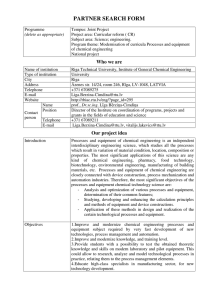

QuickPanel

RTU

GE Fanuc

Intelligent Platforms

Information you

can act on

Improve the decision effectiveness of your

water system by seamlessly connecting remote

data and your plant operations.

Managing large geographical areas is nothing new to water utilities. From occasional

manually collected data to unreliable and

slow communications, timely remote data

always seems just out of reach. Now, with

increasing pressure to improve operational

performance, growing regulatory requirements and increased energy costs, the

need to collect data seamlessly from both

local and remote data sources is a reality.

Think globally, act locally

GE Fanuc Intelligent Platforms’ powerful

QuickPanel* Remote Telemetry Unit (RTU)

applied solution enables you to easily

monitor, diagnose and maintain your water

assets and processes through flexible communication architectures. Access to timely

and accurate tracking of water chemistry

and chemical inventories with greater efficiency can eliminate critical gaps in your

water data and the need to deploy service

personnel, resulting in higher productivity.

Providing a visual interface for local operators allows site equipment to be operated

manually, mitigating the operational impact

of remote communication disruptions. The

integrated controller will keep automatic

equipment running through an outage.

QuickPanel RTU is a bundled visualization

and control solution that provides the tools

required for today’s remote application

needs. A combination of bright touch-screen

displays and award-winning Proficy*

Machine Edition software, QuickPanel RTU

delivers flexible, scalable performance on

a rugged hardware platform.

Once communications are restored,

store-and-forward capabilities and local

time stamping of alarms ensure nothing

is missed, and alarms can be arranged as

they happened.

GE Fanuc Intelligent Platforms has been partnering

with water operations all over the world to help

them seamlessly integrate critical water data.

With decades of water industry expertise and

innovative technology solutions, we can position

your operations for long-term success.

Reliable, scalable

and open

With an open and connected approach, QuickPanel RTU offers

flexible configuration to fit your unique requirements—providing

access to real-time information across your entire utility.

QuickPanel RTU can range from simple, low I/O count applications through complex

automation solutions that require the support of large numbers of I/O. It provides an

information-rich, graphical interface and has the inherent benefits of providing a smaller

footprint, centralized time synchronization, local alarm time stamping, full IEC 61131-3

language support, and remote diagnostics and maintenance via a web hosting client.

Efficient information delivery

Seamless connectivity

Built on a Microsoft® Windows® CE operating

system, QuickPanel RTU offers enhanced

data buffering and built-in web publishing

capabilities to effectively link your manufacturing operations to your business systems.

Key personnel—from operators to managers—can access accurate, comprehensive

and integrated information when and where

they need it.

Addressing your need to integrate existing and future applications from different

vendors and multiple architectures, QuickPanel RTU enables you to connect to a wide

variety of automation devices. With a large

number of built-in drivers, it can be flexibly

networked back to a centralized SCADA

system using phone line, radio, satellite and

cellular topology.

Leveraging the latest

remote monitoring

technology, QuickPanel

RTU can track and compare distribution flows with sales—offering

a proven approach that enables

utilities to significantly reduce their

non-revenue water.

Infinite scalability

As your information requirements expand,

QuickPanel RTU is exceedingly scalable to

grow with your needs. It includes a broad

range of display sizes from 6" to 15"; choice

of Monochrome or Color-TFT display;

expandable memory and communications

options; and easy configuration to run the

same program on different size models.

QUICKPANEL RTU

Simple configuration for

rapid time to solution

Built for open communications, QuickPanel RTU can connect

with most any utility operations device. With built-in drivers,

it is simple, quick and always open.

You can deploy QuickPanel RTU

in just a few easy steps:

Step 1 Select an I/O system

QuickPanel RTU supports all of GE Fanuc’s

I/O systems as well as open fieldbuses and

third-party controllers, including Rockwell,

Siemens and Group Schneider.

