Talk

TECHNICAL

ROTASYN

Talk

T

E C H N I C A L

An Absolute Inductive Transducer for

ROTASYN

Brushless Servomotors

The following is based on a technical paper presented by David T. Robinson, VP Engineering,

Admotec Inc., at the Intelligent Motion Systems

’95 conference in Long Beach CA, Sept. 1995.

INTRODUCTION

onal resolvers – is now available. This device utili-

A New Absolute Inductive Transducerzesfor

Brushless

a solid

rotor withoutServomotors

windings and overcomes

Today, frameless brushless (pancake) resolvers

the disadvantages of traditional resolvers. As

are commonly used on AC and brushless DC sersuch, it offers higher speed operation, better relivomotors to provide commutation, position, and

ability.

Introduction

velocity information to the servo controller. These available. This device utilizes a solid rotor without windangular position transducers give a constant sig- ings and overcomes the disadvantages of traditional reToday, frameless brushless (pancake) resolvers are comsuch, it offers

speed operation, better

nal representing the absolute position of the mo- solvers.

AN As

OVERVIEW

OFhigher

ANGULAR

monly used on AC and brushless DC servomotors to protor shaft within one revolution, making them well reliability,

TRANSDUCERS

and lower cost.

vide commutation,

position,

and However,

velocity information

to resolsuited for this

purpose.

traditional

the servo

controller.

These

angular

position

transducers

Overview

of Angular

Transducers

vers are complex and expensive to manufacture, An Flexible

motion

control is unthinkable

without

give a limiting

constant their

signaluse

representing

the absolute

position

in industrial

servomotors.

Rotaprecise information about the position of each

Flexible motion control is unthinkable without precise insyn resolvers

follow

differentmaking

approach

axis. For this purpose, different types of shaft

of the motor

shaft within

one arevolution,

themfor an

formation

the are

position

ofoften

each axis.

absolute

inductive

position

transducer

while

angleabout

sensors

used,

built For

intothis

thepurdriwell suited for this purpose. However, traditional resolvers

pose,

different

types

of

shaft

angle

sensors

are

used,

ofbeing and

mechanically

and

electricallylimiting

compatible

ving motors. On the basis of their physical design,

are complex

expensive to

manufacture,

their

into

the driving

motors. On

thebebasis

of theirinto

with traditional designs. A new type of absolute ten built

these

angular

transducers

can

classified

use in industrial servomotors. A new type of absolute ininductive position transducer – one that is metwo design,

main groups:

physical

these angular transducers can be classiductive position transducer—one that is mechanically and

chanically and electrically compatible with traditi- fied into two main groups:

