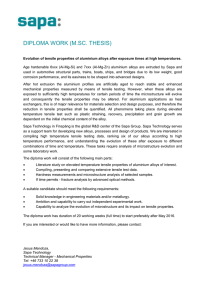

NEWSLETTER FROM SAPA AUTOMOTIVE NR 1/2009

advertisement

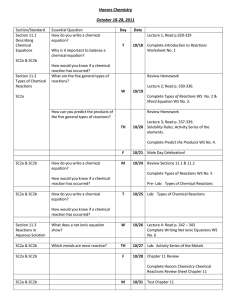

N E W S L E T T E R F R O M S A PA A U T O M O T I V E NR 1/2009 Editorial VICTOR SCHNEIDER Profitable growth Since the end of 2008 the global economy has been facing a severe crisis, which is affecting all automotive markets and resulting in dramatic volume drops. We at Sapa are not spared - flexibility and strong cost management is a mandatory exercise in these difficult times. However, we can be lucky that our mother company has a sound balance sheet, which will allow us to withstand this crisis. A crisis also offers opportunities. At Sapa Automotive we are convinced that we will come out strengthened and we are from »profiles to solutions« through CVM preparing our teams to deliver further (customer value management) is part of growth to the Sapa automotive business. our daily life at Sapa automotive. There is Aluminium will play an increasing role in a large variety of product lines, all based today’s challenges to improve fuel and on superior extrusion capabilities, that emission for cars and trucks. It will no Sapa automotive offers for car and truck applications. This inlonger be a speciality for cludes structural parts, high end vehicles, aluAluminium will play impact protection, decminium will be used in all an increasing role in orative trims, interior kind of vehicles from the today’s challenges to components to masmallest to the largest, chined engine compofrom low volume to high improve fuel and nents and housings. volume. New technoloemission for cars and We are serving a large gies, like hybrid and trucks customer base, both electric powered cars OEMs and also multiare offering new applications for aluminium due to ple tier 1 and system suppliers. Our conits outstanding heat transfer stant target is to leverage cost efficiency property combined with su- with product and process improvements. perior machining and shap- Sapa’s extended manufacturing footprint is another competitive edge which makes ing capabilities. Sapa automotive is us confident that we are on the right track preparing for the next step for profitable growth. The Sapa Automotive team is motiof profitable growth: Our sales and engineer- vated, skilled and focussed to fight for ing organisation is being re- profitable growth by offering innovative, inforced, with newly hired en- robust and flexible solutions to our cusgineers joining Sapa automo- tomers. This Extrude edition 2009-1 shows vartive. This reinforcement goes along with a »closer to the cus- ious aspects of Sapa automotive busitomer« focus while our Swedish ness, I wish you a pleasant read. central engineering and support functions offer strong know how and Victor Schneider networking support for the local sales V I C E P R E S I D E N T areas. The Sapa strategy S A P A A U T O M O T I V E sing a e r inc and e is s m u e e d l i e Prof with th ergi n e e n in li redused n and tio for he ump ss on t s n co stre n u ent im m n i n m ro envi Around 8% of the Earth´s crust consists of aluminium Y O N L 5% After iron, aluminium is the second most widely used metal in the world Ho BMW nda and the a have bec lum om leade inium co e nten rs ov t er three years the last rep GM a nd N lacing issan . have Studies ch kiloa e t tha shown used minium e of alu kg of 0 gramm 2 nishing to s a n sions saves a as emis ouse g me greenh fe ge li ti e avera over th r. of a ca iginal r o e h t of input y g r e en ed for is need g. recyclin Aluminium – a truly precious metal Aluminium is the common to corrosion and is easy to machine, mill, denominator for every Sapa drill, cut, punch, bend, weld, bond and tape. business. It’s the core of everything we do. Thankfully, Again and again and again… there’s lots of it: around 8% Aluminium can be reused for the same of the Earth’s crust consists purposes over and over again. Unlike of aluminium in the form of many other materials, aluminium does different minerals, making it not lose its unique properties during the recycling process. Furthermore, recyone of the few metals with cling requires only 5% of the original enalmost limitless availability. ergy input. In order to take advantage of A unique combination After iron, aluminium is the second most widely used metal in the world. This is largely due to its unique combination of attractive properties. It combines low weight with high strength and superior malleability. It has an excellent resistance these recycling properties, Sapa has remelting facilities in ten countries. Around 50% of our total production is uses recycled aluminium. Ideal for cars, ideal for the environment In terms of environmental impact, the motor industry has attracted a great deal of attention; the International Energy Agency estimates that around 19% of global man-made greenhouse gases are generated by the transport sector. In addition, the EU Commission in Europe has proposed binding targets to produce cars that emit no more than 130g of carbon