engineering polymer specialists

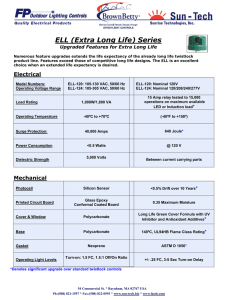

advertisement

ENGINEERING POLYMER SPECIALISTS ENGINEERING POLYMER SPECIALISTS MISSION STATEMENT & COMPANY PROFILE The mission of PTS is to strive to offer our processing customers and endusers the broadest possible array of engineering polymers with the best service and response time in the industry, at the most competitive pricing available. PTS offers a wide selection of products to meet the specific needs of our customers without the limitations of distributor that can only offer the product line of a special manufacturer ,we ensure the product meets our customer’s needs, not make the customer fit the product Who we are: • Supplier of High Quality Engineering Thermoplastics • Cover OEM and molders’ needs • Assist with planning, scheduling, material selection, processing tips, agency compliance and design assistance. Why TRISTAR® PC is right for you? Company Profile Polymer Technology and Services, LLC (PTS) is a supplier of high quality name brand and generic engineering thermoplastics. We offer the broadest range of world class resins combined with all the benefits of an efficient business model for distribution and technical services. We call it “right sized”. Service Based in Murfreesboro, Tennessee, USA since 1992, PTS offers over 150 years of combined engineering plastics experience. Our prompt and thorough personnel covers every OEM and molder’s needs, assisting with planning, scheduling, material selection, processing tips, agency compliance and design assistance. • UL recognized, UL94 V-0 and 5VA ratings • Electrical, Electronic and telecommunication market specialists • We offer superior quality materials, exceptional service, quick response time and competitive prices. Combining a broad product offer, technical expertise, and responsive customer service; PTS hopes to become your “Engineering Polymer Specialist”. A Success Story: PTS developed a resin to meet a stringent specification developed for outdoor enclosures for telecommunication applications. The product required low temperature impact (-40 C), UV stability and Support With the depth of bench at PTS, we live up to our middle name everyday and provide round-the-clock expertise that helps our customers’ staffs and machinery perform at peak levels. By prescribing the precise grade of material and providing productivity analysis, when needed, we help operators and supervisors avoid costly problems or shutdowns for corrections. We pride ourselves in keeping up with the industry’s newest technologies and thermoplastic grades - which helps improve your product quality, uptime and bottom line. Logistics PTS is located near the distribution center of the eastern two-thirds of the United States. Our central location allows us to develop specialized inventory programs to orchestrate the optimum scenario for J-I-T delivery. Our strategic location warehousing in Illinois, Indiana, Kentucky, North Carolina, New Jersey, Tennessee and Texas also helps to improve cash flow and reduce risk of damage to resin storage. Our material tracking is constantly updated between the source of manufacture and your facility to provide you instantaneous data and stronger inventory controls for your operation. improved chemical resistance. The new product offered improved impact, chemical resistance and cycle time for molding; all at a lower material cost than the competitive resin system, this is the TRISTAR® PC-10FR-GY(VIM). They trust us for their Global Business... • Schneider Electric / Square D. • Alcatel • Elster Electricity • Regal Beloit • Emerson Electric • Tyco Electronics • Hayward