Special conductors for cable extrusion

advertisement

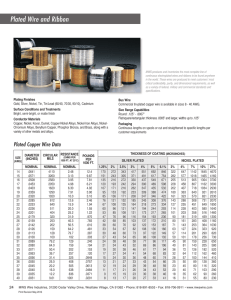

Special conductors for cable extrusion The Quality Connection 2 The Quality Connection Competence with Tradition LEONI is one of the small number of manufacturers that can be counted as market leader for the production of highly developed electrical conductors. LEONI’s roots in wire drawing can be traced back to the Middle Ages. Since the beginning of the 20th century we have been innovators in electro plating, stranding and multi-wire technology. Today LEONI offers a comprehensive range of wires, stranded conductors, ropes and braids for both the cable industry and electrical component market. www.leoni-special-conductors.com The Quality Connection www.leoni-special-conductors.com The Quality Connection Competence with Tradition Contents Quality and Environmental Management LEONI – The Global Player Page 2 3 4 5 Conductors Copper and Copper alloys 6 Surface Finishes Tables of weights for platings Electroplating options 8 10 Packaging 11 Product Range Wires 12 13 14 15 16 Single Wires Single Wires to DIN Standard Single Wires to AWG Standard Braiding Wires Product Range Stranded Conductors Bunched Conductors Highly Flexible Stranded Conductors and Ropes Concentric Stranded Conductors Semiconcentric Stranded Conductors LEONI Smooth-Bunch 17 18 19 20 24 25 LEONI news LEONI Histral® LEONI keeps you up-to-date Edition: March 2008 Subject to change and error. 26 27 3 4 The Quality Connection www.leoni-special-conductors.com Quality and Environmental Management One of LEONI’s most important success factors is the globally consistent high quality of its products. LEONI – Quality Management LEONI Draht has a universal quality management system covering all of our worldwide manufacturing locations – ensuring that all of our products and services comply with uniform quality standards. High speed multi-wire drawing places very stringent demands on raw materials and machine process stability. LEONI conductors satisfy the highest quality and reliability requirements consistent with aircraft and aerospace technology, specialist applications in the automotive industry and high speed data transmission technology. In LEONI Draht’s quality philosophy Customer satisfaction Process stability Delivery reliability Fault prevention all play a key role. Process control is the key. Computer-aided monitoring and control of manufacturing processes, continuous improvement, preventative maintenance, ongoing investment in the best manufacturing equiment and employee training are all part of LEONI formula for qualitiy. LEONI – Quality from start to finish. LEONI – Environmental Management LEONI believes in combining economic success with ecological and environmental responsibility. We acknowledge our responsibility to protect the world we live in and its natural resources to strike the right balance between environmental needs and the company’s interests. We can advise customers on the most environmentally responsible use and disposal of our products. The Quality Connection www.leoni-special-conductors.com 5 LEONI – The Global Player Proximity to the customer is a key element of our corporate philosophy. This is the reason why you will find LEONI close to you wherever you are. Please don´t hesitate to make use of our strong distribution network. Wire manufacturing sites in China, England, Germany