Energy Analysis Presentation

advertisement

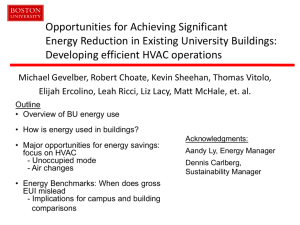

Opportunities for Achieving Significant Energy Reduction in Existing University Buildings: Developing efficient HVAC operations Michael Gevelber, Robert Choate, Kevin Sheehan, Thomas Vitolo, Elijah Ercolino, Leah Ricci, Liz Lacy, Matt McHale, et. al. Outline • Overview of BU energy use • How is energy used in buildings? • Major opportunities for energy savings: focus on HVAC - Unoccupied mode - Air changes • Energy Benchmarks: When does gross EUI mislead - Implications for campus and building comparisons Acknowledgments: Aandy Ly, Energy Manager Dennis Carlberg, Sustainability Manager Summary of Findings from GE 520/MN 500: “Energy Audit/Conservation Analysis of BU’s Charles River Campus” 2008 2009 2010 Michael Gevelber, Associate Professor Mechanical Engineering, Co-chair BU Energy Working Group, Member of BU Sustainability Comm, & Clean Energy and Environmental Sustainability Initiative (CEESI) Results of 2007 Energy Audit Total Energy Use Energy Intensity (Per Sq Foot) 1.6E+12 1.4E+12 160 68% Growth in Energy Use 18% Increase in Energy Intensity 150 Natural gas Btu 1.0E+12 8.0E+11 Electricity 6.0E+11 4.0E+11 Light oil Btu/sq. foot (1000) 1.2E+12 140 130 120 110 2.0E+11 Heavy oil 0.0E+00 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 100 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 • What are the reasons for these trends? • What can be done to reverse these trends? Cleveland, C. (2007, Oct 24). Energy and Emissions Footprint: Boston University Charles River Campus. Presentation to the BU Energy Club. Extended Team Michael Field, Former Asst. Provost Colleen McGinty, Director Construction Don DeRosa, Asst. Prof., SED Shaun Finn, LEED Certified AP Doug Zook, Assoc. Prof., SED Gary Nicksa, VP Operations SED Green Committee Eric Gauthier, IT Tom Daley, Assoc. VP Facilities William Steward, IT Bill Walter, Asst. VP Facilities Larry Valles, Lab Manager, Biology Chuck Von Lichtenberg, IT Domenic D’Alleva, HVAC Tim O’Connor, Electrical Tom Parker, Automation Building Managers: Paul Arsenault, HVAC Carlos Vazquez Tyrone Lawless Mark Harney, Asst. VP Facilities Aandy Ly, Asst. Dir., Energy Zhonghong Peng, Assoc. Dir. Roger Seale Dennis Batista Fernando Sousa Paul Rinaldi, Space Management Karen Zaharee, Analyst Outside Experts: Domenic Armano, Manager, Johnson Controls Mike Penn, OEHS Ray Thompson, Sales Manager, Andover Peter Harris, Director Operations, B&V Testing Stephen Drummey, Drummey Mechanical Building Energy Use by Fuel Charles River Campus Energy Supply 106 kBtu 2005‐2007 Energy Expenses/GHG BU Energy Use Index: kbtu/ft2, by building type LSEB (468) Energy Cost CRC 9.3 M ft2 79% 1.2 M ft2 21% 10.5 M ft2 100% (1) Total Average BUMC Energy Density 335 361 300 kBTU/Ft^2 Net Area BUMC 400 350 FY2007 Photonics (336) SMG (220) 250 248 226 200 140 BSR (140) 150 Average CRC Energy Density 117 100 50 109 106 72 125 114 141 92 89 72 CRC ‐ Focus on high energy density buildings NOTES: (1) BUMC Net Area does not include NEIDL and rental properties (2) Data sources from BU energy audit class (M. Gevelber) & Facilities (P. Zhong & A. Ly) BUMC BUMC Admin BUMC Education BUMC Research Offices Classrooms Labs Brownstone Offices Dorms Apartments Brownstone Residences Activity Retail 0 Seven Building Analysis ‐Sargent ‐SMG ‐15 St Mary’s ‐PRB ‐44 Cummington ‐LSEB ‐Photonics Energy Cost Density by Building 450 $14.00 400 $12.00 350 $10.00 250 Energy Densit y 200 $8.00 Energy Cost Density $6.00 150 $4.00 100 Gas Gas 50 Elec. $2.00 Elec. - $Sargent • • SMG 15 St. Marys PRB 44 Photonics Cummington LSEB What drives energy performance? What are opportunities for improvement? $/sq.ft. Kbtu/sq.ft. 300 HVAC Cost and Energy Implications Building Sargent SMG 15 St. Marys PRB 44 Cummington Photonics LSEB % Energy HVAC % Cost HVAC 71% 53% 69% 57% 60% 53% 61% 50% 38% 18% 52% 28% 72% 64% •HVAC accounts for 60‐70% ‐of energy