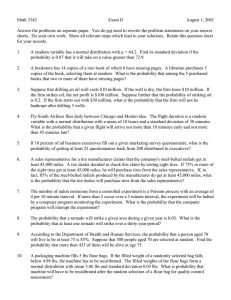

Rule Book - Dells Raceway Park

advertisement

1 Dells Raceway Park Late Model (limited) 2016 Rules 2-28-2016 General These rules and regulations are designed to govern driver and crew member conduct during DRP racing events. By participating in these events, all drivers are required to comply with these rules. While DRP makes no claim of guaranteed safety, these rules are enforced as a guide for the conduct of the sport. DRP is in the entertainment business. Drivers, Owners, Crew and DRP Staff cooperate to provide this exciting level of entertainment. All rules, race scheduling and structure, are designed and implemented to support a balance between competition and entertainment value. Drivers and crew are required to conduct themselves as professionals at all times. Periodic Rules Adjustments DRP may change any rule at any time in an effort to reduce the cost of racing, maintain equal competition, or improve safety. Rules Infraction Policy DRP Management may suspend or fine any driver, team member, or car owner for violation of track rules, policies, or procedures. Management has right to confiscate any item that is in violation of the rules. Procedural Rules: It is the goal of Dells Raceway Park management to maintain the safest possible racing conditions for all drivers, fans & track personnel. Only safety crews and wrecker crews are permitted on the track in the event of an accident. Pit crew members are not permitted on the track. Drivers are required to stay in their car in the event of an on-track incident. If a driver, for whatever reason, exits a car on the track during a caution period, the race will automatically be placed under a red flag and all cars will come to a complete stop. A driver may exit a car if requested by a safety crew member or if safety warrants in cases such as a fire or if car is upside down. Drivers that exit a car without permission, for whatever reason, are subject to fine and/or suspension at the discretion of track management. Drivers are also encouraged to drop the window nets after an accident as a sign to approaching safety crew members that they are ok, especially in a multicar situation to alert approaching safety crew members which drivers are in need of urgent attention. INDEX: A. B. C. D. E. F. G. H. I. J. K. L. M. N. O. P. Q. R. S. T. U. V. W. X. Y. Z. AA. BB. SEATS SAFETY BELTS DRIVING COMPARTMENT DRIVER AND DRIVER’S ATTIRE APPEARANCE WHEELBASE & TREAD WIDTH CHASSIS ROLL CAGE SUSPENSION SPINDLES & HUBS STEERING REAR END BRAKES ENGINE LOCATION ENGINES CARBURETOR RETURN SPRINGS & AIR CLEANER EXHAUST CLUTCH, TRANSMISSION, & DRIVESHAFT RADIATOR & COOLING FUEL & FUEL CELL BODY & APPEARANCE WEIGHT WHEELS & TIRES BATTERY MISC INSPECTION PENALTIES 2 A. Seats 1. Approved aluminum driver’s seat required. Full containment seats recommended. 2. Seat must be fastened to frame/roll cage and located to give adequate distance from driver’s arm to door bars 3. Shoulder supports on right and left sides of seat and head support on right are required B. Safety Belts 1. Minimum 3 inch wide lap belt, 3 inch wide shoulder harness and submarine (crotch) strap required 2. Belts must be anchored to roll cage or frame. Grade “5” bolts and hardware required 3. Shoulder harness must not be anchored lower than 2 inches below drivers shoulder height 4. Belts must be dated 2012 or newer 5. 6 point belts (double crotch strap) are recommended C. Driving Compartment 1. Cockpit must be completely sealed off from engine compartment and fuel cell 2. Padding required around driver including steering post 3. Securely mounted fully charged fire extinguisher with visible dial type gauge required,( fire systems recommended – with dial visible to inspectors) 4. Ribbon or mesh type window net with belt buckle release required. Buckle located at top/front recommended 5. Clearly labeled push-pull or toggle type kill switch accessible from either side of car required 6. No suspension components including stabilizer bar can be adjustable from the driving compartment. D. Driver and Driver’s Attire 1. Complete approved fire retardant driving suit and gloves required 2. Eye protection and Snell SA-2005 (SFI 31.1 2005) helmet or newer required. 