सतीश धवन अंतिरक्ष के द्र

advertisement

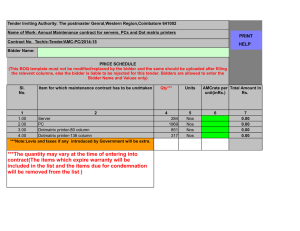

भारत सरकार अ तिरक्ष िवभाग सतीश धवन अंतिरक्ष के द्र शार ीहिरकोटा डा.घ.524124 आं.प्र. भारत टे िलफोन:+91 8623 225023 फेक्स: +91 8623 225170 Government of India Department of Space Satish Dhawan Space Centre SHAR SRIHARIKOTA P.O. 524124, AP, INDIA Telephone: +91 8623 225023 Fax: +91 8623 225170 GOVERNMENT OF INDIA :: DEPARTMENT OF SPACE SATISH DHAWAN SPACE CENTER SHAR :: SRIHARIKOTA – 524 124 SRI POTTI SREERAMULU.NELLORE DISTRICT (A.P) TENDER NOTICE NO. SDSC SHAR/HPS/PT/07/2016-17 On behalf of President of India, Head Purchase and Stores, SDSC SHAR, SRIHARIKOTA invites on line quotations for the following. Sl No 01 02 03 04 05 06 07 08 09 Ref. No. SHAR SPP 2016 00 4084 e-procurement [Two Part basis] SHAR SP 2016 00 4253 e-procurement [Two Part basis] SHAR VAST 2016 00 4426 e-procurement [Two Part basis] SHAR CMD 2016 00 4541e-procurement [Two Part basis] Description Qty. S139 Casting Fixtures and Accessories 1 LS Configuration, Design, Detailed Engineering, Manufacture, Supply, Installation, Testing & Commissioning of Special Purpose Single Column 3Axis CNC-Vertical Facing Mill Design, Manufacture, Assemble, Test, Pack, Transport & Delivery of 380kVA, LT DG set for Redundant Bogie System Supply of BEE 5 Star rated 15 Ltrs. storage type Geysers 1 Lot 1 LS Tender Fee No tender fee shall be applicable for tenders submitted through EGPS 536 Nos. SHAR SC 2016 00 4597 e-procurement [Two Part basis] SHAR SC 2016 00 4605 e-procurement [Single Part basis] SHAR SC 2016 00 4607 e-procurement [Two Part basis] SHAR SC 2016 00 4619 e-procurement [Two Part basis] Facility Cleaning and Maintenance Contract for a period 24 of TWO years.at SDSC SHAR Canteens, Sriharikota Months SHAR VAST 2016 00 4641 e-procurement [Two Part basis] Supply, Installation, Testing & Commissioning of Hydraulic Jacking System for SVAB Wheel Bogie Rate Contract for Retreading of Tyres 1 LS Security Services for 3 Housing Colonies of SDSC SHAR at Sullurupeta for a period of One year. 1 Year Manpower Rate Contract for engaging Light Vehicle Drivers on Hire Basis as and when need basis for a period of 24 Months 1 Lot 1 LS Last Date for downloading of tender documents : 20.09.2016 at 16:00 hrs. Due Date for submission of bids online : 20.09.2016 at 16:00 hrs. Due Date for Bid Sealing on : 20.09.2016 at 16:01 hrs. to 20.09.2016 at 17.30 hrs. Due Date for Open Authorization : 20.09.2016 at 17.31 hrs. to 22.09.2016 at 17:00 hrs. Due Date for opening of tenders : 23.09.2016 at 14:30 hrs. Instructions to Tenderers: 01. For full details/scope of work and terms and conditions etc., please see the enclosed annexures. 02. Interested tenderers can download the e-tender from ISRO e-procurement website https://eprocure.isro.gov.in and submit the offer on line in the e-procurement portal. Offers sent physically by post/courier/in person will not be considered. 03. Tender documents are also available on ISRO website www.isro.org; ISRO e-procurement website https://eprocure.isro.gov.in and SDSC SHAR, Sriharikota website www.shar.gov.in. The same can be down loaded and offer submitted on line in the e-procurement portal. 04. Quotations received after the due date/time will not be considered. 05. The tender documents are available for download upto 20.09.2016 at 1600 hrs. and last date for submission of tenders on line 20.09.2016 at 1600 hrs. and Tender Opening on 23.09.2016 at 14:30 hrs. 06. Head, Purchase and Stores, SDSC-SHAR, Sriharikota reserves the right to accept or reject any/or all the quotations. DT: 05.08.2016 HEAD, PURCHASE AND STORES 1 ANNEXURE -A Technical Specifications for LT 380kVA DG set ITEM No. I : Supply Portion(Refer Price bid format ) A) SCOPE The scope includes; 1. Design, manufacture, assemble, test, pack , transport & delivery of 1 No of 380kVA , LT DG set with all required subsystems and accessories complete to SDSC SHAR Sriharikota. 2. The DG set shall undergo full load test for 36 hours continuously at Manufacturers works. 3. Installation , Testing & commissioning of the above systems at site 4. Supply of specific spares as listed. 5. Providing Warrantee support during warrantee period. 6. Providing Maintenance spares support and service support for next 10 years on demand. 7. The scope also includes supply of all required accessories, materials, skilled and unskilled and special man power as required, tools and test equipments required and as per the relevant BIS and tender specifications. B) Specific requirements to be considered by the Bidder. 1. Overall dimensions including acoustic enclosure shall be less or equal to L-5.5m, W – 1.8m, H – 2.0m. 2. DG set is required to be installed in a bogie ( MS structure and space available is as mentioned above)which will be moving 30m/minute max speed when operated. 3. This DG set is to be used in Hazardous area Flame proof -IIB, Zone 1, T 4 temperature class. 