electrically compatible with traditional resolvers—is now

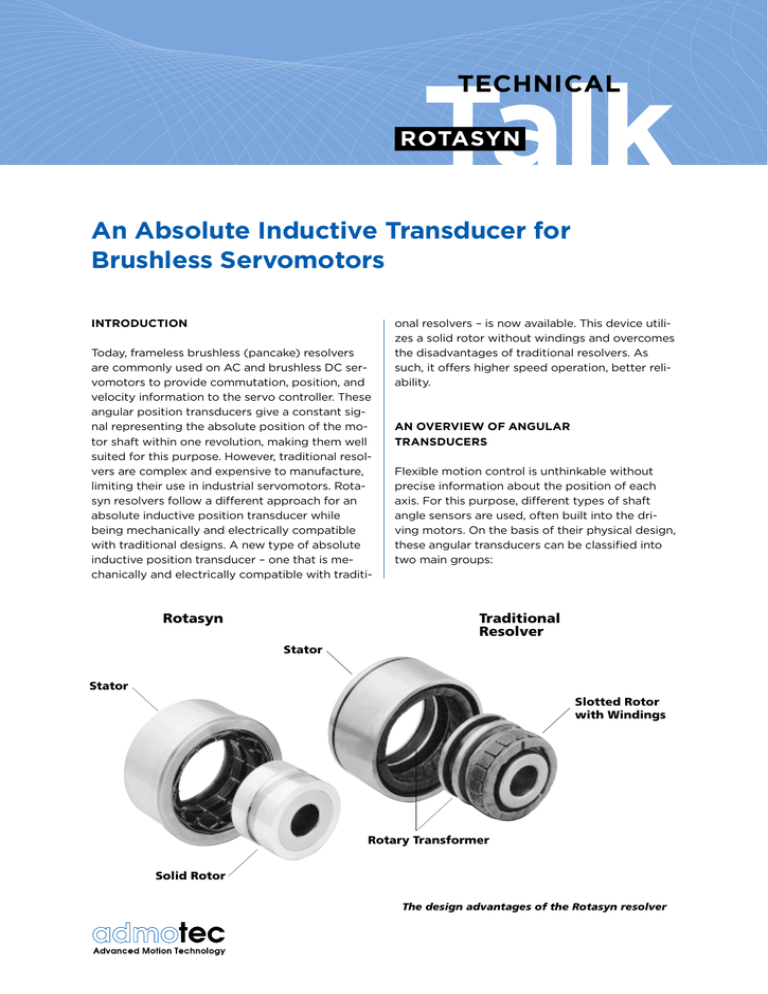

Rotasyn

Traditional

Resolver

Stator

Stator

Slotted Rotor

with Windings

Rotary Transformer

Solid Rotor

The design advantages of the Rotasyn resolver

admotec

Advanced Motion Technology

Talk

TECHNICAL

ROTASYN

Optical where a phototransistor or other light-sensitive electronic

device countsorlines

a transpaOptical

where a phototransistor

otheron

light-sensitive

rent disk mounted to the rotating shaft. The

electronic device counts lines on a transparent

most common of these devices are incremendisk mounted to the rotating shaft. The most

tal and absolute encoders.

common of these devices are incremental and

absolute encoders.

Inductive

built like small electrical motors, where inducInductive built like small electrical motors, where inductive coupling between a rotating part (the rotive coupling between a rotating part (the rotor) and a stationary part (the stator) generator) and a stationary part (the stator) generates

tes signals indicating shaft position. Resolvers

signals indicating shaft position. Resolvers and

and synchros are the most common devices.

synchros are the most common devices.

Optical transducers, especially incremental encoOptical transducers, especially incremental encoders,

ders, have found wide application because their

have found wide application because their digital outputs

digital outputs can be easily processed by both

can be easily processed by both discrete logic and microdiscrete logic and microprocessors. Nevertheless,

processors.

Nevertheless,

optical

transducers

have a

optical transducers

have

a number

of characterisnumber

of make

characteristics

thatthan

makeoptimal

them lessfor

than

optitics that

them less

many

mal

for

many

applications.

The

built-in

semiconductors

applications. The built-in semiconductors used to

used

to amplify

and format

digital

outputsignals

signals are

amplify

and format

the the

digital

output

are

sensitive

temperature

and

the

LED

light comsoursensitive

to to

temperature

and the

LED

light

sources

ces co

monly employed

are to

susceptible

to aging.

monly

employed

are susceptible

aging. Furthermore,

Furthermore,

applications

that

require

an

absoluapplications that require an absolute output signal

rete

output

signal

require

absolute

encoders,

which

quire absolute encoders, which are much more compliare much more complicated and therefore expencated and therefore expensive.

sive.

From a purely practical standpoint, the precise concenFrombetween

a purely

standpoint,

the precise

tricity

thepractical

encoder disk

and the sensors

required

concentricity

between

the

encoder

disk

and

to maintain accuracy as well as the mere presence ofthe

opsensors

required

to maintain

accuracy

as well

tical

devices

in an industrial

environment

dictate

that aas

the mere presence of optical devices in an industfully enclosed device with bearings and shaft be used in

rial environment dictate that a fully enclosed deall but the crudest applications. Since encoders are typivice with bearings and shaft be used in all but the

cally connected to a shaft having its own bearings, the

crudest applications. Since encoders are typically

user

must payto

forathe

second

set ofitshigh-quality

bearings

connected

shaft

having

own bearings,

the

inuser

the transducer

as

well

as

a

flexible

coupling

to

connect

must pay for the second set of high-quality

the

two shafts.

In many

applications,

especially

brushless

bearings

in the

transducer

as well

as a flexible

servomotor

commutation

or flux

control

of ACapincoupling to

connect the

twovector

shafts.