3. SFI-38.1 Head and neck restraints (HANS type) and fireproof shoes recommended 4. DRP officials will inspect items related to safety, but ultimately it is the responsibility of the driver to monitor, maintain and update his safety equipment. E. Appearance 1. Professional appearing paint job and lettering required. Lettering must be in good taste. 2. Numbers: 18” on both doors and roof, readable from the right side 3. 1” square rub rails allowed, mounted within 3” of ends & ends must be tapered, capped, and ground smooth F. Wheelbase & Tread Width 1. Wheelbase 104” +or- 1” (range of 103” to 105”) 2. Maximum tread width 65”, measured center to center of tires at spindle height, with frame height set no lower than 3” on left side and 3 1/2” on right side. Applies at both front suspension and at rear-end. G. Chassis 1. Tube or stock stub allowed. Frame rails must be a minimum of: 10” perimeter tubing x .120” wall thickness or 12” perimeter tubing x .095” wall thickness. 2. Minimum ground clearance rule has been deleted. Car may be placed on 4” blocks to confirm correct height of body components. H. Roll Cage 1. All roll cage tubing must be at least 1 3/4” x .090” wall. Welded gussets required on all joints. 4 minimum horizontal door bars required on left and 3 on right side. X-configuration on right side, counts as one bar 2. All door bars must be mounted to the frame rails and the main roll cage uprights 3. Door bars must be connected with a minimum of two equally spaced vertical tubes 4. Left side door bar deflector plates of at least 1/8” steel required. Diagonal bar in top hoop required 5. Floor pan under driver must be minimum thickness of 13 gauge (.083”) steel (for driver’s safety) 3 I. Suspension 1. Conventionally mounted 5” springs or coil over type suspensions. Coil bind suspension set-ups not allowed. 2. All springs must be magnetic steel, with maximum cost of $100 per spring. 3. No suspension travel limiting devices allowed, (Examples include, but are not limited to: bump stops on or in shock absorbers or added bump stop systems, rebound limiting, or spring preloading devices, chains, bolt stops, or shock mounting locations). Wheels must extend downward when jacking up the car. 4. One shock/spring per wheel 5. Maximum allowed is one spring rubber per spring 6. Rear suspension must be solidly mounted (no rubber bushings). Heim joints only. 7. No lift bar, fifth coil or other spring-loaded/ hydraulic suspension device allowed. No rear stabilizer bars. 8. Steel or aluminum bodied, non-adjustable shocks, maximum MSRP $200. No hollow shaft shocks allowed. Penske 7100 series shock is not allowed. Components must be used as designed by manufacturer, and may not be interchanged, valving is optional. Post race shock disassembly is the responsibility of the owner/crew chief. J. Spindles and Hubs 1. Any steel spindle allowed, (aluminum steering arms and ball joint mounts allowed). 2. Aftermarket hubs with 5/8” wheel studs required. No gun-drilled studs permitted. Studs must be long enough for threads to show on outside of lug nuts. 3. Wide five hubs allowed, no magnesium, with maximum MSRP of $180. Oil filled (or oil filled design) hubs do not meet price limitations and will not be allowed. 4. Roller bearings only, ball bearings not allowed. K. Steering 1. Rack & pinion, or steering box with center link style required 2. Quick release steering wheel hub required 3. Collapsible steering shaft recommended 4. No electric power steering units L. Rear End 1. Stock, or rear spur gear type quick change units with steel tubes. No mini type quick change. Maximum camber 1/2 degree. Magnetic steel axles only. Solid axles must be minimum 1.125” O.D. and will receive a weight break of 25 lb. Left side and right side gun drilled axles must have the same I.D. and O.D. Crowned axles not allowed. Traction (wrap up) axles not allowed. 2. Detroit Locker (ratchet type) and torque sensing differentials are permitted – with a 50 lb. weight penalty 3. One-piece straight spline drive plates only. 4. All plugs (drain, inspection, etc.), and two bolts on quick change rear cover, must be safety wired. $100 fine for oiling up the track. M. Brakes 1. Four wheel brakes required at all times 2. Single or dual piston (steel or aluminum) “GM” calipers – deduct 25 lbs. 3. Four (4) piston calipers allowed, maximum retail price $190. No thermlock pistons allowed. 