1.8 MVSAT.pmd - SatCom Logistics

advertisement

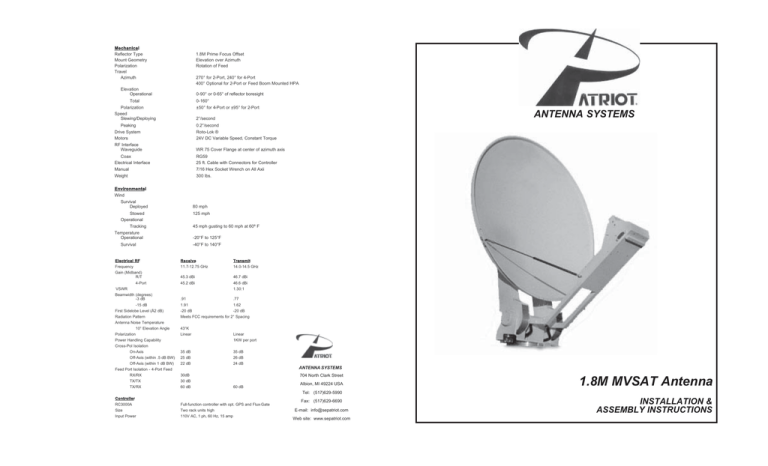

Mechanical Reflector Type Mount Geometry Polarization Travel Azimuth 1.8M Prime Focus Offset Elevation over Azimuth Rotation of Feed 270° for 2-Port, 240° for 4-Port 400° Optional for 2-Port or Feed Boom Mounted HPA Elevation Operational 0-90° or 0-65° of reflector boresight Total 0-160° Polarization Speed Slewing/Deploying ±50° for 4-Port or ±95° for 2-Port ANTENNA SYSTEMS 2°/second Peaking 0.2°/second Drive System Motors Roto-Lok ® 24V DC Variable Speed, Constant Torque RF Interface Waveguide WR 75 Cover Flange at center of azimuth axis Coax RG59 Electrical Interface 25 ft. Cable with Connectors for Controller Manual Weight 7/16 Hex Socket Wrench on All Axii 300 lbs. Environmental Wind Survival Deployed 80 mph Stowed Operational Tracking Temperature Operational 125 mph 45 mph gusting to 60 mph at 60º F -20°F to 125°F Survival -40°F to 140°F Electrical RF Receive Transmit Frequency Gain (Midband) R/T 11.7-12.75 GHz 14.0-14.5 GHz 45.3 dBi 46.7 dBi 45.2 dBi 46.6 dBi 1.30:1 .91 .77 4-Port VSWR Beamwidth (degrees) -3 dB -15 dB First Sidelobe Level (Å2 dB) Radiation Pattern Antenna Noise Temperature 10° Elevation Angle Polarization Power Handling Capability Cross-Pol Isolation On-Axis Off-Axis (within .5 dB BW) Off-Axis (within 1 dB BW) Feed Port Isolation - 4-Port Feed RX/RX TX/TX TX/RX 1.91 1.62 -20 dB -20 dB Meets FCC requirements for 2° Spacing 43°K Linear 35 dB 25 dB 22 dB Linear 1KW per port 35 dB 26 dB 24 dB ANTENNA SYSTEMS 704 North Clark Street 30dB 30 dB 60 dB 60 dB Albion, MI 49224 USA 1.8M MVSAT Antenna Tel: (517)629-5990 Controller RC3000A Full-function controller with opt. GPS and Flux-Gate Size Input Power Two rack units high 110V AC, 1 ph, 60 Hz, 15 amp Fax: (517)629-6690 E-mail: info@sepatriot.com Web site: www.sepatriot.com INSTALLATION & ASSEMBLY INSTRUCTIONS LIMITED TWELVE (12) MONTH WARRANTY This PATRIOT ANTENNA equipment is warranted to be free from defects in material and workmanship under normal use and service. PATRIOT ANTENNA shall repair or replace defective equipment, at no charge, or at its option, refund the purchase price, if the equipment is returned to PATRIOT ANTENNA not more than twelve (12) months after shipment. Removal or reinstallation of equipment and its transportation shall not be at cost of PATRIOT ANTENNA except PATRIOT ANTENNA shall return repaired or replaced equipment freight prepaid. This Warranty shall not apply to equipment which has been repaired or altered in any way so as to affect its stability or durability, or which has been subject to misuse, negligence or accident. This Warranty does not cover equipment which has been impaired by severe weather conditions such as excessive wind, ice, storms, lightning, or other natural occurrences over which PATRIOT ANTENNA has no control, and this Warranty shall not apply to equipment which has been operated or installed other than in accordance with the instructions furnished by PATRIOT ANTENNA. Claimants under this Warranty shall present their claims along with the defective equipment to PATRIOT ANTENNA immediately upon failure. Non-compliance with any part of this claim procedure may invalidate this warranty in whole or in part. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER AGREEMENTS AND WARRANTIES, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE IS LIMITED IN DURATION TO THE DURATION OF THIS WARRANTY. PATRIOT ANTENNA DOES NOT AUTHORIZE ANY PERSON TO ASSUME FOR IT THE OBLIGATIONS CONTAINED IN THIS WARRANTY AND PATRIOT ANTENNA NEITHER ASSUMES NOR AUTHORIZES ANY REPRESENTATIVE OR OTHER PERSON TO ASSUME FOR IT ANY OTHER LIABILITY IN CONNECTION WITH THE EQUIPMENT DELIVERED OR PROVIDED. IN NO EVENT SHALL PATRIOT ANTENNA BE LIABLE FOR ANY LOSS OF PROFITS, LOSS OF USE, INTERRUPTION OF BUSINESS, OR INDIRECT, SPECIAL OR CONSEQUENTIAL DAMAGES OF ANY KIND. In no event shall PATRIOT ANTENNA be liable for damages in an amount greater than the purchase price of the equipment. Some states do not allow limitations on how long an implied warranty lasts, or allow the exclusion or limitation of incidental or consequential damages, so the above limitations or exclusions may not apply to you. PATRIOT ANTENNA has the right to void the warranty when the antenna is installed by someone other then a certified installer. Product Serial Number- _________________ Date Purchased- ____________ 2 704 North Clark Street Albion, MI 49224 USA Tel: (517)629-5990 Fax: (517)629-6690 E-mail: info@sepatriot.com Patriot Antenna Systems 23 Check oil level in gearbox. Use of WARNINGS, CAUTIONS, NOTES, etc. Remove cable termination, block covers, and inspect cable terminations. Tighten springs if more than .010 gap exists. Inspect azimuth stow limit switch. Remove azimuth potentiometer cover and inspect azimuth potentiometer. Check that all azimuth bearing flat head screws, azimuth gear box bolts, azimuth potentiometr, etc. are tight. Warnings, Cautions, and Notes are included throughout this manual to provide necessary information. THEY SHOULD NOT BE IGNORED. You should know the use of WARNINGS, CAUTIONS, NOTES, and other markings. Definitions are: Warnings! Highlights an installation, operating or maintenance procedure, practice, condition, statement, etc., which, if not strictly observed, could result in injury to or death of personnel. Caution! Highlights an installation, operating or maintenance procedure, practice, condition, statement, etc., which if not strictly observed, could result in damage or destruction of equipmen t or the loss of mission