PDF (Free)

advertisement

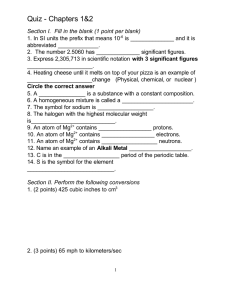

Materials Transactions, Vol. 51, No. 2 (2010) pp. 288 to 291 Special Issue on Development and Fabrication of Advanced Materials Assisted by Nanotechnology and Microanalysis #2010 The Japan Institute of Metals Preparation and Thermoelectric Properties of Bi-Doped Mg2 Si0:8 Sn0:2 Compound Weijun Luo, Meijun Yang, Fei Chen, Qiang Shen* , Hongyi Jiang and Lianmeng Zhang State Key Laboratory of Advanced Technology for Materials Synthesis and Processing, Wuhan University of Technology, Wuhan 430070, P. R. China The Bi-doped Mg2 Si0:8 Sn0:2 single phase compound is prepared by a solid state reaction (SSR)-spark plasma sintering (SPS) method. The effect of the Bi content on the thermoelectric properties of the Bi-doped Mg2 Si0:8 Sn0:2 compound is mainly investigated. The results show that the thermoelectric properties of the obtained samples are sensitive to the Bi content. With the increase in Bi content, the electrical conductivity () and Seebeck coefficient () of the samples are increased, while the thermal conductivity () is decreased slightly between 300 K and 850 K. When the Bi content is greater than 3.0 at%, the sample shows a maximum figure of merit (ZT) value (1:17 0:05) at 850 K. [doi:10.2320/matertrans.MC200908] (Received August 31, 2009; Accepted November 19, 2009; Published January 14, 2010) Keywords: Bi-doped Mg2 Si0:8 Sn0:2 , solid state reaction (SSR)-spark plasma sintering (SPS), thermoelectric properties 1. Introduction Thermoelectric (TE) materials have promising applications in cooling and power generation. Compared to the commonly used refrigeration device, a TE device has many advantages, such as no noise, no pollution, long life and free from maintenance. However, it is still not widely utilized due to its low efficiency. The efficiency of the TE device for cooling and power generation is represented by the figure of merit ZT, where T is the absolute temperature, Z is given by Z ¼ 2 =, where is the Seebeck coefficient, is the electrical conductivity and is the thermal conductivity. Many efforts have been applied to improve the ZT in the past decades. It was reported that the ZT has exceeded 1 for Sb-doped Mg-Si-Sn solid solutions.1–4) Compared to all the thermoelectric materials with ZT > 1, Mg2 Si-based compounds possess many interesting advantages, such as the great abundance of their elemental content in the earth’s crust and the non-toxicity of their processing by-products.5–7) The conventional process for a Mg2 Si1x Snx compound was direct melting metallurgy1,8) and BMA-HP.9) Due to the high vapor pressure, the oxidation of Mg, as well as the different melting points of Mg, Si, Sn, it is extremely difficult to synthesize the pure compounds and control the structure and properties. Thus, the solid state reaction combined with SPS sintering is introduced to synthesize these solid solutions, involving the low temperature and large diffusion velocity of SPS at the low temperature. Mg2 Si1x Snx (0 x 1:0) thermoelectric materials had been prepared by SSR-SPS techniques in the previous work.10) It was found that when x ¼ 0:2, the highest ZT of 0.1 at about 490 K was obtained. Simultaneously, as Y. Isoda et al. reported,4) the value of the ZT for Sb-doped Mg2 Si0:5 Sn0:5 has exceeded 1. Considering that the VB group atoms have more extra-nuclear electrons than other doping atoms such as Al and Cu, and Bi belongs to the same group *Corresponding author, E-mail: sqqf@263.net as Sb, Bi-doped Mg2 Si0:8 Sn0:2 might have lower thermal conductivity because Bi has a larger radius and heavier mass. Meanwhile, according to reports,11–13) the Bi-doped Mg2 Si samples showed the highest thermoelectric properties among doping atoms such as Sb, P, Al and Cu. Moreover, there is no research concerning the thermoelectric properties of Bidoped Mg2 Si0:8 Sn0:2 . Thus, in this study, the single phase Bidoped Mg2 Si0:8 Sn0:2 was prepared and the effect of Bi doping concentration on the thermoelectric properties of Bi-doped Mg2 Si0:8 Sn0:2 was mainly investigated. 