4. Maximum diameter 12 1/4 “ rotors, no drilling permitted 5. No floating or self centering rotors. No ABS units, brake recirculation systems, or floating caliper brackets. 6. Only one brake bias adjusting unit per car 7. No “wheel fans” or blower motor devices allowed N. Engine Location 1. GM engines must be located so that the furthest forward spark plug is no more than 2” behind the front axle centerline. Measurement is taken from center of spark plug hole. Out of tolerance engine setback on visiting cars will be subject to a weight penalty. 4 2. Ford and Chrysler allowed 4” engine set back, measured as above. 3. All engines: Oil pan must not be lower than bottom of cross-member. Options to correct are add to bottom of cross-member or raise motor. O. Engines 1. Limited Concept Enginea. Maximum 2.02” intake and 1.60” exhaust valves. Valve stem diameter must be 5/16” or larger. b. No aluminum blocks or heads c. GM & Ford-362 CID maximum, Chrysler-373 CID maximum d. All engines must meet the following specifications regardless of manufacturer: OEM or approved aftermarket replacement cast iron heads with factory valve angles (no angle milling). e. Approved GM heads: Bowtie numbers 14011058, 10134392, (casting number 14011034 and 12480034) World Products Sportsman II numbers 011150, 011250 only. f. Approved Ford heads: 351N and 352N, World Products Windsor Sr 053040 only. g. Minimum combustion chamber 62 cc h. Flat top pistons required i. A minimum of zero deck height required j. 10.8 to one maximum compression ratio k. Connecting rods must be magnetic steel, with 1.900” minimum rod journal diameter l. Oil pan depth must be a minimum of 6.5” m. A 3/4 “ NPT inspection hole in oil pan required. Must be located in line with second or third rod journal of crankshaft, on either side of pan and above sump area (oil level) n. Hole in windage tray in line with inspection hole required o. Valve spring retainers are the only titanium parts allowed p. No radius edge lifters allowed. Lifters must be able to rotate in their bores q. No roller or mushroom cam/lifters r. Maximum valve lift - .600” (measured at retainer) s. OEM style rocker arm mounting required t. Firing order must be stock u. Ignition system may not be computerized, programmable or have memory circuits v. No magnetos, crank trigger, multiple coil, or programmable ignition systems allowed w. Production type steel crankshaft with normal configuration counter weights x. No dry sump or vacuum systems of any kind allowed y. External single stage oil pump allowed on Ford engines z. OEM type mechanical fuel pump in original location required aa. Carb Adaptor: One piece, straight bore, 1 5/8” maximum thickness, with gaskets. No part of spacer may extend into intake manifold. Original orientation of carb to engine required. bb. Intake manifold must be Edelbrock Victor Jr.: 2975 for GM, 2915 or 2920 for Chrysler, and 2921, 2980, or 2981 for Ford. Plenum and port configuration must remain as produced. No adapters/ spacers between intake and heads. 2. Crate Engines a. “DRP crate motor is the GM 604 crate engine purchased directly from the DRP. It will come with GM seals, and additional seals from Wegner Automotive or REDI. The engine must: be used as purchased, must run a maximum of 6700 RPM chip (out of driver’s reach), and without any alterations or updates. At any time during the season, DRP may impound any engine, to be re-run on our certification dyno to prove legality. If legal (passes the dyno test, etc.), the cost for this will be covered by DRP. If illegal, driver will be suspended for one full year, and loss of points, fines, or engine forfeiture may result. These engines will not be allowed to be freshened. In cases of parts failures, a decision will be made as to the feasibility for repairs to be made. These repairs will only be allowed under DRP jurisdiction. Dyno recertification may be required as part of the repair process, at owners expense. Exhaust header: no stepped or 180 degree allowed. Maximum MSRP of $350 maximum. This engine receives a weight break of 75 lbs. b. Engine location will be a maximum 2” set back. 5 c. Carburetor: Holley 650-HP P/N 80541 required. No modifications or epoxy on boosters. Holley “ultra” carb not allowed. d. Allowed are updated or rebuilt GM 604 crate engines. Must have been certified at REDI (430 HP maximum) in Madison WI. within the last three years, and be run without alterations. Permitted updates are: 1.6 ratio rockers, small harmonic balancer, carb spacer of 1 5/8” maximum thickness with gaskets. These engines do not receive the “crate” weight break of 50 lbs. e. Ford and Mopar crate engines NOT allowed f. DRP officials reserve the right to impound motors for inspection and/or dyno testing. 