4. Exhaust gas pipe with spark arrestor and residential type silencer 5. Air Cooled Fluid Coil Cooler with cooler fan redundancy. C) Major Subsystems 1. One number 380 KVA output, Diesel Generator set along with all mounted accessories and auxiliaries, like governors, lub oil pump/filter & strainer, fuel oil pump & filter and injectors, turning gear, flywheel, flexible coupling, base frame, foundation bolts, anti-vibration mountings, air cooled fluid coil cooler supports & supporting structures and other auxiliaries/accessories not mentioned above for smooth running of DG set for it intended purpose. The DG set must be of continuous rating at 1500 rpm with a speed regulation of +/- 1% or better, and shall be acoustic proof. And Synchronous brush less 380kVA, 415V +/- 1%, 3 phase + Neutral, 50Hz Alternator complete with 1 excitation system, AVR, switch gear, control & protection with instruments and annunciation on it, control, signal & power cables & other electrical systems including earthing. This DG set is used in Hazardous area FLP-IIB, Zone 1, T 4 temperature class. The dimensions including acoustic enclosure is Length-5.5meter, Width – 1.8meter, Height – 2.0 meter. 2. Exhaust gas pipe with spark arrestor and residential type silencer including exhaust hood & weather cowl, expansion joint, insulation, etc. 3. Fuel system with day tank, hand filling pumps, hoses, duplex filter etc. Please note the dimensional limitation where as the day can be mounted separately . 4. Cooling system for engine, lub oil, charge air with corrosion inhibiter and air cooled fluid coil cooler. 5. Combustion & exhaust air system with inlet air filtration, residential silencer, sparks arrestor turbo-charger & charge air-cooling system. 6. Starting system with Electronic start or VRLA sealed maintenance free battery with built –in charger with in-built protections shall ensures optimum charging of the batteries always for set values. 7. Erection, testing, commissioning & supervision of erection including demonstration of performance guarantee tests at site as per relevant code of practice. 8. Warrantee service 9. List of recommended spares for Operation & Maintenance required 4 services for all mechanical, electrical, & instrumentation items except fuel. Unit rates to be indicated separately in price bid. 10. Specific spares as per the list attached 11. All first fills & consumables for testing & commissioning required for commission at site is in the scope of supplier. However the fuel oil ( max of 300 ltrs HSD ) will be supplied at free of cost by department for tests at Sriharikota. D ) Detailed specifications 1.0 380 KVA TECHNICAL SPECIFICATIONS OF ALTERNATOR: 1.1.Continuous rating (at ambient temp.) 1.2. Output & load 1.3. Type of alternator 380kVA (at 415V, 3 phase, 4 wire, 50Hz AC & 0.8 pf running at 1500rpm with speed regulation of ±1% or less) at ambient of 500 c. with solidly grounded. 380 kVA (at 415V, 3 phase, 4 wire, 50 Hz AC supply & 0.8 pf) at 500 c, 50% Motor load + 25 % lighting + 10 % Electronic loads. Self contained self excited & self regulated. 2 1.4. Type of enclosure 1.5. Mounting 1.6. Excitation 1.7. Voltage regulation 1.8. Insulation 1.9. Duty & Overload capacity 1.10. Biggest size of motor that can be started with voltage dip limited to 10% 1.11. Temperature rise 1.12. Applicable standard 1.13. Control board, instrumentation & controls Suitable frame size used with better IP & totally enclosed. Self ventilated with removable covers to provide easy access to excitation unit. Horizontal, foot mounted with end shield bearings. Brushless excitation unit mounted on the alternator.(self excited) Automatic self regulated with ± 1 % or better of nominal rated voltage from no load to full load at 0.8 power factor for both cold and hot conditions. Class H, However, the temp. Rise limited to class – B and specially protected against moisture ingress. Duty S1 and as per standard and as per Engine capability. 160 kW SQIM with star – delta starter Limited to class B insulation for alternator and for Engine as per the requirement. Conforming to is: 4722 –latest A composite board comprising two separate panels as described hereunder shall be provided. - Generator control panel comprising DG set starting, regulating and monitoring equipment. - Instrumentation& control equipment for the diesel generator has been envisaged for safe, efficient, trouble free and reliable operation, including safety to the operating personnel as well. - Auto scanner with required no. Of channel to measure the temperature of winding and bearings. - Metering shall be provided for voltage, current, frequency, speed, power etc. Provision shall be available for data logging , alarm reporting and communication port for data transfer. 1.14. Protection Overload, short circuit, reverse power, under voltage, other standard protections etc., is to be provided. 1.15. Earthing Earthing of all electrical equipment and machinery not intended to be live shall have two distinct and separate earth connections as per is: 3043 latest. 1.16 BUS-3 P+1N/ Terminal chamber Copper bus for external terminals for termination of 4 R x 3.5 Cx150Sqmm copper FRLS armoured cable 1.17 Alternator Power out going ON/OFF switch with fuse provision from alternator terminal chamber to Flame proof panel. 3 2.0TECHNICAL PARTICULARS OF DIESEL ENGINE: 4 stroke , air cooled fluid coil cooler, turbo-charged diesel 2.1 Engine: engine of driving continuously synchronous generator at 1500 rpm to give net out put of 380kVA (at 0.8 p.f) at 415V at generator terminals at rated speed under site conditions. - The engine shall be capable of taking an overload of 10% for one hour during any 12 continuous running hours. - Conveniently located inspection window to facilitate removal of big bearing, piston etc without sump removal shall be provided. - the fuel injection system shall be driven by the engine itself and the system must ensure proper timing of fuel injection, control of rate of fuel injection etc - - - - 2.2 Governor 2.3 Fuel system 2.4 Exhaust system 2.5 Cooling system 2.6 Lubricating system 2.6 Starting system 2.7 Control & monitoring system 2.8 Protection system 2.9.Filters 2.10.Pipes& fittings rate of fuel injection shall be automatically controlled in accordance with variation in engine load.