simulation of internal short circuits in lithium-ion

advertisement

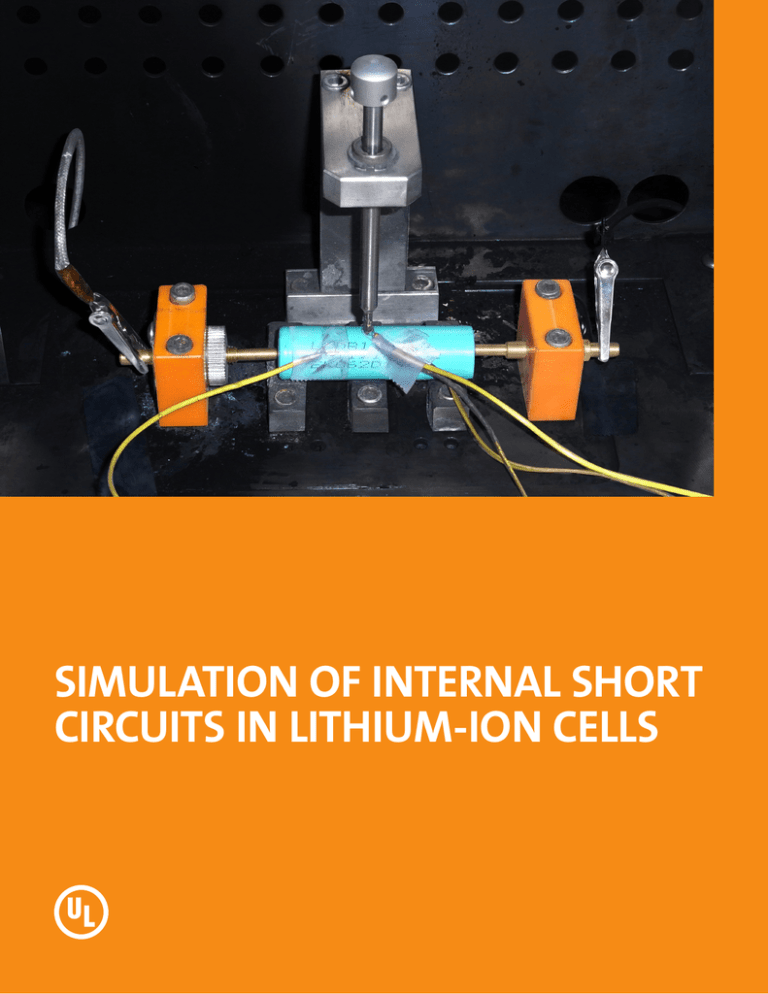

SIMULATION OF INTERNAL SHORT CIRCUITS IN LITHIUM-ION CELLS Simulation of Internal Short Circuits in Lithium-Ion Cells Simulation of Internal Short Circuits in Lithium-Ion Cells Abstract Understanding the root causes and mitigating the safety hazards associated with internal short circuits in lithium-ion cells is an active area of research and a needed White Paper by Alvin Wu update for battery safety standards. For battery safety standards, there is a need for a Mahmood Tabaddor, PhD safety performance of lithium-ion cells under the conditions of an internal short circuit. Judith Jeevarajan,1 PhD practical, safe and reliable test method for battery safety standards that can assess the In this paper, we provide details of a proposed test method which relies on external, localized indentation of cell casing to induce an internal fault that might simulate some field failures. Carl Wang, PhD Corporate Research, UL LLC 1 NASA Johnson Space Center Introduction Lithium-ion cells have been powering a wide range of electrical and electronic devices from consumer products and medical equipment to automotive systems and space applications. However, some highly publicized failures of products powered by lithium-ion cells, such as laptops and electronic toys, have been reported.2 In some instances, a large number of products have been recalled. A portion of these failures has been linked to overheating of the battery resulting in fire and explosion. Fires on some cargo planes carrying bulk shipments of lithium-ion cells have regulators (United Nations and Federal Aviation Authority in the US) concerned about safe handling procedures.3 Insurance companies have funded research to support fire protection strategies for bulk storage of lithium-ion batteries.1 Finally, the most recent and publicized fire incidents involving a GM Volt and two Boeing 787 airplanes, have brought this technology under intense governmental scrutiny. Overall, these incidents have catalyzed a great deal of research and design activities aimed at trying to understand the causes of such failures and help guide safer cell designs. 4 Though the lithium-ion cell is designed with integrated passive safeguards (and active safeguards in the case of pack designs), the sheer number of lithium-ion cells, the complexity of the cell electrochemistry, and the numerous usage conditions present challenges not only to the design of safe cells, but to the design of tests for battery safety standards. Moreover, lithium-ion cells are not only being used in small numbers to power an individual hand-held device, but many thousands of these commercial, off-the-shelf (COTS) cells are packaged together (with monitoring systems) to power electric vehicles and even spacecraft. In some cases, such as transportation, page 2 Photo Simulation of Internal Short Circuits in Lithium-Ion Cells customized lithium-ion cells are being designed and employed where field usage history, which exists for COTS, is not available yet. Considering the effort in understanding and mitigating the failure of a single cell, these challenges are likely to increase manyfold for modules/packs. The ability to access and translate the results of battery safety research and field failure information into a consensus-based safety standard is a challenge that can only be addressed through open cooperation between governmental research organizations, cell manufacturers, safety stakeholders, and standards organizations. In this paper, we describe one promising new internal short circuit simulation method that is being developed for battery safety standards by UL through such a cooperative approach with other battery research organizations. Lithium-Ion Cells Batteries basically convert chemical Basics of Cell Operation energy into electrical energy during (secondary) lithium-ion batteries (redox) reactions. For lithium-ion cells, lithium batteries are not. The main is generated by the migration of lithium-ion cell are the cathode, anode, battery is cycled, these lithium cations The electrochemically active materials active electrode materials. Specifically, oxide (such as LiCoO2) for the cathode anode during a charging condition materials are each bound to a metal foil discharging condition. Electrons travel via electrodes are electrically isolated from equilibrate charge difference between film within a non-aqueous electrolyte. current.6 In the