3. LS Spec Engine a. Wegner Automotive Research 5.3L only, must be used as produced and must match GM specifications for bore, stroke, crankshaft weight, etc. Maximum 3 1/2” set back b. Must use 4412 2 bbl carb with adapter/spacer plate supplied in engine package. c. This engine must run with: Wegner spec weight plates, 20 lbs. each, bolted one to each side of the block, or two 20 lb. lead weights bolted one to each side of front frame rail, centered fore and aft of engine block. P. Carburetor: Holley 4412-2 bbl. Holley 4412 Carburetor Rework Guidelines: 1. Body of Carbs: No polishing, grinding, or drilling of holes allowed 2. Gasket surfaces may be machined for improved sealing 3. The choke may be removed, but all screw holes must be permanently sealed 4. Choke horn may not be removed 5. Boosters may not be changed from stock 4412 6. Height, size, and shape must remain standard and unaltered 7. Venturi area must not be altered in any manner 8. Casting ring must not be removed 9. Base plate must not be altered in shape or size 10. Butterflies: Must not be thinned or tapered. Screw ends may be cut even with shafts, but screw heads must remain standard 11. Throttle shafts: Shafts must remain standard and must not be thinned or cut in any manner 12. Any attempt to pull outside air other than straight down through the venture is not permitted 13. Jets may be changed. No dial-a-jet devices 14. No addition of any material, such as epoxy, may be added to carb or parts except to seal vacated external screw holes. Exception: epoxy allowed on boosters of 4412 at main body. 15. Carb must be mounted in conventional orientation 16. Holley “ultra” carb is not allowed. Q. Return Springs & Air Cleaner 1. Double return springs required 2. Air boxes allowed with cowl inlet only 3. 25 lb. deduct for plain air cleaner and no air box, (14” max O.D. x 4” max height, plain metal round top and bottom, no carb hat or air-flow tops or bottoms). R. Exhaust 1. Headers allowed on all engines. 2. Tri-Y Headers or Merge-Collectors-NOT ALLOWED 3. Exhaust may remain under car body. If so must exit behind driver, beneath car pointing downward. Exhaust may exit out right side door as follows: must exit rear of driver, must not point up, must be no more than 12” off the ground, and end must be braced flush to body panel in a way to prevent it becoming a tire cutting hazard. All cars: 95 decibel maximum. Decibel level of all cars will be measured in order to comply with the town noise ordinance, (note: cars with exhaust exiting out the right side that have ineffective mufflers will most likely fail the 95 db rule). 6 4. No custom, one of a kind, or homemade headers 5. No coatings allowed on headers or exhaust pipes. S. Clutch, Transmission, & Driveshaft 1. Stock style transmission with operating reverse gear required. All plugs must be safety wired. $100 fine for oiling up the track. 2. Made-for-racing clutch required , with minimum of two disks at 5 1/2” minimum diameter 3. Internal clutch transmissions, aluminum case only (no magnesium), allowed with a weight penalty of 50 lbs. 4. Carbon Clutch not permitted 5. Driveshaft: 3” minimum diameter and .083” minimum wall thickness. Carbon fiber driveshaft or components not allowed. Safety hoop required on front half. Aluminum driveshaft allowed. Steel driveshaft (3”O.D.) will receive a weight break of 25 lbs. 6. Driveshaft must be painted white T. Radiator/Cooling 1. Metal radiator mounted in front of engine, between frame horns 2. Fan protection and overflow tank located in engine compartment required 3. Water pump must be stock type in stock location 4. Antifreeze is not allowed U. Fuel & Fuel Cell 1. Fuel cell complete with 1/8” steel can, interior bladder, foam baffle, and rollover valve required 2. Fuel cell must be mounted behind rear axle, between frame rails 3. No part of fuel cell can be ahead of the quick change rear cover/bolts. “U-shaped” fuel cells designed to wrap around the quick change are allowed, but must be moved back from “normal” position so all parts of the cell are behind the quick change cover and bolts. 