(electronic governor) engine shall be supplied with fly wheel along with suitable housing. flexible coupling shall be provided with necessary safety gaurds. diesel engines shall be provided with suitable lubricating system for effective lubrication of all components. the exhaust gas pipe with spark arrestor and residential type silencer including exhaust hood &weather cowl, expansion joint, insulation etc. Electronic governor with =/- 1% speed regulation HSD as per standard shall be used including suitable intake pumps /mechanism , filters, injection, overflow return etc Exhaust gas pipe with spark arrestor and residential type silencer including exhaust hood & weather cowl, expansion joint, insulation, etc Cooling system for engine, lub oil, charge air with corrosion inhibiter and air cooled fluid coil cooler The engine and rotating parts shall be continuously lubricated and shall be as per standard and suitable lub oil system and its filtering, cooling and monitoring shall be incorporated. Electronic starter / VRLA Batteries including built in charging & protection systems. Electronically controlled , monitored, displayed and with necessary protection interlocked so as to get the best efficiency and smooth operation. Provision shall be available for data logging , alarm reporting and communication port for data transfer. Over load, Over temp, Over speed ,Bearing failure and other electrical and subsystems interlocks. Air intake filters, lub oil filters and other required filters as per standard. All pipes shall conform to is:1978 latest, necessary standard bends, tees, couplings, flanges, bolts, nuts and gaskets shall be used for laying the pipelines. 4 2.11.Valves All isolating valves shall be of self lubricating, taperpug,tight shut off type and of reputed make. open / close position of valve and direction of flow shall be clearly indicated on the valve body. Oil resistant, flexible, BIS: 1435-latest 2.12. Hoses 2.13. Flanges 2.14.Fuel oil facilities 2.15. dip rod As per ANSI B 16.5 with pressure rating of 150 class minimum. Suitable metallic (MS) fuel oil storage tank of capacity 990 litres/ or 8 hrs full load running shall be provided with all accessories& fittings. the tank shall be fabricated from ms plates of minimum 14swg thickness or more conforming to is:2062 – latest and shall be complete with level switch, level gauge, vent, drain, inlet& outlet connection, manhole, and supporting structures. The fuel oil shall be brought in barrels and transferred to the above tanks by hand filling pumps. The dip rod shall be of suitable length, calibrated and made of aluminum. It shall be used to measure the contents of the oil in the tank. Diameter of dip rod shall be minimum 12mm or eqiv. 3.0 OTHER GENERAL INFORMATIONS 1. The normal ambient conditions prevailing at Site: are temperature: 50 deg. C, humidity of air: 100%, altitude above MSL: 10.5m, atmosphere: saline, highly corrosive, humid, hot and tropical atmosphere. The above conditions will have to be taken for selection of insulation materials for electrical equipments and anti corrosive treatment for joints etc 2. The exhaust gas pipe and exhaust silencer (heavy duty type) shall be made of mild steel suitable for the maximum exhaust gas temperature. suitable supports shall be provided for supporting the exhaust pipe and silencer. Suitable expansion joints / flexible connections shall be provided between exhaust pipe and exhaust manifold of the engine to ensure that no undue vibration is transmitted to the piping system. The exhaust pipe shall be suitably lagged and cladded with 20 gauge aluminium sheet for personnel protection against burning. The exhaust pipe should be taken to bottom of the DG set and trailer / bogie. Residential type Silencer shall be designed to have sound level below the acceptable limit as per the CPCB norms/ specification. 3. The DG set shall be supplied with necessary base frames, foundation / anchor bolts, nuts and washers etc. the base frames shall be supplied along with antivibration mounting. 4. Panel control wiring shall be done with control cable having minimum cross sectional area 1.5 sq.mm multi strand copper conductor of 600 V grade. Power cable shall have multi strand copper conductors of minimum cross sectional area of 2.5 sq.mm of 1.1KV grade. Colour code shall be followed for identification of power, control, DC circuits as per standards. 5 5. Internal wiring shall be neatly done, ferruled and dressed. Termination of signal and control cables shall be done in terminal strips / blocks of suitable size. Power supply terminations shall be done in separate terminal strips / blocks and suitably protected by separators/ bakelite sheets. 20% spare terminals shall be provided. 6. Available control supply voltage will be 240V AC± 10%, 50HZ+3%. Instruments shall be selected accordingly. 7. Signal & control cables used shall be of screened (100% coverage) and all signal, control and power cables shall be of FRLS type. 8. Cables shall be laid through hot dip galvanized perforated steel trays of minimum thickness of 2mm and of suitable widths as per total no. of runs of cables. 