terminology of batteries, discharge through oxidation/reduction are rechargeable while (primary) the current between the electrodes electrochemical components of a positively charged lithium-ions. As a separator and electrolyte (Figure 1). are inserted into or extracted from the for the electrodes are a lithium metal lithium-ions, travel from cathode to and graphitic carbon for the anode. These and in the reverse direction during a current collector through a binder. The external circuitry driven by a load to help one another by a micro-porous separator the electrodes thereby generating a The electrolyte allows only for transfer of ions and can be liquid, gel, polymer, or solid (such as ceramic). Research into the safety of lithium-ion cells has been ongoing for over a decade while battery safety standards have been in existence for even longer. Since lithium-ion cells bring together highly energetic materials in contact with a flammable electrolyte, when exposed to many different abuse conditions (vibration, high-temperature environments, crushing, etc.), the initiation of heat-generating reactions which can lead to fire and explosion are a concern. For that reason, the core tests within consensus-based battery safety standards, such as UL 16427 and IEC 62133,8 subject cells to anticipated abuse conditions. Cells are designed with integrated passive safety features such as a circuit interrupt device, a pressure Figure 1: Components of a cylindrical lithium-ion cell (left), and, discharging mechanism for lithium-ion cell (right) 5 vent and/or shutdown separator to help mitigate an over-current condition or excessive pressure buildup within the cell.9 However, such features cannot address all potential abuse conditions. In page 3 Simulation of Internal Short Circuits in Lithium-Ion Cells addition, cell designers and researchers Though only brief accounts of field When portions of the cell affected by options for improving cell safety, such as the presence of manufacturing defects (generally above 120°C), exothermic have been investigating a range of cell chemistries, including less reactive materials for anode, cathode, and/ or electrolyte, without compromising performance. Nevertheless, field failures have been recorded involving explosive release of energy along with fire. There have been some ideas on the underlying initiators for such failures, known as thermal runaway, in cells. One source describes some causes of internal cell faults leading to field failures: contamination, electrode damage, mechanical damage, and thermal abuse.10 Internal Short Circuits (ISC) A review of the publicly available lithium-ion battery research shows a strong focus on understanding and mitigating cell failure modes, specifically those due to internal short circuits. 18 page 4 failures are available, in some cases, has been noted to lead to internal short circuits within the cell. A particle, depending upon its size and morphology, may pierce the separator allowing for direct contact between electrodes (internal short circuit). There is also the possibility that the over-charge or over-voltage subjection of lithium-ion cells causes the formation of lithium dendrites -- small, thin, crystal,needle- like structures -- which may eventually puncture the separator leading to an ISC.11 joule heating reach certain temperatures reactions between the active electrode materials and the electrolyte are initiated. Depending upon the ability of the cell to dissipate the heat, the heat generated may continue to sustain these exothermic reactions with a rapid increase in the temperature of and pressure within the cell (thermal runaway).12 In cases, where the pressure buildup is relieved via the safety vent, then expulsion of the contents is still a chemical hazard. However, once an ISC is established, a The combined high pressure and lower the cell. This is termed joule heating and temperatures can compromise the integrity depends upon the internal resistance of volatile gases, which may further ignite. The along with other factors as shown in the lead to ignition of nearby flammable localized heat source is generated within modulus of the casing due to high the extent of the heat produced locally of the casing leading to explosive release of the cell and state of charge (current flow) high temperature of the cells could certainly figure below. objects. In the case of battery packs (or Simulation of Internal Short Circuits in Lithium-Ion Cells bundles of lithium-ion cells), the