dioxide per km by 2012 – the current average is 162 g/km. Obviously it is vital to develop the types of fuel we use, but thanks to its weight-saving properties, aluminium is already having a significant impact on fuel consumption. In fact, recent studies have shown that each kilogramme of aluminium used saves an astonishing 20 kg of greenhouse gas emissions over the average lifetime of a car. SAPA IN POLAND A MODERN SUCCESS STORY It all started in North-east Poland, in Trzcianka, a town with a population of 20,000. Sapa Poland established its first press here in 1993. Since then Sapa, with just over 600 employees, has become Trzcianka’s largest employer. Efficient cutting operation That first press is still in use, but continual Competitive automotive supplier investment has been made since then. Various types of fabrication, including Last year’s installation of a third press for welding and assembly, take place in wider profiles and harder alloys has dou- rooms next to the presses and in a buildbled the company’s capacity. Sapa in ing on the other side of Trzcianka. Sapa Poland holds a strong position in the do- produces aluminium parts and supplemestic market and is a leader in many ments them with purchased components, areas, the largest being the construction each adapted to the customer’s production needs. In some industry. Roughly 40% cases, the company of the manufactured supplies finished prodproducts are anodised. Value added ucts packed and ready There are already two solutions to the according to specificaanodising plants in Trzinternational tion. While profile procianka: one founded in duction and anodising 2006 and a new, larger, automotive industry remain the basis of the more efficient plant next company’s production, to the recently opened the real grow potential modern treatment plant. Environmental issues are of top concern, lies in components, which led to the and all aspects of the new plant will com- founding in 2009 of Sapa Components in ply with strict standards. On top of that, Łód . Sapa Components was established we also have an anodising plant in Łódź, as a competitive automotive supplier created specifically for automotive market within the Sapa group. We follow a continuous improvement approach, including requirements. the Genesis philosophy. We apply wellknown Genesis tools such as 5S, SMED and other TPM tools. Roof rails and components Sapa Components supplies aluminium value added solutions to the international automotive industry, including roof rails and other external accessories, internal components of passenger cars and structural parts for heavy vehicles, based on cut to length aluminium profiles. Our main customers are Tier1 and OEMs based in France and Sweden, but newly strengthened sales team targets Central and Eastern Europe as well as our local market. We aim to extend our current capacity and expand the current product range, in particular the process of welding and 3D stretch bending. Both technologies are of high customer’s interest as witnessed by new RFQs. The main challenge that lies ahead is to increase our business achievements with new prospects. Processing monitoring GETTING TOUGH It’s not easy being a car. The growing use of aluminium by vehicle manufacturers has created a pressing issue for manufacturers and suppliers – attack by alkalis. Even at the car wash, more aggressive cleaning fluids are taking the shine off aluminium components. Sapa has responded by developing an enhanced anodising process that offers a much-improved resistance to corrosive chemicals. »The new anodising process consists of a new type of corrosive-resistant coating that has the ability to inhibit the attack of alkalis on the surface of the anodised aluminium,« says Richard Shaw, Anodising Manager at Sapa Components Ltd in the UK. Well-guarded secret To give some idea of the improvement, Shaw says: »Standard aluminium oxide films are usually stable between a pH range of 4 to 8. The coating that we intend to offer is in excess of 12.5 pH.« As the pH scale is logarithmic with a maximum value of 14 for the strongest alkalis, the actual increase from 9 to 12.5 represents a vast improvement over existing levels. »Details of the process are a closely guarded secret«, says Tony Wall, sales director at Sapa Components Ltd. »We had to overcome considerable technical hurdles,« he says »to achieve a coating with the right physical characteristics to deal with increasingly corrosive alkali exposure«. The two-year development programme along with our main chemical partners as added an extra dimension to the anodising capabilities at Sapa Group, »The make-up of the new chemical formula is key to the process,« Wall says. Saving fuel As well as benefiting existing exterior aluminium car components, the new coating offers vehicle manufacturers the ability to use this lightweight and recyclable material more widely. Cutting the overall weight of a vehicle saves fuel consumption and reduces carbon dioxide emissions. In addition, the resistant aluminium coating