809 Sell Sheet.indd - Lighting Plastics Solutions

Preliminary Specification Sheet

Prismatic LED Post Top

The LED Lindy

®

General Description

A nostalgic globe with an LED light engine mounted at its equator. This combination provides high performance street and area lighting with Type III or V medium distributions.

This LED version of industry standard The Lindy® employs a patent pending heat sink concept which, unlike most LED post-tops, allows heat dissipation to occur outside of the fixture, reducing the ambient operating temperature of the LEDs. The LEDs are mounted 16” away from the optical surface for exceptional LED hiding. The assembly uses the existing

424 base (Type III or V) with either 8” or 9” neck options and the traditional 424 top. With over 350 square inches of surface area, the one-piece specialty aluminum heat sink can effectively dissipate up to 100W in a 25ºC ambient temperature. LED boards for the Type III are biased to provide optimal street side performance while de-emphasizing the house side.

Heat Sink

The cast aluminum heat sink is offered in raw metal or with a black powder coated finish. There are 12 internal

LED board mounting surfaces which are canted to 70 degrees from vertical. The heat sink is assembled to the 424 with four cast-aluminum mounting brackets that capture both the upper flange of the refractor and bottom flange of the 424 top. Brackets are also available either raw or painted. LexaLite offers custom machining of the heat sink to accommodate your LED board mounting.

Light Engine Requirements

Suitable light engines are 100W or less, not including driver. LEDs should have a 150º FWHM beam or narrower. Each LED, board, and mounting will be different and customers are responsible for determining the suitability of their LED package with these components.

LED Lindy Type V

Available Light Engines

LexaLite is offering one standard light engine for each the Type V and Type III versions. The light engine is available in black powder coat paint finish only (inquire for custom finishes). The specs are as follows:

Type III – 90W, 4000K CCT, includes wire harness,

wire harness bracket, power supply, and mounting

clips. See Light Engine Spec sheet for photometry,

specific details and warranty information

Type V – 80W, 4000K CCT, includes wire harness,

wire harness bracket, power supply, and mounting

clips. See Light Engine Spec sheet for photometry,

specific details and warranty information

Application

The Lindy LED is for use in parks, along walkways, roadways or areas where a distinctive, nostalgic theme is prevalent. Both the Type III and Type V provide performance comparable to HID sources of similar wattage.

Service Life

The service life of acrylic refractors is virtually unlimited when used within the recommended temperature limit.

Acrylic versions are covered by our 10 year limited warranty. Polycarbonate refractors are subject to yellowing.

Paint finish on heat sinks is covered against significant fading or peeling for a period of 5 years, due to weathering alone.

Light Engines – see the specification sheet for the light engine for details

Notice

A.L.P. Lighting Components, Inc. assumes no responsibility for suitability of luminaires and applications. The use of our molded products at excessive temperatures will cause degradation of the material.

LED Lindy

Specifications

24” high

17.1” diameter

Nostalgic post top for street and area lighting

Type III and Type V distributions

LED Lindy Type III

Efficiency >75%

Materials: Acrylic,

Acrylic Moon Glow TM and Polycarbonate

Other available light engines

Midwest Circuits

248-548-9722

Relume

248-969-3800

A.L.P. LexaLite light engines do not carry UL nor does

A.L.P. LexaLite claim the light engines are capable of meeting UL standards. The manufacturer/distributor is solely responsible for providing UL and/or adequate warnings to end users.

Prismatic LED Post Top

The LED Lindy

®

Accessories

LiteLid ® LiteLids should be utilized in light pollution-sensitive areas to redirect potentially wasted uplight into increased downward efficiencies. The

LiteLid allows just enough uplight for a pleasing glow. LiteLids are patented, aluminum reflectors which fit between the top and bottom components.

4245P Perforated LiteLid

4245N Non-perforated LiteLid

Finials - Available in either black flame or black spike design.

Neck Ring Protects fitter from metal screws.

Materials

See the LexaLite brand price list for current part numbers and material offerings. Up-to-date and detailed material specifications can be found in the Products/Technical Resources section of our web site at www.

alplighting.com.

When using an acrylic LED Lindy, the surface temperature of the refractor should not exceed 80°C. When using a polycarbonate LED Lindy, the surface temperature of the refractor should not exceed 90°C.

24.0

Section B-B

Scale 1/2

17.1

A

Preliminary Specification Sheet

Ø15.9"

[404mm] Ø0.31"

[8mm]

23.16"

[588mm]

0.68"

[17mm]

23.29"

[592mm]

HEIGHT

0.53"

[13,5mm]

Ø7.27" THRU

[185mm] HOLE

9" [229mm]

MOLDED

FITTER

Ø9.13"

[232mm]

Ø7.75" THRU

[197mm] HOLE

8" [203mm]

MOLDED

FITTER

Ø8.14"

[207mm]

2.25

B

Do not paint

Do not paint

Do not paint

8-32 thread

.625 min depth

4 places as shown

Heat Sink

B

A

Section A-A

Scale 1/2

LINDY LEDHS 2/10

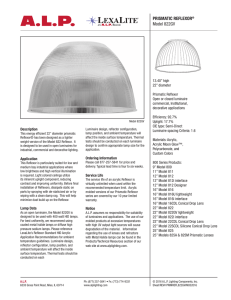

Model 809 Refl exor

5.86” high, 8.88” diameter

Effi ciency: 91.7%

Uplight: 21.4%

CIE type: Semi-direct

Luminaire spacing criteria: 1.6

Colors:

Acrylic colors:

Clear, Bead, Moon Glow, Lime Green

Acrylic Metalized

Acrylic pearlescent colors:

Blue, Green, Pink, Pearl

Polycarbonate vibrant colors:

Blue, Green, Red, Amber

Custom colors available

Accessories:

Flat Acrylic and Bead Acrylic Lenses

Flat Clear and Etched Glass Lenses

Custom mountings available,

please inquire

Model 809 Prismatic Refl exor

®

for retail, commercial, and residential decorative applications

Model 809 Prismatic Refl exor

®

for retail, commercial, and residential decorative applications

100 200

CANDELA

300 400 500

90°

Report Number: LL02729, open bottom

Total Luminaire Effi ciency: 91.7%

Uplight 21.4%

CIE type: Semi-direct

Luminaire Spacing Criteria: 1.6

0°

30°

60°

Description

For decorative lighting applications,

LexaLite offers an 8.88” diameter by 5.86” high prismatic Refl exor.

Featuring excellent performance and a clean, crystal-like appearance, the Model 809 is lightweight at 10 ounces making it ideal for track or pendant mount applications.

Standard mounting features a 3 position keyway slot mounting arrangement. Please contact your

LexaLite representative to discuss other mounting options.

Materials

Up-to-date and detailed material specifi cations can be found in the Products/

Technical Resources section of our web site at www.alplighting.com.

When using an acrylic Model 809, the surface temperature of the Refl exor should not exceed 80°C. When using a polycarbonate Model 809, the surface temperature of the

Refl exor should not exceed 90°C.

Application

The Model 809 can be used in residential, commericial, retail, or other decorative applications.

Lamp Data

The Model 809 Refl exor is designed for use with 35 watt compact metal halide or up to 42 watt compact fl uorescent lamps. Acrylic versions are designed for continuous service of up to 80°C temperature maximum. Luminaire design, refl ector confi guration, lamp position and ambient temperature will affect the inside surface temperature. Thermal tests should be conducted on each luminaire design to confi rm appropriate lamp size for the application.

Ordering Information

Please call 800-228-5275 or 231-547-6584 for price and delivery. Typical lead time is four to six weeks.

Service Life

The service life of an acrylic Refl exor is virtually unlimited when used within the recommended temperature limit. Acrylic molded versions of our Prismatic Refl exor series are covered by our 10 year limited warranty. Polycarbonate versions are virtually indestructible and are subject to yellowing when used with high ultraviolet output light sources; this effect is enhanced at high temperatures.

Notice

A.L.P. Lighting Components, Inc. assumes no responsibility for suitability of luminaires and applications. The use of lenses near and above 70°C temperatures with high UV output light sources will cause degradation of the material.

Upper Rim Detail

The upper rim of the refl ector is supplied with two styles. A three position keyway slot as shown, or with a fl at continuous surface. The fl at surface will be cut to order.