effectiveness or long term health hazards to personnel. Note: Highlights an essential installation, operating or maintenance procedure, condition, or statement. ESD: The Electrostatic Sensitive Device (ESD) appears at the beginning of any procedure or procedural step that includes the handling of equipment sensitive to damage from electrostatic discharge. Elevation Handcrank in elevation. Unit should handcrank with approximately 50-100 in-lbs. torque. Check for unusual noise in elevation pivot bearings and elevation gearbox. Run in elevation and check for unusual noise in elevation motor. Run to up limit. Check tracking of elevation drive cables. General Warnings and Cautions are also provided at the front of the manual. These warnings and cautions should be read by anyone who is involved with installation, has access to the equipment, or is assigned to perform maintenance on the equipment. Check drive cables for damage. Check for excessive backlash in gear box. Check that anti-backlash hubs are tight. Check oil level in gearbox. Remove cable termination block covers and inspect cable terminations. Tighten springs if more than .010 gap between sets of springs exists. CAUTIONARY NOTICE Although the manufacturer has attempted to detail in this manual all areas of possible danger to personnel in connection with the use of this equipment, personnel should use caution when installing, operating, and servicing this equipment. Care should be taken to avoid electrical shock, whether the hazard is caused by design or malfunction. The manufacturer is specifically not liable for any damage or injury arising from the technician=s failure to follow the instructions contained in this manual or his failure to exercise due care and caution in the installation, operation, and service of this equipment. CAUTIONARY NOTICE Polarization Run in polarization and check for unusual noise in polarization motor. The antenna and feed system supplied by AvL Technologies is designed to be integrated with various electronic equipment. This system, if integrated with high power amplifiers or travelling wave tubes, will be capable of transmitting microwave energy at varying power levels. If transmitting microwave power, AvL Technologies I cautions the end-user to review all applicable local, federal and international regulations and to comply with all such regulations in the operation and maintenance of the integrated system. Inspect polarization potentiometer. PLEASE READ THE FOLLOWING PRECAUTIONS This manual is intended as a general guide for trained and qualified personnel who are aware of the dangers of handling potentially hazardous electrical and electronic circuits. This manual is not intended to contain a complete statement of all safety precautions that should be observed by personnel in using this or other electronic equipment. 22 3 6.0 WARNING THE ELECTRICAL CURRENTS AND VOLTAGES ASSOCIATED WITH THIS EQUIPMENT, WHETHER SUPPLIED BY AvL Technologies OR OTHERS, ARE DANGEROUS. PERSONNEL MUST AT ALL TIMES OBSERVE SAFETY REGULATIONS. The installation, operation, maintenance, and service of this equipment involves risks both to personnel and equipment and must be performed only by qualified personnel exercising due care. AvL Technologies shall not be responsible for injury or damage resulting from improper procedures or from the use of improperly trained or inexperienced personnel performing such tasks. WARNING ALWAYS DISCONNECT POWER BEFORE OPENING COVERS, DOORS, ENCLOSURES, GATES, PANELS, OR SHIELDS. ALWAYS USE GROUNDING STICKS AND SHORT OUT HIGH VOLTAGE POINTS BEFORE SERVICING. NEVER MAKE INTERNAL ADJUSTMENTS OR PERFORM MAINTENANCE OR SERVICE WHEN ALONE OR FATIGUED. During installation and operation of this equipment, local building codes and fire protection standards must be observed. WARNING IN CASE OF EMERGENCY BE SURE THAT POWER IS DISCONNECTED. Do not remove, short-circuit, or tamper with interlock switches on access covers, doors, enclosures, gates, panels, or shields. Keep away from live circuits. Know your equipment and do not take risks. RF WAVEGUIDE AND ELECTRICAL CABLE SYSTEM 6.1 WAVEGUIDE SYSTEM The waveguide system is suitable for transmit only (13.75 – 14.5 GHz). The VSWR is checked and tuned to be better than 1.3:1 (-17.7 dB) with an insertion loss of better than .75 dB. The system is pressurizable to a maximum of 2 psi. The leak rate is checked to be below 100 cc/minute. Rotary joints are provided on the azimuth and elevation axis and are rated for 1 kW of power. The polarization axis is crossed with flex-guide rated for 750 watts continuous. Transmit power is input on the rotating side of the azimuth rotary joint. Therefore the waveguide interface coming from the inside of the truck must be held stationary on the passenger side of the vehicle. 6.2 CONTROL CABLES The azimuth and elevation motor power cables are SO 16 gauge, the polarization motor cable is SO 18 gauge, multi-strand wire. The motor power cables are terminated at the motor with insulated, in-line splices. They are terminated in a 9-pin MS connector at the controller end. The shield is grounded to the positioner and MS connector. The ground pin is not used. The sensor and limit switch cables are 22 gauge, shielded, stranded wire. They are terminated into 15 pin connectors. The shield / ground must “float” and not contact the positioner assembly. 