also offers the attractive finish that is used increasingly in exterior trim components. Tests have been carried out on a num- ber of automotive components such as roof rails, window surrounds and grilles with major car companies including General Motors, Ford, Jaguar and Aston Martin. And following the success of these trials, the company had its first volume product order with a major original-equipment manufacturer for finishing of a new exterior trim. Two-year lead These developments are encouraging for motor manufacturers, who will be keen to exploit the lightweight, recyclable properties of aluminium for other automotive parts. By cutting the overall weight of the vehicle, manufacturers can achieve critical reductions in both fuel consumption and carbon dioxide emissions. Sapa has invested around £500,000 in production facilities and associated equipment, in order to develop the new process. This has given them an estimated two- to three-year lead on their competitors, and will help them push on with their aim of enabling resistance to 13.5 pH. This magic figure has been already been reached in experiments, but has yet to achieved for production purposes. ium umin l a l l of a n use i l l % i 0 t 7 ss 888 i 1 m fro PA SSED New anodising process passed 12.5 pH alkaline resistance test. FAILED Conventional bright anodised anodic film failed 12.5 pH alkaline resistance test. ON CORROSION The new coating from Sapa has been tested on roof rails, window surrounds and grilles, with good results. Shaping the fu of you In our mission to support environmental friendly automotive development initiatives, Sapa recently helped a team of young engineers from Jaguar and Land Rover in a »green« race for electric powered vehicles - the Greenpower 2009. The Greenpower is an electrical car race that began in 1999. It encourages young people aged 9-21 to design, build and race an electrical vehicle in a 4-hour endurance race. It has become a tremendous success with over 400 teams competing over the years. On Sunday the 26th of April a total of 28 teams were involved in a tough competition at the Goodwood race track in the south of England. The goal of the project is to promote engineering and technology as exciting careers for young engineers and to encourage participants to further develop their own skills and knowledge. It also allows a team to stay within the competition throughout their education, involving more enthusiastic as they go. Aluminium chassis Sapa’s participation included the sourcing of custom made aluminium extrusions for the construction of the chassis of the car, as pictured below. The Jaguar Land Rover (JLR) team in- cluded around twenty graduate recruits who developed a car in just 6 months, working continuously after work in order to get the car ready for the race day. Sustainablity thanks to aluminium extrusions One of the main priorities for the JLR team in this project was sustainability, and this influenced their choice of materials: the criteria used to select the materials for the Green Power vehicle was a balance of conventional properties such as weight, strength and stiffness, with sustainable properties such as the amount of CO2 required to produce the material from its raw elements and how recyclable/reusable it was. So although carbon fibre offers excellent specific stiffness and strength, it was ruled out due to the amount of energy required to produce it, and because it is not recycleable. Instead, aluminium and recycled ABS were used for the main. Aluminium was used for the chassis and structural components. Reducing carbon footprints Julian Whitehead, director of Sustainability at Jaguar Land Rover, is positive about Greenpower and the future of sustainable manufacturing: »The next 30 years will see unprecedented change in the way we design, develop and construct motor vehicles. As our current graduates progress through their careers, they will be involved with a variety of powertrain solutions and materials. As a consequence, vehicle configuration will change, and our business carbon footprint will reduce dramatically. Their careers will be defined by the need to lower the environmental impact of motoring, and projects such as Greenpower are an essential step for the engineers of the future.« For more information on the event, please see: www.jaguarlandrovergreenpower.com The JLR-Greenpower-2009-team uture ung engineers The chassis made of Sapa extrusions. Driver Rebecca Lees focuses on the race strategy. HYDROFORMING Our starting point is an extruded aluminium profile. Hydroforming allows us to shape it three-dimensionally in a single operation. The process offers as yet unexplored possibilities. All, or parts, of a profile’s cross section can be tailored using hydroforming. In a single operation, complex parts can be created with excellent dimensional accuracy, and at the same time it is also possible to make local changes such as domes or holes. By eliminating several machining operations, lead times can be shortened. Hydroforming of aluminium