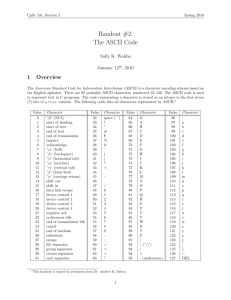

Detailed overview Technical Information

advertisement