PDF (Large 12mb)

advertisement

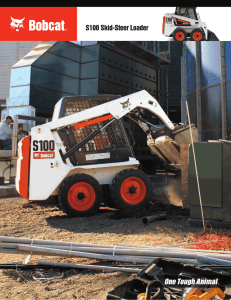

Bobcat Through the Years Storyboard 1-A 1947 E.G. Melroe, a farmer and inventor from Gwinner, N.D., opens a small factory with his four sons to manufacture an attachment he designed to pick up windrowed grain with a combine. 1948 The company builds its first factory, a 100 by 30 foot building in Gwinner, after outgrowing an old gas station and a vacant schoolhouse. 1957 Turkey farmer Eddie Velo prompts brothers Cyril and Louis Keller to design a three-wheel loader. They build the first prototype with used parts at their shop in Rothsay, Minnesota. 1958 While making sales calls in Minnesota, Les Melroe hears about the Keller’s machine and invites them to show it at the Melroe booth at the Minnesota State Fair. It causes a sensation, so Melroe Manufacturing buys the rights to manufacture it and the Keller brothers come to work for the company. The M60 goes into production. 1959 The Melroe Self-Propelled Loader, or the M200, goes into production. This forerunner ® of the Bobcat skid-steer loader has a 12.9-horsepower engine and a rear caster wheel for steering. 1960 Rear drive wheels are added to the loader. The model M400, with four-wheel drive, is the world’s first true skid-steer loader. 1961 Engineers begin working on a breakthrough design for an enclosed, lubricated drive system, solving the reliability problems which plagued the M400 and almost prompted Melroe to abandon the product. 1962 The name “Bobcat” is used for the first time on the all new model M440. It also inaugurates a new paint color for the line: white. The machine’s many industrial and construction applications begin to move the Melroe organization away from its primary focus on the agricultural market. Sales soar to over $6 million. 1965 With production of Bobcat loaders in record numbers, the company moves into the European marketplace, signing a license agreement with a manufacturing company in England, Luff & Smith. 1969 The Melroe brothers sell the firm to Clark Equipment Company of Michigan. The Melroe Division now has access to additional financial resources for vigorous expansion. Clark allows Melroe to operate autonomously and is well-rewarded by consistent profits. The Original Innovator “Everybody has a gift. I can’t play a piano, but if you [want me to] get a piece of metal and make something, I can do it.” The Melroe Family A naturally inventive mechanic, farmer E.G. Melroe (foreground) was a pioneer in agricultural technology during the Depression years. He founded Melroe Manufacturing Company in 1947 when his sons returned to Gwinner, North Dakota, after WW II. Pictured standing from left to right are sons Roger, Lester, Irving and Clifford, whose heart condition kept him out of the service. Clifford’s gift for both engineering and business made him the obvious choice for president when their father died in 1955. The Original Keller Loader Louis and Cyril Keller developed this three-wheeled, self-propelled loader for a turkey farmer (Eddie Velo, pictured) who needed a small, agile machine to clean out his twostory barns. The prototype was made with parts scrounged from junkyards and bars from the old town jail in Rothsay, Minnesota. Lester Melroe, out on a sales call, saw its potential and invited the Kellers to bring their machine to the Melroe booth at the 1958 Minnesota State Fair, where it attracted eager crowds and interested farmers. The Kellers were looking for someone who could mass produce and market their invention and struck a deal with Melroes. The Kellers came to work for the brothers in Gwinner, North Dakota in September 1958. 1958: The Melroe M60 The first Melroe M60 Self-Propelled Loader had a 6.6-horsepower engine. Its ability to turn on a dime – with one side moving forward while the other side moved backwards – made it perfect for the close quarters in barns and stockyards. 1959: The Melroe M200 Tougher and stronger, the M200 entered production with a better lift arm assembly and a 12.9–horsepower two–cylinder Onan engine. It could be outfitted with a range of attachments, from buckets and forks to angle brooms. 1960: M400 The four-wheel drive M400 was the first true skid-steer loader. The improved traction opened up a world of new uses. Its 70-30 weight ratio meant that, when empty, the machine had 70 percent of its weight on the back end and 30 on the front. When fully laden, the ratio was reversed. This enabled the loader to skid when turning, providing unprecedented maneuverability. 