Polyimide Laminate

i3 Electronics, Inc.:

i3’s Polyimide is an industry standard GPY equivalent polyimide and is

used as a dielectric prepreg or a laminate in printed circuit board and

laminate chip carrier fabrication. This material exhibits excellent performance in the field in a variety of high end applications, and is an ideal

solution for the medical, aerospace and defense and computing markets.

i3’s polyimide is also lead free compatible.

FEATURES

PERFORMANCE AT HIGH

TEMPERATURE

Compatible with MSA and lead free

bly

assem-

UL-94 HB FLAMMABILITY RATING

i3’s Polyimide prepregs and laminates are available in a wide range of

glass cloth styles, resin contents and copper weights.

Flammability meets the UL/ANSI GPY requirement

LOW MELT VISCOSITY / LONG GEL

TIME

Excellent rheological behavior assures void

free formation of thick, complex, multi-layer

printed circuit boards

HIGH RELIABILITY

Good performance in thermal cycling and

insulation resistance produces optimum

product reliability

ASSEMBLY FRIENDLY

Resists delamination

IPC4101C/40, 41

Meets industry standard requirements

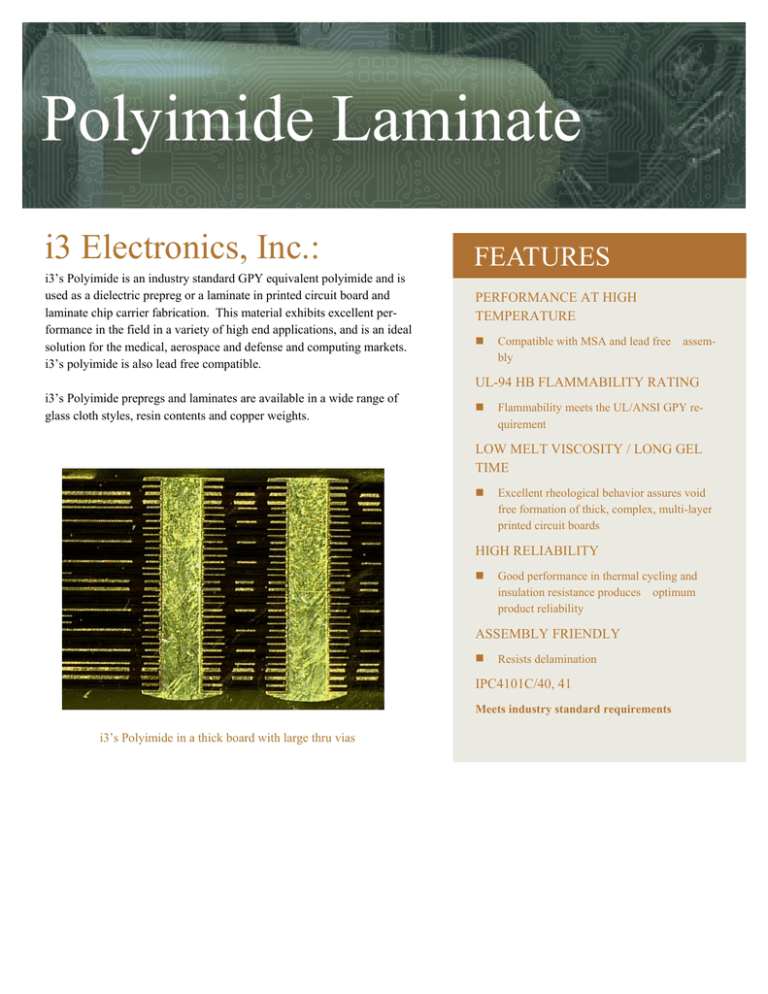

i3’s Polyimide in a thick board with large thru vias

POLYIMIDE LAMINATE PROPERTIES

PROPERTY TESTED*

TEST METHOD

ELECTRICAL

Permittivity (Dielectric Constant @ 1 GHz)

3.89

ASTM-D-150-98

Loss Tangent (Loss Factor @ 1 GHz)

0.013

ASTM-D-150-98

Electrical Strength (kV/mm)

89.1

IPC-TM-650/2.5.6.2

Dielectric Breakdown (kV)

Arc Resistance (seconds)

>45kV

IPC TM-650/2.5.6

123

IPC TM-650/2.5.1

IPC-TM-650/2.5.17.1

VOLUME RESISTIVITY (megohm-cm)

8

After Moisture

3.8x10

At Elevated Temperature

2.5x108

IPC-TM-650/2.5.17.1

SURFACE RESISTIVITY (megohm)

After Moisture

1.6x105

At Elevated Temperature

1.6x106

THERMAL

Glass Transition Temperature (0C)

300

IPC-TM-650/2.4.25

392

IPC-TM-650/2.4.24.6

Time to Delamination (minimum @ 288C)

>120

IPC-TM-650/2.4.24.1A

Flammability

HB**

UL94

0

Decomposition Temperature ( C) (5%)

PHYSICAL

Polyimide

Resin Type

Pressure Vessel Test (8hr.)

Pass

IPC-TM-650/2.6.16

Moisture, % Gain (24 hr/RT)

.52

IPC-TM-650/2.6.2.1

Peel Strength (lb/in)

6.0

IPC-TM-650/2.4.8.2

IPC-TM-650/2.4.4

FLEXURAL STRENGTH (Kpsi)

Length Direction

83.1

Cross Direction

77.4

IPC-TM-650/2.3.4.3

Chemical Resistance, Methylene Chloride (%)

X CTE Below Tg (ppm/C)

18.7

IPC-TM-650/2.4.41

Y CTE Below Tg (ppm/C)

23.0

IPC-TM-650/2.4.41

Z CTE Below Tg (ppm/C)

65.0

IPC-TM-650/2.4.41

* All properties above are based on 56% resin content 1080 style

** The flame retardant is RoHS Compliant

1093 Clark St.

Endicott, NY 13760

Phone: 866 820-4820 Fax: 607 755-7000

www.i3electronics.com

The i3 Electronics, Inc. logo and i3 Electronics, Inc. are registered trademarks

of i3 Electronics, Inc.¨ Printed in the United States of America, 2014. All rights

reserved. The information provided is believed to be accurate and reliable.

i3 Electronics , Inc.¨ reserves the right to make changes to the product described

without notice. No liability is assumed as the result of its use nor any infringement

of the rights of others.