6.3 RF AND AUXILIARY CABLES SAFETY NOTICE The following safety procedures are listed to remind those performing any work on the antenna system that safety rules must be observed. Failure to do so may result in serious injury or death. Always work safely and in accordance with established procedures. Care shall be taken in all operations to safeguard other people as well as property and to comply with all local safety procedures as established by the customer’s site representative. All persons performing work on the antenna system shall also comply with the Occupational Safety and Health Act (OSHA) standards and all other federal state and local laws, ordinances, regulations and codes relating to designated work. Unless the customer’s representative on site specifically designates an individual responsible for site safety, the AvL Technologies Site Supervisor shall be responsible for and establish a site safety program for the AvL Technologies installation work. The site safety program shall incorporate all AvL Technologies safety procedures and requirements, including the following: ! Always remove all power to the system prior to working on the antenna, the reflector assembly, the reflector backup assembly or the feed assembly. ! Always tag all circuits noting that the power is OFF, the date and your name prior to commencing any work on that system. ALWAYS WORK SAFE! Two RG59 75ohm coax cables are furnished which run from the feed housing to 10 feet beyond azimuth interface plane. In addition, a 6 conductor, 22 gauge shielded cable is provided to power the LNA, operate a waveguide switch, run warning lights, disable vehicle ignition until antenna is stowed, etc. 7.0 MAINTENANCE The Patriot Antenna 1.8 MVSAT system is designed so that any wear should never degrade performance below specifications and no maintenance will ever be required. However, since it is impossible to ascertain or test for all possible environments, the following check-up can be performed annually to assure never missing “a shot”. If any problems are observed, refer to appropriate section. 7.1 ANNUAL INSPECTION Azimuth Handcrank in azimuth. Unit should handcrank easily. Check for unusual noise in azimuth bearing and azimuth gear box. ELECTROMAGNETIC RADIATION DO NOT STAND IN THE DIRECT PATH OF THE FEED SYSTEM WHEN THE SYSTEM IS TRANSMITTING! DO NOT WORK ON THE FEED SYSTEM WHEN THE SYSTEM IS ON! 4 Run in azimuth and check for unusual noise in azimuth motor. Check drive cables for damage. Check for excessive backlash in gearbox. 21 5.0 TABLE OF CONTENTS FEED AND POLARIZATION POSITIONING SYSTEM SECTION 5.1 GENERAL The feed assembly consists of the feed boom, feed housing, RF components and polarization drive. The feed pivots about the elevation axis to eliminate additional flex-guide required when pivoting at the edge of the reflector. The pivoting is facilitated by the double bearings of the rotary joint and the delrin pivot. The elevation to polarization waveguide runs along the feed boom tubing. The feed / OMT is rotated by a chain drive and 12V DC motor. 1.0 5.3 POLARIZATION DRIVE The polarization drive motor is a 12V DC gear motor. It is housed in a polarization box, which attaches to the feed assembly itself. Since the worm gear drive will not backdrive, no brake is required. 3.0 5.4 POLARIZATION POSITION FEEDBACK 4.0 Figure 5.1 The potentiometer is mechanically set at the one-half travel position (2500 ohms) when the stow switch is actuated. The controller may also electrically zero the potentiometer. See section 4.1 of the Controller manual. 20 Waveguide System...................................................................................................... Control Cable .............................................................................................................. RF and Auxiliary Cables ............................................................................................... MAINTENANCE................................................................................................................... 7.1 7.2 8.0 General ....................................................................................................................... Feed Assembly............................................................................................................ Polarization Drive ........................................................................................................ Polarization Position Feedback..................................................................................... RF WAVEGUIDE AND ELECTRICAL CABLE SYSTEM ........................................................ 6.1 6.2 6.3 7.0 Elevation Gear Box ...................................................................................................... Elevation Motor ........................................................................................................... Elevation Roto-Lok Cable Drive .................................................................................... Elevation Position Feedback......................................................................................... Elevation Stow and Limit Switches ................................................................................ FEED AND POLARIZATION SYSTEM................................................................................. 5 5.1 5.2 5.3 5.4 6.0 Azimuth Bearing .......................................................................................................... Azimuth Gear ............................................................................................................. Azimuth Motor ............................................................................................................. Azimuth Roto-Lok Cable Drive ...................................................................................... Azimuth Position Feedback .......................................................................................... Azimuth Stow and Limit Switches.................................................................................. ELEVATION POSITIONING SYSTEM................................................................................... 