120°

(3)

TYP

20.6°

0.10"

[2,5mm]

5.86"

[148,8mm]

Ø3.48"

[88,4mm]

5°

UPPER RIM

Ø3.29"

[83,7mm]

Ø0.20"

[5,1mm]

Ø2.69"

[68,3mm]

Ø0.33"

[8,5mm]

Ø

DESIGN

LIGHT CENTER

4.21"

[107mm]

0.15"

[3,8mm]

BOTTOM RIM DETAIL

0.10"

[2,5mm]

BOTTOM RIM

Ø8.88"

0.15"

[3,8mm]

0.08"

[2mm]

Ø2.25”

[57mm]

Ø8.88"

[225,6mm]

REF

0.15"

[3,8mm]

These drawings are for reference only. Actual part dimensions will vary. Customer is urged to review actual samples to confi rm fi t and function. All specifi cations and dimensions are subject to change without notice.

Accessories

Flat Acrylic and Bead Acrylic Lenses

Flat Clear and Etched Glass Lenses

These lenses will be found in UL’s Recognized

Component Directory under the number E134182, designated 8XXSFL.

Custom mountings available, please inquire.

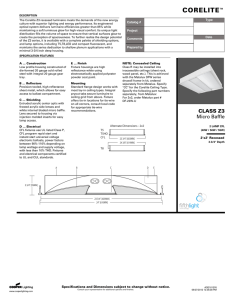

Little Lindy

®

Pedestrian Scale

Prismatic Post Top

• Upgrade your post top lighting

• Injection molded optics provides superior performance over blow molded or glass components

• Measures 19” high, 14” diameter with 8” neck fitter

• Warranty against discoloration

(acrylic versions)

• Efficiency 81%, Type III and

Type V distributions

• Available in acrylic, acrylic Moon Glow

™

white and polycarbonate

• Night Sky friendly with optional

LiteLid

®

technology

• Optional fitter (capital) available

• Available as a retrofit kit

L EXA L ITE

Model 408

CANDELA

2500 3500 1500 4500 5500

90˚

60˚

500

CANDELA

1000

0˚

30˚

Report Number: ITL54652

Total Luminaire Efficiency: 81.9%

Report Number: LL02430

Total Luminaire Efficiency: 88.46%

IES Classification: Type III, medium non-cutoff IES Classification: Type V, semi-cutoff

30˚

1500

90˚

60˚

Photometrics

The Little Lindy Model 408 is available in IES Type III and Type V distributions. Type III will classify as medium non-cutoff with lamp at 4 inches from upper rim. Type V will classify as semi-cutoff with lamp at 3.5 inches from the upper rim. The Type III, coupled with the perforated

LiteLid, prismatic acorn top, and 100W clear MH lamp, produces 5895 candela at 70 (degrees) vertical and 75

(degrees) lateral (Report No. ITL54652). The Type V, coupled with the prismatic acorn top, and 100W clear

MH lamp, produces 1689 candela at 70 (degrees) vertical (Report No. LL02430). Individual luminaire performance depends on the lamp type, lamp center position, and the top or reflector design chosen (acrylic or polycarbonate). Each luminaire design should be individually tested for proper classification. Please call for additional photometric data.

Accessories

Prismatic Top Acrylic or polycarbonate.

LiteLid

®

These LiteLids should be used in light pollutionsensitive areas to redirect potentially wasted uplight into increased downward efficiencies. For reduced uplight and improved downward efficiency use the LiteLid®—which allow just enough uplight for a pleasing glow. LiteLids are patented, aluminum reflectors which fit between the top and bottom components.

408P Perforated LiteLid.

408N Non-perforated LiteLid.

Stainless Steel Clamp Band For attachment of top.

Clips To mount top to bottom.

Finials Available in either black flame or black spike design.

Neck Ring Protects fitter from metal screws.

Post Top Fitter (Capital) Cast aluminum, painted black, with ballast bracket, fits 3” tenon. Mounting screws installed, ballast NOT included.

0.10"

[2,5mm]

0.22"

[5,6mm]

Rim Detail

0.50"

[12,7mm]

Ø14.11"

[358mm]

Ø14.11"

[358mm]

Ø1.81"

[Ø46mm]

7.59"

[193mm]

Materials

C lear acrylic: Molded in Underwriters Laboratory (UL) recognized Altuglas International Plexiglas® V-825-HID,

Lucite International Inc. Perspex® CP-75-HID, Plaskolite

Optix® CA-75HID or CYRO Acrylite®

S-10-453.

Acrylic Moon Glow white: Molded in a PMMA resin with a customized pigment additive.

11.46"

[291mm]

0.66"

[16,8mm]

Ø7.0"

[178mm]

Clear polycarbonate: Molded in UL recognized Bayer lighting grade polycarbonates including Makrolon® LTG 3123,

Makrolon® LTG 2623, or GE Lexan® grade 243. LexaLite's proprietary treatment to retard yellowing in ultraviolet environments, UvaLex®, is optional on these polycarbonate refractors.

Ø8.02"

[204mm]

This drawing is for reference only. Actual part dimensions will vary.

Customer is urged to review actual samples to confirm fit and function. All specifications and dimensions are subject to change without notice.

Please visit our web site for the most current material specifications. When using an acrylic Model 408, the surface temperature of the refractor should not exceed 80°C. When using a polycarbonate Model 408, the surface emperature of the refractor should not exceed 90°C.

408 11/07

The Lindy

®

&

The Little Lindy

® from

Need to replace globes?

Blow molded globes can yellow or crack over the years, requiring frequent replacement.

Add up the maintenance, energy and product costs and you’ll see how prismatic can save you money!

Save on maintenance costs.

LexaLite’s 10-year limited warranty provides years of maintenance free operation.

Why waste energy?

The Lindy ® Series post top prisms put the light right where you need it. Blow molded globes provide no optical control, wasting energy and polluting the sky.

Build your own assembly.

Each kit can be configured for your specific application. Choose your desired top and bottom configuration, finials, clamp bands and our Night Sky friendly LiteLids ® which reduce uplight to 10%. We also have a fitter option for the Little Lindy.

Retrofit Kits

The Lindy

Retrofit Kit

12’-20’ poles

Little Lindy

Retrofit Kit

8’-12’ poles

For more information visit www.thelindy.com

Blow Molded Acorn

Uplight: 46.2%

Downlight: 45%

Maximum Candela: 1445

The Lindy

Uplight: 11.66%

Downlight: 72%

Maximum Candela: 2977

Ordering Guide

EXA LITE

V

MODEL 408

Little Lindy

Model 408

14.55” W 18.55” H

8” neck

Medium non-cutoff

Fitter Accessory

EXA ITE

V MODEL 408

Clamp Band

Spike Finial

Flame Finial

Prismatic Top

Perforated or

Non-perforated LiteLid®

Prismatic Refractor

Neck Ring

Lamp (Not included)

Fitter

1500

CANDELA

2500 3500 4500 5500

90˚

60˚

500

CANDELA

1000 1500

90˚

0˚

Report Number: ITL54652

Total Luminaire Efficiency: 81.9%

IES Classification: Type III,

Medium Non-Cutoff

30˚ 30˚

0˚

Report Number: LL02430

Total Luminaire Efficiency: 88.46%

IES Classification: Type V,

Semi-Cutoff

60˚

The Lindy

Model 424

15.9” W 23.16” H

8” or 9” neck

Medium non-cutoff

The Lindy

Model 425

15.5” W 14.31” H

8” or 9” neck

Medium non-cutoff

Please specify the following when ordering:

1. Top/bottom material type.

2. Bottom refractor distribution: Type III (narrow) or Type V (round).

3. Accessories: Clamp band / LiteLid / Finial / Neck Ring

Clamp Band

Spike Finial

Flame Finial

Prismatic Top

2000

CANDELA

3500

5000

6500

90˚

60˚

1000

CANDELA

1500 2000 2500 3000

90˚

60˚

Perforated or

Non-perforated LiteLid®

Prismatic Refractor

0˚ 30˚

Report Number: ITL48610

Total Luminaire Efficiency = 81.25%

IES Classification: Type III,

Medium, Non-Cutoff

8" or 9" Neck

Neck Ring

0˚ 30˚

Report Number: ITL48623

Total Luminaire Efficiency = 81.72%

IES Classification: Type V,

Semi-Cutoff

2000

CANDELA

3000 4000 5000

90˚

CANDELA

1000 1500 2000 2500

90˚

Clamp Band

Spike Finial

Flame Finial

Perforated or

Non-perforated LiteLid®

Prismatic Refractor

8" or 9" Neck

Neck Ring

60˚

60˚

0˚ 30˚

Report Number: ITL48839

Total Luminaire Efficiency = 83.01%

IES Classification: Type III,

Medium, Non-Cutoff

0˚

30˚

Report Number: ITL48840

Total Luminaire Efficiency = 83.01%

IES Classification: Type V,

Non-Cutoff

Need to improve your lighting?

