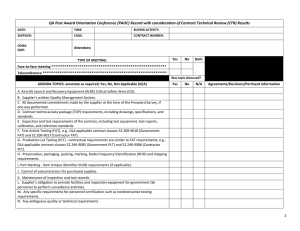

Document 253-01 12/12/2013 Lockheed Martin Space Systems

advertisement