4. Fuel cell must have a protector bar across rear of fuel cell, flush to bottom of cell or below, and braced back to main frame 5. Bottom of fuel cell must be at least 10” from the ground 6. Filler must be accessed through deck lid. Filler spout may be extended, but not connected to bodywork 7. All vents must be valved to eliminate leakage 8. Aeroquip or equivalent gas lines, must be located outside driver’s compartment, with protective routing 9. Gasoline only, must meet specific gravity of manufacturer. E-85 is not allowed. 10. Over tail chassis: 15 gallon maximum cell (25” x 18” x 10”) V. Body & Appearance 1. Five Star, ARP or equivalent only 2. Minimum roof height 47” 3. Spoiler: Single plane, 5”(measured from deck plane) x 60” (measured across rear) max 4. Deck height 34 1/2” max 5. All windows must be of Lexan, (front and rear 1/8” minimum thickness). 12” max vent (wing) window 6. Weight penalties may be assessed for bodies not conforming to ABC guidelines, dimensions, or templates 7. Hoods that utilize hinges must fold back all the way back to the windshield, cam lock hood supports that hold the hood at 45 degree angle NOT ALLOWED (interfere with tech and wrecker personnel) 8. All body dimensions will be measured with frame height set at 4”. 9. Carbon fiber body panels not allowed. W. Weight 1. Limited Concept Engine 2. Wegner 5.3L LS spec engine (with weight plates) – 3. GM 604 “DRP” Crate – 4. GM 604 Crate with any permitted updates – 5. “Open” differential (locker, torque sensing, etc.) 2850 lbs. 2875 lbs. 2775 lbs. 2850 lbs. add 50 lbs. (see L.2. above) 7 6. 7. 8. 9. 10. 11. 12. 13. 14. Internal clutch transmission add 50 lbs. (see S.3. above) Solid axlesdeduct 25 lbs. (see L.1. above) Steel 3” driveshaftdeduct 25 lbs. (see S.5. above) Single or dual piston “GM” calipers deduct 25 lbs. (see M.2. above) Plain air cleaner w/o airbox deduct 25 lbs. (see Q.3. above) All cars must meet 42% minimum right side at any time. Gas allowance: 1/2 lb. per lap All weights measured with driver in seat and steering wheel on No tungsten, lead shot, ball bearing type, or liquid type allowed. No moving weight or weight moving devices allowed. Ballast must be painted white and lettered with car number. Any loss of weight from any car for any reason, will result in a cash fine of $5 per pound, (example: a 20 lb. piece lost on the track is a $100 fine). 15. Feature winner will add “re-ward” weight of 25 lbs. to his/her spec weight for his/her next racing event. Driver & car must race with this “re-ward” weight for 2 weeks. If haven’t won during that time, “re-ward” weight is deleted. If wins again during those 2 weeks another 25 lbs. will be added, for a total of two “re-ward” weights or 50 lbs., and again, if wins for a third time before 2 more weeks pass, a third “re-ward” weight will be added, bringing the total to 75 lbs. This continues as necessary for a fourth or more feature wins. NONE of the penalty weight may be removed until driver/car has raced for 2 weeks with the “re-ward” weight and not won. After that all of the “re-ward” weight may be removed, exception: any driver with multiple feature wins will carry a minimum of 25 lbs. “re-ward” weight for the remainder of the season. X. Wheels & Tires 1. Aftermarket made for racing, steel wheels required. 