4.1 4.2 4.3 4.4 4.5 5.0 General ....................................................................................................................... Installation to Vehicle ................................................................................................... Controller Installation ................................................................................................... Controller / Positioner Verification Tests ........................................................................ Elevation Stow Switch Verification ................................................................................ Final Calibration of System........................................................................................... LNA/LNB Installation .................................................................................................... AZIMUTH POSITIONING SYSTEM....................................................................................... 3.1 3.2 3.3 3.4 3.5 3.6 The polarization position feedback is produced by a 3 turn, 5K ohm potentiometer driven by the chain drive with small spur gears. The resolution and accuracy is 0.3°. The potentiometer is rated for IP 65 environment – wind, rain, dust, etc. (Figure 5.1) Technical Description................................................................................................... Specifications .............................................................................................................. INSTALLATION AND SET-UP .............................................................................................. 2.1 2.2 2.3 2.4 2.5 2.6 2.7 The feed assembly consists of a feed horn and OMT. The feed / polarization drive box is mounted to the feed assembly. The feed horn is mechanically positioned with a template within 1/8” of the theoretical focal point of the reflector. This positioning assures the RF system provides the gain and FCC compliance as stated in the specifications. PAGE INTRODUCTI0N................................................................................................................... 1.1 1.2 2.0 5.2 FEED ASSEMBLY DESCRIPTION Annual Inspection ........................................................................................................ Spare / Replacement Parts List .................................................................................... WARRANTY........................................................................................................................ 5 1.0 INTRODUCTION 4.5 ELEVATION STOW AND LIMIT SWITCHES The purpose of this manual is to provide information for the installation, operation and maintenance of the Model 1.8 MVSAT. Should any problems arise which are not discussed within this manual, such problems should be referred to the equipment manufacturer: Patriot Antenna Systems 704 North Clark Street Albion, Michigan 49224 USA Telephone: 517-629-5990 FAX: 517-629-6690 If the antenna is mounted facing the front of the vehicle, remove the passenger side cover on the elevation axis pivot shaft to gain access to the elevation stow, down and up limit switches. The switches are fixed to reference ground (the elevation pivot blade) and are actuated by a cam on the rotating elevation shaft. (Figure 4.4) 1.1 TECHNICAL DESCRIPTION GENERAL The Patriot 1.8 MVSAT system is a light weight, reliable system. The cable driven system provides a near-zero backlash and highly reliable movement, all driven by a special minimum / adjustable backlash gearbox powered by light, but rugged, DC drive motors. All drive components are high strength steel in lightweight housings which result in the most reliable, stiff system with the minimum of weight. The feed boom pivots at the elevation axis, allowing an option of providing waveguide rotary joints on both the elevation and the azimuth axis. Also, pivoting the feed boom at the elevation axis provides maximum space for a feed boom mounted amplifier or transceiver. The Patriot Antenna System weighs only 220 lbs (100Kgs). DRIVE SYSTEM The drive system utilizes highly reliable aircraft control cables in a redundant configuration to achieve a near-zero backlash, lightweight, very stiff drive system. It achieves this high tech performance using low-tech components and simply wrapping the cable around the driver capstan several times before wrapping the larger driven drum. The method used to wrap the capstan results in a minimum length of free cable. The cables are pre-tensioned and spring loaded at the main drum attachment point, eliminating backlash during antenna positioning. SECONDARY DRIVE SYSTEM The Azimuth and Elevation drive systems are driven by an adjustable cable, minimum backlash worm gear set with a 40:1 ratio. The factory set and easily adjusted backlash of the worm gear set is 1 – 2 arc minutes which is reduced further by the cable drive ratio resulting in a backlash of only 0.005 degrees seen by the reflector system. Since the worm gear does not back drive, an additional brake is not required on the motor. The worm-input shaft is extended with a hex head end to allow manual deployment in case of power failure. Maximum