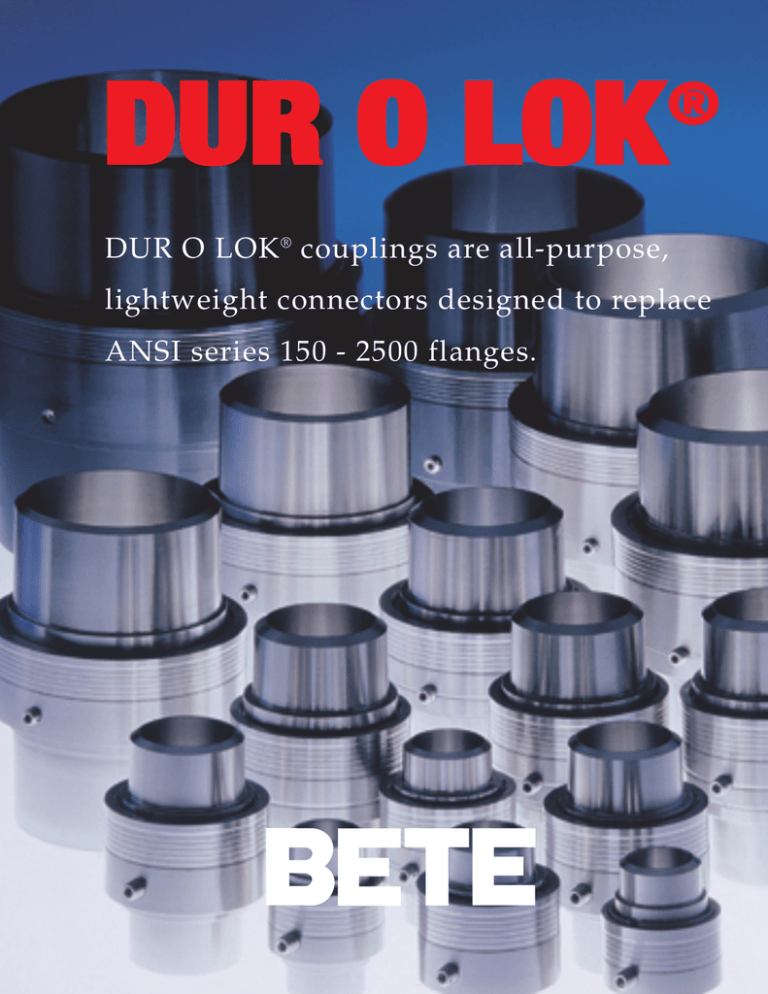

DUR O LOK® couplings are all-purpose, lightweight connectors

advertisement

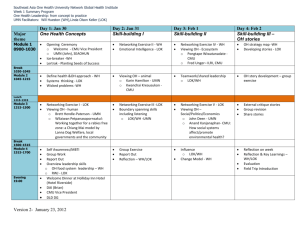

DUR O LOK ® DUR O LOK ® couplings are all-purpose, lightweight connectors designed to replace ANSI series 150 - 2500 flanges. DUR O LOK ® The Light Weight, Threadless, Boltless Coupling Alternative The performance superiority and space and weight provided by DUR O LOK® Couplings will make them the preferred choice in many pipeconnecting applications. DUR O LOK® couplings are all-purpose, lightweight connectors designed to replace ANSI series 150 - 2500 flanges. The design of DUR O LOK® couplings ensures reliable operation over a wide range of temperatures. DUR O LOK® couplings have been used in refinery applications for many years and are specified by UOP for use in CCRTM PlatformingTM, OleflexTM and SorbexTM processing units, as well as in OptimixTM FCC feed nozzles. DUR O LOK® pipe couplings are designed to reduce maintenance, reduce materials costs, and reduce space requirements for pipe racks Features: • Compact - length and outside diameter reduced by 30% - 50%, compared to flanges. Allows double the number of pipes per rack. Provides improved external flow distribution for immersed couplings. Reduces shadowing for couplings used in process vessels. • Light weight - weight reduced by 60% - 90%, compared to flanges • Simple - Number of parts reduced by 55% - 75% per connection, compared to flanges. • Fast - Save up to 10-15 minutes to make or break each connection. • Non-restrictive - Full port inside diameter eliminates pressure drop and allows "pigging". • Smooth interior bore - Minimizes flow disturbances. Eliminates attrition in catalyst and other solids conveying applications. • Boltless and threadless - No wrenches required. No torque measurements required. No bolt holes to align. No need to tighten connections after thermal cycling. Simplifies painting and insulating. • Self-energized seal - Sealing force increases with pressure. Less chance of leaks. • Thermally stable - Design minimizes thermal expansion effects on sealing. Tolerates very rapid changes of external or internal temperatures. • No interference fits or metal-to-metal sealing - Higher reliability. Less susceptible to damage. CCRSM Platforming® process, which produces high-octane gasoline or petrochemical precursors; C3 Oleflex® process, which produces polymer-grade propylene from propane feedback; C4 Oleflex® processes, which separate, convert and upgrade C 4 olefin streams to produce MTBE, acetylene-free crude butadiene, butene-1, isobutylene, and completely saturated LPG; Sorbex® processes, which separate components from mixtures by liquid-phase adsorption; Parex ® process, which recovers high-purity