R e p l a c e i n e f f i c i e n t m e t a l r e f l e c t o r s

Reflexor

®

Retrofit System

Use the Reflexor Retrofit System to replace existing metal reflectors which provide low lighting efficiencies. This system features the LexaLite acrylic prismatic Reflexor with collar, socket adapter and mounting bracket. Simply remove the metal reflector, screw in the adapter assembly, mount the Reflexor and relamp. No mounting hardware is required. The Reflexor Retrofit System will improve your lighting immediately.

Upgrade 400W (also 320W and 360W) mogul based high bay fixtures to get up to 92% light efficiency and 20% more uplight, without increasing energy costs. The

Reflexor is suitable for up to a 400W lamp with a maximum ambient temperature up to 135°F (55°C). For use with open rated lamps (Type O lamps) only.

Easy to install:

Warehouses

Manufacturing

Aisleways

Retail

BEFORE

Metal Reflectors:

No uplight

75% light efficiency

Dark ceilings

AFTER

Prismatic Reflexor:

20% uplight

92% light efficiency

Ceilings illuminated

Retrofit with the Reflexor System

• Increase lighting efficiency up to 20%

• Reduce glare

• Increase aisle/stack illumination

• Increase light levels 50% through group relamping

• Increase uplight 20% to eliminate the “cave effect”

Easy to install…

Remove metal reflector Screw in adapter

Simply remove the metal reflector, screw in the adapter assembly, mount the Reflexor and relamp. No mounting hardware is required.

Upgrade 400W (also 320W and 360W) mogul based high bay fixtures to get up to 92% light efficiency and 20% more uplight, without added increase in energy costs. The Reflexor is suitable for up to a

400W lamp with a maximum ambient temperature up to 135°F

(55°C). For use with open rated lamps (Type O lamps) only.

You’ll see immediate lighting results. Ceilings are brighter, aisle shadows are eliminated, and shelves are better illuminated from top to bottom. The superior lighting uniformity from the Reflexor, and the reduction in glare will provide a much more pleasing environment.

CANDELA

2500 4000 5500 7000

90˚

60˚

Specifications:

Assembly: 22” Acrylic Reflexor

White Aluminum Collar

Mogul Base Socket

Mounting Bracket

Safety Chain

Temperature:

Max ambient 135°F (55°C)

Open Rated Fixtures Only

Materials:

Reflexor: Lighting Grade Acrylic

Collar: Aluminum Painted White

0˚ 30˚

Report Number ITL35669

Total Luminaire Efficiency: 92.7%

CIE Type: Semi-Direct

Luminaire Spacing Criteria: 1.6:1

Ordering information

Description: Reflexor Retrofit 22 without lamp

Packaging: 4 units per carton

Item number: 805611

Mount Reflexor and relamp

Reflexor

®

Retrofit System

Clamping screw

Socket support bracket

Bracket/set screw

C-41 open rated style upper lamp adapter

Acrylic Reflexor

Mounting bracket

Safety chain

Lower lamp adapter

Mounting bracket pins

White aluminum collar assembly

Lamp (not included)

SUITABLE FOR OPEN

RATED LAMPS ONLY

The lamp holder and fittings are Underwriters Laboratory (UL) listed products found under file #E158283

Important Notes:

1. Caution: Use care in installation of this product. Install only in accordance with all national and local electrical codes and other applicable rules and regulations.

2. Caution: Turn off or disconnect all electrical power to the subject fixture prior to any attempt to remove existing parts or installation of this product.

3.

Installation should be performed only by a qualified electrician.

4. Recommended temperature and usage guidelines: The Reflexor is suitable for up to a 400W lamp with a maximum ambient temperature up to 135°F (55°C).

Follow manufacturers guidelines for Reflexor cleaning and usage. This information is available in the installation guide.

5. Not intended for use with any bottom enclosure.

6. For use with open rated lamps (Type O lamps) only.

REFRACTORS

Models 110 and 111

Description

Models 110 and 111 are 8.75” high. These

13” diameter refractors are typically used in roadway or nostalgia luminaires and have smooth exteriors for self cleaning.

Application

Model 110 is molded of impact-resistant polycarbonate, for use in areas where breakage is a concern. Model 111 is molded using ultraviolet stabilized acrylic for high efficiency in general lighting applications.

Lamp Data

Vertical base up lamps are used in these models. Previously, large mogul based incandescent or 175W-250W mercury vapor lamps were the primary lamp sources used in these refractors. Today, Models 110 and

111 are being used with 150W-175W, medium or mogul based metal halide and

HPS lamps.

Model 110

Ordering Information

Please call 877/257-5841 for price and delivery. Typical lead time is four to six weeks.

Service Life

The service life of acrylic refractors is virtually unlimited when used within the recommended temperature limit. Polycarbonate refractors are subject to yellowing especially when used with high ultraviolet output light sources; this effect is enhanced at high temperatures.

Notice

A.L.P. Lighting Components, Inc. assumes no responsibility for suitability of luminaires and applications. The use of our molded products at excessive temperatures with high UV output light sources will cause degradation of the material. Information regarding the use of lenses and refractors with Metal Halide lamps can be found in the Products/Technical

Resources section of our web site at www.alplighting.com.

Models 110 and 111

8.75” high

13” diameter

GENERAL STREET AND ROADWAY

LIGHTING APPLICATIONS

TYPE III AND TYPE V DISTRIBUTIONS

Model 110 Type III

Medium semi-cutoff

Efficiency: 71.56%

Arc Tube Voltage Rise = 1.0

Materials: Acrylic and polycarbonate

Models 110 and 111

C ANDELA

2500 4000 5500 7000

9 0°

6 0°

Photometrics

Models 110 and 111 are available in IES Type III and V photometric distributions. The interior prisms allow for flexibility in obtaining other distributions by the use of reflector baffles and lamp placement. When the Model 110 Type III is coupled with the aluminum reflector and used with a

150W clear HPS lamp, the optical assembly produces 8309 candela at 67.5° vertical and 73° lateral. Use of the aluminum reflector increases efficiency (ITL41551). Individual luminaire performance depends on the lamp center position and the reflector design chosen. Each luminaire design should be individually tested for proper classification. Please visit our web site for additional photometric data.

30°

0°

Report Number: ITL41551

Total Luminaire Efficiency = 71.56%

Downward total = 68.66%

IES Classification: Medium, Semi-cutoff, Type III

Arc Tube Voltage Rise = 1.0

Accessories

Aluminum reflector

This 13" diameter, faceted reflector increases the efficiency of Models 110 and 111, while reducing arc tube voltage rise potential. The reflector contour also controls the majority of the vertical distribution.

Stainless steel clamp band

For attachment of bottom closure.

Materials

See the LexaLite brand price list for current part numbers and material offerings. Up-to-date and detailed material specifications can be found in the Products/Technical Resources section of our web site at www.alplighting.com.

When using an acrylic Model 111, the surface temperature of the refractor should not exceed 80°C. When using a polycarbonate Model 110, the surface temperature of the refractor should not exceed 90°C.

Index

Notch

0.61"

[15,5mm]

8.75"

[222mm]

0.38"

[9,5mm]

Ø12.29"

[312mm]

Ø12.90"

[327,5mm]

0.25"

[6,5mm]

Rim Detail

0.12"

[3mm]

0.31"

[7,5mm]

0.12"

[3mm]

This drawing is for reference only. Actual part dimensions will vary.

Customer is urged to review actual samples to confirm fit and function.

All specifications and dimensions are subject to change without notice.

110/111 04/09

TEAR DROP REFRACTORS

Models 120 and 121

Description

Models 120 and 121 tear drop refractors are

11.07” high and are 13” in diameter. These refractors are typically used with up to 250W lamps in roadway or nostalgia luminaires.

Models 120 and 121 feature smooth exteriors for self cleaning.

Application

Model 120 is molded of impact resistant polycarbonate, for use in areas where breakage is a concern. Model 121 is molded using ultraviolet stabilized acrylic for high efficiency in general lighting applications.

Lamp Data

Models 120 and 121 are primarily being used with 250W metal halide and HPS lamps.

Model 120

Ordering Information

Please call 877-257-5841 for price and delivery. Typical lead time is four to six weeks.

Service Life

The service life of acrylic refractors is virtually unlimited when used within the recommended temperature limit. Polycarbonate refractors are subject to yellowing especially when used with high ultraviolet output light sources; this effect is enhanced at high temperatures.

Notice

A.L.P. Lighting Components, Inc. assumes no responsibility for suitability of luminaires and applications. The use of our molded products at excessive temperatures with high UV output light sources will cause degradation of the material. Information regarding the use of lenses and refractors with Metal Halide lamps can be found in the Products/Technical

Resources section of our web site at www.alplighting.com.