9. Cables laid in trays shall be coated with fire resistive paints along with fire resistive materials and metal covers. Routing of cable shall be done away from fire prone areas. 10. Wherever necessary, conduits, junction boxes and pull boxes shall be provided. Cables to cubicles, panels, desks shall enter from bottom and for junction boxes from bottom or sides with proper sized cable glands for each cable. 11. Instrument cable runs shall be kept as far away as possible from power cable runs & noise generating sources (transformers, motors and power switches). A minimum gap of 300 mm should be maintained between power, control and signal cables. 12. Spare cores shall be provided minimum 20% of the total no. of cores used in junction boxes. Junction boxes shall have suitable space for using 20% additional core provided in the cables. All spare cores shall be insulated and dressed inside the junction box. 13. All junction boxes shall have enclosure class of IP55 or IP54. 14. Instrument contacts, to be used for interlocking and alarm functions, shall be connected through relays. For normal operation NC contacts shall be used. 15. Cable no. as per cable schedule punched on corrosion resistive “cable tag no. plate” shall be tied at every 1 m interval and both ends of all signal, control and power cables for identification. 16. Numbers of cores in cables, conduits and types of cables shall be standardized before engineering and mutually agreed to. 17. Terminals of 240 V and above shall be labeled and isolated from terminals of lesser voltage levels. 6 18. Instrumentation and electrical equipment inside instrument cabinets shall be adequately grounded and working space as per manufacturer’s recommendations. 19. Supplier shall be confirm the Transient performance and voltage & current harmonics and it should be within the limits as per the standards. 20. Copper Bus bars, equipment’s etc shall be designed/ choose for 50KA of 1 second short circuit level. 21. Lifting hooks are to be provided. 22. Rotating Rectifier Voltage unit shall be provided on extended end shaft for easy maintenance. 23. Documents to be supplied with the tender: 1.Basic design details of the DGSET for study and approval. 2. Load reaction calculations. 3.Details of bought out materials, components and specifications. 24. PAINTING: Special attention shall be paid to the finish and general appearance of the work. The supplier shall ensure that no scratches appear on the painted surface while transporting and installing the set. Pipelines shall be painted in accordance with IS:23479 with latest amendments. The parts of the DG set installation, which are not factory painted, shall be given three coats of paint consisting of one primer coat of red oxide, one under coat and one finishing coat of epoxy/polyurethane finish paint. The exhaust pipe and silencer must be painted with heat resistant aluminum paint and should be guaranteed for one year. All the interiors of all the panel boards shall be painted with fire retardant paint. ITEM No.II : ERECTION, TESTING, COMMISSIONING a b c The erection of all plant and equipment shall be carried out according to the latest engineering practices and according to the working drawings, specification, instructions approved by SDSC. The erection shall be carried out by highly skilled work force under the supervision of engineer. The supplier shall be fully responsible for the supply of requisite tools and tackles, cable crimping tools, welding sets, welding rods, tools, jacks, gauges, ladders, and other appliances required for proper erection of the system. The supplier shall test and commission the DG set along with all connected facilities and ensure smooth operation of the same. The testing shall include both works testing and site testing. The tests, at works as well as at site including performance guarantee test shall be conducted as per ISO: 3046 /BS: 5514 – Latest. Necessary instruments / tools/ tackles required for conducting tests shall be arranged by supplier. 7 1.1 ACCEPTANCE TESTS Entire Testing, qualifications and Acceptance are to be carried out two Parts. 1) At Works and 2) At Work Site SDSC ,Sriharikota 1) AT WORKS: The DG set shall undergo the following acceptance tests: ENGINE: 01.Operational verification including Control & monitoring Panels 02.Fuel consumption test at ¼ rating , ½ rating and full rating or as per std 02.Governing test 03.Other Tests as per standards to verify the performance and specifications ALTERNATOR: 01.Measurement of Resistance 02.Phase sequence test 03.Regulation test (Cold condition) 04.Measurement of open circuit characteristics 05.Measurement of insulation resistance 06.High voltage test 07.Voltage balance test 08. Measurement of winding temperature 09. Other Tests as per standards. DG SET ( All the tests are inter related and not separate) 01.Full load (36 hrs) and over load test (1 hrs) on DG at WORKS shall be carried out. 02. Measurement of Sound level, Exhaust gas contents , vibration etc shall form part of testing at Works. 03.Factory Test certificates for the alternators and engine and all other subsystems and components shall be submitted before commencement 04 Testing and verification of all protections and interlocks as per specs and standards. 05 Protection relay testing and verification of functioning. 04 Fine tuning of Engine controller /Control panel 1.2 ACCEPTANCE TESTS AT SITE: PHASE – I On completion of all the installation works the DG sets shall undergo the following acceptance tests at site: 01.Visual examination of all parts and accessories 02.Measurement of resistance. 