para-xylene from streams containg mixed xylene isomers and other aromatic and non-aromatic impurities; Molex® process, which separates paraffins from branched chain and cyclic hydrocarbons; MX-Sorbex® process, which recovers meta-xylene from streams containing mixed A8 isomers. BETE Save Time and Money with Fast, Simple, Lightweight DUR O LOK® Pipe Couplings Set Screw Tapered I.D. Hub Split Coupler Hub Tapered O.D. O-Ring Gasket Split Coupler Wedge Shaped Teeth The DUR O LOK® wedge system The heart of the DUR O LOK® design is the system of wedge-shaped, circumferential teeth located on the outside diameter of the hubs and on the inside diameter of the mating split coupler. The wedging action of the teeth compresses the gasket and brings the hubs ends into contact with each other. The outside diameter of the split coupler is tapered. A ring with a tapered inside diameter slides over the split ring segments, forcing them together and holding them firmly in place. The tapered retaining ring is secured with a set screw. The entire connection process can be accomplished in less than a minute, without wrenches. Patented and patents pending BETE Heavy Duty Couplings Don’t Have to Weigh a Ton DUR O LOK® / Flange - Weight and Dimension Comparison DUR O LOK® Pipe Size 1 1.25 1.5 2 2.5 3 3.5 4 6 8 Weld Neck Flanges Overall Overall Approx Pipe Diameter Length Weight Schedule (in.) (in.) (lb.) 80 80 XXS 80 160 80 80 160 80 80 2.5 2.85 3 3.5 3.95 4.95 5.45 5.95 7.95 9.95 3.5 3.5 4 5 6 6.5 7 7.5 9.5 11 2.23 2.73 4.67 5.2 8.43 11.21 13.63 21.08 35.84 56.63 BETE Flange Flange OD Class (in.) 2500 600 2500 2500 600 1500 600 2500 600 600 6.25 5.25 8 9.25 7.5 10.5 9 14 14 16.5 Flange Flange Assembly Assembly Length Weight (in.) (lb.) 7.0 5.2 8.8 10.0 6.2 9.2 6.8 15.0 9.2 10.5 26.6 13.1 57.0 83.3 38.0 102.5 63.2 301.2 173.5 259.1 DUR O LOK ® Compact Pipe Coupling DUR O LOK® Materials • Carbon steel - A234 • Stainless steel - 304, 316, 321, 347 • Other materials available • Material traceability available DUR O LOK® Quality • Designed to ASME Section VIII, ANSI B31.1 and ANSI B31.3 • Quality assurance to ISO 9001 DUR O LOK ® Pipe Couplings - Dimensions (inches) and Ratings (PSI) Pipe Size Pipe Sched. “D” Pipe O.D. “B” Pipe I.D. “A” Overall Diameter “C” Tapered Ring length “L” Overall Length “W” Nominal Wall 1 1 1 1/4 1 1/4 1 1/4 1 1/2 1 1/2 1 1/2 1 1/2 2 2 2 2 1/2 2 1/2 2 1/2 3 3 3 3 3 1/2 3 1/2 4 4 4 4 4 5 5 6 6 8 8 40 80 40 80 160 40 80 160 xxs 40 80 160 40 80 160 10 40 80 160 40 80 10 40 80 120 160 40 80 40 80 40 80 1.315 1.315 1.660 1.660 1.660 1.900 1.900 1.900 1.900 2.375 2.375 2.375 2.875 2.875 2.875 3.500 3.500 3.500 3.500 4.000 4.000 4.500 4.500 4.500 4.500 4.500 5.563 5.563 6.625 6.625 8.625 8.625 1.049 0.957 1.380 1.278 1.160 1.610 1.500 1.338 