label to the back of the fuse panel.

5.7 Fuse Installation

Replace the dummy fuses in the fuse holder(s) with the appropriate type and value fuses.

Leave the dummy fuses in unused fuse positions.

6

TESTING THE FUSE PANEL

Caution: This equipment employs electrical voltage and amperage levels which may be

considered an electrical hazard. Care should be exercised to assure that only qualified

personnel are allowed to install, operate, maintain, or otherwise come in contact with this

equipment when the fuse panel is energized. Only insulated tools should be used on energized

elements of the fuse panel.

6.1 Quality Control

Each unit is thoroughly tested at the ADC Telecommunications factory. The following tests

are recommended, however, to assure that no damage has occurred during shipping or

handling. Both bus A and bus B input circuits (if applicable) need to be tested.

6.2 Resistance Test

Caution: Before performing this test, verify that the input and output power is not connected

to the fuse panel connectors.

Measure the resistance at each bus input with a multimeter connected to the BATT and RTN

input terminals. A resistance of at least 500 ohms should be read on the meter (some meters

will indicate a resistance of several Megohms because their input voltage is not high enough

to break down the forward conductance of the diodes used in the alarm circuit). Any

resistance higher than 500 ohms is acceptable.

6.3 Connection Polarity Test

To verify that the input power wires are connected to the correct terminals, measure the

voltage between the input return connector (RTN) and the chassis ground using a multimeter.

The voltage should be less than 2.0 Vdc. If the voltage is more than 2.0 Vdc, reverse the input

power wires and measure the voltage between the input return connector (RTN) and the

chassis ground again to determine that the voltage is less than 2.0 Vdc.

Page 27

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

6.4 Wiring Connections Measurements

Measure the torque of all input, output, chassis ground and fuse alarm relay contact

connections stated in the Wiring Connections paragraphs above using a torque screwdriver

that is calibrated in pound-inches (Newton-meters).

6.5 Power Indication Test

After checking input resistance according to the Resistance Test above, the input power wires

can be connected to the fuse panel. Upon power application, the fuse alarm indicators will not

light unless no fuse is in the fuse holder or a fuse that has failed is in the fuse holder.

Note: The KLM fuse positions require a load connected to the corresponding outputs to

light the indicators.

The fuse alarm relay should indicate an open circuit between the normally open (NO) contact

and the common (C) contact at the alarm contacts. When input power is not applied, a short

circuit will be indicated between these contacts.

6.6 Fuse Alarm Test

6.6.1

GMT and TPA Fuse Alarm Test

Place a fuse that has failed in one of the fuse positions on each bus. The visual fuse alarm

LED(s) will change from unlit to lit (red light), and the fuse alarm relay will operate.

6.6.2

KLM Fuse Alarm Test

Perform the following tests:

Note: The KLM fuse positions require a load connected to the corresponding outputs to

light the fuse alarm indicators.

1. With the fuse panel powered, no load on the outputs, and no KLM fuses installed,

observe that no fuse alarm LED is lit (no red light). Observe that the fuse alarm relay

indicates an open circuit between the NO contact and the C contact at the fuse alarm

contacts.

2. Connect a 10 kohm, ½ watt resistor between each KLM fuse output (labeled BATT) and

return (labeled RTN). Observe that each KLM fuse alarm LED lights (red light) when

the corresponding load is connected. Observe that the fuse alarm relay indicates a short

circuit between the NO contact and the C contact at the fuse alarm contacts.

3. Insert a known good KLM fuse in each fuse position, one at a time, and observe that the

corresponding fuse alarm LED is unlit.

Page 28

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

7

OPERATION

Caution: This equipment employs electrical voltage and amperage levels which may be

considered an electrical hazard. Care should be exercised to assure that only qualified

personnel are allowed to install, operate, maintain, or otherwise come in contact with this

equipment when the fuse panel is energized. Only insulated tools should be used on energized

elements of the fuse panel.

All fuse panel circuits are operational as soon as power is applied to the input connectors. The

alarm indicator should not light when power is applied.