profiles becomes a competitive choice at annual volumes of around 20,000 units upwards. The principle The profile is placed in a die that has an inner geometry exactly replicating the shape of the finished component. The die is locked securely in position and hydrostatic pressure is then set up in the pipe (profile). As the profile is pressed against the die, it takes on the shape of the die. The automotive industry – Research and series deliveries Since the end of the 90’s, along with Volvo and Ford, Sapa has been involved in research projects on, and prototype production of, vehicle side beams hydroformed from extruded aluminium profiles. Today, Sapa has world-leading and unique expertise and experience in the hydroforming of long aluminium beams. In the autumn of 2001, Sapa began series deliveries to Volvo. Profile design, dimensions and tolerances In discussions, Sapa has contributed advice in respect of a wide range of designs for, amongst others, the automotive, furniture, electronics and engineering industries. In design discussions, it has become clear that hydroforming opens the way to unique solutions for a wide range of design problems. It is not easy to give simple rules for profile design, dimensions and tolerances. Instead, why not contact Sapa’s hydroforming department in Vetlanda, Sweden, for further details. Example product: Side beam for a Space Frame Simulation, using the FE method, to study the critical points in the forming process. an om ts fr star n ctio rodu 1. P s goe g. in then ipe bend p he aw 2. T ugh dr thro The shaped component. Note the cross-sectional changes throughout its length . pipe inium m lu da ude extr Cross-sectional change so that the profile can fit into a narrow passage. In order to make a hole during the hydroforming process, a punch is included in the tooling. Punching extends process time by a few seconds nt. e only. The hole is precisely positioned and no further machining is required. n o p om dc e h s fini he 3. T The result – very good dimensional accuracy and exactly the geometry required by the product and production. ely xtrem e h t i sw uracy c x part c e l a p l na Com ensio m i d good Low weight – High strength Compared with traditional steel/plate bodies, hydroforming gives weight savings of around 50%. Equal strength and formability, but much lighter same, same – but different renc e. Sa me at m ot i pa utomotive.com sa r ve – r ea d m o e am ,s di f fe uto b ig Aluminium weighs a third of the equivalent amount of steel. This huge weight difference has a multitude of benefits. For example, when used in freight vehicles, your load capacity increases and at the same time fuel consumption decreases. This saves a significant amount of money over time, and contributes to a reduced impact on the environment. Using aluminium instead of steel gets to the same final result, but makes a e but different with Sapa A Inspection of a truck´s renewable opportunities. D R E L AIM D A RO S K C TRU W O SH A ! E B O T S S E S V E PRO E SUCC G U H On March 18th, Sapa Automotive, with support from Sapa North American Technical Center, successfully completed its first Road Show on site at the Daimler Trucks North America Headquarters in Portland, Oregon. The main goals of the Road Show were to: • increase the Daimler contact base • illustrate Sapa’s global capabilities • increase brand awareness • indentify key opportunities in converting steel parts into aluminum extruded solutions Inspiring presentation Sapa’s team helped to inspire around 65 Daimler’s product designers, engineers and purchasers of the possibilities that aluminum extrusions has to offer. We had brought over 40 automotive sample parts to help Daimler’s designers see the solutions that aluminum has to offer. The event was also a great opportunity for Sapa to present the CVM concept and market the upcoming USA Profile Academy! The day began with a 9:30am breakfast presentation followed by a lunch presentation and wrapped up with a late after- Some of all the sample parts presented. noon presentation. The majority of attendees showed up during the lunch presentation. During the day, many conversion opportunities were identified including converting battery box brackets as well as Turbo Air intake from steel to aluminum, air cylinder line brackets and the longitudinal cross beams. These are just a few of the opportunities identified. Conversion opportunities The Road Show proved to be a positive event to get closer to our customers, giving them lots of new ideas and inspiration for greater lightweight and cost effective design solutions. One of the presentations from Sapa. A solution tailored for the environment When the EU banned lead as an additive in aluminium alloys, a plant in Italy set out to find a substitute. »Creating an alloy mix is like tailoring a suit,« says Sergio Sannicolo, location manager for Sapa Profili s.r.l. in Bolzano, Italy. Just as custom suits are designed for the wearer, the hard alloys used in the aluminium profiles produced by the Bolzano plant