gear efficiency and minimum wear is achieved by sealing the gear sets in continuously lubricated housings. MOTOR DRIVES Lightweight reliable servo quality DC motors with integral gearboxes are used for the Azimuth and Elevation drive systems. These motors were selected because they provide the best torque to weight ratio. Maximum reliability is achieved from the printed circuit armatures. These motors produce constant torque over the speed range with uninterrupted travel at low speeds, ensuring smooth operation during antenna peaking. The 18V DC design provides current limiting torque control and will allow, if necessary, vehicle-battery powered operation. The motors have their own weather tight covers but are covered with secondary covers to assure maximum weather protection. CONSTRUCTION The trunnion, backing structure, feed booms and covers are all of aluminum construction. Optional aluminum gear housings are available for minimum weight. Precision ground bearings are used in all axes to assure long life and smooth positioning. The reflector is a carbon fiber composite sandwich construction manufactured in a multiple lay-up operation. The lay-up mold surface provides the surface accuracy required for optimum performance. 6 Figure 4.4 The elevation stow switch is actuated by the adjustable screw on the cam. It should be verified after the system is installed on the truck so the reflector still clears the feed horn by approximately 1 inch. Adjust the switch in small increments to allow for possible coasting of the elevation drive after power is cut. The elevation down limit switch is located at the 6 o’clock position. It rides up on the cam when the elevation angle is below 5°. This prevents lowering the reflector / feed system below 5° until the azimuth and polarization positioning systems are in their stow position. The elevation up limit is located at the 10 o’clock position. It electrically terminates upward movement at approximately 87°. The mechanical limit is 90° and may be achieved if desired by bending the actuator slightly. 19 1.2/1.5/1.8-METER SPECIFICATIONS MECHANICAL 1.2/1.5/1.8-METER MECHANICAL SPECIFICATIONS Azimuth Travel +130°continuous travel Elevation Travel 5° - 90° of reflector boresight 0° - 65° for CE approved Polarization Travel +95° (for 2-port feed) Drive Rates 2° / second (Az/El/Pol.) +55° (for 4-port feed) 0.1° / second (peaking – Az/El) Reflector Carbon Fiber Aluminum Feed 2 port and 4 port Ku band, Co and Cross pol Finish White Weight 220 lbs (100 kgs) Stow Height 18 inches (460 mm) Electrical Interface 25 foot (7.6 m) cable pre-connectorized for various controller options ENVIRONMENTAL 1.2/1.5/1.8-METER ENVIRONMENTAL SPECIFICATIONS Operational Winds Pointing Loss* Figure 4.3 If the antenna is mounted facing the front of the vehicle, remove the driver side cover on the elevation axis pivot shaft to gain access to the inclinometer. The inclinometer is covered with an aluminum cover to protect it from weather and mechanical damage. One mounting screw hole is slotted. The inclinometer is mechanically set at the correct boresight position of 12.8° for the 1.2m, 15.8° for the 1.5m and 18.8° for the 1.8m antenna when the reflector face surface is perpendicular to gravity. This is accomplished by loosening the allen screw (9/64 allen wrench) and rotating the inclinometer. The inclinometer may also be electrically zeroed using the controller. See section 4.1.1 of the Controller manual. 20 mph (32 km/h) winds 30 mph (48 km/h) winds gusting to 45 mph (72 km/h) Survival Winds (any position) 1.2-Meter 1.5-Meter 1.8-Meter 0.10 dB RMS loss 0.15 dB RMS loss 0.23 dB RMS loss 0.32 dB RMS loss 0.50 dB RMS loss 0.72 dB RMS loss 80 mph (128 km/h)* Survival Winds (stow position) 120 mph (192 km/h)* Ambient Temperature Operational: +5° to 122°F (-15° to 50°C) Rain (Operational and Survival) Up to 4 in/h (10 cm/h) Survival: -22° to 140°F (-30° to 60° C) Relative Humidity 0% to 100% with condensation Solar Radiation 360 BTU/h/ft (1000 Kcal/h/m ) Radial Ice (Survival) 1 inch (25 mm) on all surfaces, ½ inch (12 mm) on all surfaces with 80 mph (128 km/h) wind gusts* Corrosive Atmosphere As encountered in coastal regions and /or heavily industrialized areas. • 18 45 mph (72 km/h) gusts to 60 mph (97 km/h)* 2 2 Loss does not include contribution of deflection due to the foundation mount. 7 2.0 INSTALLATION AND SET-UP 2.1 GENERAL The 1.8 MVSAT antenna has been fully tested with the controller prior to shipment. All position feedback, limit sensing, limit switches and motors have been calibrated or set. The installation involves securing to vehicle, connecting waveguide, installing LNB’s, connecting coaxial cable, connection of control cables to controller and connecting auxiliary control cable as necessary. The vehicle roof should be reinforced with a substructure capable of handling the wind loads as specified on the interface drawings for each size antenna. A 12-inch diameter hole should be in the mounting surface. The mounting surface must be flat within 0.005 inch to prevent binding the azimuth bearing after torquing the mounting bolts. No obstruction should be above the interface surface in a 20-inch diameter envelope. Any other roof-mounted equipment such as air conditioners should be more than 92 inches from center of interface bolt pattern. The 16-inch diameter, 12-bolt pattern must be oriented properly with two bolts 15° on either side of the centerline of the vehicle. Reference vehicle interface drawing for proper orientation. 