and the US LEONI Draht GmbH Treuchtlinger Strasse 20 91781 Weissenburg Germany Phone +49 9141-918-240 Fax +49 9141-918-101 special-conductors@leoni.com LEONI Draht GmbH Windorfer Strasse 1 93444 Bad Koetzting Germany Phone +49 9941-404-0 Fax +49 9941-404-40 special-conductors@leoni.com LEONI Wire (Changzhou) Ltd. No. 209 Huashan Road National Hi-Tech District Changzhou 213022 Jiangsu, P.R. China Phone +86 519-510-3456 Fax +86 519-510-4313 E-mail LEONI Temco Ltd. Whimsey Industrial Estate Cinderford, Glos. GL14 3HZ England, UK Phone +44 1594-820-100 Fax +44 1594-823-691 E-mail general@leonitemco.com LEONI Wire Inc. 301 Griffith Road Chicopee, MA 01022 USA Phone +1 413-593-6618 Fax +1 413-593-6639 E-mail info@leoniwire.com Conductors 6 www.leoni-special-conductors.com Copper and Copper Alloys Our main raw material is copper (Cu). In our wire manufacturing we primarily use Cu-ETP 1 for all standard applications and Cu-OF 1 (oxygen free copper) where specific requirements dictate, e.g. resistance to hydrogen as in ISO 2626. In addition to copper we process a number of copper alloys for special applications. Typical alloys include CuSn (copper/tin), CuNi (copper/nickel), CuAg (copper/silver), LEONI Histral®, Copper Clad Aluminium (CCA) and Copper Clad Steel (CCS). Excerpt from EN 1977 “Copper and copper alloys – Copper drawing stock (wire rod)” Symbol International specification Material number Composition Density Melting point % IACS min. Comments in %-by-weight g/m3 in °C CW 003 A Cu ≥99.90 6 Oxygen max. 0.040 8.9 1083 101 Electrolytic tough pitch copper with an electrical conductivity in annealed condition of ≥58.58 m/Ωmm2 at 20 °C (101 % IACS). Electrolytic copper Cu-ETP1 (E-Cu) EN 13602 Oxygen-free copper Cu-OF1 (OF-Cu) EN 13602 CW 007 A Cu 99.95 8.9 1083 101 Oxygen free copper is purer containing less impurities and trace elements which evaporate in a vacuum and has an electrical conductivity in the annealed condition of ≥58.58 m/Ωmm2 at 20 °C (101 % IACS). It is suitable for semi-finished products that require resistance to hydrogen as in ISO 2626 66, ultrasonic welding and hard soldering (brazing), and for use in the fields of vacuum technology and electronics. Cu-OF1 (Cu OFE) EN 13602 CW 008 A Cu 99.99 8.9 1083 101 5 ppm oxygen 6 The standard of purity is achieved when the electrical conductivity in annealed condition is 58.58 m/Ωmm2 in the case of Cu-ETP1. Details of sampling and test methods are available. International Annealed Copper Standard = IACS Electirical conductivity of copper = min. 58 m/Ωmm2 = 100 % IACS 66 Hydrogen resistance is tested and measured according to international technical specifications. If individual customers have particular requirements these must be stipulated at the time of order. Conductors www.leoni-special-conductors.com Symbol International specification Material number Composition Density Melting point in %-byweight g/m3 in °C % IACS min. 7 Comments Copper alloys Histral – – 8.9 1090 80 A high strength copper alloy, as an alternative to other cadmiumcontaining copper alloys. With an electrical conductivity of 80 % IACS CI203 – – 8.9 1084 80 A high strength copper alloy, as an alternative to other cadmiumcontaining copper alloys. With an electrical conductivity of 80 % IACS CW452K 94 8.9 1100 20 Copper tin resistance alloy with an electrical resistance of 0.11 m/Ωmm2 UNS No. C50700 98 8.9 1100 34.5 Copper tin resistance