Pool • Motorola • Pace © 2013 Polymer Technology & Services, LLC CH3 C CH3 Bisphenol A What are the properties of polycarbonate? Before starting to list properties of polycarbonate, it is probably wise to explain why the properties are the way they are. First, the technical stuff. Take a look at the above diagram. In it, you will see two six-sided structures. These are called phenyl groups. You will also see two groups identified by the label CH3. These are methyl groups. The presence of the phenyl groups on the molecular chain and the two methyl side groups contribute to molecular stiffness in the polycarbonate. This stiffness has a large effect on the properties of polycarbonate. First, attraction of the phenyl groups between different molecules contributes to a lack of mobility of the individual molecules. This results in good thermal resistance but relatively high viscosity (i.e., low melt flow) during processing. The inflexibility and the lack of mobility prevent polycarbonate from developing a significant crystalline structure. This lack of crystalline structure (the amorphous nature of the polymer) allows for light transparency. Now for the clearer, less technical version of the properties. Polycarbonate is naturally transparent, with the ability to transmit light nearly that of glass. It has high strength, toughness, heat resistance, and excellent dimensional and color stability. Flame retardants can be added to polycarbonate without significant loss of properties. The general properties can be summarized as follows: excellent physical properties excellent toughness very good heat resistance fair chemical resistance transparent moderate to high price fair processing 8 10 12 14 16 How is polycarbonate sold? In general, the primary distinguishing characteristic of a grade of polycarbonate is its melt flow. The only exceptions are glass fiber reinforced grades, which are sold based on the percentage of glass fiber used in the production of the plastic. Other properties (such as UV stabilization, mold release, impact modification, and flame retardancy) typically differentiate grades of the same melt flow or percentage of glass fiber. Changes in melt flow have an effect on other physical properties. When specifying a grade of polycarbonate, it is necessary to know the conditions under which it will be used. Criteria such as wall thickness, length of flow, environmental conditions including low and/or elevated temperatures, UV exposure, chemical environment and impact requirements all must be considered. In electrical and telecommunication applications, UL flammability and Telcordia specifications must also be considered. Your PTS representative can help you navigate through this application maze. 6 Nylon 6/6&6 PBT/PET ACRYLIC PPO PS PVC ABS PC/ABS PC ft.-lb./in. Other engineering applications include the following: equipment housings exterior automotive components outdoor lighting fixtures nameplates and bezels fiber optic enclosures brackets and structural parts medical supply components circuit protection devices 4 Notched Izod How is polycarbonate used? It can be injection molded, blow molded, and extruded and is an ideal engineering plastic with good electrical insulating properties, finding applications in electric meter housings and covers, casket hardware, portable tool housings, safety helmets, computer parts, and vandal-proof windows and light globes. The price of polycarbonate restricts its use to mainly engineering applications. Notched Izod Impact Strength vs. Temperature (1/8” thickness) 0 2 Impact Strength How do these properties compare to other materials? One of the biggest