Step 2 Select a QuickPanel

You can choose the display size and type

that best fits your needs, as we offer

user-friendly units ranging from 6 inches

to 15 inches and Monochrome, or

Color-TFT options.

Supporting communications to all new and

legacy RTU hardware solutions, Proficy iFIX

and Proficy CIMPLICITY—both industry-leading HMI/SCADA software solutions—enable

you to share real-time information throughout your operations.

Step 3 Select the connectivity device

QuickPanel RTU supports any Ethernetbased connectivity scheme, including MESH

Radio, local wireless, serial, cellular and

satellite communications. It is also product

agnostic—enabling you to connect to thirdparty equipment.

Open communications

QuickPanel RTU is a powerful solution that can integrate with existing

PLC hardware locally and other RTU

throughout the system—seamlessly

delivering connectivity across your

operations. Its open communications makes it ideal for mixed

system architectures, as you can

connect a QuickPanel RTU directly

to your existing PLC to upgrade

legacy PLCs and RTUs to Ethernet

communications with store and

forward capabilities.

Step 4 Select your SCADA software

To learn more about how QuickPanel RTU

can help your water operations deliver

high performance for the long term, visit

www.gefanuc.com/quickpanelrtu.

et

Ethern

QuickPanel RTU Solution

4

Software

In addition to seamless hardware connection, our Proficy* software supports the

communication to all new and legacy RTU hardware solutions—providing a single,

streamlined SCADA solution that enables you to easily troubleshoot issues and

coordinate with the field. QuickPanel RTU also works with many leading HMI/SCADA

software solutions.

3

Connectivity Options

2

QuickPanel

1

I/O Options

Addressing your need to integrate existing and future applications from different

vendors and multiple architectures, QuickPanel RTU enables you to connect to a

wide variety of automation devices. With a large number of built-in drivers, it can

be flexibly networked back to a centralized SCADA system using phone line, radio,

satellite and cellular topology.

With Proficy Machine Edition automation software, you can simplify your efforts and

reduce costs by leveraging an integrated development environment that deploys

all your HMI, motion and multi-target control applications. In addition to leveraging

open industry standard technologies, all components and applications within

Machine Edition share a single workspace and tool set, including a standardized

user interface and an efficient, user-friendly design. GE Fanuc offers a multitude of options when connecting to field equipment,

including our VersaMax, 90-30 and Genius I/O systems. The QuickPanel RTU

also supports connectivity to popular fieldbuses PROFIBUS and DeviceNet as

well as third-party controllers.

Proficy HMI/SCADA – CIMPLICITY*

Trinity

Cellular Radio

6" Mono

VersaPoint

Proficy HMI/SCADA – iFIX*

TranSphere* Spread

Spectrum Radio

6" TFT-Color

VersaMax I/O

Landline

Telephone

8" TFT-Color

3rd Party

Fiber/Copper

Ethernet

12" TFT-Color

Field Control

Genius I/O

3rd Party

15" TFT-Color

3rd Party

QuickPanel Control

Typical Applications

Features

Available Sizes

Medium-to-large applications that require

integrated visualization and control;

capable of simultaneously communicating

to multiple I/O networks and controllers.

• Connectivity: Serial, Ethernet and Fieldbus

I/O networks

• View and VB Scripting

• Compact Flash and USB

• Document Viewers (doc, xls, pdf)

• Historian Collector

• Web Publishing

• View and Integrated Control

15" TFT-Color

12" TFT-Color

8" TFT-Color

6" TFT-Color

6" Mono

IC754C†L06MTD

IC754C†L06CTD

IC754C†F08CTD

IC754C†F12CTD

IC754C†F15CTD

Display

Type

Resolution

Size 6" Mono

8" Color-TFT

12" Color-TFT

15" Color-TFT

320 x 240 pixels

6” Color-TFT

800 x 600 pixels

800 x 600 pixels

1024 x 768 pixels

5.7" (Diagonal)