2.2 INSTALLATION TO VEHICLE Remove the top of the shipping crate. Remove the narrow side at the azimuth platform end of the crate. Using the hand crank furnished, hand crank the elevation axis until the reflector support structure is vertical. Remove the bolts attaching the positioner to the shipping base. Adjust the forks on a fork lift to just straddle the azimuth ring and under the elevation pivot assemblies. Place cardboard pieces between the positioner and the forks. Carefully raise the antenna out of the crate and guide the control cables to prevent their catching on the crate. Safety strap antenna to the fork lift truck. Remove the wooden antenna interface board from the antenna. To serve as guides to position azimuth ring directly over the vehicle’s bolt circle, cut two 5/16-18 all thread rods to a length sufficient to allow protrusion into the vehicle interior for removal once the antenna is seated into position. Grind one end of each rod to a rounded point to further help guide antenna into the vehicle interface holes. Install these guides into holes diametrically opposed in the antenna azimuth bearing. Maneuver the antenna to a position approximately two feet above the vehicle interface. Note: Antenna must be installed with azimuth cable spring block aligned o centerline of vehicle.(Figure 2.1) IF INTERFACE SURFACE ISNOT FLAT apply a thin layer of structural epoxy grout between azimuth ring and vehicle surface. Thread control cables into the 12-inch diameter hole. Lower the antenna to the antenna interface. APPLY LOCKTITE 242 OR EQUIVALENT TO BOLTS, install and snug bolts finger tight. Allow epoxy to cure before final tightening. Figure 4.2 4.4 ELEVATION POSITION FEEDBACK IF INTERFACE SURFACE IS FLATAPPLY A THIN COAT OF SILICONE BETWEEN AZIMUTH RING AND SURFACE. Thread control cables into the 12-inch diameter hole. Lower the antenna to the antenna interface. APPLY LOCKTITE 242 OR EQUIVALENT TO BOLTS, install and snug bolts finger tight. The elevation position feedback is produced by an electronic inclinometer. Since the drive has nearly no backlash, the position feedback is as accurate as the resolution and accuracy of the inclinometer The inclinometer has a resolution of 0.1 degrees with the accuracy / linearly of 1% in the 0 - 45° range and monotonic in the 45 - 90° range. The inclinometer is rated for an outdoor environment. (Figure 4.3) TIGHTEN ALL 12 BOLTS TO 18 -20 FT. LBS. 3 CONTROLLER INSTALLATION Install controller into electronics rack. Connect P1 and P2 to J1 and J2. Note cables and jacks are marked. Connect MS motor power cable to MS jack. Confirm voltage is correct. Connect AC power cable to controller. Figure 2.1 8 17 The motor drives the input worm via a quill / female hole and square key. The worm shaft is extended with a hex shape for the hand crank. The dual elevation drive shafts are driven with a square key. Zero backlash hubs are used to eliminate any backlash between keyed shafts. They are factory tightened and should never be tightened again. Over-tightening can bind gearbox bearings. The elevation capstan is secured to the dual output shafts with four cap screws. These screws are the “safety link” and will shear under excessive loading conditions to protect the elevation drive system if the reflector is not stowed and hits an obstacle while the vehicle is in motion. The low backlash is achieved with a variable pitch worm. The width of the worm tooth slowly increases along the worm. Since only one small portion of the worm tooth is meshing with the worm gear moving the worm axially allows one to vary which section / width of the worm tooth is being used to drive the worm gear. Therefore the backlash can always be minimized to 1 – 3 arc minutes. (Figure 3.2) The gear box contains synthetic oil filled half way to the level plugs. Due to the design capacity of the gear box, low rpm and comparative limited cycles experienced by an SNG system, no wear or maintenance is expected. 2.4 CONTROLLED / POSITIONER VERIFICATION TEST Turn power on. Wait for self-check to complete. Hit mode button once to reach display / function mode. Since positioner is vertical, the display should read: SLOW ELEVATION AZIMUTH POLARIZATION 20.0 DEGREES 0.0 DEGREES 0.0 DEGREES (APPROXIMATELY) STOW (WITHIN 1°) STOW (WITHIN 1°) Press speed button to change speed to FAST Caution! HAVE SOMEONE OUTSIDE AND ELEVATED SO THEY CAN OBSERVE ANTENNA MOVEMENT DURING TEST! Push El UP button. Antenna elevation reading should increase. Move until elevation reading is 18.8 degrees for the 1.8M. Push Az CW and reading should increase. Run to CW Limit (120°). 4.2 ELEVATION MOTOR Observe antenna movement for potential interference. The elevation drive motor is a flat armature, servo quality, 18V DC motor with integral 75:1 spur gear train. The motor armature rotates at up to 7000 rpm causing a high frequency noise that will vary depending on the loading condition of the motor. (Figure 4.1) The maximum output speed is 80 rpm. The output shaft is a standard keyed shaft. The output torque capacity of the motor is rated for the operational wind load. Since the low backlash worm gear drive isolates the backlash from the motor, any backlash between the square key or motor gear train will never be seen by the reflector boresight. Any backlash at any of these points is of no consequence to the system performance. No maintenance or wear of the elevation motor is expected. 