In many

plications,

especially

brushless

duction

motors,

the additional

lengthservomotor

of the optical commutationshaft,

or flux

vectorand

control

of AC

induction

encoder’s

bearings,

coupling

is too

great and

motors,

the

additional

length

of

the

optical

the optical encoder cannot be used.

encoder’s shaft, bearings, and coupling is too

On

the and

otherthe

hand,

inductive

transducers

such

resolvgreat

optical

encoder

cannot

beasused.

ers are intrinsically absolute and require no semiconducOn on

thethe

other

hand,itself—the

inductiveraw

transducers

such

tors

transducer

output signal

can as

be

resolvers

are

intrinsically

absolute

and

require

no

transmitted over distances of more than 100 meters. In

semiconductors

the primarily

transducer

itself –and

thesteel,

raw

addition,

since they on

consist

of copper

output

signal

can

be

transmitted

over

distances

resolvers are virtually insensitive to temperature over a

of more than 100 meters. In addition, since they

consist primarily of copper and steel, resolvers

are virtually insensitive to temperature over a

wide range. Because no sensitive electronics or

optics are employed, resolvers are often supplied

in anrange.

unhoused

(also

called frameless

wide

Because

no sensitive

electronics or

or pancake)

optics are

configuration and can be mounted directly to the

employed, resolvers are often supplied in an unhoused

shaft whose position is to be measured. Cost and

(also called frameless or pancake) configuration and can

length savings are realized by the user since no

be mounted directly to the shaft whose position is to be

shaft-to-shaft coupling or extra bearings are

measured.

required. Cost and length savings are realized by the

user since no shaft-to-shaft coupling or extra bearings are

required.

While resolvers were originally developed for military and aerospace applications, in recent years

While resolvers were originally developed for military

industrial automation has shown more interest in

and aerospace applications, in recent years industrial

these rugged and precise absolute position transautomation

has shown more

in these

ducers. Nevertheless,

theinterest

expansion

of rugged

the useand

of

precise

absolute

position

transducers.

Nevertheless,

thesiresolvers was often limited by the fact that the

expansion

of the userequired

of resolvers

was often limited

by the

gnal conversion

cumbersome

circuitry

fact

the signal resolver

conversionproduction

required cumbersome

cirandthat

automated

was difficult.

Now,and

however,

inexpensive

and easy-to-implecuitry

automated

resolver production

was difficult.

menthowever,

monolithic

ICs thatand

perform

complete resolNow,

inexpensive

easy-to-implement

ver-to-digital

conversion

are available.

These R/D

monolithic

ICs that

perform complete

resolver-to-digital

converters

give

an

absolute

or

incremental

outconversion are available. These R/D converters give

an

put with a resolution of up to 65,536 counts per

absolute or incremental output with a resolution of up to

revolution. A typical two-chip solution is shown

65,536 counts per revolution. A typical two-chip solution

below.

is shown below.

Resolver

Excitation

Oscillator

(AD2S99)

Digital

Position

Data

R/D

Converter

(AD2S90)

Ref

Sin

Cos

Simple R/D conversion using two monolythic ICs

Simple R/D conversion using two monolythic ICs

The resolver signals are low bandwidth amplitude-moduThe resolver signals are low bandwidth amplitulated sine waves. Since these sine wave signals contain

de-modulated sine waves. Since these sine wave

only a single frequency component rather than the virtusignals contain only a single frequency compoally infinite frequency spectrum of an optical encoder’s

nent rather than the virtually infinite frequency

square

waveof

signals,

they are

inherentlysquare

much more

spectrum

an optical

encoder’s

waveimsimune

to

the

high-frequency

noise

generated

by

PWM to

gnals, they are inherently much more immune

motor

drives and other noise

industrial

machinery.

the high-frequency

generated

by PWM motor drives and other industrial machinery.

Finally, since the resolver itself was handicapped by a

high

levelsince

of manual

labor, some

manufacturers

have

Finally,

the resolver

itself

was handicapped

opted

to transfer

low labor-cost

countries.

by a high

levelproduction

of manualtolabor,

some manufacturers have opted to transfer production to low labor-cost countries.

Talk

TECHNICAL

ROTASYN

While lowering unit costs, this reduces their ability to respond to the market needs and does not

allow them to quickly meet customer demands.

