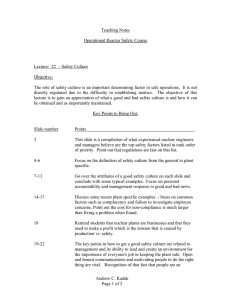

High Bridge Associates, Inc. June 29, 2015

advertisement