use and 50‐65% of energy cost in a building. How does a Building HVAC system work? How much energy can be saved in a building? Outdoor Air Temp: 30 Degrees Exhaust Air Damper Intake Dampers AHU Heating And/Or Cooling •Currently energy enriched air is being exhausted around the clock—not based on occupancy •How can energy use be decreased without affecting comfort? •Setback/Increase of temperature in winter/summer Return Air •Dehumidify only when necessary •Reduce exhaust of conditioned air during low occupancy Building: 70 Degrees 40,000 CF Building Circulation Building Energy Use Average Daily Temp. 2007 Cooling season: May‐Late August •Cool to 55, then heat to 70 Heating season: Sept – Mid April Indoor Temperature Energy Use Determined By: Outdoor Conditions • Temperature • Humidity Indoor Air temp Settings Percent of outside air needed fo air quality Outdoor Temperature Heating Cooling $/CFM by Building Fans Cooling Winter Heating Summer Reheat Average $/CFM Breakdown Winter Building Heating Reheat Cooling 19% Average 24% 14% Fans 43% •$3-5/CFM => Reduce CFM Set Back Analysis 15 St Mary’s St. First Case Study 50,000 sq ft office/class building Analysis of Summer Results (15 St Mary’s) Before Unocc. 140 120 kWh 100 80 60 40 Average Summer kWh 2008 Weekday User Demand ~40 kWh Weekend Unocc. Mode Savings 2009 Unocc. mode 180 Should change start up to avoid spike User 140 Demand 120 100 80 60 40 20 20 0 0 1:00 4:00 7:00 10:00 1:00 4:00 7:00 10:00 AM AM AM AM PM PM PM PM Time Weekday Average Summer kWh 2009 160 kWh 180 160 With Unocc. Weekend Minimal Fan/AC Why so high? 1:00 4:00 7:00 10:00 1:00 4:00 7:00 10:00 AM AM AM AM PM PM PM PM Time • Profound drop in demand (38%) during Unocc period • 11 hour unoccupied • Some implementation issues observed Original Estimate Updated Reduce Nighttime Exhaust (8 hrs) Estimate of Potential Setback Savings •Find energy used to condition a unit volume of air Cooling electricity savings •Find volume of air exhausted Heating oil savings •Add energy used to condition air across all units of air exhausted Estimated Savings $12,522 21% •11% of total oil ($7,400) •7% of total electric. ($10,900) 13% ~$20k Estimated Implementation Cost $50k <2 $17,500—about 1 year payback $17.5k to Andover The rest is Rebalance! Was it needed? Implementation Lessons 80 Need to spec out more thorough implementation – OA Damper Stuck open – Winter AHU heating level 100% – Spike when heat comes on 78 Temperature(F) • Room Temp 76 74 72 70 68 Setpoint 66 64 12:00 PM 6:00 PM 12:00 AM 6:00 AM 12:00 PM • • Utility and AHU level analysis: check to see what’s really happening. Need to coordinate between HVAC staff, automation, and energy. What was really necessary – Rebalancing? Flow (cfm) Time of Day 20000 18000 16000 14000 12000 10000 8000 6000 4000 2000 0 SAFlow RAFlow 12:00 6:00 AM 12:00 6:00 PM 12:00 AM PM AM Time of Day Energy Savings: Solving for the Hidden Costs of HVAC Achieving Energy Efficiency in Existing Commercial Buildings Our Focus: HVAC is 50‐70% of ALL energy used in mid/large size buildings Strategy: Reduce high air flow rates which were implemented when energy was cheap. Our Solution • Develop new tool to re-optimize HVAC control • This is not addressed by current tools • Based on real buildings, experience and data Funded by MA Clean Energy Center Professor Gevelber & Professor Wroblenski BU Mechanical Engineering Basis for Opportunity/Value • • • • Many buildings designed when energy was cheap so used high air flow to assure ventilation, humidity, and thermal needs were met. For existing buildings, hard to know “how low you can go” Should base design on minimum air flow for ventilation & lab safety Our system provides easy basis to re‐optimize Overall Building ACH vs. Energy $/sq.ft. Office/ Class Lab ACH 14 Office/ Class 12 13.03 Lab 10 8.93 8 Vent for 100%Lab 6.18 6 4 2 4.75 Target Target 3.2 3.2 Req. for Ventilation 0 Sargent SMG 15 St. Marys PRB Photonics LSEB Our