FEEDBACK REQUIREMENTS FOR AC

While lowering unit costs, this reduces their ability to reSERVOMOTORS

spond to the market needs and does not allow them to

quickly meet customer

Commutation

of ACdemands.

and brushless DC servomotors can be done with Hall-effect sensors to

Feedback Requirements for AC

switch current into the proper phase at the proServomotors

per time. However, a tachometer and encoder are

then

required

the velocity

and position

Commutation

of to

ACclose

and brushless

DC servomotors

can

loops

inwith

the Hall-effect

drive. sensors to switch current into the

be done

Using

resolver

theHowever,

number aoftachometer

transduproper aphase

at thereduces

proper time.

cers

on

the

motor

from

three

to

only

one.

and encoder are then required to close the velocityIndeed,

and

from

a single

position

loops intransducer

the drive. it is possible to generate

all three of the required signals: high resolution

Using aposition

resolver reduces

the number

of transducers

on

digital

information

is available

directly

the

motor

from

three

to

only

one.

Indeed,

from

a

single

from the R/D converter; this position data allows

generation

ofpossible

sine wave

signalsallfor

commutation

transducer it is

to generate

three

of the refrom

lookuphigh

table;

and adigital

velocity

signal

is

quiredasignals:

resolution

position

information

available

thefrom

R/D

chipthis

to replace

is availablefrom

directly

theconverter

R/D converter;

position

the

ingeneration

analog drives.

completely

datatach

allows

of sineIn

wave

signals fordigital

comdrives,

the

basic

absolute

shaft

position

informamutation from a lookup table; and a velocity

signal

is

tion

can from

be used

to derive

velocity

and commutaavailable

the R/D

converter

chip to replace

the tach

tion

signals

within

the microprocessor.

In fact,

in analog

drives.

In completely

digital drives, the

basic a

fast DSP can perform the R/D conversion itself by

absolute shaft position information can be used to derive

synchronously sampling the resolver signals.

velocity and commutation signals within the microprocessor. In fact, a fast DSP can perform the R/D conversion

itself by synchronously sampling the resolver signals.

TRADITIONAL BRUSHLESS RESOLVERS

Traditional Brushless Resolvers

Rotary

Transformer

Sin Output

(Secondary)

Cos Output

(Secondary)

Rotary

Transformer

Rotor Input

(Primary)

Secondary

Primary

The traditional brushless resolver consists of a

The traditional

resolver

consistsbelow.

of a wound

rowound

rotor brushless

and stator

as shown

The wintor

and

stator

as

shown

below.

The

windings

on

the

rotor

dings on the rotor generate an AC magnetic field

generate

an AC magnetic

field withThis

a sinusoidal

diswith

a sinusoidal

distribution.

field induces

tribution.

This

field

induces

voltages

in

the

two

stator

voltages in the two stator windings whose ampliwindings

amplitudes

onangle

the rotatudes

arewhose

dependent

onare

thedependent

rotational

of

tional

angleTo

of provide

the rotor. sine

To provide

sine and

cosine sigthe

rotor.

and cosine

signals,

the

Traditional brushless

brushless resolver

Traditional

resolverwith

withwound

woundrotor

rotor

and rotary transformer

and rotary transformer

two secondaries are wound in space quadrature

(90 physical degrees apart) in the stator.

Electrical energy has to be supplied to the rotor

to generate its AC magnetic

T Efield.

C HHowever,

N I C A as

L the

rotor must be able to rotate freely it is not possible to use wires. The use of slip rings is also not

R O T they

A S Yare

N subject to wear,

recommended because

generate signal noise, and compromise the mechanical

of wound

the resolver.

nals,

the tworuggedness

secondaries are

in space quadrature

Traditional brushless resolvers therefore use a ro(90 physical degrees apart) in the stator.

tary coupling transformer to transfer energy from

the stator

to the

rotor.

The primary

of this

rotary

Electrical

energy

has to

be supplied

to the rotor

to genertransformer

is built

the stator.

The secondary

ate

its AC magnetic

field.into

However,

as the rotor

must be

is mounted

on the

and connected

able

to rotate freely

it is rotor

not possible

to use wires.directly

The use

to

the

resolver

primary.

Because

of

the

energy

of slip rings is also not recommended because they are

lost intoenergizing

thissignal

two-stage

transformer

subject

wear, generate

noise, and

compromise(basically

two

transformers

in

series),

many

turns of

the mechanical ruggedness of the resolver.

wire are required to generate usable output sigTraditional

brushlessThe

resolvers

use

rotarymeans

counal amplitudes.

largetherefore

number

ofaturns

thattransformer

a traditional

resolver

is a from

relatively

high-impling

to transfer

energy

the stator

to the

pedance

device,

use at high

excitation

rotor.