1962: M440 First to bear the name “Bobcat”, the M440 also had a new logo and a new white paint job. It had an impressive 1,000 pound lift capacity, but could be carted around in a pickup truck. The new Bobcat found new uses beyond the farm, in construction, landscaping and industrial plants. Early problems with broken drive chains were solved by enclosing them and lubricating them in an oil bath. Storyboard 1-B – Cyril Keller Bobcat Through the Years 1970 The exclusive Bob-Tach™ mounting system is introduced. It allows fast, easy attachment changes, transforming the Bobcat loader into a multi-job machine. 1971 Despite “kopykat” products that eat into the Bobcat loader’s market share, the Melroe Division contributes $28.7 million to Clark’s bottom line. Bobcat uses dealer meetings and road shows to demonstrate the latest additions to its lineup, the M970 and the M371. 1972 Melroe Company celebrates its 25th anniversary in business. Melroe acquires the Kirschmann Manufacturing Company of Bismarck, N.D., makers of the Spra-Coupe crop sprayer. 1973 Melroe acquires the chisel plow business of Gysler Manufacturing of Fort Benton, Montana. The M700, with a 1,200-pound-rated lift capacity, joins the Bobcat line. 1974 Melroe expands with a 28-acre agricultural products plant in Bismarck, North Dakota. 1975 Bobcat Master Service Technician Schools are introduced to factory train mechanics on skid-steer loader repairs. 1976 The B-series 520 is launched, the first of the company’s “New Breed” family of hydrostatic loaders that are stronger, faster, and offered more lift capacity and easier serviceability. 1977 A new logo updates the Bobcat image. Melroe company wins its second “E” award for Export Excellence from the U.S. Dept. of Commerce. The new breed 530 and 630 are introduced. The first issue of WorkSaver magazine is published. Four issues a year help build a community of Bobcat user/owners and reinforce brand loyalty with news of innovations and profiles of successful owners. Storyboard 2-A Bobcat Firsts 1958 Three-Wheeled Loader Louis & Cyril Keller team up with Melroe brothers to develop first production three-wheeled loader. 1960 M400 Melroe Manufacturing Company introduces world’s first skid-steer loader – the M400. 1962 M440 First use of “Bobcat” trademark and white paint scheme on the M440. 1970 M970 M970 “Big Bob” is the first hydrostatic skid-steer loader. 1971 M371 M371 “Mini Bob” is the world’s smallest skid-steer loader. 1987 Bobcat 980 Bobcat 980 is world’s largest skid-steer loader with 4,000-lb. rated operating capacity. 1989 Compact Excavator Bobcat manufactures first compact excavator in the U.S.A. 1990 (BOSS) Bobcat Operation Sensing System (BOSS ), state-of-the-art diagnostic and monitoring system, on the 50 Series skid-steer loaders. 1999 Deluxe Instrumentation Deluxe instrumentation panel displays seven different languages with shutdown system, keyless start and vital loader operating information. 2001 A220 Bobcat A220, world’s first loader to combine all-wheel steer and skid-steer operation. 2003 Toolcat 5600 Toolcat™ 5600 utility work machine is first vehicle of its kind. 2003 Bobcat 430 and 435 Bobcat 430 and 435 zero house swing (ZHS) excavators debut. 2003 Joystick Controls (SJC) Selectable joystick controls (SJC) option for skid-steer loader and compact track loaders enables operator to choose preferred joystick control pattern for loader steering and hydraulic functions. 2004 MT52 Mini Track Loader The MT52 mini track loader is introduced with first ride-on platform that is easily detached for walk-behind operation. 2004 Bobcat 2200 IntelliTrak Bobcat 2200 is first utility vehicle with IntelliTrak drive system, equipped with automatic locking differentials that engage immediately when a wheel loses traction. 2005 Speed Management Speed Management feature enables operators to match loader travel speed to operation requirements. Bobcat 2300 Rapid Link Bobcat releases the 2300 utility vehicle with RapidLinkTM attachment system. 2006 Storyboard 2-B ® ® Bobcat Through the Years 1978 Bobcat expands its 30-Series line with a heavy-duty 731 model. 1979 Bobcat sales soar to $210 million, thanks to a booming farm economy and overseas expansion. 1970s -1980s 1980 1981 European operations become firmly established in Belgium, and the company exports machines directly from North Dakota. The company also expands into Latin America and the Pacific Rim and arranges with a licensee to manufacture and market in Japan. Bobcat installs its first robot in a bucket welding station, ushering in an era of re-engineered manufacturing processes that significantly improve efficiency and productivity. The safety seat bar – a secondary restraint system and armrest – is introduced and became Bobcat’s best selling loader of its time. The 743 is introduced. 