2013 Denver seminar - IAEI

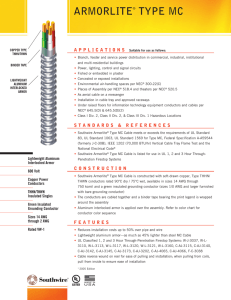

advertisement