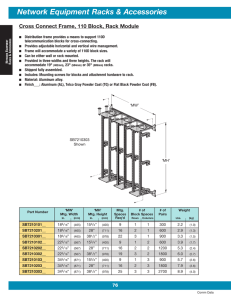

Racks and rack features

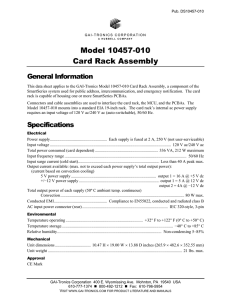

advertisement