Core Concept Room-by-room experiments run through existing BAS Chiller VAV Box Determine actual ACH for each room (No plans needed) Establish minimum ventilation needs Reset ACH through existing BAS software Control Air handling unit Building HVAC Schematic Aggregation enables building-level optimization Enables monitoring/ diagnostics & commissioning Which EUI should we use for analysis? Energy Stars (based con CBECS data), and AASHE Stars program are based on gross square feet • Does using gross area hide or distort both campus and building energy efficiencies? • Key issues: - buildings with larger parking lots & - large interior spaces that are not conditioned EUI Case Study: Medical Campus • 19 buildings including 2 parking garages Total Gross Area (sq. ft) Total Net Area (sq. ft) 2,455,222 1,738,909 Gross Parking (sq. ft) Net Parking (sq. ft) 969,998 620,491 Downtown Campus: Parking is 40% of Gross Area. Net is 71% of gross (but incl. parking since assignable) . How does considering net & parking affect EUI Analysis (kbtu/sq ft)? Analysis of Medical Campus EUI What are the effects of parking? Gross EUI* Inc. Parking Net EUI Inc. Parking 136 190 Gross EUI w/o Parking Net EUI w/o Parking 218 289 •Using Gross EUI, including parking, hides major energy use! •212% difference between net w/o Parking and Gross EUI Why does this happen? parking uses 10-20 kbtu/ft^2, BUT need to consider net area includes parking since assignable! *EUI = Energy Use Intensity in kBtu/sq. ft Analysis of BU Charles River Campus • 280 Buildings • Gross Area: 11,690,000 sq. ft. • Net Area: 9,362,500 sq. ft. • (80% of gross) • Building Parking: 701,400 ft2, 6% of area Analysis of BU Charles River Campus • While parking is only 6% area, its EUI is so low (10‐20 kBtu/sq. ft) that it distorts EUI calculation Gross EUI w/ Parking 124 w/o Parking 132 Net EUI 155 167 • 25% difference in EUI net to gross, but 35% difference in EUI for net and gross area w/o parking Analysis of Individual Buildings Gross & Net Areas w/ Parking Gross Area (sq.ft) Net Area (sq.ft) Parking (sq.ft) Gross EUI Net EUI Net EUI w/o Parking SMG classroom/offices 481,100 325,300 23,100 159 235 267 575 Comm: Dorm 87,600 79,000 33,000 82 90 160 808 Comm Art Space / Office 266,000 244,400 38,000 71 77 99 • For individual buildings, taking account of net area & parking yields significantly different results ( 68%-95%). • Important for obtaining good building priority list Summary • What is the EUI of different buildings, org. by types: provides roadmap – Consider net area and w/o parking • HVAC should be a major area of focus: 70% of energy – require better coordination amongst facility groups, some special experts and manpower, , but offer substantial cost reduction and green benefits • Implementing unoccupied modes – Low cost: <1 yr payback & 10-15% Energy savings • Deeper savings: focus on ACH – Energy cost ACH….and we are over-ventilating our buildings – Mostly reprogramming, but rebalancing possibly required. Average Electrical Use Breakdown •Much of energy use is hidden both to occupants & building managers. *HVAC elec is 58% 590 Comm Setback • Unoccupied Hours: – Offices 6pm – 7am – Classrooms 11pm – 7am • Affected area: – 55,000 ft2 (50’% area) – 222 terminal boxes • Timeline: – Proposal – Implementation • Project Managers: – Colleen Mcginty – Robbie Choate Dec‐2009 Feb‐2010 Background/Overview • Existing commercial buildings offer significant energy savings opportunity 36% of US electricity • HVAC ~ 50‐70% of building energy use, but use is hidden. 20‐35% of electricity used to push air! • Key: reduce air flow. • Our solution: Re‐optimize building HVAC system based on software approach. • Works with existing Building Automation System (BAS) • Unique: Solves problem not addressed by current tools. • Nega‐watt: cheapest energy “source” by 4‐10x Building Floor Area Profile Charles River Campus 2007 Building Energy Use Profile Electricity Heating Oil & Gas