alloy with an electrical resistance of 0.04 m/Ωmm2 CuSn 94/6 BS EN 12166 CuSn 98/2 CuNi 98/2 DIN 17471 2,0802 98 8.9 1090 34.5 Copper nickel resistance alloy to DIN 17471 with an electrical resistivity of 0.05 m/Ωmm2 CuNi 95/5 DIN 17471 2,0807 95 8.9 1095 18 Copper nickel resistance alloy to DIN 17471 with an electrical resistivity of 0.10 m/Ωmm2 CuNi 90/10 DIN 17471 2,0811 90 8.9 1100 11.5 Copper nickel resistance alloy to DIN 17471 with an electrical resistivity of 0.15 m/Ωmm2 UNS No. C70900 85 8.9 1100 8.6 Copper nickel resistance alloy with an electrical resistivity of 0.20 m/Ωmm2 CuNi 85/15 CuNi 75/25 DIN 17471 2,0881 75 8.9 1150 5.75 Copper nickel resistance alloy to DIN 17471 with an electrical resistivity of 0.30 m/Ωmm2 CuNi 55/45 DIN 17471 2,0842 55 8.9 1280 3.5 Copper nickel resistance alloy to DIN 17471 with an electrical resistivity of 0.49 m/Ωmm2 in %-Cu-bydiameter g/m3 Other material Cu Clad Aluminium 15 % ASTM B566 Class 15 4 3.6 65.7 Composite material with Cu cladding around an alumium core, resulting in much lighter material (41 % compared to Cu) Cu Clad Steel 30% ASTM 452 Class 30 6.5 7.9 30 Composite material with Cu cladding around a steel core and having electrical conductivity of 30 % IACS Cu Clad Steel 40% ASTM 452 Class 40 7.9 40 Composite material with Cu cladding around a steel core and having electrical conductivity of 40 % IACS 10 Surface Finishes 8 www.leoni-special-conductors.com Tables of weights for platings at a specific weight (kg/dm3) of 7.28 Sn (= tin), 8.9 Ni (= nickel), 10.5 Ag (= silver). AWG-wires – plating thickness 1 µm Ø of wire AWG No. mm 0.050 0.064 0.070 0.080 0.090 0.100 0.114 0.120 0.127 0.130 0.140 0.150 0.160 0.180 0.200 0.220 0.226 0.250 0.254 0.260 0.280 0.300 0.320 0.360 0.400 0.450 0.500 0.600 0.650 0.700 0.750 0.800 0.850 0.900 0.950 1.000 1.150 1.250 1.300 1.400 1.450 1.500 1.600 1.700 1.800 44 42 41 40 39 38 37 36 35 34 33 32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 Tin Sn Nickel Ni Silver Ag g/kg g/kg g/kg 65.4 51.1 46.7 40.9 36.3 32.7 28.7 27.3 25.7 25.2 23.4 21.8 20.4 18.2 16.4 14.9 14.5 13.1 12.9 12.6 11.7 10.9 10.2 9.1 8.2 7.3 6.5 5.5 5.0 4.7 4.4 4.1 3.8 3.6 3.4 3.3 2.8 2.6 2.5 2.3 2.3 2.2 2.0 1.9 1.8 80.0 62.5 57.1 50.0 44.4 40.0 35.1 33.3 31.5 30.8 28.6 26.7 25.0 22.2 20.0 18.2 17.7 16.0 15.7 15.4 14.3 13.3 12.5 11.1 10.0 8.9 8.0 6.7 6.2 5.7 5.3 5.0 4.7 4.4 4.2 4.0 3.5 3.2 3.1 2.9 2.8 2.7 2.5 2.4 2.2 94.4 73.8 67.4 59.0 52.4 47.2 41.4 39.3 37.2 36.3 33.7 31.5 29.5 26.2 23.6 21.5 20.9 18.9 18.6 18.2 16.9 15.7 14.8 13.1 11.8 10.5 9.4 7.9 7.3 6.7 6.3 5.9 5.6 5.2 5.0 4.7 4.1 3.8 3.6 3.4 3.3 3.1 3.0 2.8 2.6 Surface Finishes www.leoni-special-conductors.com 9 AWG-wires, plating thicknesses according to ASTM The table is a tool to calculate the weight and plating thickness for tin, nickel and silver. Please not, that tin plated wires will not have a plating thickness of 1 µm, as stated, but will be manufactured in accordance with EN 13602. Samples for thin platings < 2 µ Example 1: How many grammes of silver do you require for a wire with a diameter of 0.18 mm, if the plating thickness is to be 1.5 µm? 0.18 mm with 1 µm = 26.2 g; 0.18 mm with 1.5 µm = 26.2 x 1.5 = 39.3 g = ~ 40 g of silver for 1 kg copper wire Example 2: Which plating thickness will be achieved if you use 39.3 g silver per kg for a 0.18 mm Ø wire? 39.3 : 26.2 = 1.5 µm AWG No. 50 49 48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33 