Automatic Guitar Tuner - Department of Electrical Engineering and

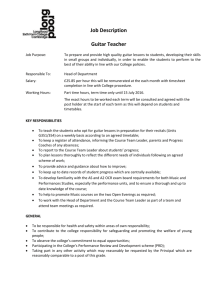

advertisement