advantages of polycarbonate is its impact strength. The following diagram compares the impact strength of polycarbonate to other commonly sold plastics. What is a glass fiber reinforced grade of polycarbonate? The addition of glass fibers to polycarbonate significantly increases the tensile strength, flexural strength, flexural modulus, and heat deflection temperature of the polycarbonate while causing a decrease in the impact strength and tensile elongation. The greater the amount of glass fiber added to the polycarbonate, the greater the effect on each property will be. Notched Izod Impact Strength — ft.-lb./in. 20 18 7 MFI 16 Polycarbonate does have its disadvantages. It has only fair chemical resistance and is attacked by many organic solvents. However, through modification with special additives, TRISTAR® PC grades have been developed to pass Bellcore/Telcordia GR-49 Chemical Resistance requirements. 14 10 MFI 18 MFI 12 10 8 6 4 2 0 -60 -40 © 2013 Polymer Technology & Services, LLC -20 0 20 40 60 Temperature— °F. 80 100 3 PRODUCT INTRODUCTION What is polycarbonate? Polycarbonates are long-chain linear polyesters of carbonic acid and dihydric phenols, such as bisphenol A. UL Approval UL (Underwriters Laboratories) performs various tests on products sold in the United States. One such test, UL94, is used to measure the resistance of plastics to a flame source. For polycarbonate, the test will normally result in a mark of V-0, V-1, V-2. V-0 is the most flame retardant and V-2 is the least flame retardant of the marks typically given to polycarbonate. If the material does not pass the test for V-0, V-1, or V-2; then the product is not UL approved. UL approval is given for a particular product at a measured thickness which is reported with the rating. Hence, saying that a given product is V-2 is insufficient information without also specifying at what thickness the rating is valid. UL approval is required for certain applications of polycarbonate. CONDITION Maximum time any one specimen can burn after removal of 2nd application of flame Maximum glowing time permitted for any one sample after removal of 2nd application of flame Total flaming combustion time allowed (maximum) for the 10 flame applications Ignition of cotton from dripping, flaming particles Flaming combustion up to the holding clamp 94HB Conditions: 1.Shall not have a burning rate exceeding 1.5 inch/minute over a 3 inch span for specimens having a thickness of 0.120 inch and above. 2.Shall not have a burning rate exceeding 3.0 inch/minute over a 3 inch span for specimens having a thickness of under 0.120 inch. UL INFORMATION 3.Shall cease to burn before the flame reaches the 4 inch reference mark but shall not comply with 94 V-0, V-1, or V-2 requirements. The second part of the UL94 test determines the Relative Thermal Index (RTI) of the material. The RTI is the temperature at which a specific property will decrease to half of its original value after 60,000 hours of exposure at that temperature. If a material has not been tested, the generic RTI for the material is assigned. The generic RTI for polycarbonate is 80°C. PTS TRISTAR® polycarbonate grades have elevated RTI as shown below. TRISTAR® T PC-10GFR-GY(V) POLYCARBONATE, 10% GLASS FILLED, FLAME RETARDANT UL94 V-0 AT 1.5 mm, 5VA @ 2.4mm, UV RESISTANT 94V-0 10 sec 30 sec 94V-1 30 sec 60 sec 94V-2 30 sec 60 sec 50 sec not permitted not permitted 250 sec not permitted not permitted 250 sec permitted not permitted What is FDA certification? Materials that are used in applications that are in contact with food require FDA certification. What is UV stabilization? UV stabilizers are added to