32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 Ø of wire 25 microinches 0.635 µm Tin Sn 50 microinches 1.27 µm Nickel Ni 40 microinches 1.016 µm Silver Ag Silver thickness pore-free quality g/kg mm g/kg g/kg g/kg 0.025 0.028 0.032 0.036 0.040 0.045 0.051 0.056 0.064 0.071 0.079 0.089 0.102 0.114 0.127 0.142 0.160 0.180 0.203 0.226 0.254 0.287 0.320 0.361 0.404 0.455 0.511 0.574 0.643 0.724 0.813 0.912 1.024 1.151 1.290 1.450 1.628 1.829 83.1 74.2 65.9 58.3 52.0 46.5 40.7 37.1 32.4 29.2 26.3 23.3 20.4 18.2 16.4 14.6 13.0 11.5 10.2 9.2 8.2 7.2 6.5 5.8 5.1 4.6 4.1 3.6 3.2 2.9 2.6 2.3 2.0 1.8 1.6 1.4 1.3 1.1 203.2 181.4 161.3 142.7 127.3 113.6 99.6 90.7 79.4 71.5 64.3 57.1 49.8 44.6 40.0 35.8 31.8 28.2 25.0 22.5 20.0 17.7 15.9 14.1 12.6 11.2 9.9 8.9 7.9 7.0 6.2 5.6 5.0 4.4 3.9 3.5 3.1 2.8 191.8 171.3 152.2 134.7 120.2 107.3 94.0 85.6 74.9 67.5 60.7 53.9 47.0 42.1 37.8 33.8 30.0 26.6 23.6 21.2 18.9 16.7 15.0 13.3 11.9 10.5 9.4 8.4 7.5 6.6 5.9 5.3 4.7 4.2 3.7 3.3 2.9 2.6 AWG = American Wire Gauge 61 50 40 30 25 20 12.5 ASTM = American Society for Testing and Materials 10 Surface Finishes www.leoni-special-conductors.com Electroplating options Electroplating options – For plated copper/wires we use tin, silver or nickel, depending on what is required from the conductor. tin solderability effective protection against corrosion good silver high temperature resistance (up to 200 °C) high conductivity (Skin-effect, important for HF-applications) gold-plated corrosion resistance high bondability chemical resistance nickel corrosion and temperature resistance (up to 250 °C) Barriers of diffusion high enamelled protection and insulation for ultra-fine wires Temperature Ratings of conductor materials CSA-C22.2 No. 210.2 states the following temperature ratings of conductor materials: Temperature range max. 150 °C plain and tin plated with single wire Ø ≤ 0.38 mm Copper clad steel (e.g. STAKU) with single wire Ø ≤ 0.38 mm Copper Temperature range max. 200 °C plated copper Silver plated copper clad steel Silver plated copper alloys Silver Temperature range max. 250 °C plated copper Nickel plated copper clad aluminium (CCA) Nickel plated copper clad steel (CCS) Nickel plated high strength alloys Nickel plated steel composites Nickel LEONI wires and concentric stranded conductors are available bare and with a range of surface finishes manufactured to industry, national and international standards as well as to individual customer specifications. Packaging www.leoni-special-conductors.com 11 Packaging Type d1 d3 l2 l1 d2 Ø of flange Ø of bore Traverse Overall Width Ø of barrel Capacity mm mm mm approx. kg Plastic reels DIN 80 80 16 64 80 50 0.7 DIN 100 100 16 80 100 63 1.4 DIN 125 125 16 100 125 80 3.5 DIN 160 160 22 128 160 100 8 DIN 200 200 22 160 200 125 13 DIN 250/36 250 36 160 200 160 22 DIN 400 400 127 250 330 250 80 DIN 500 500 36 180 250 315 103 DIN 560 560 127 350 450 315 200 DIN 630 630 127 350 450 390 200 K 1600 K 2500 K 2506 K 2534 K 3550 K 4007 K 5600 K 5606 K 6307 160 250 250 250 355 400 555 560 630 22 22 127 127 36 32.7 127 127 127 128 160 160 160 160 205 280 380 380 160 200 200 200 200 243 355 480 430 100 160 160 160 224 250 355 315 320 8 20 25 25 40 70 180 250 350 Type d1 d3 l2 l1 d2 Ø of flange Ø of bore Traverse Overall Width Ø of barrel Capacity mm mm mm approx. kg Pay off pack O/All Diameter (POP) 508 mm Steel reels B 4006 400 127 