Models 120 and 121

11.07” high

13” diameter

GENERAL, STREET AND ROADWAY

LIGHTING APPLICATIONS

TYPE III AND TYPE V

DISTRIBUTIONS

Model 120 Type III

Medium non-cutoff

Efficiency: 78.87%

Downward total: 76.27%

Arc Tube Voltage Rise = 3.8

Materials: Acrylic and polycarbonate

Models 120 and 121

3000

C ANDELA

4500 6 000 7500

9 0°

6 0°

30°

0°

Report Number: ITL50864

Luminaire Efficiency = 71.32%

Downward total = 68.48%

IES Classification: Medium, Non-cutoff, Type III

3000 5000

C ANDELA

7000 9 000 11000

9 0°

6 0°

30°

0°

Report Number: ITL50865

Luminaire Efficiency = 78.87%

Downward total = 76.27%

IES Classification: Medium, Non-cutoff, Type III

Arc Tube Voltage Rise = 3.8

Photometrics:

Models 120 and 121 are available in IES Type III and

V distributions. The interior prisms allow for flexibility in obtaining other distributions by the use of reflector baffles and lamp placement. The assembly of the

Model 120 Type III, coupled with the aluminum reflector and with a 250W clear BT-28 MH lamp, produces 8911 candela at 69° vertical and 75° lateral. (ITL50864). The assembly of the Model 120

Type III, coupled with the aluminum reflector and with 250W clear ED-18 HPS lamp, produces 13222 candela at 67° vertical and 74.1° lateral.

(ITL50865). Individual luminaire performance depends on the lamp center position and the reflector design chosen. Each luminaire design should be individually tested for proper classification.

Please call for additional photometric data.

Accessories

Aluminum reflector

This 13” diameter faceted reflector increases the efficiency of Models 120 and 121, while reducing arc tube voltage rise potential. The reflector contour also controls the majority of the vertical distribution.

Stainless steel clamp band

For attachment of bottom closure.

Materials

See the LexaLite brand price list for current part numbers and material offerings. Up-to-date and detailed material specifications can be found in the Products/Technical Resources section of our web site at www.alplighting.com.

When using an acrylic Model 121, the surface temperature of the refractor should not exceed 80°C. When using a polycarbonate Model 120, the surface temperature of the refractor should not exceed 90°C.

Index

Notch

0.61"

[15,5mm]

11.07"

[281mm]

0.38"

[10mm]

Ø12.90"

[327mm]

Ø12.29"

[312mm]

REF

Rim Detail

0.12"

[3mm]

0.30"

[8mm]

0.25"

[6mm]

0.13"

[3mm]

Ø12.29"

[312mm]

This drawing is for reference only. Actual part dimensions will vary. Customer is urged to review actual samples to confirm fit and function. All specifications and dimensions are subject to change without notice.

120/121 04/09

OVATE LUMINAIRE COVER

Model 130

Description

Model 130, a roadway luminaire cover, is produced in polycarbonate, which makes this lens nearly unbreakable and provides excellent vandal resistance. The Model 130 roadway luminaire cover includes a built-in hinge feature for easy relampling and a channel to hold a perimeter gasket for production of a watertight luminaire. The surface of Model

130 is smooth and self-cleaning, which minimizes light depreciation losses. This Model is 10.3" long, 8.13" wide and 2.86" tall.

Application

Model 130 is developed specifically for low wattage roadway, rural, area and security lighting applications.

Lamp Data

This enclosure was designed to be used with

70 watt high pressure sodium lamps. It can also be used with low wattage compact fluorescents, as long as the temperature is above 40° F and other HID lamps up to 70

Model 130 watts. Each roadway luminaire cover should be thermally tested with the appropriate lamp to determine the enclosure is not exposed to operating temperatures on the interior surface greater than 90°C for maximum useful life.

Ordering Information

Please call 877-257-5841 for price and delivery.

Typical lead time is four to six weeks.

Service Life

Polycarbonate refractors are subject to yellowing especially when used with high ultraviolet output light sources; this effect is enhanced at high temperatures.

Notice

A.L.P. Lighting assumes no responsibility for suitability of luminaires and applications. The use of our molded products at excessive temperatures with high UV output light sources will cause degradation of the material.

Model 130

Length: 10.3”

Width: 8.13”

Depth: 2.86”

ROADWAY, RURAL, AREA AND

SECURITY LIGHTING APLICATIONS

Efficiency: 83.3%

IES Classification:

Medium, non-cutoff, Type II

Arc Tube Voltage Rise = 2.1

Material: Polycarbonate

Model 130

1000

C ANDELA

2000 3000 4000

9 0°

6 0°

Photometrics:

This cover is carefully designed to have parallel walls, which minimizes the possibility of internal reflection losses in the body of the part. Carefully designed to minimize internal reflections Model

130 will allow the luminaire designer greater flexibility in the use of reflector contours. The cover also maximizes the use of the reflector performance toward designs in either luminance and illuminance distributions. Model 130, when mated with a cast metal ballast housing, formed specular metal reflector and clear 70W HPS horizontal lamp produces 4369 candela at 72° vertical and 79.8° lateral. Efficiency is 83.3% (ITL49112). Individual luminaire performance depends on the lamp center position and the reflector design chosen. Each luminaire design should be individually tested for proper classification. Please visit our web site for additional photometric data.

30°

0°

Report Number: ITL49112

Total Luminaire Efficiency = 83.3%

IES Classification: Medium, Non-Cutoff, Type II

Arc Tube Voltage Rise = 2.1

0.55"

[14mm]

Materials

See the LexaLite brand price list for current part numbers and material offerings. Up-to-date and detailed material specifications can be found in the Products/Technical Resources section of our web site at www.alplighting.com.

When using a polycarbonate Model

130, the surface temperature of the lens should not exceed 90°C.

0.21"

[5mm]

1.09"

[28mm]

8.13"

[206,5mm]

2.86"

[72,5mm]

0.48"

[12mm]

0.76"

[19mm]

0.76"

[19mm]

10.32"

[262mm]

0.19"

[4,5mm]

Rim Detail

0.09"

[2,5mm]

0.05"

[1,5mm]

0.19"

[4,5mm]

0.05"

[1,5mm]

0.07"

[2mm]

This drawing is for reference only. Actual part dimensions will vary. Customer is urged to review actual samples to confirm fit and function. All specifications and dimensions are subject to change without notice.

130 04/09

TAPERED REFRACTORS

Models 200, 205, 210 and 215

Description

These 15.9” diameter refractors are designed for use with up to 400W HID lamps in roadway, area and industrial lighting applications. Open bottom refractors provide relamping and maintenance ease, while closed bottom refractors provide additional protection for the light source. Models 200 (closed bottom) and

205 (open bottom) are impact resistant polycarbonate refractors for use in areas where breakage is a concern. Models 210 (closed bottom) and 215 (open bottom) are ultraviolet stabilized acrylic refractors for high efficiency operation in general applications.

Lamp Data

When using Models 205 and 215 (open bottom versions) with a vertically burning lamp, up to

400W HID lamps may be used. When using

Models 200 and 210 (closed bottom versions) up to 250W HID lamps may be used. Thermal tests should be conducted on each luminaire design with the proposed light source in its selected position to confirm lamp size and suitability, and to predict service life of the refractor.

Model 200

Ordering Information

Please call 877-257-5841 for price and delivery. Typical lead time is four to six weeks.

Service Life

The service life of acrylic refractors is virtually unlimited when used within the recommended temperature limit. Polycarbonate refractors are subject to yellowing especially when used with high ultraviolet output light sources; this effect is enhanced at high temperatures.

Notice

A.L.P. Lighting Components, Inc. assumes no responsibility for suitability of luminaires and applications. The use of our molded products at excessive temperatures with high UV output light sources will cause degradation of the material.

Information regarding the use of lenses and refractors with Metal Halide lamps can be found in the Products/Technical Resources section of our web site at www.alplighting.com. * See second page for important UL information.

Models 200, 205,

210 and 215

8.12” high

15.9” diameter

STREET, ROADWAY AND AREA

LIGHTING APPLICATIONS

Model 215 Type V

Efficiency: 62.2%

IES Classification: Type V, Semi-cutoff,

Arc Tube Voltage Rise = 1.8

Materials: Acrylic and polycarbonate

Models 200, 205, 210 and 215

2000

C ANDELA

3000 4000 5000

9 0°

6 0°

Photometrics:

All models are available in symmetrical IES Type V distribution for general area lighting. Model

215 V, when used with a 250W HPS lamp, in typical post-top applications, produces 5623 candela at 70° above nadir as shown at left. (ITL37326) An asymmetrical IES Type II distribution is available and may be used in various roadway or interior aisle lighting applications. Luminaires have been designed with specific off-axis lamp centers to produce IES Type I, III or IV distributions for special lighting applications. Please call for details. Individual luminaire performance depends on the lamp center position and the reflector design chosen. Each luminaire design should be individually tested for proper classification. Please visit our web site for additional photometric data.