polycarbonate to help protect the material from the effects of exposure to the Sun. Radiation from the Sun, especially in the UV portion of the spectrum, degrades the properties of polycarbonate. The addition of UV stabilizers allows the material to sustain exposure to the Sun for a longer period of time. What is mold release? Adding a mold release agent to polycarbonate makes processing easier. It acts in a way similar to a lubricant in the injection molding process. Amorphous: The molecular chains have no distinct uniformity or pattern. The chains are farther apart than a crystalline resin. • Benefits: Low in mold shrinkage • How established: Low mold temperatures Crystalline: Refers to the molecular structure of the resin (polymer). The degree of crystallinity refes to uniformity and closeness of the molecular chains forming the polymer and resulting from the formation of solid crystals with a definite geometric pattern. • Benefits: dimensional stability, low post mold shrinkage • How established: High mold temperatures 4 © 2013 Polymer Technology & Services, LLC E155285 Component - Plastics POLYMER TECHNOLOGY & SERVICES L L C 2315 SOUTHPARK DR, MURFREESBORO TN 37128 PC-10FRN-BK(V)(e)(f1) Polycarbonate (PC), “Tristar”, furnished as pellets Min Thk Flame RTI RTI RTI Color (mm) Class HWI HAI Elec Imp Str BK 1.5 V-0 3 0 125 115 125 2.5 V-0, 5VA 3 1 125 115 125 3.0 V-0, 5VA 2 1 125 115 125 3.8 V-0 125 115 125 Comparative Tracking Index (CTI): 2 Inclined Plane Tracking (IPT): Dielectric Strength (kV/mm): 24 Volume Resistivity (10x ohm-cm) : 15 High-Voltage Arc Tracking Rate (HVTR): 3 High Volt, Low Current Arc Resis (D495): 6 Dimensional Stability (%): 0 Relative Thermal Index (RTI): A numerical rating expressed in degrees Celsius, which results from long-term thermal aging and the evaluation of a specific property. The value assigned is based on a comparison of new material against a known or control material. Test Name Glow-Wire Flammability (GWFI) Glow-Wire Ignition (GWIT) Test Method IEC 60695-2-12 IEC 60695-2-13 Units C C Thickness Tested (mm) 3.8 3.8 Value 960 775 ANSI/UL 94 small-scale test data does not pertain to building materials, furnishings and related contents. ANSI/UL 94 small-scale test data is intended solely for determining the flammability of plastic materials used in the components and parts of end-product devices and appliances, where the acceptability of the combination is determined by UL. Report Date: 1995-05-26 Last Revised: 2008-11-13 © 2013 UL LLC E155285 Component - Plastics POLYMER TECHNOLOGY & SERVICES L L C TRISTAR ® PC 10FR GY02VIK POLYCARBONATE, FLAME RETARDANT, UL94 V-0 AT 3.0 mm, UV AND CHEMICAL RESISTANT 2315 SOUTHPARK DR, MURFREESBORO TN 37128 PCA-2201NHV (b), PCA-2201NH (b) Polycarbonate/Acrylonitrile Butadiene Styrene (PC/ABS), furnished as pellets Min Thk Flame RTI RTI RTI Color (mm) Class HWI HAI Elec Imp Str ALL 1.5 V-0 3 1 60 60 60 2.0 V-0, 5VB 3 1 60 60 60 3.0 V-0, 5VA 2 1 60 60 60 Comparative Tracking Index (CTI): 0 Inclined Plane Tracking (IPT): Dielectric Strength (kV/mm): 18 Volume Resistivity (10x ohm-cm) : High-Voltage Arc Tracking Rate (HVTR): High Volt, Low Current Arc Resis (D495): Dimensional Stability (%): - UL INFORMATION (V) - Represents three to four digits denoting color. (e) - Represents a two to four digit alphanumeric code indicating color. (f1) - Suitable for outdoor use with respect to exposure to Ultraviolet Light, Water Exposure and Immersion in accordance with UL 746C. NOTE - Material designations may be followed by numbers and/or letters representing color and/or granulation and/or lubrication. (b) - Represents a six to eight digit character