Application Note

MFCs for Gas Control

In Case Hardening Processes

PROBLEM

Surface hardening is a high temperature process that creates

hard surface alloy layers that improve a metal’s wear resistance.

The technique has been used for many years, however, precise

control of the surface alloy composition is difficult since

accurate control of the gas chemistry is challenging in these

processes, which in turn makes it difficult to control the

composition of the surface alloy. Poor control leads to high

part rejection rates, inefficient use of furnace operating time,

and higher than necessary ambient gas costs.

BACKGROUND

Case Hardening

System case hardening is a high temperature, batch furnace

process in which gaseous hardening agents (a carbon

monoxide/hydrogen mixture generated in an endothermic gas

generator) are cracked on the steel surface to produce carbon

that then diffuses into the microstructure of the steel, raising

the carbon content (up to ~0.9% C) of a surface layer and

hardening it relative to the tough, ductile core. The surface

layer thickness (“case depth”) depends on process temperature,

composition of the carbon source, time-at-temperature, and

the carbon chemical potential at the surface during diffusion.

The carrier gas is produced using a precisely metered mixture

of methane and other hydrocarbons that are reacted with just

enough oxygen to produce the desired carbon monoxide/

hydrogen ratio. Alternatively, the need for endothermic gas

generators can be avoided by direct injection of a nitrogen/

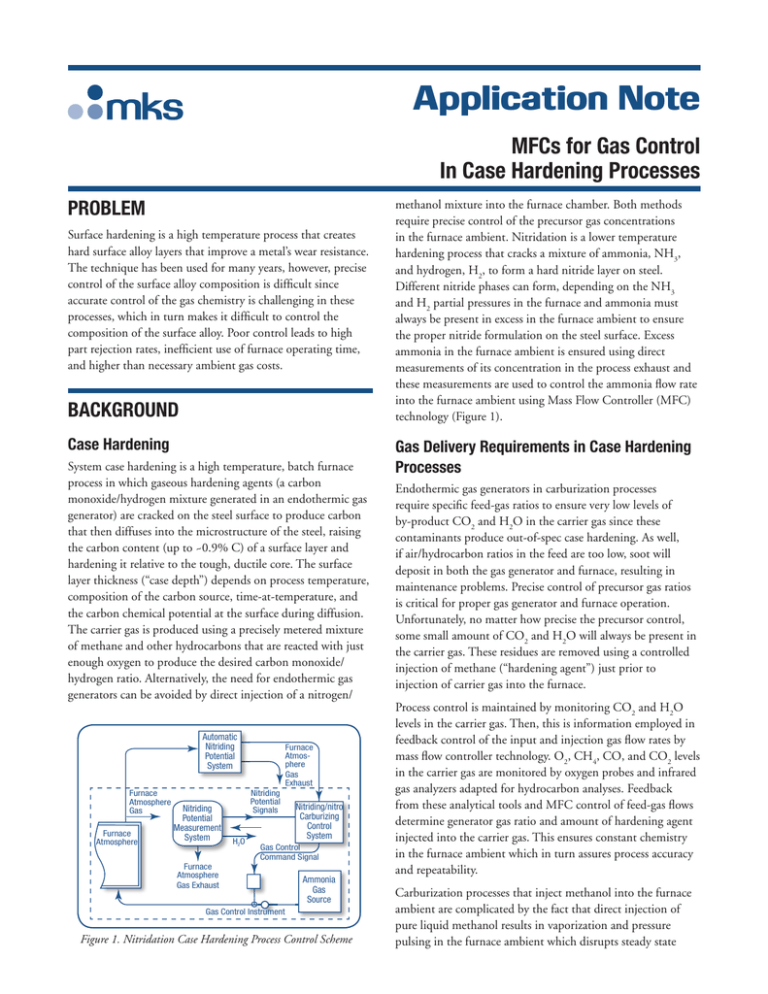

Automatic

Nitriding

Potential

System

Furnace

Atmosphere

Gas

Furnace

Atmosphere

Nitriding

Potential

Measurement

System

Furnace

Atmosphere

Gas Exhaust

Furnace

Atmosphere

Gas

Exhaust

Nitriding

Potential

Signals

H2O

Nitriding/nitro

Carburizing

Control

System

Gas Control

Command Signal

Ammonia

Gas

Source

Gas Control Instrument

Figure 1. Nitridation Case Hardening Process Control Scheme

methanol mixture into the furnace chamber. Both methods

require precise control of the precursor gas concentrations

in the furnace ambient. Nitridation is a lower temperature

hardening process that cracks a mixture of ammonia, NH3,

and hydrogen, H2, to form a hard nitride layer on steel.

Different nitride phases can form, depending on the NH3

and H2 partial pressures in the furnace and ammonia must

always be present in excess in the furnace ambient to ensure

the proper nitride formulation on the steel surface. Excess

ammonia in the furnace ambient is ensured using direct

measurements of its concentration in the process exhaust and

these measurements are used to control the ammonia flow rate

into the furnace ambient using Mass Flow Controller (MFC)

technology (Figure 1).