Operation of the fuse panel consists of removing and replacing fuses when a fuse fails. If a fuse

fails, the alarm indicator lights, and the external and remote alarms are activated (if present).

8

MAINTENANCE

Caution: This equipment employs electrical voltage and amperage levels which may be

considered an electrical hazard. Care should be exercised to assure that only qualified

personnel are allowed to install, operate, maintain, or otherwise come in contact with this

equipment when the fuse panel is energized. Only insulated tools should be used on energized

elements of the fuse panel.

8.1 Inspection

Inspect the fuse panel periodically (every six months is recommended) for damage to the

fuses, damaged or broken wires on the power outputs and the external alarm connections.

Inspect for excessive dust and dirt that block the vents.

8.2 Cleaning

If excessive dirt is found during the inspection, brush or wipe dust and dirt from the fuse panel with

a soft bristle brush or soft cloth. Care should be taken to not damage the fuses or any wiring.

8.3 Adjustments

No adjustments in the field are indicated or required. If a circuit is not operating properly,

contact ADC customer assistance (see Section 9).

8.4 Fuse Removal

The GMT fuses can be removed with the aid of a wire hook or tweezers-type fuse puller. A

fuse puller is an available accessory. A TPA or KLM fuse may be removed by pulling the

fuses straight out from the fuse holders.

Page 29

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

8.5 Power-On LED Replacement

The Power-On LEDs may be replaced as follows:

1. Pull LED out slowly from the front of the fuse panel.

2. Disconnect both mating terminals (quick-connects or fastons) on the wires from the tabs

on the LED.

3. On the replacement LED, connect the mating terminal on the red wire to the tin tab and

connect the mating terminal on the black wire to the brass tab.

9

CUSTOMER INFORMATION AND ASSISTANCE

For customers wanting information on ADC products or help in using them, ADC offers the

services listed below. To obtain any of these services by telephone, first dial the central ADC

telephone number, then dial the extension provided below.

The central number for calls originating in the U.S.A. or Canada is 1-800-366-3891. For calls

originating outside the U.S.A. or Canada, dial country code “1” then dial 952-946-3000.

Sales Assistance

Extension 63000

• Quotation Proposals

• Ordering and Delivery

• General Product Information

Systems Integration

Extension 63000

•

•

•

•

•

•

•

Complete Solutions (from Concept to Installation)

Network Design and Integration Testing

System Turn-Up and Testing

Network Monitoring (Upstream or Downstream)

Power Monitoring and Remote Surveillance

Service/Maintenance Agreements

Systems Operation

BCG Technical Assistance Center

Extension 63475

E-Mail: bcg_tac@adc.com

•

•

•

•

•

•

Technical Information

System/Network Configuration

Product Specification and Application

Training (Product-Specific)

Installation and Operation Assistance

Troubleshooting and Repair

Product Return Department

Extension 63748

E-Mail: repair&return@adc.com

• ADC Return Authorization number and instructions must

be obtained before returning products.

Product information may also be obtained using the ADC web site at www.adc.com or by

writing ADC Telecommunications, Inc., P.O. Box 1101, Minneapolis, MN 55440-1101, U.S.A.

Page 30

2000, ADC Telecommunications, Inc.

ADCP-80-526 • Issue 1 • November 2000

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice. In

no event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits and ADC further

disclaims any and all liability for indirect, incidental, special, consequential or other similar damages. This disclaimer of

liability applies to all products, publications and services during and after the warranty period.

This publication may be verified at any time by contacting ADC’s Technical Assistance Center at 1-800-366-3891, extension

63475 (in U.S.A. or Canada) or 952-946-3000 (outside U.S.A. and Canada), or by writing to ADC Telecommunications, Inc.,

Attn: Technical Assistance Center, Mail Station #71, P.O. Box 1101, Minneapolis, MN 55440-1101, U.S.A.

© 2000, ADC Telecommunications, Inc.

All Rights Reserved

Printed in U.S.A.

Page 31