03.Insulation resistance test. 04.Protection relay functioning testing 04.Tests for normal operations of all protective relays and instruments. 05.Earth resistance measurement. 06.No load test to check the normal performance of engine, alternator, control panel and all other accessories. 1.3 ACCEPTANCE TESTS AT SITE: PHASE – II On satisfactory completion of phase –I tests the DG set shall undergo full load test for 06 hours continuously, by directly loading the DG set or as decided by SDSC. The SDSC will provide necessary load. HSD required for the above tests will only 8 be provided by the department at free of cost. The supplier should supply the engine complete with the first filling of lubricating oil. (a) During the above test following parameters shall be checked: 01.Cooling system temperature 02.Lubricating oil temperature 03.Lubricating oil pressure to the engine and turbo charger 04.Fuel oil consumption 05.Speed cum frequency variation on throwing ‘ON’ and ‘OFF’ at full load 06.Voltage variations. 07.Transient voltage dip test 08.Testing of failure conditions by simulation. 09.The overall efficiency of DG set at 25% load,50% load&100% full load shall be worked and compared with figures given by the supplier. (b) Following measurements are also to be conducted at site: 01.Phase sequence test. 02.Regulation test 03.Temperature of stator and rotor windings after continuous full load test. 04.Winding & Bearing temperatures while running the DG set. 06.Functional/operational/redundancy verification 07.Other Pre – Commissioning tests as per standards 1.4 Supplier is required to obtain necessary statutory clearances from pollution board clearance from AP state for the DG set as required and as applicable. 1.5 COMMISSIONING & TAKING OVER: If the acceptance tests as described above does not show satisfactory results, the supplier shall at his own expense rectify and replace the defective components or any part there of as directed by the authorized representative of the department within one week. The installation shall be re – tested after rectification/ replacement of the defective components without any extra cost. For such tests the cost of fuel and engine oil shall be born by the supplier. The following documents (original+2 copies) shall be prepared and submitted. 01. Final as built layouts/drawings and fabrication drawings soft & hard copies. 02. Operational/Maintenance manuals of; (a) Engine and Alternator with drawings. (b) MCCBs, Relays, Meters and other switch gear components etc 03. Control wiring diagram for DG sets, Control Panels, Power distribution panel. 04. Factory test and site test certificates. 05. Warrantee certificates for DG and other auxiliary systems 06. Pollution control board certificate. 07. Operating handles, interlocks, operating keys, rubber mats in front of power &control panels, danger boards and other accessories. 9 Item No.III: Specific spares extra for future O&M Following specific spares are also to be supplied and other essential spares for 4 services may be included. SNO 01 02 03 04 Item B checks related spares with out oil RRA / RRU AVR Engine controller like powercom Quantity 12 sets 2 sets 2 sets 1 set General Terms & Conditions: GUARANTEE and WARRANTY 1. The supplier shall provide complete system guarantee for the DG set to achieve the desired performance with the specified accuracy for a warrantee period not less than 12 months from the date of commissioning. 2. Supplier shall modify/ replace any part or complete equipment to achieve guaranteed performance during guarantee period at his own cost. 3. Supplier has to attend any deficiency in the performance of supplied systems during warrantee period immediately with in 48 hrs of reporting. 4. Delivery period 1 Submission of drawings and BOM 2 Clarification/Suggestion if any and drawing clearance by SDSC Manufacturing & assembly and factory QA tests Inspection call 3 4 5 6 7 8 5 CLIP inspection by SDSC & delivery clearance Delivery Installation, testing and commissioning subject to site clearance by SDSC Handing over /Taking over Within 3 weeks from PO Within 2 weeks from the submission With in 8 weeks from the above With in 1 week of readiness With in 4 weeks With in 3 weeks With in 4 weeks Subject to site condition With in 2 weeks 3 weeks 5 weeks 13 weeks 14 weeks 18 weeks 21 weeks 25 weeks 27 weeks AMC service: The supplier shall extend AMC service for DG set and all auxiliary systems for up – keeping the system in good working condition. However the department will enter into an AMC contract separately with the supplier if required after completion of warrantee period. 10 6 TRAINING: the supplier shall arrange on the site training to the departmental staff for the operation of DG set and its auxiliaries.( Max One week after commissioning) 7 PBG As per Terms & conditions 8 LD/SD As per Terms & conditions 9 EDEC As per Terms & conditions 10 VAT/CST As per Terms & conditions 11 Service Tax As per Terms & conditions 12 Payment As per Terms & conditions &&&& 11 ANNEXURE -B TECHNICAL & Commercial BID FORMAT Supply, Installation, Testing and Commissioning of DG set: 1. 1No. 380 KVA, 415V, 3 Phase, 50Hz, 1500 RPM Diesel Generator set with other Accessories at SDSC SHAR SLP/VAB facility. Bidders to confirm / clarify / furnish all the information as per the technical particulars and enclose technical catalogues / test certificates. Where ever details are to be entered attachment no. can be referred in bidders specification. 