2. Experimental Procedures Bi-doped Mg2 Si0:8 Sn0:2 solid solutions were prepared by SSR-SPS. Considering the evaporation of Mg, the nominal excess Mg content of 4 mol% deviating from the stoichiometric composition was used. Mg, Si, Sn and Bi powders with a purity of >99:99% and particle size of 30 mm were mixed homogeneously in an agate mortar and dry-pressed into cylinders, and were then placed in a furnace for solid state reaction under argon atmosphere via long time annealing. Finally, the compound after solid state reaction was sintered at 970 K for 10 min at 40 MPa in a graphite die (20 mm in diameter) under argon atmosphere by the SPS method. The density of the samples was greater than 99.9% of the theoretical value. The solid solutions phases were examined by X-ray diffraction (D/Max-IIIA, Japan) analysis with Cu K radiation. The microstructures were observed by scanning electronic microscopy (S-3004N Hitachi, Japan). The samples were cut into rectangular bars with a size of 3 mm 3 mm 10 mm for the measurement of and using the ULVAC ZTM-1 system (Japan) from room temperature to 850 K. The thermal diffusivity (D) and the specific heat capacity (Cp) were measured by the laser flash method, using a thermal constant analyzer (ULVAC TC-7000, Japan) in vacuum. The was calculated according to the following formula: ¼ DCp , where is the bulk density, which was measured by the Archimedes method. Preparation and Thermoelectric Properties of Bi-Doped Mg2 Si0:8 Sn0:2 Compound 289 (220) (111) (311) (400) (331) (422) 3.0 at.% (511) (440) Intensity (a.u.) 2.5 at.% 2.0 at.% 1.3 at.% 0.75 at.% 0.5 at.% no doped 20 30 40 50 60 2θ, degree / ° 70 80 90 Fig. 1 The X-ray diffraction patterns of Bi-doped Mg2 Si0:8 Sn0:2 samples with different Bi contents. 3. Results and Discussion Figure 1 shows the X-ray diffraction patterns of Bi-doped Mg2 Si0:8 Sn0:2 samples with different Bi contents. The major peaks of the patterns can be indexed to an anti-fluorite-type structure (space group, Fm 3m), indicating that the single phase of the Bi-doped compound has been successfully synthesized. Simultaneously, all the peaks gradually shift right with the increase of Bi content. Jun-ichi T.11) revealed that Bi atoms are expected to primarily locate at the Si sites in Mg2 Si based on first-principles calculation. According to Bragg’s equation, because the ionic radius of Bi is larger than that of Si and Sn, the small shifting indicates the solubility of Bi. The microstructures of the fractured surface of the samples are shown in Fig. 2. It is clearly seen that essentially no pores exist after SPS processing. Also, based on the BSE images, no impurity is detected, indicating the formation of homogeneous solid solutions after sintering by SPS. Figure 3(a) shows the effect of temperature on the of Bidoped Mg2 Si0:8 Sn0:2 . It is observed that is increased with the Bi content and that the sample with 3.0 at% Bi content shows the highest . When the temperature is below 500 K, the Bi-doped Mg2 Si0:8 Sn0:2 samples show semiconducting behavior, while when the temperature is over 500 K, the samples exhibit metal behavior. According to the report of Jun-ichi T.,11) the increase in is attributed to the substitution of univalent