ADDENDUM NO. TWO ROCK EAGLE SUTTON HALL

advertisement

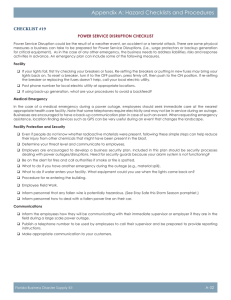

ADDENDUM NO. TWO ROCK EAGLE SUTTON HALL RENOVATION, PHASE II UNIVERSITY OF GEORGIA EATONTON, GEORGIA Bid 25019364 January 12, 2012 01. BID DATE The bid due date is hereby extended to January 24, 2012 at 2:00 pm legally prevailing time. 02. SPECIAL CONDITIONS A. ASBESTOS SURVEY REPORT: Report is expected to be available and issued by Addendum on January 16, 2012. The bid due date has been adjusted accordingly, as shown above. B. FIRE PROTECTION SPRINKLER SYSTEM: A fire hydrant flow test(s) dated December 22, 2009 by Gwinnett Sprinkler is provided. Bidders may assume new fire hydrant installed under this contract will have similar flow rates and pressures. Based on this test report, a fire pump is not required for the Sutton Hall fire protection sprinkler system. Bidders shall include in their Bid Proposal pricing for a complete fire protection sprinkler system for Sutton Hall based on the 2009 flow test report without a fire pump. C. SUBSTITUTION: Approved substitute product(s): 1. Specification Section 15740.2.7.C: Add Raywall, Model RCH Series Electric Ceiling Heaters as equal. 2. Specification Section 15800.2.2.A: Add ATCO, Model UPC #039 Flexible Ductwork as equal. 3. Contract Drawing Sheet M0-2: Add Pennbarry Model WCC Roof Mounted Hood as equal. 4. Contract Drawing Sheet P0-1: Add Noritz Model NRC199 series Tankless Water heater as equal. Reminder – Rock Eagle used LP Gas only. D. ADD: Technical Specification Section 16400 “Service and Distribution, pps 1-3 is added. E. CORRECTION: Note on Contract Drawing Sheet M1-2, Detail 1/M1-2 at the supply & return ductwork turndown in Gift Shop refers to AHU-2 and should read: “20x18 Supply and Return Ducts Drop Down in Chase to AHU-2 in Basement” Addendum Two - Page 1 of 3 Sutton Hall Renovation, Phase II Bid 25019364 F. RFI CLARIFICATION – ANTICIPATED START DATE: Based on past experience, and allowing 30 days after bid opening date for submission of contract documents, bonds, insurance & affidavits, the Owner anticipates a verbal Notice To Proceed (NTP) being issued on or about March 1, 2012. Pre-Commencement activities may begin prior to this date in accordance with General Conditions Section 2. Owner cannot guarantee early start date, but Sutton Hall will be available for start of work on or about March 1, 2012 if UGA Procurement Officer has issued a verbal NTP. G. RFI CLARIFICATION – ALLOWANCES: There are NO allowances or unit prices specified in this bid. Delete all references to Section 01019 to include references found in Section 01400.1.07.A; Section 01650.1.05.A; Section 02300.1.3.A; and Section 02300.1.3.B. H. RFI CLARIFICATION – ROCK EAGLE WATER DISTRIBUTION SYSTEM: The Rock Eagle water system is Owned & Operated by Rock Eagle under State EPD permit. Andy Smith is the licensed, system operator. All tests & inspections shall be witnessed & accepted by Rock Eagle. Delete paragraphs1.1B and 1.2.B, Section 02510 and all references to Athens Clarke County. I. RFI CLARIFICATION – UTILITIES: Existing water, power & LP gas utilities at Sutton Hall are not metered. Consequently, the Owner will furnish water, power & LP Gas at existing points and capacities at no cost to the Contractor. It is expected that the Contractor will be a good steward of these utilities and only use them for active construction activities (i.e. not leave the lights on all night or water running when not in use). J. RFI CLARIFICATION – ROLLER SHADES: Technical Specification, Section 12494 “Roller Shades” shall apply to Window Tab/Frame Types G, H, J & K as shown on Sheets A1-1 and A3-1 and as called for on Detail 1/A3-2 “New Motorized Shades w/Valance”. K. RFI CLARIFICATION – RIGID INSULATION: New 4” Foil Faced Rigid Insulation Board as shown & called for on Detail 1/A3-2 is to be installed in Assembly Room 103 and Assembly Room 104 only. L. RFI CLARIFICATION – CONCRETE DEMOLITION: Demolish the concrete floor slab(s) at the covered porches as shown & called for on Sheet C1.0 and install new concrete floors as shown & called for on Sheet C2.0. Covered porches are outside & adjacent to Vestibules 195G, C, F & H and Storage 103B & 104B. Replacement covered porch floors shall have even, smooth transition(s) with existing Sutton Hall finished floors and new sidewalks in compliance with Life Safety Code for emergency egress. New floor shall be installed in accordance with Detail A/C3.0. M. RFI CLARIFICATION – BOILER DEMOLITION: The Oil Fired, Steam Boiler shown in Detail 1/M1-3 may be dismantled and cut into small pieces prior to “Turn Addendum Two - Page 2 of 3 Sutton Hall Renovation, Phase II Bid 25019364 Over to Owner” as called for in Keyed Demolition Note 3. The Owner does not intend to re-use the boiler and is only interested in the scrap metal value of the boiler. N. RFI CLARIFICATION – AUDIO VISUAL SYSTEMS: A/V scope of work for this bid is limited to electrical rough-in. Contractor shall