MIL-HDBK-705 Rev. C

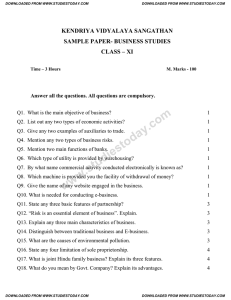

advertisement