250 B 5600 560 127 355 B 6300 630 127 400 Sheet metal reels B 6305 630 127 435 Wooden reels G 0800 800 81 400 G 1000 1000 80 560 Plastic braider bobbins FSP75 75 10 50 K0751 FSP80/ 80 10 80 K0804 WSN01/16 cc 66 16 69 K0660 WSN02/24 cc 66 16 104 K0661 O/All Height 150 mm 35 280 395 475 224 315 355 115 280 400 475 355 400 550 700 400 500 750 1000 100 24 1.5 100 23 2.0 80 34 1.0 116 34 1.6 The chart depicts the most common reel sizes. Special types are available upon request. Note: The net weights given for DIN reels are nominal capacities. l1 l2 The main dimensions of a reel: d1 ➔ Flange diameter d3 ➔ Bore diameter d3 d2 d1 Additionally useful are: l2 ➔ Traverse l1 ➔ Overall Width d2 ➔ Barrel diameter 12 Wires Product Range Wires Single Wires Single Wires to DIN Standard Single Wires to AWG Standard Multi Wires Braiding Wires www.leoni-special-conductors.com Wires www.leoni-special-conductors.com Wires We manufacture copper wires in line with international standards and individual customer specifications. Product Range In addition to CU-ETP1 and CU-OF1 in bare, tin plated, nickel plated, silver plated or gold plated finish, we also process high strength copper alloys. Delivery Wires can be supplied as: n n n Single wire Reel weight range from 8 to 200 kg. Range of single wire diameters: 0.05 mm–2.7 mm Multi wire The reel weight ranges from 25 to 500 kg. Range of single wire diameters: 0.05 mm–0.52 mm Braiding wire The reel weight ranges from 0.5 to 3 kg. Range of single wire diameters: 0.05 mm–0.52 mm Common constructions: 2–16 wires For wire specifications please refer to the tables on the following pages. 13 Wires 14 www.leoni-special-conductors.com Single Wires to DIN Standard DIN dimensions for single copper wires in accordance with DIN 46 431 ”Round Copper Wires for Electrical Purposes, Exactly Drawn” (these Standards apply only to plain wires as the parameters change as a result of the extrusion process and the associated wire elongation). Diameter Nominal value d Tolerance Min. value Max. value Nominal cross-section Weight DC resistance at 20 °C ✖ Yield mm mm mm mm mm2 approx. kg/km Ω/m nom. value approx. km/kg 0.047 0.060 0.068 0.077 0.087 0.097 0.107 0.120 0.135 0.155 0.175 0.195 0.219 0.243 0.273 0.308 0.348 0.391 0.441 0.491 0.551 0.621 0.698 0.738 0.788 0.838 0.888 0.938 0.988 1.044 1.104 1.164 1.234 1.304 1.384 1.480 1.580 1.680 1.775 0.053 0.066 0.074 0.083 0.093 0.103 0.117 0.130 0.145 0.165 0.185 0.205 0.229 0.257 0.287 0.322 0.362 0.409 0.459 0.509 0.569 0.639 0.722 0.762 0.812 0.862 0.912 0.962 1.012 1.076 1.136 1.196 1.266 1.336 1.416 1.520 1.620 1.720 1.825 0.00196 0.00312 0.00396 0.00503 0.00636 0.00785 0.00985 0.01227 0.01539 0.02011 0.02545 0.03142 0.03941 0.04909 0.06158 0.07793 0.09898 0.1257 0.1590 0.1964 0.2463 0.3117 0.3959 0.4418 0.5027 0.5675 0.6362 0.7088 0.7854 0.8825 0.9852 1.094 1.227 1.368 1.539 1.767 2.011 2.270 2.545 0.0175 0.0278 0.0353 0.0447 0.0566 0.0699 0.0878 0.109 0.137 0.179 0.226 0.280 0.351 0.437 0.548 0.694 0.882 1.12 1.42 1.75 2.19 2.78 3.53 3.93 4.47 5.05 5.66 6.31 6.99 7.86 8.78 9.75 10.90 12.20 13.70 15.70 17.90 20.20 22.60 8.80 5.53 4.35 3.43 2.71 2.196 1.750 1.402 1.120 0.8573 0.6774 0.5487 0.4375 0.3512 0.2799 0.2213 0.1743 0.1372 0.1084 0.0878 0.0700 0.0553 0.04354 0.03902 0.03429 0.03038 0.02710 0.02432 0.02195 0.01954 0.01750 0.01577 0.01405 0.01260 0.01120 0.00976 0.00858 0.00760 0.00677 57.10 36.00 