30°

0°

Report Number: ITL37326

Total Luminaire Efficiency = 62.2%

IES Classification: Type V, Semi-cutoff

Arc Tube Voltage Rise = 1.8

Accessory

LiteLid ®

For applications requiring reduced uplight and improved downward efficiency, use our Model 415 LiteLid; a patented, perforated, aluminum reflector, which mates with this component. The LiteLid component should be utilized in light pollution sensitive areas.

Materials

See the LexaLite ® brand price list for current part numbers and material offerings. Up-to-date and detailed material specifications can be found in the Products/Technical Resources section of our web site at www.alplighting.com.

When using acrylic Models 210 and 215, the surface temperature of the refractor should not exceed 80°C. When using polycarbonate Models 200 and 205, the surface temperature of the refractor should not exceed 90°C.

0.31"

[8mm]

Ø15.90"

[403,5mm]

0.17"

[4mm]

Rim Detail

0.40"

[10mm]

0.31"

[8mm]

0.17"

[4mm]

Ø9.25" THRU

[235mm]

Ø9.75"

[247,5mm]

0.94"

[23,5mm]

Index Notch

8.12"

[206mm]

This drawing is for reference only. Actual part dimensions will vary. Customer is urged to review actual samples to confirm fit and function. All specifications and dimensions are subject to change without notice.

*Effective June 30, 2010, lenses associated with this product will no longer be UL recognized components. A.L.P. LexaLite recommends the use of open rated lamps with any polymeric lens.

These lenses should not be used as arc retention devices.

200/205/210/215 03/10

STRAIGHT-SIDED REFRACTORS

Models 220, 225, 230, 235 and 237

Description

These 9.5” diameter refractors are designed for use in residential areas, parks, decorative post-top, commercial and industrial applications. Open bottom refractors provide relamping and maintenance ease, while closed bottom refractors provide additional protection for the light source. Models 220

(closed bottom) and 225 (open bottom) are high impact polycarbonate refractors for use in areas that may be subject to breakage.

Models 230 (closed bottom) and 235 (open bottom) are UV stabilized acrylic refractors for high efficiency operation in general application usage. Model 237 (open bottom) is a UV stabilized lightweight acrylic refractor for economical, high efficiency operation in general application usage.

Lamp Data

This refractor series is widely used with 35W

- 150W, medium based HID lamps. When using Models 225 and 235 (open bottom versions) in exterior applications, 175W

HID lamps are the maximum wattag we recommend using. Thermal tests should be conducted on each luminaire design with the proposed light source in its selected position

Model 220 Type V to confirm lamp size and suitability, and to predict service life of the refractor.

Ordering Information

Please call 877-257-5841 for price and delivery. Typical lead time is four to six weeks.

Service Life

The service life of acrylic refractors is virtually unlimited when used within the recommended temperature limit. Polycarbonate refractors are subject to yellowing especially when used with high ultraviolet output light sources; this effect is enhanced at high temperatures.

Notice

A.L.P. Lighting Components, Inc. assumes no responsibility for suitability of luminaires and applications. The use of our molded products at excessive temperatures with high UV output light sources will cause degradation of the material. Information regarding the use of lenses and refractors with Metal Halide lamps can be found in the Products/Technical

Resources section of our web site at www.alplighting.com.

Models 220, 225,

230, 235 and 237

5.70” high

9.5” diameter

COMMERCIAL, INDUSTRIAL,

ROADWAY, STREET AND

DECORATIVE LIGHTING

APPLICATIONS

Model 235 Type V

Efficiency: 87.18%

IES Classification: Type V, Semi-cutoff

Arc Tube Voltage Rise = 0.3

Materials: Acrylic and polycarbonate

Models 220, 225 230, 235, 237

1000

C ANDELA

1500 2000 2500 3000

9 0°

6 0°

Photometrics

Models 220, 225, 230 and 235 are available in IES Type V symmetrical distribution for general area lighting and IES Type III two-way asymmetrical distributions for parking facilities, off-roadway or area lighting. Model 235 Type III refractor produces a maximum of 9774 candela at 70° vertical, 65° lateral with a 150W clear, medium based, HPS lamp (ITL35512). Model 235 Type V produces 3312 candela at 67.5° vertical with a 100W clear HPS lamp, as shown at left

(ITL41894). The vertical angle of maximum candela can be adjusted approximately 6° with movement of the light center position. Individual luminaire performance depends on the lamp center position and the reflector design chosen. Each luminaire design should be individually tested for proper classification. Please visit our web site for additional photometric data.

30°

0°

Report Number: ITL41894

Total Luminaire Efficiency = 87.18%

IES Classification: Type V, Semi-cutoff

Arc Tube Voltage Rise = 0.3

Materials

See the LexaLite brand price list for current part numbers and material offerings. Up-to-date and detailed material specifications can be found in the Products/Technical Resources section of our web site at www.alplighting.com.

UvaLex® is LexaLite's proprietary treatment to retard yellowing in ultraviolet environments and is standard on these polycarbonate refractors.

When using acrylic Models 230, 235 and

237 the surface temperature of the refractor should not exceed 80°C. When using polycarbonate Models 220 and

225, the surface temperature of the

Reflexor should not exceed 90°C.

0.13"

[3,5mm]

0.25"

[6,5mm]

Rim Detail

0.20"

[5mm]

Ø 9.50"

[241,5mm]

Ø 8.80"

[223,5mm]

0.62"

[15,5mm]

5.70"

[144,5mm]

Ø 6.60"

[167,5mm]

Ø 7.00"

[178mm]

This drawing is for reference only. Actual part dimensions will vary.

Customer is urged to review actual samples to confirm fit and function.

All specifications and dimensions are subject to change without notice.

220/225/230/235/237 04/09

REFRACTORS

Models 240, 245, 250 and 255

Description

These 12” diameter refractors are used with vertical burning HID lamps in pendant-mount or post-top luminaires, street lighting, indoor industrial applications and parking facilities.

Open bottom refractors provide relamping and maintenance ease, while closed bottom refractors provide additional protection for the light source. Models 240 (closed bottom) and

245 (open bottom) are polycarbonate refractors for use in areas where breakage is a concern.

Models 250 (closed bottom) and 255 (open bottom) are ultraviolet stabilized acrylic refractors for high efficiency operation in general application usage.

Lamp Data

These refractors are capable of handling up to

175W HID lamps. When using Models 245 and

255 (open bottom versions) in exterior applications, 250W HID lamps are the maximum wattage we recommend using.

Thermal tests should be conducted on each luminaire design with the proposed light source in its selected position to confirm lamp size and suitability, and to predict service life of the refractor.

Model 240

Ordering Information

Please call 877-257-5841 for price and delivery.

Typical lead time is four to six weeks.

Service Life

The service life of acrylic refractors is virtually unlimited when used within the recommended temperature limit. Polycarbonate refractors are subject to yellowing especially when used with high ultraviolet output light sources; this effect is enhanced at high temperatures.

Notice

A.L.P. Lighting Components, Inc. assumes no responsibility for suitability of luminaires and applications. The use of our molded products at excessive temperatures with high UV output light sources will cause degradation of the material.

Information regarding the use of lenses and refractors with Metal Halide lamps can be found in the Products/Technical Resources section of our web site at www.alplighting.com. *See second page for important UL information.

Models 240, 245,

250 and 255

6.80” high

12” diameter

INDUSTRIAL, ROADWAY

STREET AND AREA LIGHTING

APPLICATIONS

Model 250 Type V

Efficiency: 85.84%

IES Classification: Type V, Semi-cutoff,

Arc Tube Voltage Rise = 0

Materials: Acrylic and polycarbonate

Models 240, 245, 250 and 255

1000

C ANDELA

1500 2000 2500 3000

9 0°

6 0°

Photometrics:

All models are available in asymmetrical IES Types I, II, III, IV two-way, and symmetrical Type V distributions for general area lighting. Model 250 Type V produces a maximum of 3500 candela at

70° vertical with a 150W HPS as shown at left (ITL38882). The vertical maximum candela can be adjusted approximately 6° with small movements in light center position. Individual luminaire performance depends on the lamp center position and the reflector design chosen. Each luminaire design should be individually tested for proper classification. Please call for additional photometric data.