highly manner. For example, the number of battery safety standards such as UL 1642 a condition where one cell failure could prior to testing may vary. However, a fast-changing pace of lithium-ion cell dense configuration of the cells creates spread to adjacent cells without proper external battery thermal management. Battery Safety Standards Battery safety standards contain a menu of abuse tests. Table 1 shows the extent of harmonization of some major safety samples and the state of sample charge review of international safety standards related to lithium-ion cells reveals that, despite harmonization across a large number of abuse tests, only a few are considering the inclusion of specially designed internal short circuit tests.13 standards for batteries. Though it should As product recalls undermine public procedures in the various standards, the the safe commercialization of lithium-ion be noted that for similarly named test confidence, it is imperative to promote test details may not be strictly identical cells by ensuring that consensus-based Table 1: Survey of international battery safety standard abuse tests page 5 and IEC 62133 effectively capture the safety and design knowledge. Therefore, the key activity for the safety standards for lithium-ion cells is the development of an internal short circuit test suitable for such standards. Quite often research-level testing cannot meet the best-practices requirements for acceptable safety tests for standards. In addition, the challenges associated with the myriad possible root causes for Simulation of Internal Short Circuits in Lithium-Ion Cells an ISC and the various configurations of Currently, there are only two new Generally, the disassembly of a cell is and pouch) and multi-cell (module/ (ISC) tests, which are either under in safety standards, especially, as this lithium-ion cells (cylindrical, prismatic, pack) configurations may preclude the possibility of a single ISC-specific safety test. A review of publicly available ISC tests (Figure 2) shows that most require either access to the cell during manufacturing to insert a particle (FISC test), compromise integrity of casing 14 (ITRI test) or rely upon disassembly of a production cell to insert a particle (SNL test).19 Figure 2: List of ISC tests for lithium-ion cells page 6 simulated internal short circuits consideration or part of some consensus-based standards. One is the Forced Internal Short Circuit (FISC) test and the other is based on an indentationtype approach. The FISC requires the disassembly of the cell with testing being conducted on the jelly-roll (cell internals without the casing) making it useful mainly for research studies. not considered a best practice for tests operation for a lithium-ion cell involves a hazardous condition. Instead, we have chosen an approach that will be called an Indentation Induced ISC test. This test is based on a history of indentation type testing by UL in collaboration with NASA 15, 16 and more recently with Oak Ridge National Laboratory (ORNL),20 with the intention of bringing the best ideas into a single ISC test method. Simulation of Internal Short Circuits in Lithium-Ion Cells Indentation Induced ISC Test Indentation testing evolved from previous methods that depended upon an object either penetrating (nail penetration test) or crushing (rod circumference crush test) the cell.17 In the penetration approach, there is little deformation of the cell, however, the nail acts as a bridge generating an ISC that is not localized. The breach of the casing also dissipates any hazardous pressure buildup. For Figure 3: Pictures of Indentation Induced ISC test for cylindrical lithium-ion cells the rod circumference crush test, the deformations of the cell are large and generally the safety mechanisms relieve the pressure. Of course, both these may be necessary if they match abuse conditions that the cell can be subjected to in the field. However, neither generates the localized ISC within a closed cell that is considered to simulate the field failures noted previously. The current Indentation Induced ISC test setup for cylindrical lithium-ion cells is shown in Figure 3. The cell is placed in a holder that prevents rotation or translation of the cell. An indenter with Figure 4: CT scan images of cylindrical lithium-ion cell prior to testing (left) and single CT scan image of cell after indentation (right) a smooth profile presses from above against the cell casing at a constant speed (0.01 – 0.1 mm/s). Test