have to be suited to specific client needs. Since the Bolzano plant specialises in profiles for automotive and industrial applications (largely hard alloy screw machine stock for mechanical, electrical and electronic equipment), the alloys it uses need to fit the requirements of those industries. colo recalls. Sapa would have preferred that the eu specifies a substitute alloy, but Brussels left it up to the market. So for the past several years Sapa has focused on developing a lead-free alloy that would retain lead’s desirable properties. After many months of research, the company developed an alloy of aluminium mixed with magnesium, silicon, copper, tin and bismuth. The additives, notably the tin and bismuth, mimic lead in that they enhance the characteristics of the alloy. A healthier alternative »The initial results were very good, just about as good as alloys with a lead additive, and the shaving problem was handled well,« says Sapa marketing analyst Claudio Del Furia. »Of course it’s not quite like Lead prohibitation Until recently, Sapa had used lead in its lead, but it is rather satisfactory and much healthier.« Once Sapa alloy mixes, because the had an alloy mix it addition of up to two thought might work, it percent lead helped enbegan testing the mix hance productivity in the with a German client in Creating an alloy manufacturing process. the automotive industry Lead reduced excess mix is like tailorto see how it actually metal shaving and ining a suit performed. The client creased speed and acwas so pleased that he curacy. But two has ordered 600 tonnes European Union regulaof the new alloy for tions passed by the European Parliament in 2002 and 2003, 2009, notes Sannicolo. coming into effect in 2006 and this year, essentially prohibited lead as an additive Strives for perfection in aluminium alloys. (Up to 0.4 percent »We would say that we have reached the lead is still acceptable, but only if it’s al- 80 percent mark in terms of a solution to the lead-free issue.« ready present in recycled aluminium.) Nevert heless , Sapa continues to work on the alloy to refine it. Research is ongoFocus on lead-free alloy »These edicts created significant prob- ing at the company’s research centre in lems for our industry,« Sanni- Sweden to reduce the waste from metal shavings, as well as improve quality control. Automotive processes are high speed In the a lumini and highly automated. If a metal is of infeum cyc the me le, rior quality, it threatens both the speed of tal can be reus output and the quality of the final product. for the ed same p »We should always be striving for perurpose over an fection, no?« says Sannicolo. do ver aga in. Unlike many o ther materia ls, alum inium does no t lose it s uniqu e propert ies. Sapa Automotive MAIN SPONSOR FOR AUTOSLOVAKIA09 Sapa Automotive has been sponsoring one of the largest Automotive conferences in Central Europe: AutoSlovakia09. The conference took place in Bratislava, Slovakia, the 25th and 26th of February 2009. The event gathered 75 delegates from the automotive industry among which representatives from PSA, KIA Motors, Volkswagen, Hyundai, Ford, Brose, Kongsberg Automotive, Johnson Controls, Visteon and Continental to name a few. Sapa exposed key products as well as documentation, displays and logotypes and participated in fruitful networking meetings. Brand knowleadge The conference covered topics such as local OEM sourcing strategies, strategies of growth, managing the relationship between OEM and suppliers, localisation vs regionalisation, networking roundtables, lean management, working with VW, cost management, supply chain optimisation, etc. This event was a key marketing activity to increase the brand knowledge of Sapa in Central Europe. One of the interesting messages we took with us is the fact that global OEM are looking for suppliers with both global footprint and local supply bases, which is one of the strength of Sapa. Related Links: www.autoslovakia.com Lorem ipsum dolor sit amet Lotus Evora THE EUROPEAN ALUMINIUM AWARD WINNER Lotus provides an automotive structure with a unique approach. They combined adhesive bonding techniques with mechanical joining resulting in innovative and creative solutions. The jury considered the design to be very innovative and versatile. Moreover the design is very courageous, and Lotus took quite a risk building this structure. Lotus used the expertise and know-how in lightweight materials to complete this structure, achieving a low weight and a high structural stiffness and therefore ensuring a major impact on environmental and sustainable performance. Lotus Lightweight Structures manufacture the chassis complete for Lotus cars. We su uniqu pply most finish e sections i of the Sapa long leng n millPr th (Har ofiles Neth from derwi erlan Light jk) to Lotu ds w s Struc eight tures. SOURCE: LOTUS CARS Lotus Evora wins the Overall Jury Prize of the European Aluminium Award competition 2008. The Jury awarded Lotus Evora to give special emphasis on the environmental and sustainable