4.3 ELEVATION CABLE DRIVE The elevation drive produces a near zero backlash, high stiffness, low wear, no lubrication, maximum reliability drive system. The system consists of sixteen 3/32, 9 x 17 stainless steel aircraft control cables reverse wrapped three times around the capstan with a solid connection on one end and high force, belleville springs on the other end occurring at the elevation cable termination block. It requires only eight of the cables to provide enough capacity to withstand the required 80-mph wind load. The additional cables are used to provide increased stiffness and drive redundancy. If a cable becomes damaged during use merely cut off cable and continue to use the positioner. The cable may b replaced as time permits at a typical mainten ance facility. The cables are sized to last the life of the positioner. No replacement from wear is expected. The spring package at one end will automatically compensate for any elongation of the cable. At installation the belleville springs are collapsed until no “air” is seen between the springs. You should check this condition yearly to account for the slow settling of the cable strands. Use a 3/16 open wrench or pliers to hold stud and 7/16 box end wrench to tighten nut. Care should be taken to not over tighten the assembly, the belleville springs should be almost fully collapsed to provid the necessary tension on the cables. (Figure 4.2) 16 Push Az CCW and reading should increase. Run to CCW Limit (-120°). The Az CCW and CW limits can be increased depending on waveguide and control wire clearance at truck interface. Refer to Section 3.6 of this manual and Section 4.1.3 of controller manual. Push Az CW and reading should increase. Run to approximately -15°. Push Pol CW and reading should increase. Run to CW Limit (55°). Push Pol CCW and reading should decrease. Run to CCW Limit (-55°). Push STOW, then BACKSPACE. Antenna should begin moving to 0° Polarization in slow speed. It should stop at approximately 0° (+ / - 5°). STOW indication should occur in polarization. Antenna should begin moving in fast speed in azimuth and slow down when approaching 0°. STOW indication should occur in azimuth. If not, see Section 3.6. Antenna should begin moving down in fast speed. PRESS STOP WHEN ELEVATION DOWN LIMIT IS REACHED! Verify that both azimuth and polarization CW and CCW are disabled. 2.5 ELEVATION STOW SWITCH VERIFICATION NOTE: This step is provided in the event that the stow height must be adjusted. The stow switch is set at the factory. If the antenna is mounted facing the front of the vehicle, remove passenger side cover on the elevation axis to gain access to elevation limit switches. Press SPEED button to change to slow speed. Press El Down button and watch system stow. 9 Have personnel on both sides of truck observing orientation of gas strut U-joints. Watch reflector surface approach feed horn. STOP WHEN REFLECTOR GETS WITHIN 6 INCHES OF FEED HORN. NOTE: Elevation display has been disabled because electronic inclinometer produces erroneous information at these angles. Adjust stow switch adjustment screw in small increments until stow indication occurs at controller when reflector surface is approximately 1” from padded reflector support. Check that padded rest screws are tight. Raise in elevation approximately 10°, change speed to fast, and run down. Keep finger on STOP button! Motors will stop when switch is actuated but the reflector will coast very slightly. Continue to adjust stow limit actuation until reflector is preloaded against padded support and clearing feed horn by at least ½”. The feed boom should be depressing roof very slightly. The padded rest may be adjusted in height if necessary. Due to the fact that stow switch actuation occurs at slightly different positions depending on the direction of approach, clockwise or counterclockwise, the azimuth stow may vary approximately 1° from the actual 0° heading. The mount has the mechanical capability of 270°. However, the limits must be set at +120° per section 4.1.2 of controller manual to prevent damage to the azimuth rotary joints on a 4-port system. 4.0 ELEVATION POSITIONING SYSTEM The elevation pivot assembly consists of two elevation drum assemblies pivoting between two clevis blades that house the precision aircraft torque tube bearings. These bearings are precision ground with lifetime seals. They are permanently lubricated with synthetic grease. No wear or maintenance is expected. 4.1 ELEVATION GEAR BOX The elevation gearbox is a patented low backlash worm gear box. The worm gear drive si olates backlash in the motor drive from the system. Also, since it is a 40:1 ratio it will not backdrive eliminating any need for a brake on the drive train. (Figure 4.1) Raise reflector 30-45°, and observe in full stow mode by pressing STOW, BACKSPACE. Retighten cradle screws. A roll-pin pilot hole is provided for pinning the cradle if desired. Reinstall elevation limit switch cover. 2.6 FINAL CALIBRATIONOF SYSTEM If feed / reflector is not stowed centered on truck roof, the azimuth stow switch may be adjusted to center on roof. Stow with positioner having to approach stow from both directions. See Section 3.6 if azimuth stow position needs adjusting. If azimuth readout is not zero + / -2° when azimuth antenna is stowed adjust zero voltage per Section 4.1.1 of controller manual. 