2. Any deviation may be clearly brought out. 3. Specifications /Requirements given are approximate. Any standard specifications nearer to the given specifications will also be considered for evaluation. 4. As all items put to tender are inter related , Price comparison will be made on Grand total basis including all charges/taxes etc. Sl. No 01 Description SDSC Specification Engine Make 02 Alternator Make 03 Quality Standard Caterpillar / Cummins/ Perkins / Greaves / Volvo Penta AVK / Stamford / Crompton Greaves / Lory somer BIS, IEC, ISO and other relevant standards like IEEE 04 Diesel Engine Bidder to specify Model BHP for 380 KVA at 0.8 Bidder to specify pf 1500 RPM Air Cooled Fluid Coil Cooler Cooling System With Fuel Pump, ECPG and Filters etc. Fuel System With Oil Pump, Cooler, Filter etc. Lubricating System With Dry Filter, Turbo Charger after Cooler Air In-take System 4.1.1 4.1.2 4.1.3 4.1.4 4.1.5 4.1.6 4.1.7 4.1.8 Bidder’s specification etc. With Silencer and spark arrestor Exhaust Exhaust System Piping, Supports etc. as per the specifications Electronic with 1% regulation Governing system Electronic start / Electrical, 24V DC Starting system Provision for remote Bidder to specify monitoring & status with: Starting Switch, LCD display for Lub. Oil Pr., Water Temp, RPM, Runhour, Battery Voltage and safety controls etc, 12 Sl. No 4.1.9 4.1.10 Description Bidder’s specification Electronic board / SMF type batteries with built in charger , with built in protection Electronics Bidder to specify AH capacity Bidder to specify Make and Model Bidder to specify Base Frame Mounting on moving Vibration free pads electronic start / Battery 5.1 5.2 5.3 5.4 5.5 5.6 structure Spare Pads Alternator make Model Self Excited, Brush less, Solid state AVR with 1%, 1500 RPM, 415V, 50Hz, 3Phase, 4wiire, 0.8 PF lag, suitable for the above Diesel Engine Rated Capacity Efficiency Insulation Class Over load capacity Enclosure Terminals Transient Response Accessories 5.7 6.0 6.1 Earthing Terminals Control and Protection Metering 6.1.1 6.1.2 Ammeter Volt Meter 5.0 SDSC Specification Bidder to confirm Bidder to specify Bidder to specify Bidder to confirm 380 KVA Bidder to specify Class H with gel coat Bidder to specify IP 54 or better 3 Line and Neutral Bidder to specify Space heaters, bearing temperature monitoring and other components as per standards. Bidder to specify Digital with 240V AE/MECO/as approved 0-800A 0-500V Aux. Make: 13 Sl. No 6.1.3 6.1.4 6.1.5 6.1.6 6.1.7 6.2 6.2.1 6.2.2 6.2.3 6.2.4 6.2.5 6.2.6 6.3 6.4 6.5 6.6 6.7 6.8 6.9 6.9.1 6.9.2 6.9.3 7.0 8.0 8.1 Description SDSC Specification Bidder’s specification Make to be specify PF Meter Make to be specify Frequency Meter Make to be specify KW Meter Make to be specify Multi function Meter For excitation Field DC Ammeter & Volt Meter Protective Relays Electro-Mechanical-Electronic type For 380 KVA DG IDMTL Combined O/C & EF Instantaneous Short Circuit Bidder to specify Reverse Power Bidder to specify Reverse KVAR Under Voltage with Time Bidder to specify delay Bidder to specify Other Standard Protections All with LED Indications Bidder to specify Built-in battery charger Bidder to specify Built-in Spare and actuators Push Buttons and Actuators Bidder to specify Bidder to specify Control Switches Bidder to specify Auto Temperature Scanner Remote monitoring / Bidder to specify Annunciation as specified Note: Composite protection and metering will also be considered. In any case, separate V, I, Hz meters with LED display, monitor with data logger shall be provided. Switch Fuse unit Rating and 630A, 415V, 4 pole Type for Output control CTs Resin cast : 600/5A for 380 KVA Bidder specify Measurement protection Safety Features as specified Bidder to specify Accessories as specified Bidder to specify Bidder to specify Fuel Tank as specified Painting as specified shade, Bidder to confirm and thickness of paint for suitable at sea costal area (highly corrosive and humidity area). Items like Acoustic enclosure etc This set is used in Bidder to confirm Hazardous location. Bidder should not use any flammable materials used in and around Acoustic proof enclosure. 14 Sl. No 8.2 Description SDSC Specification Bidder to confirm 9.0 9.1 9.2 9.3 9.4 10.0 11.0 DG set shall conform to CPCB norms. Tests Routine / type Tests Acceptance Tests at works Acceptance Test-I at site Acceptance Test-2 at site Commissioning as specified Warranty 12.0 AMC service 13.0 14.0 14.1 14.2 Training General Company Company Profile 14.3 List of customers 14.4 a b c d 14.5 14.6 Statuary Registrations Company Registration IncomeTax Registration Sales Tax PF for Labour Communication Facilities Any other relevant information Confirm all the above are integrated in a framed structure and enclosed with suitable enclosure that is weatherproof, spark arrestor and residential type/ acoustic proof as per CPCB norms Total size of DG including acoustic proof shall be below this dimensions L-5.5m, W – 1.8m, H – 2.0 m. 14.7 15.0 Bidder’s specification Bidder to confirm Bidder to confirm Bidder to confirm Bidder to confirm Bidder to confirm Min. 12 months from the date of commissioning Bidder to confirm. (Furnish the AMC services address) Bidder to specify OEM Public / Private Ltd. (Furnish the details) At least 5 similar DG sets during last five years. Furnish Furnish Furnish Furnish Furnish Furnish Bidder to confirm Authorised signatory 15 ANNEXURE -C PRICE BID FORMAT Supply, Installation, Testing and Commissioning of DG set: 1 1No. 380 KVA, 415V, 3 Phase, 50Hz, 1500 RPM Diesel Generator set with other Accessories at SDSC SHAR SLP/VAB facility. 