1.100 2.067 1.939 1.687 2.469 2.323 2.125 3.260 3.068 2.900 2.624 3.548 3.364 4.260 4.026 3.826 3.624 3.438 5.047 4.813 6.065 5.761 7.981 7.625 2.5 2.5 2.85 2.85 2.85 3.00 3.00 3.00 3.00 3.50 3.50 3.50 3.95 3.95 3.95 4.95 4.95 4.95 4.95 5.45 5.45 5.95 5.95 5.95 5.95 5.95 6.95 6.95 7.95 7.95 9.95 9.95 1.45 1.45 1.45 1.45 1.45 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 2.95 2.95 2.95 2.95 2.95 2.95 3.50 3.50 3.50 3.50 3.50 4.00 4.00 4.00 4.00 5.00 5.00 5.00 6.00 6.00 6.00 6.50 6.50 6.50 6.50 7.00 7.00 7.50 7.50 7.50 7.50 7.50 8.50 8.50 9.50 9.50 11.00 11.00 0.133 0.179 0.140 0.191 0.250 0.145 0.200 0.281 0.400 0.154 0.218 0.344 0.203 0.276 0.375 0.120 0.216 0.300 0.438 0.226 0.318 0.120 0.237 0.337 0.438 0.531 0.258 0.375 0.280 0.432 0.322 0.500 Approx. Pressure Rating (PSI)* Weight Carbon 304 (lbs.) Steel Stainless Steel 2.09 2.23 2.52 2.73 2.96 3.44 3.74 4.15 4.67 4.63 5.20 6.21 6.32 7.26 8.43 8.00 9.76 11.21 13.41 11.64 13.63 10.51 13.75 16.37 18.88 21.08 22.19 26.55 28.24 35.84 43.03 56.63 2850 3950 2350 3275 4400 2100 2975 4225 6175 1775 2575 4225 1950 2700 3600 900 1675 2375 3600 1525 2200 700 1425 2075 2725 3150 1250 1850 1125 1775 1000 1425 3025 4175 2475 3475 4675 2225 3150 4575 6850 1875 2725 4475 2050 2850 3800 975 1775 2525 3800 1625 2325 750 1500 2175 2900 3325 1325 1950 1200 1900 1050 1500 *Per Appendix 24 of the 1988 ASME Code, Section VIII, Div. 1. Maximum Temperature: 400°F (204°C) with viton o-ring, 450°F (232°C) with silicon rubber o-ring. Gaskets with higher temperature ratings available. BETE Fog Nozzle, Inc. • 50 Greenfield Street • P.O. Box 1438 • Greenfield, MA 01301 Phone: 413-772-2166 • Fax: 413-772-6729 • e-mail: sales@bete.com • www.bete.com DUR O LOK® Quote Information Thank you for your inquiry about DUR O LOK® couplings. Please provide the information below to assist us in supplying the right coupling for your application. Customer Information: Name: Company: Address: City: State: Phone: Fax: Zip: Country: e-mail: I am interested in the DUR O LOK® couplings because: (check all that apply) • I want to save space • I want to save weight • I want to simplify my piping • I’m attracted to the unique seal benefits • I want to save maintenance time • Other Piping Service Requirements: temperature: pressure: material transported: industry: application or process: external loading (shear, bending, torsion, etc) and magnitude: Coupling Requirements: Seal: pipe size: • Viton O-ring (400°F max) schedule: • Silicone rubber O-ring (450°F max) material: • Grafoil® flat gasket (1500°F max) number required code requirements Notes: carbon steel couplings are supplied with black oxide finish. Bete Fog Nozzle, Inc. 50 Greenfield St Greenfield, MA 01301 USA 413-772-0846 (phone) 413-772-6729 (fax) e-mail:sales@bete.com