30°

0°

Report Number: ITL38882

Total Luminaire Efficiency = 85.84%

IES Classification: Type V

Arc Tube Voltage Rise = 0

Materials

See the LexaLite ® brand price list for current part numbers and material offerings. Up-to-date and detailed material specifications can be found in the Products/Technical Resources section of our web site at www.alplighting.com.

UvaLex® is LexaLite's proprietary treatment to retard yellowing in ultraviolet environments and is standard on these polycarbonate refractors.

When using acrylic Models 250 and

255, the surface temperature of the refractor should not exceed 80°C.

When using polycarbonate Models 240 and 245, the surface temperature of the refractor should not exceed 90°C.

Ø 12.00"

[305mm]

0.64"

[16mm]

6.80"

[172,5mm]

Ø 9.25"

[235mm]

0.31"

[8mm]

0.10"

[2,5mm]

Rim Detail

0.10"

[2,5mm]

0.40"

[10mm]

0.13"

[3,5mm]

0.31"

[8mm]

Ø 9.75"

[247,5mm]

This drawing is for reference only. Actual part dimensions will vary. Customer is urged to review actual samples to confirm fit and function. All specifications and dimensions are subject to change without notice.

*Effective June 30, 2010, lenses associated with this product will no longer be UL recognized components. A.L.P. LexaLite recommends the use of open rated lamps with any polymeric lens. These lenses should not be used as arc retention devices.

240/245/250/255 03/10

TAPERED REFRACTORS

Models 260, 265, 270 and 275

Description

These 12” diameter tapered refractors feature precise optics that provide maximum luminaire efficiency and uniformity of illumination.

Designed for use with vertical burning lamps, these refractors are widely used in pendantmount and post-top luminaires in roadway, area and industrial lighting applications. Open bottom refractors provide relamping and maintenance ease, while closed bottom refractors provide additional protection for the light source. Models 260 (closed bottom) and

265 (open bottom) are impact resistant polycarbonate refractors for use in areas where breakage is a concern. Models 270 (closed bottom) and 275 (open bottom) are ultraviolet stabilized acrylic refractors for high efficiency operation in general application usage.

Lamp Data

This refractor series is capable of being used with 150W and 175W HID lamps. When using

Models 265 and 275 (open bottom versions) in exterior applications, 250W lamps are the maximum wattage we recommend using.

Thermal tests should be conducted on each luminaire design, with the proposed light source in its selected position to confirm lamp size and suitability, and to predict service life of the refractor.

Model 270 Type V

Ordering Information

Please call 877-257-5841 for price and delivery.

Typical lead time is four to six weeks.

Service Life

The service life of acrylic refractors is virtually unlimited when used within the recommended temperature limit. Polycarbonate refractors are subject to yellowing especially when used with high ultraviolet output light sources; this effect is enhanced at high temperatures.

Notice

A.L.P. Lighting Components, Inc. assumes no responsibility for suitability of luminaires and applications. The use of our molded products at excessive temperatures with high UV output light sources will cause degradation of the material.

Information regarding the use of lenses and refractors with Metal Halide lamps can be found in the Products/Technical Resources section of our web site at www.alplighting.com. *See second page for important UL information.

Models 260, 265,

270 and 275

6.90” high

12” diameter

INDUSTRIAL, ROADWAY,

STREET AND AREA

LIGHTING APPLICATIONS

Model 275 Type V

Efficiency: 81.11%

IES Classification: Type V, Semi-cutoff,

Arc Tube Voltage Rise = 0.3

Materials: Acrylic and polycarbonate

Models 260, 265, 270 and 275

1000

C ANDELA

1500 2000 2500 3000

9 0°

6 0°

Photometrics:

All models are available in IES Type I, II, III, IV and V and Type II four-way distributions. A special

Type III for use with phosphor coated lamps, combined I/II three-way and I/II four-way distributions are also available. Model 275 Type V refractor produces 3142 maximum candela at 70° vertical using a 150W HPS as shown at left (ITL41576). Model 275 Type III produces over 11010 candela at the 72.5° vertical and 84° horizontal, with an overall efficiency of 82.91% using a 150W HPS

(ITL37278). Individual luminaire performance depends on the lamp center position and the reflector design chosen. Each luminaire design should be individually tested for proper classification. Please call for additional photometric data.

30°

0°

Report Number: ITL41576

Total Luminaire Efficiency = 81.11%

IES Classification: Type V, Semi-cutoff

Arc Tube Voltage Rise = 0.3

Materials

See the LexaLite ® brand price list for current part numbers and material offerings. Up-to-date and detailed material specifications can be found in the Products/Technical Resources section of our web site at www.alplighting.com.

UvaLex® is LexaLite's proprietary treatment to retard yellowing in ultraviolet environments and is standard on polycarbonate refractors.

When using acrylic Models 270 and

275 the surface temperature of the refractor should not exceed 80°C.

When using polycarbonate Models 260 and 265, the surface temperature of the refractor should not exceed 90°C.

6.9"

[175mm]

Ø11.50"

[292mm]

Ø12.00"

[305mm]

0.61"

[15,5mm]

0.04"

[1mm]

0.17"

[4,5mm]

Rim Detail

0.11"

[2,5mm]

0.06"

[1,5mm]

0.31"

[8mm]

Ø6.00"

[152,5mm]

This drawing is for reference only. Actual part dimensions will vary. Customer is urged to review actual samples to confirm fit and function. All specifications and dimensions are subject to change without notice.

*Effective June 30, 2010, lenses associated with this product will no longer be UL recognized components. A.L.P. LexaLite recommends the use of open rated lamps with any polymeric lens. These lenses should not be used as arc retention devices.

260/265/270/275 03/10

DUSK-TO-DAWN REFRACTORS

Models 280, 285, 290, 295 and 297

Description

These 12” diameter straight-sided refractors are recommended for applications requiring low cost. They are designed for use with vertical burning lamps and are used in residential, post top and street lighting applications. Open bottom refractors provide relamping and maintenance ease, while closed bottom refractors provide additional protection for the light source. Models 280 (closed bottom) and 285 (open bottom) are molded of polycarbonate for use in areas where breakage is a concern. Models 290 (closed bottom) and

295 (open bottom) and 297 lightweight (open bottom) are molded of ultraviolet stabilized acrylic for high efficiency in general lighting applications.

Lamp Data

Vertical burning HID lamps up to 175W may be used with all models. Models 285, 295 and

297 may be used with up to 250W HID lamps in outdoor applications.

Thermal tests should be conducted on each luminaire design, with the proposed light source in its selected position to confirm lamp size and suitability, and to predict service life of the refractor.

Model 290 Type V

Ordering Information

Please call 877-257-5841 for price and delivery.

Typical lead time is four to six weeks.

Service Life

The service life of acrylic refractors is virtually unlimited when used within the recommended temperature limit. Polycarbonate refractors are subject to yellowing especially when used with high ultraviolet output light sources; this effect is enhanced at high temperatures.

Notice

A.L.P. Lighting Components, Inc. assumes no responsibility for suitability of luminaires and applications. The use of our molded products at excessive temperatures with high UV output light sources will cause degradation of the material.

Information regarding the use of lenses and refractors with Metal Halide lamps can be found in the Products/Technical Resources section of our web site at www.alplighting.com.

Model 280, 285, 290,

295 and 297

6.88” high

12” diameter

ROADWAY, STREET, AREA,

COMMERCIAL, INDUSTRIAL AND

DECORATIVE LIGHTING

APPLICATIONS

Model 295 Type V

Efficiency: 85.26%

IES Classification: Type V, Semi-cutoff,

Arc Tube Voltage Rise = 0

Material: Acrylic and polycarbonate

Models 280, 285, 290, 295 and 297

1000

C ANDELA

1500 2000 2500 3000

9 0°

6 0°

Photometrics:

All models are available in an IES Type V symmetrical distribution for general area lighting. Model

297 is also available in a Type II, III and IV two-way, asymmetrical distribution for street parking or interior aisle lighting. Model 295 Type V produces a maximum of 3133 candela at 70° vertical with an overall efficiency of 85% with a 150W HPS lamp, as shown at left (ITL42090). Individual luminaire performance depends on the lamp center position and the reflector design chosen.

Each luminaire design should be individually tested for proper classification. Please call for additional photometric data.

0° 30°

Report Number: ITL42090

Total Luminaire Efficiency = 85.26%

IES Classification: Type V, Semi-cutoff

Arc Tube Voltage Rise = 0.0

Materials

See the LexaLite brand price list for current part numbers and material offerings. Up-to-date and detailed material specifications can be found in the Products/Technical Resources section of our web site at www.alplighting.com.