28.30 22.40 17.67 14.31 11.39 9.17 7.30 5.59 4.42 3.57 2.85 2.29 1.825 1.441 1.134 0.893 0.704 0.571 0.457 0.36 0.283 0.254 0.224 0.198 0.177 0.158 0.143 0.127 0.114 0.103 0.0917 0.082 0.073 0.0637 0.0559 0.0495 0.0442 0.05 0.063 0.071 0.08 0.09 0.1 0.112 0.125 0.14 0.16 0.18 0.2 0.224 0.25 0.28 0.315 0.355 0.4 0.45 0.5 0.56 0.63 0.71 0.75 0.8 0.85 0.9 0.95 1 1.06 1.12 1.18 1.25 1.32 1.4 1.5 1.6 1.7 1.8 ± 0.003 ± 0.005 ± 0.007 ± 0.009 ± 0.012 ± 0.016 ± 0.020 ± 0.025 ✖ m Calculated with a conductivity of 58 Ω · mm2 at 20 °C. The maximum resistance value in the case of a diameter using the full acceptable negative m deviation range must be suitable for a conductivity of at least 57.5 Ω · mm2 at 20 °C. Wires www.leoni-special-conductors.com 15 Single Wires to AWG Standard The most popular AWG (American Wire Gauge) sizes, diameters and cross-sectional areas in accordance with ASTM B 258 “Standard Nominal Diameters and Cross-Sectional AREAS OF AWG SIZES for Solid Round Wires used As Electrical Conductors”. Diameter Cross-section AWG cmils Size mils mm mm 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 72.0 64.1 57.1 50.8 45.3 40.3 35.9 32.0 28.5 25.3 22.6 20.1 17.9 15.9 14.2 12.6 11.3 10.0 8.9 8.0 7.1 6.3 5.6 5.0 4.5 4.0 3.5 3.1 2.8 2.5 2.2 2.0 1.8 1.6 1.4 1.2 1.1 0.99 1.829 1.628 1.450 1.290 1.151 1.024 0.912 0.813 0.724 0.643 0.574 0.510 0.455 0.404 0.361 0.320 0.287 0.254 0.226 0.203 0.180 0.160 0.142 0.127 0.114 0.102 0.089 0.079 0.071 0.064 0.056 0.051 0.045 0.040 0.036 0.032 0.028 0.025 2.625 2.082 1.652 1.307 1.039 0.821 0.654 0.517 0.411 0.324 0.259 0.205 0.162 0.128 0.102 0.0806 0.0648 0.0507 0.0401 0.0324 0.0255 0.0201 0.0159 0.0127 0.0102 0.0081 0.0062 0.0049 0.0040 0.0032 0.0025 0.0021 0.0016 0.0013 0.00099 0.00078 0.00062 0.00050 Conversion factors: mils x 0.0254 = mm cmils x 0.0005067 = mm2 sq.inch x 645.16 = mm2 2 5180 4110 3260 2580 2050 1620 1290 1020 812 640 511 404 320 253 202 159 128 100 79.20 64.00 50.40 39.70 31.40 25.00 20.20 16.00 12.20 9.61 7.84 6.25 4.84 4.00 3.10 2.46 1.96 1.54 1.23 0.98 mm x 39.37 = mils mm2 x 1973.55 = cmils mm2 x 0.00155 = sq.inch sq. inch 0.00407 0.00323 0.00256 0.00203 0.00161 0.00128 0.00101 0.000804 0.000638 0.000503 0.000401 0.000317 0.000252 0.000199 0.000158 0.000125 0.0001 0.0000785 0.0000622 0.0000503 0.0000396 0.0000312 0.0000246 0.0000196 0.0000159 0.0000126 0.00000962 0.00000755 0.00000616 0.00000491 0.0000038 0.00000314 0.00000243 0.00000194 0.00000154 0.00000121 0.000000968 0.00000077 Weight Yield approx. kg/km approx. km/kg 23.40 18.50 14.70 11.60 9.24 7.32 5.81 4.61 3.66 2.88 2.30 1.82 1.44 1.14 0.908 0.715 0.575 0.450 0.357 0.288 0.227 0.179 0.141 0.113 0.0912 0.0721 0.0552 0.0433 0.0353 0.0282 0.0218 0.0180 0.0140 0.0111 0.00883 0.00693 0.00556 0.00440 0.0428 0.054 0.0681 0.086 0.108 0.137 0.172 0.217 0.273 0.347 0.435 0.549 0.693 0.878 1.10 1.40 1.74 2.22 2.80 3.47 4.40 5.59 7.08 8.88 11.00 13.90 18.10 23.10 28.30 35.50 45.90 55.50 71.70 90.10 113.00 144.00 180.00 228.89 16 Wires www.leoni-special-conductors.com Braiding Wires Braiding wires for cable screening. Production programme In order to better reflect customer requirements LEONI has extended its multi wire product range to include pre-wound braid bobbins. LEONI‘s long known multi wire competency, high quality wires with very narrow diameter and elongation tolerances, means that customers can expect to manufacture excellent braids. The