furnish & install wiring, conduit, boxes & devices as required to complete IWB (AV Interface Wall Box); PJ (Video Projector electrical junction box); and Projector Screen electrical junction box as shown & called for on A/V Drawings and electrical drawings, Sheet E-1. This contract work does NOT include any A/V equipment (i.e. No projector, screen, speakers or console) ALL BIDDERS MUST ACKNOWLEDGE RECEIPT OF ADDENDUM ON BID PROPOSAL FORM End of Addendum Addendum Two - Page 3 of 3 Sutton Hall Renovation, Phase II Bid 25019364 Report of Inspection/Test Annual Hydrant December 22, 2009 Property: UGA 4-H Center Owner: UGA 4-H Center Inspection Ref: 2570 Hydrant Flow Test Inspection Sutton Hall Sutton Hall Mueller 584N 2008 5¼ 2½ 70 50 1062 40 .90 Hydrant Location Make Model Year Size Outlet Size Static Pressure Residual Pressure Total GPM Pitot Pressure Discharge Coefficient Hydrant Inspection Sutton Hall Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes NA Yes Yes Yes Yes NA NA NA Is the hydrant wrench available and accessible? Free from ice or water in barrel ? Free from leaks or cracks at outlets and top of hydrants? Threads,outlets,caps & stem in good condition and lubricated? Pumper and nozzle caps are slightly more than hand tight? Exposed piping is properly secured and free from leaks or physical damage? Is paint in good condition? Operating nut not worn, twisted or broken? Operating nut turns without difficulty? Road box and shutoff valve is visible and accessible? Hydrant flowed until clear (min 1 Minute)? Dry Barrels drain in at least 1 hour? Dry barrels requiring pumping are identified? Control valves operated through full range? Hydrant shuts off completely? Strainers, if installed, not blocked and corrosion free? Strainers cleaned (if possible)? Monitor nozzles moved through full range? Monitor nozzle flowed acceptable water? Monitor nozzle lubricated? Hydrant Flow Test Inspection Cabin 19 Cabin 19 Mueller 584N 2008 5¼ 2½ 70 52 1062 40 .90 Print Hydrant Location Make Model Year Size Outlet Size Static Pressure Residual Pressure Total GPM Pitot Pressure Discharge Coefficient 12/23/2009 (All "NO" answers are to be fully explained.) Copywrite 2002-5 Life Safety Inspector, OnSite Software, Inc. Page 2 of 3 ROCK EAGLE – SUTTON HALL, PHASE 2 MENEFEE ARCHITECTURE SERVICE AND DISTRIBUTION 16400 SECTION 16400 – SERVICE AND DISTRIBUTION 1.0 GENERAL 1.1 RELATED DOCUMENTS: 1.2 A. The General and Supplementary Conditions, and General Requirements (Division 1), apply to the work specified in this Section. A. APPARATUS: A. All apparatus and equipment specified hereinafter in this Section Fully conform to current standards of NEMA to the extent applicable to each type and class of equipment and apparatus described; and individually bear the seal of the Underwriter’s Laboratories. B. To the maximum extent feasible, all such apparatus and material shall be of one and the same manufacturer. C. The type, classes, and catalog numbers hereinafter stated, and employed are to establish the class and quality of apparatus and equipment required for this work. In general, all catalog numbers given are Square “D” Company; however, apparatus and equipment effectively equal in all respects to that described as manufactured by General Electric, Westinghouse, Siemens/ITE, or Cutler Hammer shall be acceptable. 2.0 PRODUCTS 2.1 PANELBOARDS: A. Panelboards shall be of the automatic circuit breaker type, factory assembled by the manufacturer of the circuit breakers. Panelboards shall be new and the manufacturer’s latest standard catalogued design. Panelboards shall be the product of the same manufacturer as the cabinets and shall bear UL labels. B. Panelboards shall be for service voltage with number of branch circuits of capacity scheduled. Unless otherwise indicated, panels and sections thereof shall have main lugs only of capacity equal to or greater than the rating or setting of the over current protective device next back on line. C. Panelboard Boxes shall be constructed of code gauge steel, 20” minimum width by 5-3/4” deep. Panels having through feed shall have 8” bottom and side gutters. D. Panelboard trims shall be flush or surface type as scheduled on the plans, constructed of code gauge steel, finished with rust inhibitings prime coat and baked enamel finish. Trims to be complete with indicating adjustable trim clamps, door with chromium plated combination cylinder lock and catch, and directory of glass or clear plastic. All locks shall be keyed alike. Directory to be type-written with spares indicated in pencil. All panel trims shall have an angle bracket welded to the back near bottom to support the weight of the trim. Trims exceeding 48” in height shall vault handle and three point latch system. The trims on all flush mounted 20” Project 201117 Page 1 ROCK EAGLE – SUTTON HALL, PHASE 2 MENEFEE ARCHITECTURE SERVICE AND DISTRIBUTION 16400 wide panels shall have trim clamps and hinges concealed when the door is closed. Trims shall not be removable with the door in the locked position. Trims shall have door-in-door access. 