UvaLex® is LexaLite's proprietary treatment to retard yellowing in ultraviolet environments and is standard on these polycarbonate refractors.

When using acrylic Models 290, 295 and 297 the surface temperature of the refractor should not exceed 80°C.

When using polycarbonate Models 280 and 285, the surface temperature of the efractor should not exceed 90°C.

Ø11.44"

[290,5mm]

Ø12.00"

[305mm]

0.62"

[15,5mm]

6.88"

[174,5mm]

0.12"

[3mm]

Rim Detail

0.31"

[8mm]

0.13"

[3,5mm]

0.10"

[2,5mm]

0.17"

[4,5mm]

Ø9.25"

[235mm]

Ø9.7"

[246,5mm]

This drawing is for reference only. Actual part dimensions will vary.

Customer is urged to review actual samples to confirm fit and function.

All specifications and dimensions are subject to change without notice.

280/285/290/295/297 04/09

REFRACTORS

Models 303 and 304

Description

These 20 x 20 inch lenses utilize unique prismatic configurations that produce either a symmetrical or asymmetrical light pattern for maximum design flexibility. Designed to use up to 400W vertically or horizontally mounted HID sources, these lenses are used for outdoor area lighting including service station and parking lot applications. Model 303 is molded of ultraviolet stabilized acrylic for high efficiency in applications where ambient heat is not excessive. Model 304 is molded of impact resistant polycarbonate for use in areas where vandal resistance is required.

Lamp Data

These lenses are primarily used with 250W and 400W HID lamps. To avoid detrimental internal reflections and high temperatures, proper reflector and luminaire design is required. Thermal testing should be conducted on each luminaire, with the proposed light source in its selected position to confirm lamp size suitability, or to predict service life of the lens.

Model 303

Ordering Information

Please call 877-257-5841 for price and delivery.

Typical lead time is four to six weeks.

Service Life

The service life of acrylic refractors is virtually unlimited when used within the recommended temperature limit. Acrylic versions are covered by our 10 year limited warranty.

Notice

A.L.P. Lighting Components, Inc. assumes no responsibility for suitability of luminaires and applications. The use of our molded products at excessive temperatures with high UV output light sources will cause degradation of the material.

Information regarding the use of lenses and refractors with Metal Halide lamps can be found in the Products/Technical Resources section of our web site at www.alplighting.com. *See second page for important UL information.

Models 303 and 304

Dimensions: 20” x 20”

Depth: 2.5”

STREET AND AREA LIGHTING

APPLICATIONS

Efficiency: 64%

Materials: Acrylic and polycarbonate

Models 303 and 304

.5

Photometrics

While the exact photometrics are dependent on the luminaire design, a few generalizations are possible. When the lens is used with a simple curved, reflective sheet material and a horizontal source with the socket in the “X” position, it yields a rectangular asymmetrical “bow tie” pattern, as shown in the Iso footcandle plot at left. In the same luminaire, rotating the lens 90° and placing the socket in the “A” position, a symmetrical square pattern is obtained. Various other distributions may be obtained using alternate lamp position, light sources, and reflector contours. Individual luminaire performance depends on the lamp center position and the reflector design chosen. Each luminaire design should be individually tested for proper classification.

Please visit our web site for additional photometric data.

10

5

2

1

0.30"

[7,5mm]

.2

.1

Report Number: ITL47860

Total Luminaire Efficiency = 64%

20.0"

[508mm]

SQUARE

Materials

Clear acrylic: Model 303 is molded in

Underwriters Laboratory (UL) recognized

Altuglas International Plexiglas® V(825)-

UVA-5A, Lucite International Inc. Perspex®

CP-75UVA, CYRO Acrylite® S-10-343, or

Plaskolite Optix® CA-75UVA.

Clear polycarbonate: Model 304 is molded in UL recognized Bayer lighting grade polycarbonates including Makrolon® LTG

3123, Makrolon® LTG 2623, or GE Lexan® grade 243.

LexaLite's proprietary treatment to retard yellowing in ultraviolet environments,

UvaLex®, is optional on these polycarbonate refractors.

Please visit our web site for the most current material specifications.

When using an acrylic Model 303, the surface temperature of the refractor should not exceed 80°C. When using a polycarbonate Model 304, the surface temperature of the refractor should not exceed 90°C.

303/304 03/10

Rim Detail

0.46"

[11,5mm]

0.05"

[1mm]

0.30"

[7,5mm]

0.12"

[3mm]

0.25"

[6,5mm]

0.20"

[5mm]

2.5"

[63,5mm]

This drawing is for reference only. Actual part dimensions will vary. Customer is urged to review actual samples to confirm fit and function. All specifications and dimensions are subject to change without notice.

*Effective June 30, 2010, lenses associated with this product will no longer be UL recognized components. A.L.P. LexaLite recommends the use of open rated lamps with any polymeric lens.

These lenses should not be used as arc retention devices.

DROP LENSES

Models 305, 306, 315 and 316

Description

These 12 x 12 inch lenses have a 2.5 inch depth and precise optics, making them excellent for use in relatively low mounting height installations where brightness and glare control are important considerations. They are available in two configurations. Horizontal—for use as a drop lens in area and canopy lighting.

Vertical—for wallmount and tunnel lighting.

Models 306 (horizontal) and 316 (vertical) are molded of polycarbonate for use in areas where vandal resistance is required. Models

305 (horizontal) and 315 (vertical) are molded of ultraviolet stabilized acrylic for high efficiency in applications where ambient heat is not excessive.

Lamp Data

These lenses are primarily used with up to

175W HID lamps. Proper reflector and luminaire design is required to avoid detrimental internal reflections and high temperatures. Thermal testing should be conducted on each luminaire with the proposed light source in its selected position to confirm lamp size suitability, or to predict service life of the lens.

Model 305

Ordering Information

Please call 877-257-5841 for price and delivery.

Typical lead time is four to six weeks.

Service Life

The service life of acrylic refractors is virtually unlimited when used within the recommended temperature limit. Polycarbonate refractors are subject to yellowing especially when used with high ultraviolet output light sources; this effect is enhanced at high temperatures.

Notice

A.L.P. Lighting Components, Inc. assumes no responsibility for suitability of luminaires and applications. The use of our molded products at excessive temperatures with high UV output light sources will cause degradation of the material.

Information regarding the use of lenses and refractors with Metal Halide lamps can be found in the Products/Technical Resources section of our web site at www.alplighting.com. *See second page for important UL information.

Models 305, 306,

315 and 316

Dimensions: 12” x 12“

Depth: 2.5”

STREET AND AREA

LIGHTING APPLICATIONS

TYPE II AND TYPE V

DISTRIBUTIONS

Models 305 and 306

Short-cutoff, Type II

Efficiency: 53.17%

Arc Tube Voltage Rise = 2.9

Materials: Acrylic and Polycarbonate

2

1

0

1

Models 305, 306, 315 and 316

.2

.1

.05

.5

2

1

Photometrics

While the exact photometrics are dependent on the luminaire design, a few generalizations are possible. Models 305 and 306 produce a symmetrical square pattern when used with a curved reflective sheet and the horizontal lamp and socket set in the “A” position. By rotating the lens

90° and locating the horizontal lamp and socket in the “X” position, an asymmetrical rectangular pattern is produced as shown at left (ITL41903). Models 315 and 316—the lamp must be horizontally oriented in the upper third of the lens' vertical profile. The reflector shape can be a simple curved sheet or a parabolic cylinder contour. Individual luminaire performance depends on the lamp center position and the reflector design chosen. Each luminaire design should be individually tested for proper classification. Please visit our web site for additional photometric data.

2

3

3 2 1 0 1

Report Number: ITL41903

Total Luminaire Efficiency = 53.17%

IES Classification: Short-cutoff, Type II

Arc Tube Voltage Rise = 2.9

2

Materials

See the LexaLite ® brand price list for current part numbers and material offerings. Up-to-date and detailed material specifications can be found in the Products/Technical Resources section of our web site at www.alplighting.com.

UvaLex® is LexaLite's proprietary treatment to retard yellowing in ultraviolet environments and is standard on these polycarbonate refractors.

When using acrylic Models 305 and

315, the surface temperature of the lens should not exceed 80°C. When using polycarbonate Models 306 and

316, the surface temperature of the lens should not exceed 90°C.