measurements include temperature of the casing surface at a point near the indentation site, distance traveled by indenter (amount of cell casing deflection), applied force through indenter, and open circuit voltage. The cells can be at different states of charge (SOC) or stages of aging. This entire setup is placed within a chamber that allows for control of ambient temperature. As the indenter presses against the casing, layers of separator, anode page 7 and cathode immediately below the voltage (100-500 mV), there is a rapid localized high curvature (Figure 4). The high as 700°C) with an outcome involving indentation region are deformed due to resulting high stress/strain will lead to a mechanical failure of the separator allowing for direct contact between increase in cell surface temperature (as explosive release of gases and flames (Figure 7). electrodes at a distance only a few layers Now the typical risk measure consists Though this mechanical event cannot be probability of failure. In forcing a failure, the effect of the separator failure is a measuring the severity of cell failure. This (Figure 6). For some cells, seconds after NASA in screening of COTS rechargeable below the casing surface (Figure 5). of severity of failure multiplied by observed and documented in real time, the Indentation Type ISC test is basically sudden drop in the open circuit voltage approach is one that has been adopted by a measured drop in the open circuit batteries for space applications. Cells that Simulation of Internal Short Circuits in Lithium-Ion Cells Figure 5: CT scan image of cell showing breakdown of layers directly below indentation region Figure 6: Measurements taken during the indentation test for a cell undergoing thermal runaway Figure 7: Picture of cells experiencing thermal runaway (left) and one example of explosive failure of a lithium-ion cell during indentation test (right) page 8 Simulation of Internal Short Circuits in Lithium-Ion Cells do not perform well under this type of apparent. This hole has been measured cells subjected to this indentation type stringent secondary testing schedule that SOC, some localized heating is apparent. performance (observed severity of failure) test would then be subjected to a more might help establish the probability of ISC cell failure. Though the method does not rely on a particle-induced defect of the separator, the key question is whether the damage to have a radius of 1-2 mm. For the 50% It was also determined that the puncture penetrated several layers, again a feature of the internal short circuit expected for particle-related field failures. These ISC test shows a correlation between test to energy density, thermal stability of active materials, material changes (such as STOBA in Figure 9), and chemistry of the cell. observations strongly suggest that the Other Form Factors conditions that might be representative has been modified to test prismatic test method is suitable for simulating ISC The UL indentation test for ISC simulation of field failures for lithium-ion cells. and pouch cells. The main challenge for inside, the test was run on a cell at 0% Aside from simulating an internal short of puncturing the soft casing, especially the cell that would make measurements the relevant design changes that might to the separator is similar to that might be expected in field failures involving particles. To determine what is happening and 50% SOC to help reduce damage to impossible. Figure 8 shows the layers within the cell where a puncture is Figure 8: Cell windings subjected to indentation under 0% SOC (top pictures) and 50% SOC (bottom pictures) page 9 circuit, the test should be sensitive to affect the resulting ISC performance. To date, an analysis of results from many pouch cells is the expected inevitability when it inflates due to outgassing from exothermic reactions set off by the ISC. However, the trends in the data are very similar to those for cylindrical cells. Figure 9: Data from 18650 type NMC (1950 mAh) cell without STOBA (top) and with STOBA (bottom) Simulation of Internal Short Circuits in Lithium-Ion Cells Summary Lithium-ion cells are expected to be a dominant portable energy/power source for electrical and electronic devices for the near future. However, the energetic nature of the active materials within a lithium-ion cell presents safety challenges. One of these challenges is insight into thermal runaway within a cell believed to be responsible for field failures over the last few years. As