code. All colors. NOTE - Material designations may be followed by numbers and/or letters representing color and/or granulation and/or lubrication. Test Name Glow-Wire Flammability (GWFI) Glow-Wire Ignition (GWIT) Test Method IEC 60695-2-12 IEC 60695-2-13 Units C C Thickness Tested (mm) 1.5 1.5 Value 925 700 ANSI/UL 94 small-scale test data does not pertain to building materials, furnishings and related contents. ANSI/UL 94 small-scale test data is intended solely for determining the flammability of plastic materials used in the components and parts of end-product devices and appliances, where the acceptability of the combination is determined by UL. Report Date: 2013-03-13 Last Revised: 2013-03-13 © 2013 UL LLC E155285 Component - Plastics POLYMER TECHNOLOGY & SERVICES L L C 2315 SOUTHPARK DR, MURFREESBORO TN 37128 PCA-30G-(z)-(a) Polybutylene Terephthalate/Polycarbonate (PBT/PC), glass reinforced, furnished as pellets Min Thk Flame RTI RTI RTI Color (mm) Class HWI HAI Elec Imp Str ALL 1.5 HB 75 75 75 3.0 HB 75 75 75 Comparative Tracking Index (CTI): Inclined Plane Tracking (IPT): Dielectric Strength (kV/mm): Volume Resistivity (10x ohm-cm): High-Voltage Arc Tracking Rate (HVTR): High Volt, Low Current Arc Resis (D495): Dimensional Stability (%): (a) - Represents a six to eight digit character code. All colors except clear (z) - Represents glass content 0-33%. NOTE - Material designations may be followed by numbers and/or letters representing color and/or granulation and/or lubrication. Test Name Glow-Wire Flammability (GWFI) Glow-Wire Ignition (GWIT) Test Method IEC 60695-2-12 IEC 60695-2-13 Units C C Thickness Tested (mm) - Value - ANSI/UL 94 small-scale test data does not pertain to building materials, furnishings and related contents. ANSI/UL 94 small-scale test data is intended solely for determining the flammability of plastic materials used in the components and parts of end-product devices and appliances, where the acceptability of the combination is determined by UL. Report Date: 1995-05-26 Last Revised: 2008-11-13 © 2013 UL LLC © 2013 Polymer Technology & Services, LLC TRISTAR® PC-10FR-GY(VIM) POLYCARBONATE, FLAME RETARDANT, UL94 V-0 AT 3.0 mm, UV AND CHEMICAL RESISTANT, TESTED TELCORDIA GR49 5 PROPERTY Physical Mechanical Impact Thermal Electric UL Relative Thermal Index Flammability Specific Gravity, solid Melt Flow Index, 300°C,1.2Kg* Melt Flow Index, 260°C,2.2Kg* Melt Flow Index, 250°C,3.8Kg* Mold Shrinkage Water Absorption, 24 hours 73°F Tensile Strength, yield, 0.125” Tensile Elongation, break, 0.125” Flexural Strength, yield, 0.125” Flexural Modulus, 0.125” Rockwell Hardness Izod Impact Str., Notched, 0.125 ” Heat Deflection Temp. @ 264 PSI HDT @1.8MPa Dielectric Strength, 0.125” Volume Resistivity, 40 hours @ 23°C, 50% RH Volume Resistivity, 96 hours @ 90°C, 50% RH Hot Wire Ignition (HWI), 1.62 mm Hot Wire Ignition (HWI), 3.0 mm High Current Arc Ignition (HAI), @ 23°C, 50% RH, 1.62 mm High Current Arc Ignition (HAI), @ 23°C, 50% RH High Voltage Arc Tracking (HVTR), 3.0 mm High Voltage, Low Current Arc Resistance, 3.0mm Comparative Tracking Index (CTI), 3.0 mm High Voltage Arc Resistance to Ignition, 1.6 mm RELATIVE THERMAL INDEX UL 746B Electrical Mechanical with impact Mechanical without impact Flammability All Colors All Colors Black, Gray, Beige Only Black Only Limited Oxygen index IEC GWFI IEC GWIT UNIT TEST METHOD • g/10 min g/10 min g/10 min % % PSI (MPa) % PSI (MPa) 105 PSI (MPa) R-Scale ft.