第18版 - 潤工社

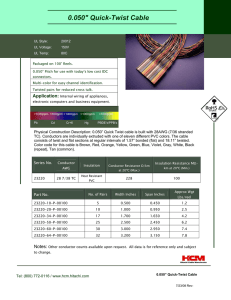

advertisement