braiding wires are available across the full range of LEONI‘s wire products including alloys. Construction LEONI‘s range of braid bobbins fits all modern braiding machines. Standard available diameter range: 0.05mm–0.254mm Standard wire range: 4–12 wires per bobbin Standard bobbin types Type d1 d3 l2 l1 d2 Flange diameter Bore diameter Traverse Overall width Barrel diameter Capacity (max.) mm mm mm ca. g 75 80 66 66 10 10 16 16 24 23 34 34 1500 2000 1000 1600 Plastic braid bobbins FSP75 / K0751 FSP80 / K0804 WSN01 / K0660 WSN02 / K0661 50 80 69 104 100 100 80 116 www.leoni-special-conductors.com Product Range Stranded Conductors Bunched Conductors Highly Flexible Stranded Conductors and Ropes Concentric Stranded Conductors Semiconcentric Stranded Conductors LEONI Smooth-Bunch Stranded Conductors 17 Stranded Conductors 18 www.leoni-special-conductors.com Bunched Conductors This type of conductor is made up of bunched multi-wires. The wires are twisted together in a random pattern. Standard bunched conductors are widely used in the cable industry. Construction The average diameter of a bunched conductor can be calculated using the table and the formula: D = d • f (D = Ø of bunched conductor, d = Ø of single wire) n = no. of wires f = multiplication factor (average) n 1 2 3 4 5 7 10 12 14 16 Example: Stranded conductor 16 x 0.20 mm (= 0.50 mm2) D = 0.20 x 4.7 D = 0.94 mm f 1.00 2.00 2.15 2.41 2.70 3.00 4.00 4.15 4.41 4.70 n 19 24 26/27 28/30 31/32/33 37 44 48 52 56 f 5.00 6.00 6.15 6.41 6.70 7.00 8.00 8.15 8.41 8.70 n 61 70 75 80 85 91 102 108 114 120 f 9.00 10.00 10.15 10.41 10.70 11.00 12.00 12.15 12.41 12.70 Typical constructions for multi-wire, fine-wire and ultrafine-wire bunched conductors AWG ➔ Cross-section 0.1 0.14 0.25 0.34 0.38 0.5 0.75 1 1.5 2.5 4 6 10 16 25 35 50 70 95 120 150 185 240 Ø of wire in mm ➔ 44 41 38 36 34 32 30 0.05 51 x 0.05 72 x 0.05 128 x 0.05 173 x 0.05 192 x 0.05 256 x 0.05 385 x 0.05 511 x 0.05 770 x 0.05 1274 x 0.05 2016 x 0.05 3192 x 0.05 0.07 25 x 0.07 36 x 0.07 66 x 0.07 88 x 0.07 88 x 0.07 130 x 0.07 196 x 0.07 259 x 0.07 392 x 0.07 651 x 0.07 1036 x 0.07 1548 x 0.07 2556 x 0.07 4116 x 0.07 0.10 12 x 0.10 18 x 0.10 32 x 0.10 42 x 0.10 48 x 0.10 64 x 0.10 96 x 0.10 128 x 0.10 189 x 0.10 320 x 0.10 511 x 0.10 756 x 0.10 1281 x 0.10 2037 x 0.10 3213 x 0.10 4410 x 0.10 6370 x 0.10 8917 x 0.10 12348 x 0.10 15435 x 0.10 19110 x 0.10 23373 x 0.10 30870 x 0.10 0.127 8 x 0.127 11 x 0.127 20 x 0.127 27 x 0.127 30 x 0.127 39 x 0.127 59 x 0.127 79 x 0.127 118 x 0.127 196 x 0.127 322 x 0.127 476 x 0.127 784 x 0.127 1260 x 0.127 0.16 0.20 0.254 7 x 0.16 12 x 0.16 17 x 0.16 19 x 0.16 25 x 0.16 37 x 0.16 50 x 0.16 75 x 0.16 124 x 0.16 196 x 0.16 294 x 0.16 504 x 0.16 798 x 0.16 8 x 0.20 11 x 0.20 12 x 0.20 16 x 0.20 24 x 0.20 32 x 0.20 48 x 0.20 80 x 0.20 118 x 0.20 189 x 0.20 315 x 0.20 7 x 0.254 8 x 0.254 10 x 0.254 15 x 0.254 19 x 0.254 30 x 0.254 50 x 0.254 79 x 0.254 Stranded Conductors www.leoni-special-conductors.com 19 Highly Flexible Stranded Conductors and Ropes Highly flexible round concentric stranded conductors and ropes These products have high flexibility and are suitable for cables used in dynamic environments. Construction The examples shown in the table below can be manufactured both as bunched conductors and as 7 way ropes. n lay length of bunched conductors 25–50 times the overall diameter of the strand n lay length of 7 way