8.5" (Diagonal)

12.1" (Diagonal)

15.1" (Diagonal)

Memory

Flash

32 MB

DRAM

Expandable

32 MB

To 64 MB or 96 MB

64 MB

64 MB

To 96 MB or 128 MB

Communications

Serial: Com #1

RS232/RS485

Serial: Com #2

RS232

Ethernet: LAN #1

10/100 Mbps

Ethernet: LAN #2

None

10/100 Mbps

Comm. ExpansionGE Fanuc 90-30 I/O, VersaMax I/O, VersaMax Micro Expansion I/O, Genius I/O, DeviceNet Master, PROFIBUS Master

USB

V1.1 Compatible

Compact Flash

One, Type 2

Environmental

Operating

Temperature

-10 to 60 Deg C

(14 to 140 Deg F)

0 to 60 Deg C

(32 to 140 Deg F)

0 to 60 Deg C

(32 to 140 Deg F)

0 to 50 Deg C

(32 to 122 Deg F)

0 to 50 Deg C

(32 to 122 Deg F)

AgenciesUL - Class 1 Div 2 (A, B, C, D), ATEX - Class 1 Zone 2, CE Mark

Environmental

Panel Cut-Out

(W x H x D)

Power Requirements

6.14" x 4.86" x 2.76"

158 mm x 126 mm x 70 mm

12.0 to 30.0 VDC

24 watts

† S = Standard overlay, B = Blank overlay, G = GE Fanuc overlay, K = Kit

NEMA 4/4x

8.93" x 7.34" x 3.03"

228 mm x 186 mm x 77 mm

12.0 to 30.0 VDC

48 watts

11.88" x 8.96" x 2.37"

302 mm x 228 mm x 60 mm

14.93" x 12.03" x 2.78"

379 mm x 305 mm x 71 mm

12 VDC @ +/- 20% or 24 VDC @ +/- 20%

48 watts

Proficy Software Modules

Plant Performance and Execution

6 Proficy Workflow

6 Proficy Plant Applications – Efficiency

6 Proficy Plant Applications – Production

6 Proficy DataMart

6 Proficy Tracker

6 Proficy Machine Tool Efficiency

Plant Data Repository

6 Proficy Historian

Integrated Quality

6 Proficy Plant Applications – Quality

6 Proficy Non Conformance Reporting

6 Proficy Shop Floor SPC

6 Proficy RX™

HMI / SCADA

6 Proficy HMI/SCADA – iFIX*

6 Proficy HMI/SCADA – CIMPLICITY*

6 Proficy View – Machine Edition

Asset Management

6 Proficy Remote Monitoring and Diagnostic

6 Proficy Change Management

6 Proficy Maintenance Gateway*

Real-Time Information Portal

6 Proficy Real-Time Information Portal

Programming & Control

6 Proficy Logic Developer

6 Proficy Motion Developer – Machine Edition

Process Solutions

GE Fanuc Support & Services

6 Proficy

Process Systems*

Batch Execution

6 Proficy Plant Applications – Batch Analysis

6 PACSystems* RX3i and RX7i

6 PAC8000 Controllers

6 PAC8000 SafetyNet

6 8000 Process I/O

6 GlobalCare*

6 Proficy

6 Professional

GE Fanuc Intelligent Platforms

Information Center

Additional Resources

Headquarters:

1 800 GEFANUC

1 800 322 3616

1 434 978 5100

Support

Services

6 Training

For more information, please visit the

GE Fanuc Intelligent Platforms web site at:

www.gefanuc.com

Global Regional phone numbers

are available on our web site

www.gefanuc.com

©2009 GE Fanuc Intelligent Platforms, Inc. All Rights Reserved.

*Trademark of GE Fanuc Intelligent Platforms, Inc.

All other brands or names are property of their respective holders.

03.09 GFA-1147