this research is ongoing, it presents a further challenge to new test development for battery safety standards. Considering the effort in understanding and mitigating the failure of a single cell, these challenges are likely to be increased manyfold for battery modules and packs. For example, one commercially available electric vehicle contains over 6,000 cylindrical (18650) lithium-ion cells. As this is a very challenging area, an open and cooperative dialogue to share information on the failure modes of lithium-ion cells and to help develop ISC test(s) for consensus-based safety standards is ever-more important. With the expected growth in using COTS for a variety of applications, it is important the regardless of how the OEM may choose to subject the cells to further in-house testing incoming cells be certified according to a suite of comprehensive abuse tests. This approach is taken by NASA, whereby they select certified COTS cells and still subject the cells to their space application-specific testing. Even if the cell is customized for an application, subjecting the cell to tests prescribed by safety standards (possibly with some modifications) could help filter and rank different designs and provide greater confidence in safe field performance over the expected life of the battery system. Acknowledgments The authors would like to acknowledge the tremendous support given by Dr. Hsin Wang (ORNL). page 10 Simulation of Internal Short Circuits in Lithium-Ion Cells References 1 Mikolajczak, C., et al., Lithium-ion Batteries Hazard and Use Assessment, FPRF report, July 2011. 2 Fire Hazard Causes Dell to Recall Laptop Batteries, Washington Post, August 15, 2006. 3 Stroller, G., Are lithium-ion batteries the next threat to airline safety? USA Today, 8/16/2010. 4 Balakrishnan, P.G., Safety Mechanisms in Lithium-ion Batteries, Journal of Power Sources, 155, 2006. 5 Brain, M., How Lithium-ion Batteries work, www.howstuffworks.com. 6 Jacobi, W., Lithium Batteries: The Latest Variant of Portable Electrical Energy, Battery Technology Handbook, 2003. 7 UL 1642 Lithium Batteries, Underwriters Laboratories Inc., 4th Edition, September 19, 2005. 8 IEC 62133, Secondary cells and batteries, International Electrotechnical Commission, 1st Edition, 2002. 9 Yen, K.H., et al., Estimation of Explosive Pressure for Abused Lithium-Ion Cells, 44th Power Sources Conference, 2010. 10 Jeevarajan, J., Safety Limitations Associated with Commercial 18650 Lithium-ion Cells, Battery Safety Conference, 2010. 11 Smart, M.C., et al., On the possibility of lithium plating in a Li-ion cell under strenuous charge conditions, Pacific Rim Meeting on Electrochemical and Solid State Science, 2008. 12 Kim, G.H., Analysis of Heat Dissipation in Li-Ion Cells & Modules for Modeling of Thermal Runaway, 3rd International Symposium on Large Lithium-ion Battery Technology and Application, 2007. 13 Jones, H., et al., Critical Review of Commercial Secondary Lithium-Ion Battery Safety Standards, 4th IAASS Conference, Making Safety Matter, 2010. 14 Activities for Safety of Li-ion batteries, Battery Association of Japan presentation at PRBA, 2008. 15 Wu, A., et al., Blunt Nail Crush Internal Short Circuit Lithium-Ion Cell Test Method, NASA Battery Workshop, 2009. 16 Jeevarajan, J., Determination of Tolerance to Internal Short Circuits and Its Screening in Lithium-ion Cells, NASA-JSC Method, NASA Battery Workshop, 2008. 17 Mikolajczak C.J., et al., A scientific methodology for investigation of a lithium-ion battery failure, IEEE Portable 2007 International Conference on Portable Information Devices, IEEE No. 1-4244-1039-8/07, Orlando, FL, March 2007. 18 Barnett, B., et al., Lithium-Ion Battery Safety, in Batteries for Sustainability, Springer, 2013. 19 Orendorff, C.J., et al., Experimental Triggers for Internal Short Circuits in Lithium-ion Cells, Journal of Power Sources, Vol. 196, Issue 15, 2011. 20 Cai, W., et al., Experimental Simulation of Internal Short Circuit in Li-ion and Li-ion-polymer cells, Journal of Power Sources, Vol. 196, Issue 28, 2011. 21 Wu, S.W., et al, The Study of Safety Test for Internal Short Circuit in Lithium-ion Battery, www.materialsnet.tw, 2012. 22 Peng, A., et al., Li-ion Battery with High Safety STOBA Technology Inside, the 25th World Battery, Hybrid and Fuel Cell Electric Vehicle Symposium, China, Nov. 2010. UL and the UL logo are trademarks of UL LLC © 2013. No part of this document may be copied or distributed without the prior written consent of UL LLC 2013. page 11