2 Refer Tender document, Technical & price bid format Sl 01 02 03 04 Item Supply of 380KVA DG set as per the specifications in the Tender document Installation, Testing, commissioning and warrantee service for the above supplied items Cost of specific spares with break up as per the technical bid. Attach details Taxes Excise duty: EDEC for DG set will be provided CST & applicable items VAT & applicable items Service Tax applicable items Packing & forwarding Transportation Any other charges Provide beak up Grand total Rate Qty Amount Authorised signatory 16 Satish Dhawan Space Center SHAR Page Destination: Tender Header Format Type : Normal .: GOVERNMENT OF INDIA DEPARTMENT OF SPACE SATISH DHAWAN SPACE CENTRE PURCHASE DIVISION Tele No.08623-225023/225174/225127 Fax No.08623-225170/22-5028 e-Mail ID : hps@shar.gov.in, hasan@shar.gov.in, sselvan@shar.gov.in STANDARD TERMS & CONDITIONS 1.OFFERS SHALL BE SENT ONLINE ONLY USING STANDARD DIGITAL SIGNATURE CERTIFICATE OF CLASS III WITH ENCRYPTION / DECRYPTION. THE TENDERS AUTHORISED ONLINE ON OR BEFORE THE OPEN AUTHORISATION DATE AND TIME ONLY WILL BE CONSIDERED AS VALID TENDERS EVEN THOUGH THE BIDS ARE SUBMITTED ONLINE. 2.THE TENDERER MUST AUTHORISE BID OPENING WITHIN THE TIME STIPULATED IN THE SCHEDULE BY SDSC SHAR. OTHERWISE THE ONLINE BID SUBMITTED WILL NOT BE CONSIDERED FOR EVALUATION. PHYSICAL COPY WILL NOT BE CONSIDERED EVEN THOUGH IT IS RECEIVED BEFORE THE BID SUBMISSION DATE. In case of two-part tenders, parties shall submit their offers as follows:1) Part-I – Techno-commercial Bid (No price details shall be mentioned in this bid and shall not upload the details of price along with the techno-commercial bid) 2) Part-II – Price Bid In view of Two Part Tender, the Offers submitted contrary to above instructions will be summarily rejected. 3.In case, the tenderer is not interested to participate in the tender, the tenderer shall submit regret letter giving reasons, failing which future enquiries will not be sent. 4.Offer Validity: The validity of the offers / tenders should be 90 days (in case of single part tender) and 120 days (in case two part tender) from the date of opening of the tenders. Tenders with offer validity less than the period mentioned above, will not be considered for evaluation. 5.Excise Duty - SDSC-SHAR is eligible for Excise Duty Exemption under Notification No. 64/95 dated 16.03.1995 as amended by Notification No. 15/2007 dated 01.03.2007 and as amended by Notification No. 07/2008 dated 01.03.2008 and necessary Exemption Certificate will be provided. No claim, whatsoever, for payment of Excise Duty or Cenvat reversal will be allowed later. The suppliers have to take this into account while submitting quotations. Excise Duty Exemption Certificte will be issued only to finished product as per the PO/Contract. EDEC shall not be issued in favour of third parties for raw materials, other components that go in to the manufacture of the end product. Excise Duty Exemption Certificate will be issued in favour of original equipment manufacturer provided (i) the tender has been received from the sole selling agent of OEM concerned (for which documentary proof shall be produced) and (ii) a request for issue of Excise Duty Exemption Certificate was made in the original offer itself. 6.CST - With effect from 01.04.2007, Form-D has been withdrawn for Inter-State purchases by Government Departments. Now the percentage of CST on the Inter-State sales to Government Departments shall be the percentage of VAT/State Sales Tax as applicable in the State of the Seller/Dealer. Accordingly, the suppliers have to indicate clearly the % (full rate of tax) of CST applicable against each item in their offers. 7.Customs Duty - SDSC-SHAR is eligible for 100% Customs Duty exemption as per Notification No. 12/2012 dated 17.03.2012. This may be taken into account while quoting for import items, if any. In case tenderers offering items considering customs duty exemption, they should also indicate the bill of materials and price, separately, with Customs Duty component and terms and conditions thereto. 8.Advance Payment - Wherever advance payment is requested, Bank Guarantee from any Nationalized Bank/Scheduled Bank should be furnished. In case of advance payments, if the party is not supplying the material within the delivery schedule, interest will be levied as per the Prime Lending Rate of RBI plus 2% penal interest. Interest will be loaded for advance payments/stage payments as per the prime lending rate of RBI and will be added to the landed cost for comparison purpose. In case of different milestone payments submitted by the parties, a standard and transparent methodology like NPV will be adopted for evaluating the offers. 9.Liquidated Damages - In all cases, delivery schedule indicated in the Purchase Order/Contract is the essence of the contract and if the party fails to deliver the material within the delivery schedule, Liquidated Damages will be levied @ 0.5% per week or part thereof subject to a maximum of 10% of total order value. 10.Performance Bank Guarantee - Performance Bank Guarantee for 10% of the order value should be furnished in the form of Bank Guarantee from nationalized/scheduled bank or by Demand Draft valid till warranty period plus sixty days as claim period. 