impact of lightweight constructions and products as represented in this ‘green sportscar’. The Overall Jury Prize was this year awarded to Lotus to give special emphasis on the environmental and sustainable impact of lightweight constructions and products as represented in this ‘green sportscar’. It has been demonstrated that vehicles offering excellent protection for occupants and vulnerable road users can be designed using aluminium. possible for full-aluminium vehicles or hybrid structures with safety-relevant aluminium parts. Succeeding in terms of safety is rather a matter of design and dimensioning than it is of the material. Several car models on the market show that it is possible for full-aluminium vehicles or hybrid structures with safety-relevant aluminium parts. In a statement by Univ.-Prof. Dr.-Ing. Stefan Gies, Head of the »Institut für Kraftfahrzeuge«, RWTH Aachen University, he said: »It has been demonstrated that vehicles offering excellent protection for occupants and vulnerable road users can be designed using aluminium. Several car models on the market and the examples in the presentations compiled by the European Aluminium Association show that this is For more information: www.aluminium-award.eu www.grouplotus.com/cars/home.html ment, then consumers’ misconception of heavy cars having safety benefits has to be put into perspective.« Further information: www.ika.rwth-aachen.de A weight issue At the end of the day, the materials used in cars will be determined by the costs per kg weight saved using a certain material and the strategy of the car manufacturer, i.e. how much the different OEMs are willing to pay for weight reduction. Consequently, the materials industry will be challenged to offer innovative solutions that enable further weight savings or open up options for lightweight cost reduction. Finally, if the cars of the future are to be comfortable and safe, as well as sustainable, as strongly demanded at the mo- Presentations compiled by the European Aluminium Association: aludrive@eaa.be APPLICATION CENTRE IN MUNICH Sapa Automotive Sapa Application Centre Leopoldstraße 244 D-80807 München www.sapaautomotive.com In Automotive´s quest to have a closer relationship with our customers, and to be nearer and more accessible, on April 1st we opened a new Application Centre in Munich. The office is centrally located in Munich, only two minutes from Highway A9, and 20 minutes from the airport. The office has two Application Engineers, Harald Krentzer and Sönke Holzkamm (see below). Sönke Ayk Holzkamm Harald Krenzer APPLICATION ENGINEER , GERMANY Harald is 38 years old and born in Fulda. He now lives outside Munich in Kirchheim with his family. He has worked for BMW and Hydro, both as a vehicle engineer and a project manager. He loves to spend his free time with his family, as well as running, cycling, hiking or skiing in the Alps. APPLICATION ENGINEER , GERMANY Sönke is 31 years old and he studied automotive engineering at the University of applied sciences in Hamburg before settling in Munich. He has designed rollover protection systems and wind guards for BMW before becoming a freelancer in the supplier business. He enjoys travelling, reading, socialising and long country walks. Andrew Tzang NEW BUSINESS SEGMENT MANAGER , CHINA Arnaud Blanchard KEY ACCOUNT MANAGER , FRANCE Arnaud is 42 years old and lives in Paris. He is married with three children. He started working as a Key Account Manager with Sapa Automotive in April. He has 15 years’ experience in the automotive industry, as a development engineer, project leader and salesperson. His main hobby is playing music in a band. Andrew has 13 years of experience in the automotive industry, eg trim product design, project management and dept. management, familiar with the molding technology, design and process solutions and manufacturing processes. He has been program manager and new product design for key OEMs as Tata, Chrysler, Chang´an Ford, Chery Porsche etc. Andrew is 35 years old and lives in Shanghai. He got married last year, and he and his wife would like to spend their holiday in Sweden. They love delicious dinners and to watch movies. Louis Jin KEY ACCOUNT MANAGER , CHINA Louis is 33 years old and lives in Shanghai, China. He has been working as a Key Account Manager with Sapa Automotive since January. He has nine years’ experience in the automotive industry and has previously worked as a designer at JCI and Autoliv. His interests include football and a love of history. Gary Diao APPLICATION ENGINEER , CHINA He is 31 years old, married, born in Hebei province. He majored in material foaming & control from Henan University of technology. FACTUM REKLAMBYRÅ Global total supplier HEAD OFFICE SAPA AUTOMOTIVE SALES OFFICES Sapa Automotive SE-574 81 Vetlanda Sweden Telephone +46 383 941 00 Fax +46 383 101 85 Sweden France United Kingdom Germany Poland The Netherlands For further information: www.sapaautomotive.com China USA RESPONSIBLE PUBLISHER LAURENT ANDRZEJEWSKI Sapa locations around the world