when ordering parts, be sure to state serial

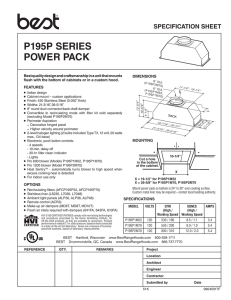

advertisement