-lb./in. (J/m) °F (°C) °F (°C) kv/m ohm-cm ohm-cm PLC PLC PLC PLC ASTM D-792 ASTM D-1238 ASTM D-1238 ASTM D-1238 ASTM D-955 ASTM D-570 ASTM D-638 ASTM D-638 ASTM D-790 ASTM D-790 ASTM D-785 ASTM D-256 ASTM D-648 ISO 75-A ASTM D-149 ASTM D-257 ASTM D-257 ASTM D-3874 ASTM D-3874 UL 746A UL 746A PLC UL 746A 3 • 3 PLC ASTM D-495 6 • 6 PLC ASTM D-3638 2 • 2 seconds UL 746A 16 • 16 UL94 UL94 UL94 UL94 ASTM D-2863 IEC 695-2-1/2 IEC 695-2-1/2 125 115 125 V-O V-O 5VA • 37.6 960 775 • • • V-O • • • • • • 125 115 125 V-2 V-O • • 36.9 960 775 1.5 mm 3.0 mm 2.5 mm 1.5 mm % °C °C UNFILLED PC-10FRN-(V)(f1) PC-09FRN-(WT) 1.23 1.23 15 9 • • • • 0.5-0.7 • 0.18 0.18 8,500 (59) 8,500 (59) 75 100 12,500 (86) 10,900 (75) 3.1 (2,137) 3.0 (2,070) 120 120 13.0 (693) 13.0 (695) 250 (121) 265 (129) 273 (134) 284 (140) 24 • 6.00E+15 • 3.00E+15 • 3 • 2 • 0 • 1 • PC-10FR ( 1.23 12 • • 0.5 - 0.7 0.18 9,000 (62 75 13,000 (90 3.2 (2,200 120 14.0 (747 260 (127 279 (137 24 6.00E+1 3.00E+1 3 2 0 1 *Other melt flow are available, please see Reference Sheet on page 14 Disclaimer: ALTHOUGH ANY INFORMATION, RECOMMENDATIONS, OR ADVICE CONTAINED HEREIN IS GIVEN IN GOOD FAITH, PTS MAKES NO INCORPORATING PTS MATERIALS, PRODUCTS, RECOMMENDATIONS OR ADVICE. No statement contained herein concerning a possible or suggested use of any material, product or design is intended, or should be con other intellectual property right. © 2013 Polymer Technology & Services, LLC ECO-FRIENDLY / FLAME RETARDANT PC & PC/ABS GLASS REINFORCED (f1) PC-10R(V) (f1) PC10GFR (f2) 1.20 1.25 10 • • • • • 7 0.5-0.7 0.2 - 0.4 0.15 0.12 2) 9,000 (62) 9,000 (62) 100 15 0) 13,000 (90) 14,000 (96) 0) 3.2 (2,200) 4.5 (3,100) 120 120 7) 15.0 (800) 2.0 (107) 7) 260 (127) 280 (138) 7) 279 (137) 286 (141) 25 19 15 6.00E+15 6.00E+15 15 3.00E+15 3.00E+15 3 2 2 2 0 0 1 0 PC/PBT ALLOY PC20GFR 1.34 • • • 0.1 - 0.3 0.12 16,000 (110) 5 19,000 (130) 7.8 (5,400) 120 2.0 (107) 285 (141) • • • • • 1 • 0 PC30GFR 1.43 • • • 0.1 - 0.3 0.12 18,500 (127) 3.0 22,500 (155) 11 (7,600) 120 2.0 (107) 290 (143) • • • • • 1 • 0 PC10FRNH 1.23 12 • • • 0.18 8,900 (61) 75 14,000 (96) 3.4 (2,340) 120 13.0 (695) 260 (126) 275 (135) • • • • • • • PCA-2201NH 1.17 • 16 • 0.004-0.006 • 8,700 (60) 65 12,900 (89) 3.9 (2,690) • 11.0 (585) 185 (85) • • • • • • • • PCA-30G30 1.43 • • • • • 15,000 (103) 4 20,000 (138) 10(6894) • 2.7 (144) 226 (108) • • • • • • • • 3 • • • • PCA-3013 1.21 • • 20 0.75-1.0 0.03 7,500 (51.7) 150 9,200 (63.3) 2.66 (1833) • 13 (694) 212 (100) • • • • 4 3 0 PC/ABS ALLOY PCAFR PCA-1012 1.20 1.15 • • 16.0 20.0 • • 0.4 - 0.7 0.4 - 0.6 0.03 • 9,000 (62) 9,000 (62) 40 • 14,000 (96) 14,000 (96) 3.7 (2,570) 3.5 (2400) • • 10 (534) 12(640) 190 (88) 235 (113) • • • • • • • • • • • • • • • • 0 3 0 • • • • • 6 7 6 6 • • • • 2 3 4 4 • • • 16 • • • • • • 0 • 125 115 125 V-2 V-2 • • • 960 775 125 115 125 V-O 5VA (@2.4mm) • • 37.1 960 800 80 80 80 • V-O • V-O • • • 80 80 80 • V-0 • • • • • • • • • V-0 • • • • • • • • • V-O • • • • • 75 75 75 HB • • • • • • 75 75 75 • HB • • • • • • • • • 60 60 60 V-O • • • • • • • • • • • • • • • • WARRANTY OR GUARANTEE, EXPRESS OR IMPLIED, (I) THAT THE RESULTS DESCRIBED HEREIN WILL BE OBTAINED UNDER END-USE CONDITIONS, OR (II) AS TO THE EFFECTIVENESS OR SAFETY OF ANY DESIGN nstrued, to grant any license under any patent or other intellectual property right covering such use or design, or as a recommendation for the use of such material, product or design in the infringement of any patent or © 2013 Polymer Technology & Services, LLC What is PC/ABS? A compounded blend of Polycarbonate and ABS. The PC contributes impact and heat distortion resistance, while the ABS contributes processability and chemical stress resistance, and cost reduction below PC. PRODUCT INTRODUCTION What are the properties of PC/ABS? Properties of PC/ABS include the following: • impact resistance between ABS and PC, (10-14 ft.