1982 New “pick and place” robots move the Bobcat production system ahead by moving hydraulic cylinder parts from work station to work station. 1984 Melroe’s new “Flying M” logo signifies its change from a division of Clark Equipment Company to a business unit of the company and the return of the “Melroe Company” name. 1985 Sales rose to $195 million; new axle-cell robots enter the Bobcat production system. 1986 The Bobcat compact excavator is introduced, eventually to achieve enormous popularity around the world. It is the only compact excavator manufactured in the United States. A delegation of 33 Melroe employees travel to Japan to study their manufacturing processes. They return home with new insights that lead to sweeping changes and new efficiencies in the factory. Bobcat acquires the Midmark Trencher Company of Dayton, Ohio, and enters the trencher business. Storyboard 3-A The Machine that Changed the World Off to the Mines Always ready to adapt the skid-steer loader to customer requirements, the company developed the M600 electric for use in mines. It was built low to meet height restrictions, and had explosion-proof lights. The M600 electric was also used to unload the grain from boxcars, where the potential for a grain dust explosion made gas, propane or diesel engines too dangerous. Can you spell that in Arabic? In the 1970s, Bobcat expanded into new markets throughout Europe, Africa, Asia, Latin America, Australia and the MiddleEast. Friends in the Right Places In Japan, Toyo Umpanki was licensed to produce several skidsteer loaders for Asian markets. In It To Win It The brand logos look familiar but this racetrack is in Turkey – Bobcat Goes Global where a Bobcat telescopic tool carrier lifts a disabled race car This promotional piece was designed to help spread the Bobcat brand around the world. from the track. Melroe’s first international move was into the UK in 1965, leading to the establishment of Melroe Ltd. in Southampton, England. By the 1990’s international markets would be a significant growth driver for Bobcat. Go Green Often found in recycling centers, Bobcat does its part by moving materials being processed for reuse. Extreme North Bobcat compact machines get the job done as far north as the Arctic Circle. This Brushcat rotary cutter is used for trail and right-of-way maintenance. Storyboard 3-B Bobcat Through the Years 1987 Bobcat Europe hosts the “Winning Combination” dealer and press event in Brussels to introduce the expanded Bobcat line. 1988 Fortune magazine names the Bobcat skid-steer loader to its “America’s Best” list – 100 American-made products that represent the best of their kind, anywhere in the world. 1989 Bobcat’s transportation fleet numbers 38 tractor-trailers as it drives growth across the country. 1990 Bobcat launches the 50 Series skid-steer loaders, with improved durability and performance, plus a new diagnostic and monitoring system, the Bobcat Operation Sensing System, or BOSS. 1991 Bobcat’s skid-steer loader makes Fortune magazine’s “America’s Best” list a second time. 1992 The winter issue of WorkSaver magazine is re-invented as the WorkSaver BobCatalog. Spring, Summer and Fall issues continue as before. The 7753 “lift and carry” loader is introduced. Its multiple linkage lift arm creates a vertical lift path, with greater capacity and a longer wheelbase for a smoother ride. 1993 Bobcat’s third generation of compact excavators enters production, while the 1600 and 2410 articulated loaders and the 980 skid-steer loader are dropped from the lineup. Bobcat introduces the first comprehensive operator training course for the skid-steer loader. 1994 Storyboard 4-A Bobcat sales soar to $604 million. “The Swiss Army Knife of Machines” “The Swiss Army Knife of Machines” With owner-operators intent on using their Bobcat machines for as many jobs as possible, it was inevitable that attachments grew in importance. The first attachments for the skid-steer loader were the buckets and forks needed in poultry barns, and company engineers went to work on devising a better way to hook attachments to the Bobcat loader. Bobcat M610 M970s This angle broom attachment on a Bobcat M610 sweeps up at These twin M970s clear streets after a North Dakota snowstorm The result was the Hydraulic Power Bob-Tach the Gwinner airport. in 1975. attachment mounting system, which was unveiled in 1970 along with the M970 and M600. Its secret was a triple-wedging design that cinches the attachment tighter during use, rather than traditional pin-mounted systems, which tended to rattle loose on the job. The new Bob-Tach mounting system revolutionized the skid-steer loader, making the compact Bobcat