Chapter 3 Section 2

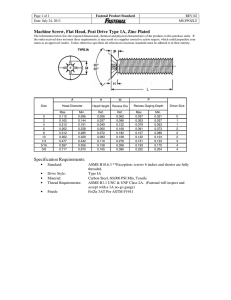

advertisement