15” x 8” maximum 2. No tire pressure bleeders. Remove bleeders from wheels and weld holes shut. 3. Chemical treatment of tires (softening) not permitted 4. Approved tire: Hoosier R750 only, based on a tire bank system allowing two new tires per night, and using the same four tires throughout a night of racing. a. Teams must register a maximum of four tires into their initial tire bank, during the first racing event of the season. b. Teams can add to their tire bank two new tires per week of competition. If you decide not to purchase tires on any particular week, and our records show that you were here in competition, we will let you purchase it at a later date. c. A tire card must be turned in to the tech building before qualifying, showing your 4 tires for the night d. Tires purchased that night do not have to be raced; you may bank them for a future night. e. Tire bank follows the driver. f. Used tires purchased from another driver must be registered into your tire bank, and will count as new tires. g. All tires used in competition, (heats, dash, feature, etc.), must come from that competitor’s tire bank. h. Visiting teams will be allowed four new tires, which will go into their tire bank. i. Issues with tires must be discussed with DRP tire Marshall. His decision will be final. Y. Battery 1. 12 volt system max 2. Batteries must be securely mounted ahead of rear axle, away from fuel cell & lines 3. Batteries not allowed in driving compartment 4. Battery (negative post) disconnect switch recommended Z. Misc 1. Radios: All radio frequencies must be registered with the tech officials. All teams must have a spotter in the spotter stand during competition. All drivers mandatory (one week grace period) to have and use a 8 2. 3. 4. 5. 6. 7. “RACECEIVER”, for communication from the tower, on regular points events. Spotters may also have a raceceiver- but that does not count toward the driver’s requirement. These will be available at the racetrack. Tow Hooks: on front and rear required, painted bright color and/or labeled as TOW HOOK Transponder location: 12” behind centerline of rear axle Team driving: championship points will not be awarded to “teams”. Cars may be driven by more than one driver, but points will be awarded only to the driver on that night. Payoff will be sent to the car owner on file. Championship points will be awarded per your finishing position. If drivers are disqualified, drivers behind them do not advance. Not allowed: super chargers, turbo chargers, nitrous or other injection systems, pressure or electric fuel systems, aluminum blocks (see exc.), ABS units, floating brake brackets, brake recirculators, external oil pumps (see exc.), or traction control. No blowers allowed (brakes, tires, wheel beads, etc.) AA. Inspection 1. All cars are subject to inspection ANYTIME before, during, or after a race 2. Officials reserve the right to disqualify cars, require changes, confiscate illegal parts, etc. Officials decision is final, and will be based upon fair play, safety, and to protect the “Spirit of Stock Car Racing”. 3. Any interference with any official(s) and his/her duties will result in an automatic disqualification, and/or possible suspension. 4. Official’s decisions will be based upon fair play, safety, and to protect the “Spirit of Stock Car Racing” 5. Disqualification (except weight violation) is retroactive to ALL previous events competed in that race meet 6. Non-compliance with these specifications will subject the participants (owner/driver) to disqualification 7. All non-complying components may be seized by track officials 8. Any driver/owner refusing to allow the track officials to inspect a car will lose points and money earned and will have the subject car impounded until inspection is performed with crew chief and driver present 9. Owner/driver must provide tools BB. Penalties The chart below will be applied for violations as shown. Once a penalty has been applied, a subsequent violation will be counted as 2nd offense, etc., regardless of category. Manipulation of this system for your advantage will not be allowed. POINTS FINE 1 TO 5 lbs. Lite 1st Offense Warning 0 2nd Offense 10 Points $25 3rd Offense 20 Points $50 WEIGHT LEFT % 6 TO 50 lbs. Lite Any Offense 2 Points per pound $10 per pound Over 50 lbs. Lite Any Offense DQ DQ UP TO 0.2 % High 1st Offense 2nd Offense 3rd Offense POINTS Warning 2 Points 5 Points FINE 0 0 $50 0.3 TO 0.5% High 1st Offense 2nd Offense 3rd Offense 2 Points 10 Points 20 Points $25 $50 $75 OVER 0.6% High 1st Offense 2nd Offense 20 Points DQ $75 DQ 9 TRACK 1st Offense 2nd Offense 3rd Offense POINTS Warning 2 Points 5 Points FINE 0 0 $50 3/16” TO 1/2" Wide 1st Offense 2nd Offense 3rd Offense 2 Points 10 Points 20 Points $25 $50 $75 OVER 1/2" Wide 1st Offense 2nd Offense UP TO 1/8” Wide 20 Points DQ $75 DQ