Bi5 for quadrivalent X4 (X ¼ Si, Sn), which causes the electron concentration to increase with the Bi content. It is known that is determined by the combination of carrier concentration (n) and carrier mobility (). With the increase in temperature, the scattering of carriers is enhanced; thus the mobility distance is shortened and the carrier mobility is reduced. However, more and more electrons transit from the impurity level to the conduction band driven by the thermo-power, and as a result, the n increases. Because the effect of n is more dominant than that of , is increased with the temperature below 500 K. When the temperature is above 500 K, the effect of is more dominant than that of n, so the samples show metal behavior. However, the Bi-doped Mg2 Si0:5 Sn0:5 samples show a lower Fig. 2 (a) SEM and (b) BSE images of Mg2 Si0:8 Sn0:2 samples, respectively. compared to Sb-doped compounds. According to the report on Sb-doped Mg2 Si0:5 Sn0:5 ,4) the Sb atoms can be fully ionized at low temperature with a low doping content, suggesting that it is much more difficult for Bi to transit to the conduction band than Sb, due to the higher barrier energy between the impurity level and the conduction band. The effect of temperature on the of Bi-doped Mg2 Si0:8 Sn0:2 compound is shown in Fig. 3(b). It is observed that the value is negative, Bi atoms act as donors, and is increased with the Bi content. On the other hand, the of non-doped Mg2 Si0:8 Sn0:2 is as large as 420 50 mVK1 at 320 K, and when the Bi content is increased to 3.0 at%, it reaches 100 7 mVK1 at 320 K. The effect of the Bi content on is given by: kB 3 þ n n ¼ ð1Þ q 2 Ec Ef n ð2Þ ¼ ln n ¼ Nc kB T where kB is the Boltzmann constant, Ec is the conduction band level, Ef is the Fermi level, n is the carrier concentration, and Nc is the density of state. It is seen that with the increase in Bi content, n is increased, causing n to be reduced, which resulted in the increase in n . The total of is commonly given by: ¼ ph þ el ð3Þ 290 W. Luo et al. (a) 100 (a) 80 60 -1 -1 Lattice Thermal Conductivity, κph / wm K 3 Electrical Conductivity, σ / 10 Sm -1 Non-doped 0.5 at.% 0.75 at.% 1.3 at.% 2.0 at.% 2.5 at.% 3.0 at.% 40 20 0 300 400 500 600 700 800 900 Temperature, T / K 2.0 1.5 1.0 0.5 Non-doped 0.5 at.% 0.75 at.% 1.3 at.% 2.0 at.% 3.0 at.% 300 400 500 600 700 800 Temperature, T / K (b) -1 (b) -1 -1 Carrier Thermal Conductivity, Κel / wm K -100 Seebeck Coefficient, α / µVK 2.5 -150 -200 -250 -300 Non-doped 0.5 at.% 0.75 at.% 1.3 at.% 2.0 at.% 2.5 at.% 3.0 at.% -350 -400 -450 300 400 500 600 700 800 900 Temperature, T / K 1.2 0.8 Non-doped 0.5 at.% 0.75 at.% 1.3 at.% 2.0 at.% 2.5 at.% 3.0 at.% 0.4 0.0 300 400 500 600 700 800 900 Temperature, T / K Fig. 3 (a) The effect of temperature on the of Bi-doped Mg2 Si0:8 Sn0:2 compound; (b) The effect of temperature on the of Bi-doped Mg2 Si0:8 Sn0:2 compound. (c) 3.00 -1 -1 Thermal Conductivity, κ / wm K where ph and el are phonon and carrier components of respectively. el can be calculated based on the WiedemanFranz law using the Lorentz number L and as follows: el ¼ LT ð4Þ In this study, el was calculated using L ¼ 2:45 108 V2 K2 in eq. (4). Because can be tested as described in the Experimental Procedures, ph can be calculated according to eq. (3). Figure 4 shows the effect of temperature on the el , ph and of Bi-doped Mg2 Si0:8 Sn0:2 compounds. It is observed that the el is increased while and ph are decreased with the Bi content and temperature. The reduction in ph is derived from the crystal distortion by doping Bi atoms enhanced by the scattering of phonons. Compared with Sbdoped Mg2 Si0:5 Sn0:5 samples, Bi-doped