2.7 LNA/LNB INSTALLATION Install LNB/LNA’s to the ports in the feed boom housing. Figure 4.1 10 15 3.0 AZIMUTH POSITIONING SYSTEM 3.1 AZIMUTH BEARING The azimuth bearing is a precision ground Slim Line ball bearing with a dynamic and static moment capacity of over four times the worst-case wind load specification. It is press / shrink fit into a special aluminum bearing ring consisting of main internal and external rings with clamping rings. Both sides of the bearing are sealed against contaminants with Teflon O-rings. The bearing is packed with Mobil 1 synthetic grease at assembly. Because of the excess capacity, low rpm, and low number of cycles compared to the bearings B10 design life, no wear is expected. No maintenance should be required over the life of the positioner. A grease fitting is furnished for the azimuth bearing to flush out contaminants if the positioner is operated in extreme environments. Over time, some of the oil in the grease will separate from the binder. Since this oil is very thin, it may seep past the 0-rings. It will be red in color. If this occurs it is considered quite normal and should not be considered a problem unless it is excessive. If so, use a standard grease gun with Mobil 1 synthetic grease to repack bearings. Pump in grease very slowly as the unit rotates in azimuth. Look for grease to begin to seep past O-ring seal between az platform and az bearing ring. 3.2 AZIMUTH GEAR BOX Figure 3.4 The azimuth gearbox is a patented low backlash worm gear box. The worm gear drive isolates any backlash in the motor drive from the system. Also, since it is a 40:1 ratio it will not backdrive eliminating any need for a brake on the drive train. (Figure 3.1) The potentiometer is mounted in an adapter that sits down into the bearing bore of the azimuth gearbox. Since the torque required to turn a potentiometer is minimal, the mounting adapter is held in place by a setscrew. The potentiometer is protected with an aluminum cover from the weather and the use of the elevation handcrank. The azimuth potentiometer is slotted and driven with a cross pin in the output of the worm gear box. The potentiometer is mechanically set at the one-half travel position when the azimuth cable termination block is directly across from it. This is accomplished by loosening the setscrew (1/8 allen wrench) and rotating the adapter. The potentiometer may also be electrically zeroed by the controller. See section 4.1 of Controller manual. 3.6 AZIMUTH STOW AND LIMIT SWITCHE S. The Controller uses the azimuth potentiometer voltage to determine limits. Therefore, the positioner is equipped with only an azimuth stow position switch. Limit switch mounting holes are provided if needed for other brand controllers. The azimuth stow and limit switches are mounted under the azimuth platform accessible through the 12 inch diameter access hole on the base. The switches are fixed to reference ground (the truck) and are actuated by falling into a concave notch in the azimuth bearing clamp ring. The azimuth stow switch holes are slotted for + / - 2° adjustment. Figure 3.1 The motor drives the input worm via a quill / female hole and square key. The worm shaft is extended with a hex shape for the handcrank. The azimuth capstan is secured to the output shaft with a square key and zero backlash hub. 14 11 The low backlash is achieved with a variable pitch worm. The width of the worm tooth slowly increases along the worm. Since only one small portion of the worm tooth is meshing with the worm gear, by moving the worm axially, you can vary which section / width of the worm tooth is being used to drive the worm gear. Therefore the backlash can always be minimized to 1-3-arc minutes. (Figure 3.2) The gearbox contains synthetic oil filled half way to the level plugs. Because of the design capacity of the gearbox, low rpm and comparative limited cycles experienced by an SNG system, no wear or maintenance is expected. If azimuth backlash of the positioner ever exceeds 0.020°, it may be brought back to 0.005° factory setting by adjusting backlash in gearbox. (Figure 3.2). Figure 3.3 Figure 3.2 Since all systems seek the condition of lowest potential energy, the cables after an adequate time for break in will eventually stop stretching. At installation the belleville springs are collapsed until no “air” is seen between the springs. You should check this condition yearly to account for the slow settling of the cable strands. Use a 3/16 open wrench or pliers to hold the stud and 7/16 box end wrench to tighten nut. Be sure not to over tighten the cables, but the belleville springs should almost be fully collapsed.(See Figure 3.3) 3.4 AZIMUTH CABLE DRIVE The azimuth drive produces a near-zero backlash, high stiffness, low-wear, no lubrication, maximum reliability drive system. The system consists of four 3/32, 9 x 17 stainless steel aircraft control cables reverse wrapped twice around the grooved capstan with solid connections on one end and high force, belleville springs on the other end occurring at the azimuth spring block. One cable has the capacity to withstand the 80-mph wind load. The additional cables are used to provided increased stiffness and drive redundancy. If a cable becomes damaged during usage, merely cut off cable and continu to use positioner. The cable can be replaced whenever time permits at a typical maintenanc facility. The cables are sized to last the life of the positioner. No replacement from wear is expected. The spring’s package at one end will automatically compensate for any elongation of the cable. (Figure 3.3) 12 3.5 AZIMUTH POSITION FEEDBACK The azimuth position feedback is produced by a 10 turn, 1K ohm potentiometer driven by the output shaft of the worm gear box. Since the drive has nearly no backlash, the position feedback is as accurate as the resolution and accuracy of the potentiometer and the backlash between the potentiometer and the output shaft of the worm gear box. The potentiometer is rated for IP 65 environment – wind, rain, dust, etc. (See Figure 3.1 and 3.4) 13