machines more versatile than ever – the “Swiss Army Knife of Machines.” Hydraulic Power Bob-Tach Adapted Bob-Tach System Today’s hydraulic Power Bob-Tach system is controlled from The Bob-Tach system was successfully adapted to other products, Now the International Standards Organization’s inside the cab. as the soil conditioner used with this Toolcat 5600 utility work (ISO) coupler design, the Bob-Tach system machine demonstrates. solidified the company’s market leadership. Owners are a constant source of product suggestions and improvements for attachments. Do It All They inspired numerous new bucket designs, This ad from 1993 demonstrated the hydraulic breakers, and the landscape rake versatility the Hydraulic Power Bob-Tach attachment mounting system brought to attachment that preps seedbeds and collects the skid-steer loader. Today more than rocks and debris. 80 different attachments are designed, built and backed by Bobcat. “ The best patent Bobcat ever had.” – Global Product Manager, Paul Anderson Storyboard 4-B Bobcat Through the Years 1995 The Clark organization is acquired by Ingersoll-Rand Company of Woodcliff Lake, N.J. A leading manufacturer of construction equipment and industrial machinery, Ingersoll-Rand has nearly 50,000 employees worldwide. 1998 The company purchases Palm Attachments of Grove City, MN, which had supplied attachments for Bobcat loaders since 1987. 2000 Bobcat Company enters the telescopic handler market when the first Bobcat telescopic tool carrier is introduced to the North American and European markets. 2001-2002 Several new product lines are introduced, including all-wheel steer loaders; the 2100 utility vehicle; and the innovative Toolcat™ 5600 utility work machine. 2003-2004 Bobcat introduces the world’s first Zero House Swing excavator with FastTrack all-hydrostatic drive; the MT52 mini track loader; and the 2200 utility vehicle. 2004 2005-2007 2008 Storyboard 5-A The American Society of Agricultural Engineers recognizes the skid-steer loader as “a historic landmark of agricultural engineering” that changed the world of work on the farm and elsewhere. The Bobcat 2300 revolutionizes the utility vehicle market with its one-of-a-kind RapidLink™ attachment mounting system. Bobcat also introduces Radio Remote Control, enabling operators to work in more jobsites. Bobcat celebrates the 50th anniversary of the compact loader. The Bobcat brand leads the worldwide compact equipment industry in design, development, marketing and distribution—thanks to an innovative, pioneering spirit that has always been a vital part of the Bobcat philosophy. Bobcat Reports for Duty Bobcat Reports for Duty The tough, highly maneuverable Bobcat machines are a natural for military applications that include digging trenches, moving gear, and clearing debris for reconstruction projects. For obvious reasons, these machines are among the few not to wear the traditional white Bobcat paint job. We’re in the Army Now Bobcat Builds the World Bobcat loaders in the Army shown here with troops in training at This enlisted Bobcat enthusiast brings the Bobcat message to Fort Campbell, Kentucky. the rebuilding of Iraq. An Adaptable Machine Flying High Soldiers need to be creative, and military Bobcat operators are Bobcat plays a role in the war on terror. Here a machine with a no exception, as this home-made gun rack illustrates. camouflage-colored paint job is being dropped into a remote Afghani village for reconstruction work. “ Bobcat’s loaders have made combat engineer platoons more effective by improving the survivability, mobility, productivity and morale....” – U.S. Senator Byron Dorgan Bobcat Serves America Proud members of the 618th Engineering Company were happy to have this T250 compact track loader. Storyboard 5-B Safety First An Industry Leader in Safety This seat bar was introduced as a secondary restraint system and armrest in 1981. “If it weighs over 50 pounds, go get the loader.” – Melroe Manufacturing Company This early catchphrase sums up one of the Bobcat loader’s most obvious benefits: it spared the backs of workers on jobs involving heavy lifting. As the company’s product line and sales grew, Bobcat engineers worked to Extreme Safety Testing add and improve safety features on every Seatbelts and rollover protective structures Bobcat machine. came first. In 1972 Bobcat was an industry leader with its decision to ship every machine with an overhead guard. In one test of the new rollover protective structure (ROPS) this M610 was rolled down a hill. Once righted, it started right up. Lights, Camera, Action! 