Contents 5 Selector Guide · Technical Data in Brief 9 Metallized

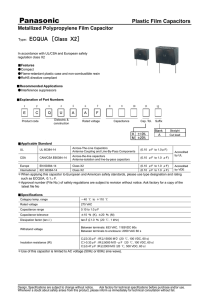

advertisement