-lb./in.) • strength and stiffness between PC and ABS • heat resistance superior to ABS, less than PC • flame retardant system more stable in processing than ABS • very good indoor UV light color stability • low temperature impact and ductility • superior processability to PC When should PC/ABS be used? PC/ABS should be used for appearance housings, and structural parts which need stiffness, gloss, impact and heat resistance which is higher than ABS, but requiring costs below Polycarbonate. Housings requiring UL V0, but not 5VA-that is, portable electronic devices, not permanently fixed electric devices are also good applications for PC/ABS. Others include appearance parts requiring color fastness under interior UV light, automotive interior parts where temperature environment is between 180 F and 230 F - “above the beltline” applications, and where non-shattering ductility is required like instrument panel retainers. Applications such as painted exterior automotive parts requiring low temperature impact greater than 10 ft.-lb./in. is another place PC/ABS should be used. Any outdoor application should be painted. What is made with PC/ABS? • portable appliances, flashlights, phones • laptop computer cases • keyboards, monitors, printer enclosures • automotive instrument panel retainers • wheel covers, small tractor hoods • non-professional safety helmets What is PC/PBT? A compounded blend of Polycarbonate and PBT. The PC contributes impact, stiffness and heat resistance, while the PBT contributes chemical resistance. The usual moisture sensitivity of the crystalline PBT is overcome by the PC in the blend. Some grades are made using PET instead of PBT. What are the properties of PC/PBT? • impact resistance, • low temperature impact resistance, ductility • heat resistance • chemical resistance When should PC/PBT be used? PC/PBT is effective where impact and chemical resistance are where low temperature impact, requiring needed, and a ductile failure mode (non-shattering breaks) is necessary. Applications such as bumpers and body moldings on autos and lawn & garden equipment, where toughness and resistance to stress cracking from fuels and lubricating fluids are required are good uses for PC/PBT. The shrinkage varies based upon the relative content of the PBT, and therefore tool may be unique for this material, that is, it is not easy to substitute it for other polymers. What is made with PC/PBT? • automotive bumpers • automotive side moldings • lawn and garden tractor hoods • hand tool housings • irrigation components • wiring connectors (PC/PET) TRISTAR® PC-10R-WT(V15) POLYCARBONATE, 15 MELT, UL94 V-2 AT 1.5mm, UV RESISTANT 8 © 2013 Polymer Technology & Services, LLC TRISTAR® PC-10R-BK(14) POLYCARBONATE, 14 MELT, UL94 V-2 AT 1.5mm APPLICATIONS, TESTING Flexural Test TRISTAR® PC-10FRN-BK(V) POLYCARBONATE, FLAME RETARDANT, UL94 5VA AT 2.5 mm, UV RESISTANT TRISTAR® PC-10GFR-GY(V) POLYCARBONATE, 10% GLASS FILLED, FLAME RETARDANT UL94 V-0 AT 1.5 mm, 5VA @ 2.4mm, UV RESISTANT PCA-403: PC/PBT ALLOY, UV AND CHEMICAL RESISTANCE, IMPROVED LOw TEMPERATURE IMPACT 9 © 2013 Polymer Technology & Services, LLC COMPANY TRADE NAME PTS LLC TRISTAR® SABIC IP LEXAN® BAYER MAKROLON® STYRON CALIBRETM 101, 101R 201, 201R 3100 3105 300-6, 301-6 103, 103R 203, 203R 3103, 3107 302-6, 303-6 5-8 MFI -UV PC-06*, PC-10R-(6), PC-08*, PC-10R-(8) PC-10R-(V6), PC-10R-(V8) -FR(V-0@3.0 mm) -FR with UV PC-10FR-(8) PC-10FR-(V8) 950AR 953AR - - -GP PC-10*, PC-10R 141, 141R 241, 241R 2800, 2805 300-10, 301-10 -UV PC-10R-(V) 143, 143R 243, 243R 2803, 2807 302-10, 303-10 -FR(V-0@3.0 mm) -FR with UV PC-10FR PC-10FR-(V) 