1973 “Bobcat Kid” is the first skid-steer loader safety video. Bobcat has been an industry leader in safety instruction through live interactions, video, and Operator Training Kits. Storyboard 7-A Bobcat Cares Crazy Horse Memorial The donation of an 873 Bobcat loader, with its 2,400-lb. capacity, is speeding work on the Crazy Horse Memorial in the Black Hills of South Dakota. It Takes a Village...and a Bobcat Loader It takes a village (of contractors) and 24 Bobcat machines...to raise a house in 106 hours. ABC Extreme Makeover: Home Edition celebrity Ty Pennington brought cameras and crew to Minot, North Dakota, to build a new wheelchair-accessible house for the Bliven family. Son Aaron had been born with cerebral palsy, and his needs outgrew the family home just as his father Bill had two heart attacks and could no longer lift his son. To help, Bobcat donated the use of two dozen machines and seven attachments brought in from North Dakota and Minnesota. Skid-steer loaders, compact track loaders, an all-wheel-steer loader, a compact excavator, a VersaHandler telescopic tool carrier, and utility vehicles helped wrap up the job in just 106 hours. Village Family Service Center The Bobcat North Dakota State Open at Fargo Country Club has been attracting golf fans and raising money for the Village Family Service Center since 1984. The Village is home to Big Brothers Big Sisters and offers a range of counseling and social service programs to the Fargo community. Bobcat machines have long been popular in the golf industry for their ability to work quickly with minimal damage to turf. Arlington National Cemetery One of many projects supported by Bobcat is the annual landscaping project at Arlington National Cemetery. As an associate sponsor of the Professional Landcare Network (PLANET) event, Bobcat donated the use of Bobcat machines and operators. Storyboard 7-B Over the years Bobcat has given back to the communities it serves, locally and nationally. Pride and Partners Through the Years With its roots in the agricultural business, the company grew by cultivating close relationships with its dealers, who were treated as part of the extended Melroe family. Not to be Missed Bobcat dealer meetings were not-to-be missed events. New products were introduced with great fanfare and yes, it’s true – they did bring in circus elephants one year. The dealer meetings truly gave Bobcat an opportunity to connect with and inspire this passionate group of dealers, many of whom have been in the Bobcat family for decades. The meetings always proved powerful and emotional as the dealer pride came through with an increased intensity each time they gathered. Bobcat’s Best Resource – Dealers and Customers Their confidence and ability operating the machines translated to successful demonstrations and sales to their customers at home. Going to Camp Dealers continue to send their salespeople to Gwinner, North Dakota, for weeklong “Bobcat Boot Camps”, Dealers in touch with local markets regularly provided customer feedback that helped the company improve its products and offered tips that led to the development of new products. This meeting introduced the Mini-Bob M371 and Big-Bob M970. where trainers – including loader inventor Cy Keller – put them in the driver’s seat starting in the mid 1960s. Strong Partnerships Nearly 1000 Dealers support the company’s efforts in more than 90 countries around the world. Picking Up After Nature Sometimes you really need a Bobcat machine. In the aftermath of Hurricane Betsy in 1965, a dealer helps clear debris from this New Orleans neighborhood. Storyboard 8-A “Bobcat proved to me that they took care of their dealers and customers. Bobcat has always been one of the best suppliers with whom we have done business.” – Harry Rawley, Valley Implement Sales, Inc. Bobcat IS the Worksaver Over the decades, the market for skid-steer loaders shifted from primarily farmers and growers to a broad base of construction landscaping and industrial businesses, many of them owneroperators. This growing customer base enthusiastically adopted compact Bobcat machines for tasks such as landscaping, contracting and demolition. Many began as subcontractors who rented the machines, but soon bought machines and hired employees, becoming successful small business operators. Because of them, the expression BYOB at Bobcat means, WorkSaver WorkSaver is a quarterly magazine created to reinforce brand loyalty among these important customers with product updates and features about other successful Bobcat owners. Hundreds of thousands of people read the quarterly magazine. Louis Klumker Louis Klumker, shown here in a cover photo, was one of the successful owner/operators profiled in the magazine. The Klumker family bought