The primary

of limiting

this rotaryits

transformer

is built

into

frequencies

or rotational

speeds.

the

stator. The secondary

is mounted

on the rotor and

Becausedirectly

a traditional

resolver

has aBecause

woundofrotor,

connected

to the resolver

primary.

the

its

maximum

speed

is

limited

since

the

windings

energy lost in energizing this two-stage transformer

(basitend

fly out of the

rotormany

due to

centrifugal

cally

twototransformers

in series),

turns

of wire are

force.

Typical

maximum

speeds

are

10,000 RPM

required to generate usable output signal amplitudes.

The

or less.

large number of turns means that a traditional resolver is

a relatively high-impedance device, limiting its use at

high excitation frequencies or rotational speeds.

THE ROTASYN™

Talk

Because a traditional resolver has a wound rotor, its

Unlike the

traditional

brushless

resolver,

maximum

speed

is limited since

the windings

tend the

to flyRotasyn

has

both

primary

and

secondary

windings

out of the rotor due to centrifugal force. Typical maximum

in theare

stator

and

thus

no rotary transformer is

speeds

10,000

RPM

or less.

required – the Rotasyn is intrinsically brushless!

™

The

TheRotasyn

transferred

energy remains magnetic from

the primary coil through the air gap to the sinuUnlike the traditional brushless resolver, the Rotasyn has

soidally shaped poles of the solid rotor.

both primary and secondary windings in the stator and

The Rotasyn is similar to a rotary variable diffethus no rotary transformer is required—the Rotasyn is inrential transformer (RVDT) in which the rotor

trinsically

The transferred

energy remains

acts as brushless!

a magnetic

valve completing

the flux

magnetic

from

the

primary

coil

through

to the –

path. The total flux through the the

gapairisgap

constant

sinusoidally

poles ofthe

theangular

solid rotor.

the rotor shaped

determines

position within

the stator bore where the coupling occurs, and

The Rotasyn is similar to a rotary variable differential

thus the relative amplitudes of the output sigtransformer (RVDT) in which the rotor acts as a magnetic

nals.

valve completing the flux path. The total flux through the

The primary coil is wound circumferentially betgap is constant—the rotor determines the angular posiween the two stators. The two secondary wintion

within

thewound

stator bore

where

the coupling

dings

are

in the

stator

slots inoccurs,

spaceand

quathus

the

relative

amplitudes

of

the

output

signals.

drature (shifted by 90 physical degrees) similar

to a traditional resolver. Hence the induced volThe primary coil is wound circumferentially between the

tage amplitudes correspond to the sine and cotwo stators. The two secondary windings are wound in

sine of the rotor angle as in a traditional resolver.

Talk

T

the stator slots in space quadrature (shifted by 90 physi-

R

cal degrees) similar to a traditional resolver. Hence the

induced voltage amplitudes correspond to the sine and

cosine of the rotor angle as in a traditional resolver.

Primary

Reference Input

(Primary)

Solid Rotor

Cos Output

(Secondary)

Sin Output

(Secondary)

Secondary

Rotasyn resolver

resolver with

Rotasyn

with solid

solidrotor

rotor

This new design (EC patent; US patent pending) gives the

Rotasyn

somegives

uniquethe

advantages

bothunique

traditional

This

design

Rotasynover

some

adbrushless resolvers

and traditional

optical encoders:

vantages

over both

brushless resol-

vers and optical encoders:

More Reliable The rotor coils of traditional resolvers

are subject to very high accelerations

More Reliable

andof

forces

in today’s

high speed,

The rotor coils

traditional

resolvers

arehigh

subhit-rate

applications.

These

forces

can

ject to very high accelerations and forces in

a wire

orhit-rate

wear theapplications.

insulation.

today’s highbreak

speed,

high

Since

its

solid

rotor

has

no

coils,the

the inRoThese forces can break a wire or wear

tasyn

virtually

speed

accelerasulation. Since

itshas

solid

rotornohas

no or

coils,

the

limitations.

And since

the Rotasyn

Rotasyn hastion

virtually

no speed

or acceleration

has only

halfthe

the Rotasyn

windings of

a tradilimitations. And

since

has

only

half the windings

of a traditional

resolver,

tional resolver,

its MTBF (mean

timeits

beMTBF (mean

time

between

failure)

is

double

tween failure) is double that of a tradithat of a traditional

resolver.

tional resolver.