Mg2 Si0:8 Sn0:2 samples show a lower , due to the larger radius and heavier mass of Bi, which is enhanced by the scattering of phonons. The effect of temperature on the thermoelectric figure of merit (ZT) is shown in Fig. 5. It is observed that the value of ZT is increased with temperature, which appears the same as that for Bi-doped Mg2 Si.11) When the Bi content is greater than 0.75 at% and the value of ZT > 1, the sample with 3.0 at% Bi content shows the highest ZT of 1:17 0:05 at about 850 K, which is greater than the value of Al-doped Mg2 Si0:9 Sn0:1 (ZT ¼ 0:68 at 864 K)14) and the reports on P, Sb, Bi, Al, Cu-doped Mg2 Si.12,13) According to the report of Non-doped 0.5 at.% 0.75 at.% 1.3 at.% 2.0 at.% 3.0 at.% 2.75 2.50 2.25 2.00 1.75 1.50 300 400 500 600 700 800 Temperature, T / K Fig. 4 Carrier contribution (el ), lattice contribution (ph ) and of Bidoped Mg2 Si0:8 Sn0:2 compound. Y. Isoda et al., the value of ZT for Sb-doped Mg2 Si0:5 Sn0:5 could reach 1.2 at 620 K; our result shows the same value as theirs though by different preparation method.4) 4. Conclusions The single phase of a Bi-doped Mg2 Si0:8 Sn0:2 solid solution has been successfully obtained by the SSR-SPS method. The electrical conductivity, Seebeck coefficient and thermal conductivity of the samples are strongly affected by the Bi content. The addition of Bi significantly decreases thermal conductivity and increases the electrical conductivity and the Seebeck coefficient. When the doping concentration Preparation and Thermoelectric Properties of Bi-Doped Mg2 Si0:8 Sn0:2 Compound REFERENCES 1.25 Non-doped 0.5 at.% 0.75 at.% 1.3 at.% 2.0 at.% 3.0 at.% Figure of Merit, ZT 1.00 0.75 0.50 0.25 0.00 291 300 400 500 600 700 800 900 Temperature, T / K Fig. 5 The effect of temperature on the thermoelectric figure of merit (ZT) for Bi-doped Mg2 Si0:8 Sn0:2 samples. of Bi is greater than 3.0 at% (nominal molar percent), the ZT of the sample shows the highest value, 1:17 0:05 at 850 K. Acknowledgement This work is financially supported by the Major State Basic Research Development Program of China (973 Program, Grant No. 2007CB607501). 1) V. K. Zaitsev, M. I. Fedorov, E. A. Gurieva, I. S. Eremin, P. P. Konstantinov, A. Y. Samunin and M. V. Vedernikov: Proc. 24th Int. Conf. on Thermoelectrics, (2005) pp. 18–24. 2) V. K. Zaitsev, M. I. Fedorov, E. A. Gurieva, I. S. Eremin, P. P. Konstantinov, A. Y. Samunin and M. V. Vedernikov: Phys. Rev. B 74 (2006) 045207–045211. 3) M. I. Fedorov, V. K. Zaitsev and M. V. Vedernikov: Proc. 25th Int. Conf. on Thermoelectrics, (2006) pp. 111–114. 4) Y. Isoda, T. Nagai, H. Fujiu, Y. Imai and Y. Shinohara: Proc. 25th Int. Conf. on Thermoelectrics, (2006) pp. 406–410. 5) E. N. Nikitin, V. G. Bazanov and V. I. Tarasov: Phys. Sol. State 3 (1961) 2648–2651. 6) V. K. Zaitsev, M. I. Fedorov, A. T. Burkov, E. A. Gurieva, I. S. Eremin and P. P. Konstantinov: Proc. 21th Int. Conf. on Thermoelectrics, (2001) pp. 151–154. 7) M. I. Fedorov, D. A. Pshenay, V. K. Zaitsev, S. Sano and M. V. Vedernikov: Proc. 22th Int. Conf. on Thermoelectrics, (2003) pp. 142– 145. 8) Q. Zhang, T. J. Zhu, A. J. Zhou, H. Yin and X. B. Zhao: Phys. Scr. 129 (2007) 123–126. 9) R. B. Song, T. Aizawa and J. Q. Sun: Mater. Sci. Eng. B 136 (2007) 111–117. 10) W. J. Luo, M. J. Yang, F. Chen, Q. Shen, H. Y. Jiang and L. M. Zhang: Mater. Sci. Eng. B 157 (2009) 96–100. 11) T. Jun-ichi and K. Hiroyasu: Physica B 364 (2005) 218–224. 12) T. Jun-ichi and K. Hiroyasu: Thermoelectric Jpn. J. Appl. Phys. 46 (2007) 3309–3314. 13) T. Jun-ichi and K. Hiroyasu: Intermetallics 16 (2008) 418–423. 14) T. Jun-ichi and K. Hiroyasu: J. Alloy. Compd. 466 (2008) 335–340.