a new Bobcat loader every year for 33 years. “Be Your Own Boss” – or another “Build Your Own Business” WorkSaver BobCatalog Beginning in 1992, the winter issue was transformed into the WorkSaver BobCatalog. It contained the entire product listing and showcased the latest enhancements and new products. PBS Show – This Old House Roger Cook, the landscaping expert for the PBS shows “This Old House” and “Ask This Old House”, was another big Bobcat fan. At the time of this article in the summer of 2004, Cook and his employees operated three Bobcat loaders: a 743, an 843 and an 853. Storyboard 8-B Roots on the Farm In the 1980s, it was clear that the skid-steer Turkey farmer Eddie Velo – who helped establish a major turkey processing plant in Pelican Rapids, Minnesota – is seated on the loader business was the star of the Bobcat original Keller self-propelled loader. It was Velo who came to show. Farming was vulnerable to recessions, the Keller brothers in 1956 with his need for a loader that could which brought a cyclical, low-profit pattern turn, scrape and dump within the tight confines of a turkey barn. This machine, the great-grandfather of the Bobcat machines in to the agricultural equipment business. One use today, is still on display in the Otter Tail County Museum in by one, the company sold off historically Fergus Falls, Minnesota. important but untenable businesses – grain drills, plows, and harrows, even the original Melroe pickup. Proceeds were invested in the future and the booming Bobcat lineup. The Bobcat Loader was designed to maneuver easily in the tight spaces of livestock barns. Here, operator John Landby impresses the resident hogs with a tight turning radius. The M444, an upgrade of the M440, emerges from this dairy barn. By 1967 the Melroe Company was having great success with its white Bobcat loader, but continued In 2004, Bobcat was honored by the American to sell the products pioneered by founder E. G. Melroe: the harroweeder, the windrow pickup, and Society of Agricultural Engineers, who the moldboard plow acquired from another North Dakota manufacturer, Reiten Mfg. Those first products were profitable enough to fund the company’s backing of the Keller brothers’ new three- recognized the skid-steer loader as “an wheeled loader back in 1958. historic landmark of agricultural engineering.” In 1964, nine years after the passing of founder E.G. Melroe, On February 14, 2001, the 500,000th Bobcat skid-steer loader rolled off the assembly line employees gather in Gwinner to pose with the company’s at the Gwinner manufacturing facility, now just one of the company’s many plants. Here 4,000th windrow pickup. employees pose for a group photo with the 773 model. 600,000 was surpassed in 2004, more than all other brands combined. Storyboard 9-A Innovation in Manufacturing Bobcat began making hydraulic cylinders inhouse in the late 1970s. Soon after, other equipment manufacturers came calling. In the early years, manufacturing was a hands-on affair. Here an Others attach tires near the end of the assembly line. (1970) employee stud-welds bolts on the side tanks of a Bobcat loader. (1970) An employee applies the Melroe badge to a Bobcat machine in “ They wanted to buy our cylinders, proving that our costs were okay, and our quality competitive.” 1970. – VP of Manufacturing, 1970, Jim Strand Bobcat, which operates large factories in Bismarck and Gwinner, is North Dakota’s largest exporter, shipping $550 million in machines to all corners of the globe annually. In 1980 the Gwinner facility gets its first welding robot from Clark’s operations in Michigan, where the auto industry was embracing robotics. The use of robots required much greater precision in parts and processes. Alarmed at the news that Toyota planned to enter the skid-steer loader business – it had already captured Clark’s forklift business – Bobcat went on the offensive, sending a delegation to Japan to study Japanese manufacturing processes. The lessons they learned – including just-in-time supply chain logistics – were successfully applied at home, and Bobcat was able to fend off Toyota. Product design moved from pencil and paper in the beginning years to ink on Mylar for the B-Series designs in 1975…to Computer-Aided Design, or CAD, in the 1980s. Robotics have been integrated throughout the Bobcat production process since the early 1980s. The machine’s frame is welded almost entirely by robots. Here a skid-steer loader’s wheel rims are welded at the Gwinner plant. Today, Bobcat also manufactures loaders and excavators in the Czech Republic and telescopic tool carriers in France, in addition to manufacturing in the U.S.A. Storyboard 9-B