2.2 2.3 E. Circuit breakers shall be thermal and magnetic molded case type quick-make and quick-break bolt on manual and on automatic operation. Breakers shall be of the over-the-center toggle operating type, with the handle going to a position between “ON” and and “OFF” to indicate automatic tripping. All multi-pole breakers shall have internal common trip, and have all load side connectors of the same gutter. Breaker shall be bolton type. F. 208/120 volt, 3 phase, 4 wire panelboards shall be square “D” type NQOD, or approved equal. Circuit breakers in panelboards shall have interrupting capacity as scheduled. Breakers intended to interrupt more than 5,000 amperes shall be labeled to conform to N.E.C. Article 240-83 ( c ). Circuit breakers used as switches for lighting circuits shall be approved for such switching duty. Low voltage panels shall have main breakers as scheduled on the drawings. Panelboard bussing shall be silver-plated copper. No aluminum allowed. G. Special panelboard arrangements shall be provided as indicated on the drawings. DISCONNECT SWITCHES: A. Sub-feeder switches and disconnect switches shall be “HeavyDuty” rated, except as otherwise noted, and in damp locations or exposed to the weather shall be NEMA 3R (Raintight). Disconnect switches shall be horsepower rated for the motor or load actually installed. B. Disconnect switches for single phase motors sized 1 horsepower and below shall be Square “D” No. KG-1 for dry locations and No. KW-1 for damp locations or where the switch will be exposed to the weather. C. All disconnect switches shall have factory installed provisions for padlocking in either the “ON” or “OFF” position. D. Unless otherwise noted, disconnect switches shall be of the same manufacture as the main switchboard and panelboards. E. All switches shall have nameplates as specified in another Section of this specification. PADLOCKS: A. Provide two (2) forged brass padlocks on all fused and non-fused disconnect switches located outside of the building. One lock shall be used to lock the switch door to prevent unauthorized opening, and the other shall be used to lock switch in the “OFF” or “ON” position. B. Padlocks shall be pull-on operation, five-pin tumblers, similar and Equal to Yale and Towne Manufacturing Company No. 830. All locks shall be keyed alike. Furnish two (2) keys for each lock. Project 201117 Page 2 ROCK EAGLE – SUTTON HALL, PHASE 2 MENEFEE ARCHITECTURE 2.4 SERVICE AND DISTRIBUTION 16400 FUSES: A. Provide all fuses. All fuses shall be of the same manufacturer. All fuses shall be of the high interrupting rating, current limiting type and manufactured by Bussman or Gould-Shawmut. Fuses shall be provided for each fuse cutout and the specified quantity of fuses shall be furnished for spares. B. Circuits 0 to 600 ampere shall be protected by rejection type, current limiting BUSSMAN LOWPEAK Dual Element Fuses LPN-RK (250 volts) or LPS-RK (600 volts). All dual-element fuses will have separate over-load and short –circuit elements. Fuse shall incorporate element having a 284 degree F. melting point alloy and shall be independent of the short-circuit clearing chamber. The fuse must hold 500% of rated current for a minimum of 10 seconds and be listed by Underwriters Laboratories Inc., with an interrupting rating of 100,000 amperes RMS symmetrical. The fuses shall be UL Class RK-1. D. E. 2.5 Spare fuses: Provide and turn over to the Owner or Owner’s representative a minimum of one (1) set of spare fuses (set consisting of three fuses) for each type and rating of fuses installed. When the number installed exceeds five (5) sets, provide an additional spare set of fuses for each five (5) or fraction thereof. Provide a cabinet in which to store all spare fuses. Bussman Catalog No. SFC. EQUIPMENT ANCHORING: A. Time switches for the control of lighting and other circuits as shown shall have number of poles, throws, and Ampere ratings as indicated. Units shall be driven by synchronous motor and furnished with 7 day astronomic dials. Dials shall be provided with sufficient operators for “ON-OFF” operation as shown. Units shall be provided with proper enclosure for surface or flush installation as shown, or shall be mounted within the panel, controlled as permitted by codes. Where time switches are used in conjunction with contactors, or relays, they shall be properly coordinated, furnishing all necessary miscellaneous appurtenances as required for proper operation. All such time switches shall be furnished with manual override. .0 EXECUTION 3.1 INSTALLATION: A. Shop drawings shall indicate that all of the function requirements of the specifications have been met. In addition, the UL approved RMS symmetrical interrupting capacity shall be indicated for each circuit breaker, and a certification that these are UL ratings shall be attached. END OF SECTION Project 201117 Page 3