11.Security Deposit – Security Deposit for 10% of the order value is mandatory, if the ordered value is Rs.5.00 lakhs and above. Party shall furnish the Security Deposit in the form of Bank Guarantee from nationalized/scheduled bank or by Demand Draft valid till completion of the contract period plus sixty days towards claim period for faithful execution of the contract. 12.BANK GUARANTEE FOR FIM: Supplier has to submit Bank guarantee for equal value of Free Issue of Materials (FIM) issued by the Department from Nationalised / Scheduled Bank valid till receipt and acceptance of supply and satisfactory accounting of FIM plus sixty days as claim period. 13.The delivery period mentioned in the tender enquiry, IF ANY, is with the stipulation that no credit will be given for earlier deliveries and offers with delivery beyond the period will be treated as unresponsive. 14.The Department will have the option to consider more than one source of supply and final orders will be given accordingly. 15.The bidders should note that conditional discounts would not have edge in the evaluation process of tenders. 16.Non-acceptance of any conditions wherever called for related to Guarantee/ Warranty, Performance Bank Guarantee, Security Deposit, Liquidated damages are liable for disqualification. 17.Wherever installation/ commissioning involved, the guarantee/warrantee period shall reckon only from the date of installation and commissioning. 18.Purchase/Price Preference will be extended to the MSMEs under the Public Procurement Policy for MSMEs formulated under the Micro, Small and Medium Enterprises Development Act, 2006 and instructions issued by Government of India from time to time. Vendors who would like to avail the benefit of MSME should clearly mention the same and submit all the documentary evidences to substantiate their claim along with tender itself. 19.The drawings, specifications, end use etc., given by the Centre/Unit along with the tender enquiry are confidential and shall not be disclosed to any third party. 20.SPECIAL CONDITIONS FOR SUBMITTING QUOTATIONS IN FOREIGN CURRENCY BY THE INDIAN AGENTS The Tenderer should submit the following documents/information while quoting:a)Foreign Principal's proforma invoice/quote indicating the commission payable to the Indian Agent and nature of after sales service to be rendered by the Indian Agent. b)Copy of Agency agreement with the Foreign Principal and the Indian Agent, precise relationship between them and their mutual interest in the business. c)Registration and item empanelment of the Indian Agent. d)Agency Commission will be paid only Indian Currency. e)Compliance of the tax laws by the Indian Agent. 21. High Sea Sales- Against High Sea Sale transactions: a.Offers shall be on all inclusive basis including delivery upto Sriharikota at the risk and cost of the supplier. Customs Clearance is the responsibility of the supplier and at his cost and risk. b.100% payment will be made within 30 days after receipt and acceptance of the items at our site. c.Sales Tax is not applicable d.Customs Duty Exemption Certificate and other relevant documents required for Customs clearance will be provided. e.High Sea Sales Agreement furnished by the supplier in accordance with the terms and conditions of our purchase order will be signed and issued by SDSC-SHAR. 22.The following information/ documents are to be submitted wherever applicable. 1.Product Literature 2.Core banking account number of SBI, RTGS Details 3.PAN No. in quotation and invoices 4.Excise Duty, VAT, Service Tax Registration details. 5.In case of MSME, registration details / documents from Competent Authority. 23.EXCLUSION OF TENDERS The following tenders shall be summarily rejected from the procurement process a.Tenders received from vendors who have not qualified in terms of their registration. b.Tenders received against publishing of a limited tender in the CPP portal. c.Tenders of vendors who have been removed from the vendor list or banned/debarred from having business dealings. d.Unsolicited tenders from vendors. e.The tenders which materially depart from the requirements specified in the tender document or which contain false information. f.The tenders which are not accompanied by the prescribed Earnest Money Deposit. g.The tenders of vendors who have not agreed to furnish Security Deposit, Performance Bank Guarantee and Liquidated Damages. h.The validity of the tenders is shorter than the period specified in the tender enquiry. i.The tenders received from vendors or their agents or anyone acting on their behalf, who have promised or given to any official of the Centre/Unit/Department, a gratification in any form, or anything of value, so as to unduly influence the procurement process. j.The tenders received from vendors, who, in the opinion of the Centre/Unit, have a conflict of interest materially affecting fair competition. k.The tenders received from Indian agents on behalf of their foreign Principals/OEMs (in cases where the Principals/OEMs also submit their tenders simultaneously for the same item/product in the same tender). l.In case two or more tenders are received from an Indian agent on behalf of more than one foreign Principal/OEM, in the same tender for the same item/product. m.If a firm quotes ‘NIL’ charges / consideration, the bid shall be treated as un-responsive and will not be considered.