0.30"

[7,5mm]

12.00"

[305mm]

SQUARE

2.51"

[63,5mm]

0.10"

[2,5mm]

0.19"

[4,5mm]

Rim Detail

0.10"

[2,5mm]

0.30"

[7,5mm]

0.38"

[9,5mm]

0.30"

[7,5mm]

0.43"

[10,5mm]

This drawing is for reference only. Actual part dimensions will vary. Customer is urged to review actual samples to confirm fit and function. All specifications and dimensions are subject to change without notice.

*Effective June 30, 2010, lenses associated with this product will no longer be UL recognized components. A.L.P. LexaLite recommends the use of open rated lamps with any polymeric lens.

These lenses should not be used as arc retention devices.

305/306/315/316 03/10

OVATE REFRACTORS

Models 310 and 320

Description

This roadway Refractor is suitable for commercial and residential lighting requirements and can be used with an ovate luminaire reflector. Model 310 is an ultraviolet stabilized acrylic Refractor for high efficiency operation in general applications. Model 320 is a polycarbonate Refractor for use in areas where vandal resistance is a requirement.

Lamp Data

These Refractors are primarily used with horizontal 150W-250W HID lamps. To avoid detrimental internal reflections and high temperatures, proper reflector and luminaire design is required. Thermal testing should be conducted on each luminaire with the proposed light source in its selected position to confirm lamp size suitability, or to predict service life of the Refractor.

Model 310 Type III

Ordering Information

Please call 877-257-5841 for price and delivery.

Typical lead time is four to six weeks.

Service Life

The service life of acrylic refractors is virtually unlimited when used within the recommended temperature limit. Polycarbonate refractors are subject to yellowing especially when used with high ultraviolet output light sources; this effect is enhanced at high temperatures.

Notice

A.L.P. Lighting Components, Inc. assumes no responsibility for suitability of luminaires and applications. The use of our molded products at excessive temperatures with high UV output light sources will cause degradation of the material.

Information regarding the use of lenses and refractors with Metal Halide lamps can be found in the Products/Technical Resources section of our web site at www.alplighting.com.

Models 310 and 320

Length: 13.94”

Width: 11.69”

Depth: 5.53”

ROADWAY, STREET AND AREA

LIGHTING APPLICATIONS

TYPE I, II AND III

DISTRIBUTIONS

Model 310 Type II

Medium, Non-cutoff

Efficiency: 79.83%

Arc Tube Voltage Rise = 2.8

Materials: Acrylic and Polycarbonate

Models 310 and 320

2

.5

1

.2

.05

.02

.1

Photometrics

When used with proper reflector design, the Refractor is capable of producing IES Type I, II or III short, medium and long distributions, and cutoff, semi-cutoff or non-cutoff classifications. The various distributions provide excellent uniformity, spacing and illumination levels; however, lamp position and reflector design are key factors in achieving this uniformity. Model 310, Type II in a

“cobra-head” with a clear 150W HPS horizontal lamp produces 10788 candela at 70° vertical and

76° horizontal. Efficiency is 79.83% (ITL37249). Individual luminaire performance depends on the lamp center position and the reflector design chosen. Each luminaire design should be individually tested for proper classification. Please visit our web site for additional photometric data.

Report Number: ITL37249

Total Luminaire Efficiency = 79.83%

IES Classification: Medium, Non-cutoff, Type II

Arc Tube Voltage Rise = 2.8

Location of Max-Candela = X

Location of Half Max-Candela = ---

Materials

See the LexaLite brand price list for current part numbers and material offerings. Up-to-date and detailed material specifications can be found in the Products/Technical Resources section of our web site at www.alplighting.com.

UvaLex® is LexaLite's proprietary treatment to retard yellowing in ultraviolet environments and is standard on these polycarbonate refractors.

When using an acrylic Model 310, the surface temperature of the Refractor should not exceed 80°C. When using a polycarbonate Model 320, the surface temperature of the Refractor should not exceed 90°C.

0.20"

[5mm]

0.23"

[5,5mm]

Rim Detail

0.49"

[12,5mm]

0.30"

[7,5mm]

0.25"

[6mm]

13.94"

[354mm]

11.69"

[297mm]

5.53"

[140,5mm]

This drawing is for reference only. Actual part dimensions will vary.

Customer is urged to review actual samples to confirm fit and function.

All specifications and dimensions are subject to change without notice.

310/320 04/09

OVATE REFRACTORS

Models 330 and 340

Description

This refractor can meet both commercial and residential roadway lighting requirements when used with any of several presently available ovate luminaire reflectors. Model 330 is an ultraviolet stabilized acrylic refractor for high efficiency operation in general applications.

Model 340 is an impact resistant polycarbonate refractor for use in areas where vandal resistance is a requirement.

Lamp Data

Model 330 is primarily used with HID lamps up to 250W. Model 340 is used with up to 400W

HID lamps. To avoid detrimental internal reflections and high temperatures, proper reflector and luminaire design is required.

Thermal testing should be conducted on each luminaire with the proposed light source in its selected position to confirm lamp size suitability, or to predict service life of the refractor.

Model 340 Type III

Ordering Information

Please call 877-257-5841 for price and delivery.

Typical lead time is four to six weeks.

Service Life

The service life of acrylic refractors is virtually unlimited when used within the recommended temperature limit. Polycarbonate refractors are subject to yellowing especially when used with high ultraviolet output light sources; this effect is enhanced at high temperatures.

Notice

A.L.P. Lighting Components, Inc. assumes no responsibility for suitability of luminaires and applications. The use of our molded products at excessive temperatures with high UV output light sources will cause degradation of the material.

Information regarding the use of lenses and refractors with Metal Halide lamps can be found in the Products/Technical Resources section of our web site at www.alplighting.com.

Models 330 and 340

Length: 16.75”

Width: 14.05”

Depth: 6.60”

ROADWAY, STREET AND AREA

LIGHTING APPLICATIONS

TYPE I, II AND III

DISTRIBUTIONS

Model 340 Type III

Medium, Non-cutoff

Efficiency: 75.01%

Arc Tube Voltage Rise = 4.4

Materials: Acrylic and Polycarbonate

Models 330 and 340

2

5

1

.5

.2

.1

.05

.02

Report Number: ITL48819

Total Luminaire Efficiency = 75.01%

IES Classification: Medium,

Non-cutoff, Type III

Arc Tube Voltage Rise = 4.4

Location of Max-Candela = X

Location of Half Max-Candela = ---

Materials

See the LexaLite brand price list for current part numbers and material offerings. Up-to-date and detailed material specifications can be found in the Products/Technical Resources section of our web site at www.alplighting.com.

UvaLex® is LexaLite's proprietary treatment to retard yellowing in ultraviolet environments and is standard on these polycarbonate refractors.

When using an acrylic Model 330, the surface temperature of the refractor should not exceed 80°C. When using a polycarbonate Model 340, the surface temperature of the refractor should not exceed 90°C.

Photometrics

When used with proper reflector design, these refractors are capable of producing IES Type I, II and III, short, medium and long distributions, and cutoff, semi-cutoff or non-cutoff classifications.

The various distributions provide excellent uniformity, spacing and illumination levels; however, lamp position and reflector design are key factors in achieving this uniformity. Model 340, Type

III in a “cobra-head” with a clear 400W HPS horizontal lamp produces 30683 candela at 70° vertical and 75° horizontal. Efficiency is 75.01% (ITL48819). Individual luminaire performance depends on the lamp center position and the reflector design chosen. Each luminaire design should be individually tested for proper classification. Please visit our web site for additional photometric data.

0.10"

[2,5mm]

Rim Detail

16.75"

[425,5mm]

0.10"

[2,5mm]

0.30"

[7,5mm]

0.40"

[10mm]

0.31"

[8mm]

0.25"

[6,5mm]

This drawing is for reference only. Actual part dimensions will vary.

Customer is urged to review actual samples to confirm fit and function.

All specifications and dimensions are subject to change without notice.

14.50"

[368,5mm]

6.60"

[167,5mm]

330/340 04/09

DROP LENSES

Models 350, 351, 360 and 361

Description

These 16” diameter drop lenses are designed for use with vertical burning HID lamps in 16” diameter reflectors, in medium-bay and lowbay industrial and commercial lighting applications. These lenses produce excellent illumination and uniformity when combined with our Model 816 Reflexor ® .Models 350

(with lifting prisms) and 351 (without lifting prisms) are ultraviolet stabilized acrylic lenses for high efficiency operation in general applications. Models 360 (with lifting prisms) and 361 (without lifting prisms) are polycarbonate lenses for use in areas where breakage is a concern.

Lamp Data

These drop lenses are used with up to 250W

HID lamps. To avoid detrimental internal reflections and high temperatures inside the drop lens, proper luminaire design is required.