940A, 940AR 943A, 943AR 6455, 6457 891 -FR(VO@1.5 mm, 5VA@2.1 mm) -FR with UV PC-09FRN-WT PC-09FRN-WTV 9925 FR7067 - -NON Cl, NON Br FR (VO@1.5 mm) -FR with UV PC-10FRNH PC-10FRNH-(V) 945 6557 EMERGE™ 8600 -GP PC-10R-(12) 141L, 141LR -UV PC-10R-(VE) -FR(V-0@1.5 mm) -FR with UV REFERRENCE - POLYCARBONATE -GP 9-12 MFI 12-14 MFI - 143L, 143LR 2600, 2605 2603, 2607 PC-10FRN PC-10FRN-(V) 920R, 940R 923R, 943R 6485 - PC-10FRN-(V)** - 6485 - 2500, 2505 2503, 2507 6355, 6357 300-15, 301-15 302-15, 303-15 PC-10FR-(16) PC-10FR-(V16) 121, 121R 221, 221R 123, 123R 223, 223R 920AR 923AR -GP PC-10R-(18), PC-10R-(22) HF1110 2405 300EP-22, 301EP-22 -UV PC-10R-(V18), PC-10R-(V22) HF-1130 2407 302EP-22, 303EP-22 -FR(V-0@3.0 mm) -FR with UV PC-10FR-(18) PC-10FR-(V18) - 6255, 6257 - 500R, 503R 9415 5101 3412 8325 5201 3413 - - -FR(5VA@3.0 mm),** with UV 15-17 MFI -GP PC-10R-(15) -UV PC-10R-(V15) -FR(V-0@3.0 mm) -FR with UV 18-24 MFI - - Glass Reinforced Grades V-O @ 1.5mm, 5VA @ 2.4mm -10% -10% with UV -20% -20% with UV -30% -30% with UV PC-10GFR PC-10GFR-(V) PC-20GFR PC-20GFR-(V) PC-30GFR PC-30GFR-(V) TRISTAR® is a registered trademark of Polymer Technology & Services, LLC. LEXAN® is a registered trademark of SABIC IP CALIBRE® is a registered trademark of STYRON, LLC. MAKROLON® is a registered trademark of Bayer. *Extrusion Grades **5VA Flame Retardant grades are available only in Black, Gray and Beige Colors. The PTS LLC. grades listed are suggestions only. Due to variable conditions or methods of processing, NO GUARANTEES OR WARRANTIES ARE EXPECTED OR IMPLIED, INCLUDING THE IMPLIED WARRANTY OF MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE. The above information is not to be construed as a license or recommendation to infringe on any patents. © 2013 Polymer Technology & Services, LLC COMPANY TRADE NAME PTS LLC PTS SABIC IP CYCOLOY® BAYER BAYBLEND® TRIAX® STYRON PULSE® -ID PCA-1012 C1110 MC8002 T85MN 830 -GP PCA-1011 C1000 T65MN 930 -HF PCA-1010H C1950 T45MN 600 -FR PCA-FR C2800 C2950HF FR90 1725 PC/ABS -5VA FR PCA-2010 PCA-2008 FR (Non Cl, non Br) PCA-2010NH PCA-2010NHV C6200 FR (Non Cl, non Br 5VA) PCA-2201NH PCA-2201NHV C6600 COMPANY TRADE NAME FR3000 Emerge™ 7700 PTS LLC PTS SABIC IP XENOY® BAYER MAKROBLEND® -LT PCA-3015 5720 UT 1018 -GP PCA-3013 PCA-30G30 5220 UT 250 ABBREVIATIONS: GP: General Purpose FR: Flame Retardant HF: Hi Flow ID: Impact Ductile LT: Low Temperature CYCOLOY® AND XENOY® are registered trademarks of Sabic IP. PULSE® is a registered trademark of STYRON, LLC. BAYBLEND®, TRIAX®, and MAKROBLEND® are registered trademarks of Bayer. The PTS LLC. grades listed are suggestions only. Due to variable conditions or methods of processing, NO GUARANTEES OR WARRANTIES ARE EXPECTED OR IMPLIED, INCLUDING THE IMPLIED WARRANTY OF MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE. The above information is not to be construed as a license or recommendation to infringe on any patents. TRISTAR® PC-10FR-GY(VIM) POLYCARBONATE, FLAME RETARDANT, UL94 V-0 AT 3.0 mm, UV AND CHEMICAL RESISTANT, TESTED TELCORDIA GR49 © 2013 Polymer Technology & Services, LLC 11 ABOUT PTS AND TRISTAR® REFERENCE - ALLOYS PC/PBT 2315 Southpark Drive • Murfreesboro, TN 37128 USA Phone (电话): +1-615.898.1700 • Fax (传真): +1-615.898.1697 Email: pts@ptsllc.com • Web: www.ptsllc.com Polymer Technology & Services (Suzhou) Trading Ltd. Suite 901B, Kinwick Centre - 32 Hollywood Road, Central - Hong Kong - PRC Polymer Technology & Services (Suzhou) Trading Ltd. Room 1902, Xinhai International Plaza, No. 200 Xinhai Street, Suzhou Industrial Park, 215021, Suzhou, China Phone (电话): +86 (0)512-6280-9167, 6280-0789 Fax (传真): +86-(0)512-6280-0739