High

Speed

High

SpeedSince the solid rotor has no windings,

thererotor

are no

problems

at very high

Since the solid

has

no windings,

there

speeds.

standard

Rotasyn

are no problems

atWhile

very the

high

speeds.

Whileis

to 30,000

RPM,to

higher

speeds

are

the standardrated

Rotasyn

is rated

30,000

RPM,

higher speeds

areasimply

a matter

of mechanisimply

matter of

mechanical

balance.

cal balance. The

Thetop

top

speed

is primarily

speed

is primarily

limitedlimited

by the

by the excitation

frequency.

excitation

frequency.

E C H N I C A L

Talk

O T A S Y N

TECHNICAL

relatively few turns of wire. Fewer turns

ROTASYN

translates to lower source impedance

which means less susceptibility to noise

pickup andpickup

less sensitivity

to long

runs.

and less sensitivity

to cable

long cable

The Rotasyn

can

be

excited

at

frequencies

runs. The Rotasyn can be excited at fre-up

to 40 kHz quencies

and beyond.

up to 40 kHz and beyond.

Reduced

Ripple Ripple

In traditional resolvers, rotor slots passReduced

ing resolvers,

stator slots induce

pulsations

on thestaIn traditional

rotor slots

passing

output pulsations

signals that manifest

tor slots induce

on the themselves

output sigas velocitythemselves

ripple. The poles

on the Rotanals that manifest

as velocity

ripple. The poles

the

Rotasyn

have no

synon

rotor

have

no slotsrotor

and therefore

slots and therefore

produce

a smooth

produce a smooth

output

with no output

slot

with no slot

ripple

effects.

ripple effects.

Lower

Cost Cost

Since the Rotasyn is mechanically simLower

pler than aistraditional

resolver,

it can be

Since the Rotasyn

mechanically

simpler

manufactured

moreitefficiently

than a traditional

resolver,

can be than

manufacresolvers.

The solid rotor

is

tured moretraditional

efficiently

than traditional

resolvers. The solid

is much

less costly

toamamuch rotor

less costly

to manufacture

than

nufacture than

wound

rotor. Inthe

addition,

wounda rotor.

In addition,

lack of the

lack of slots

on

the

rotor

means

that

stator

slots on the rotor means that thethe

stator

slots can be

wider,

winding

easier witslots

can bemaking

wider, making

winding

hout introducing

slot ripple.

easier without

introducing slot ripple.

Conclusions

CONCLUSIONS

The advantages of this new inductive transducer (Rotasyn)

for absolute positioning make it ideally suited for sinusoiThe advantages of this inductive transducer

dal commutation of AC and brushless DC servomotors as

(Rotasyn) for absolute positioning make it ideally

well as for flux vector control of AC induction motors. This

suited for sinusoidalcommutation of AC and

type of low-cost angular transducer will find broad applibrushless DC servomotors as well as for flux veccation,

not onlyofinAC

industrial

automation

butThis

also as

a of

tor control

induction

motors.

type

component

in

increasingly

sophisticated

automotive

con-not

angular transducer will find broad application,

trol

systems.

only in industrial automation but also as acomponent in increasingly sophisticated automotive

control systems.

admotec

Advanced Motion Technology

LowLow

Impedance

The Rotasyn’s efficient single-stage magImpedance

netic

design brings

the advantage

of

The Rotasyn’s

efficient

single-stage

magnetic

high

electrical

efficiency,

so that

powerdesign brings

the

advantage

of high

electrical

fulthat

output

signals are

produced

usingare

efficiency, so

powerful

output

signals

Admotec Inc.

85 Mechanic Street

Lebanon NH 03766-1500 USA

Tel: +1 603.448.7000

Fax: +1 603.448.7007

produced using relatively few turns of wire.

Fewer turns translates to lower source impedance which means less susceptibility to noise

E-mail: Admotec@Valley.net

©1996–2000 by Admotec Inc. All rights reserved.

TT01-0200

Admotec Precision AG

Kieselgasse 12

CH-8008 Zürich

Telefon +41 44 422 22 75

Fax +41 44 422 22 76

www.admotec.com

© 2016 by Admotec Inc. All rights reserved.