Gas Delivery Requirements in Case Hardening

Processes

Endothermic gas generators in carburization processes

require specific feed-gas ratios to ensure very low levels of

by-product CO2 and H2O in the carrier gas since these

contaminants produce out-of-spec case hardening. As well,

if air/hydrocarbon ratios in the feed are too low, soot will

deposit in both the gas generator and furnace, resulting in

maintenance problems. Precise control of precursor gas ratios

is critical for proper gas generator and furnace operation.

Unfortunately, no matter how precise the precursor control,

some small amount of CO2 and H2O will always be present in

the carrier gas. These residues are removed using a controlled

injection of methane (“hardening agent”) just prior to

injection of carrier gas into the furnace.

Process control is maintained by monitoring CO2 and H2O

levels in the carrier gas. Then, this is information employed in

feedback control of the input and injection gas flow rates by

mass flow controller technology. O2, CH4, CO, and CO2 levels

in the carrier gas are monitored by oxygen probes and infrared

gas analyzers adapted for hydrocarbon analyses. Feedback

from these analytical tools and MFC control of feed-gas flows

determine generator gas ratio and amount of hardening agent

injected into the carrier gas. This ensures constant chemistry

in the furnace ambient which in turn assures process accuracy

and repeatability.

Carburization processes that inject methanol into the furnace

ambient are complicated by the fact that direct injection of

pure liquid methanol results in vaporization and pressure

pulsing in the furnace ambient which disrupts steady state

Application Note

Page 2

operation. This is avoided by injecting an entrained

N2/methanol gas with tightly controlled ratios that are

maintained using MFC control.

Nitridation processes require a controlled excess of ammonia

in the furnace ambient that is maintained by exhaust analyses

and MFC control of feed-gases similar to that employed for

carburization. As well, precision gas flow control in nitridation

processes minimizes operational costs due to ammonia gas and

any need for high temperature processing steps.

SOLUTION

MKS Instruments has developed advanced thermal mass flow

controller technology for carburization- and nitridation-based

case hardening applications. MKS MFCs directly relate

volumetric gas throughput at standard reference conditions to

mass throughput per unit time, yielding measurements that are

independent of variations in the gas temperature and pressure.

Rugged industrial

applications such

as case hardening

require MFCs that

can withstand high

dust and moisture

environments. MKS

meets this need with

the I-Series family of Thermal Mass Flow Controllers and

Mass Flow Meters specifically designed for applications in

harsh environments. The enclosure of I-Series MFCs is

IP66-rated against direct water spray and fine dust. I-Series

MFCs feature the following characteristics:

•

•

•

•

•

•

Flow Rates from 5 sccm to 1000 slm

Ingress protection rating IP66 (dustproof & waterproof )

Multi-range/multi-gas capability; 1% of set point

accuracy

Single sided power supply: 15 to 25 VDC

Analog I/O options: 0 to 5 VDC; 4 to 20 mA

Digital I/O options: Profibus; RS485, Embedded

Modbus and Ethernet user interface

The integration of MKS Instruments’ digital MFC technology

with sensor technologies in closed loop control ensures

continuously adjustable gas flows and steady state conditions

during case hardening processes. In multi-step nitridation

processes with changing temperature profiles, MKS MFC’s

permit controlled, time-dependent gas flow ramps tailored to

furnace temperature transitions.

MKS Instruments offers a variety of standard industrial

communication protocols and is continually expanding MFC

options based on industry communication requirements

for other digital protocols such as EtherCAT and Profinet.

On board diagnostics, accessible via Ethernet TCP/IP

communications protocols, provide customers with the

ability to modify the setup of the MFC to control the

flow of different gases and to change the scale of the flow

measurement and control. The on-board diagnostics can

also be used to troubleshoot the functionality of the device,

providing plot functions for critical MFC variables.

CONCLUSION

The product quality and operational costs associated with

case hardening heat treatment processes such as carburizing

and nitriding are determined by the ambient gas atmosphere

and temperature in the furnace. Significant improvements in

throughput, reductions in gas costs, and improved run-to-run

consistency can be achieved by coupling appropriate sensor

technology with advanced MFC technology to achieve

real-time, adjustable gas flow rate control that maintains a

constant chemical composition in the furnace, which in turn

maintains a constant concentration of the hardening agent

at the gas/steel interface. MKS Instruments’ I-Series MFC

family of IP66-rated Thermal Mass Flow Controllers and Mass

Flow Meters for Industrial Environments have all the features

necessary for successful integration into case hardening

applications.

For more information on MKS Instruments’ I-Series MFC

Technology, link to: http://www.mksinst.com/product/

category.aspx?categoryid=415

For a general catalog of MKS Products, follow this link:

http://www.mksinst.com/index.asp

App. Note 05/16 - 7/16

© 2016 MKS Instruments, Inc.

All rights reserved.

MKS products provided subject to the US Export Regulations. Diversion or transfer

contrary to US law is prohibited. mksinst™ is a trademark of MKS Instruments, Inc.,

Andover, MA.

MKS Instruments, Inc.

Global Headquarters

2 Tech Drive, Suite 201

Andover, MA 01810

978.645.5500/800.227.8766

www.mksinst.com