conductors 8–16 times the overall diameter of the strand Nominal cross-section Min. number of wires mm2 Ø of wire 0.05 mm 0.020 10 0.029 15 0.041 21 0.059 30 0.079 40 0.100 51 0.140 72 0.200 102 0.250 128 0.350 180 0.500 266 0.750 385 1.000 525 Ø of wire 0.07 mm 0.081 21 0.140 36 0.250 66 0.350 90 0.500 130 0.750 195 1.000 259 Product Range Available with bare, silver, nickel or tin plated copper wires. Ø of stranded conductor Weight Nominal cross-section mm kg/km mm2 0.18 0.22 0.26 0.31 0.36 0.40 0.50 0.60 0.65 0.75 0.95 1.15 1.35 0.175 0.262 0.367 0.524 0.700 0.890 1.260 1.780 2.240 3.240 4.750 7.060 9.390 0.36 0.50 0.65 0.75 0.95 1.10 1.35 0.719 1.240 2.230 3.080 4.550 6.910 9.310 Min. number of wires 1.50 392 2.50 650 4.00 1050 6.00 1575 Ø of wire 0.1 mm 0.50 64 0.75 96 1.00 126 1.50 189 2.50 322 4.00 511 6.00 777 10.00 1281 16.00 2058 25.00 3185 35.00 4508 50.00 6370 70.00 8918 100.00 12348 120.00 15336 150.00 19110 185.00 23373 240.00 30870 Ø of stranded conductor Weight mm kg/km 1.65 2.25 2.90 3.60 14.10 23.40 37.80 56.60 0.95 1.15 1.30 1.65 2.25 2.90 3.60 4.80 6.10 7.60 9.20 10.80 12.80 15.00 16.72 18.66 20.64 23.72 4.56 6.84 9.13 13.70 23.40 37.10 56.50 94.90 153.00 236.00 334.00 472.00 661.00 879.10 1154.10 1461.20 1818.60 2473.00 20 Stranded Conductors www.leoni-special-conductors.com Concentric Stranded Conductors In concentric stranded conductors each single wire occupies a specific position within the formation, guaranteeing a regular construction. Product Range / Construction The superior quality of LEONI’s concentric stranded conductors is due to: n layer wound traversing allowing smooth running at high extrusion speeds n uniform net weight or reel lengths resulting in a significant reduction in waste, particularly in extrusion of multicore and ribbon cables n uniform elongation of the individual wires. n tight tolerances – substantially better than ASTM requirements n higher yield m/kg by manufacturing in the negative tolerance range. This type of conductor allows cable manufacturers to either increase insulation wall thicknesses without impacting upon the overall diameter of the cable for safety purposes, or to achieve smaller overall diameters whilst maintaining standard insulation wall thicknesses thereby saving space and weight. 7-strand (1 + 6) Examples of concentric strand constructions LEONI strands are free of high riding wires which can cause insulation problems. Concentric stranded conductors are made up as follows: 7-strand = 1 + 6 19-strand = 1 + 6 + 12 37-strand = 1 + 6 + 12 + 18 etc. More details can be found in ASTM B 354. Cable technology favours 7 or 19 strand formations especially for electronic wiring. Due to the exact position of the single wires the strands have a very even surface and a constant diameter. They are ideally suited for thin wall insulation using higher value insulation materials. 19-strand (1 + 6 + 12) 37-strand (1 + 6 + 12 + 18) Stranded Conductors www.leoni-special-conductors.com LEONI produces four types of concentric strands. Unilay ➔ Unilay Concentric n n n n n ➔ Unidirectional n Concentric n n same lay direction same lay length manufactured in one working step nearly round construction Direction of stranding same lay direction different lay lengths for each working step manufactured in two working steps more round than unilay concentric Different lay lengths impact on the roundness of the strand Longer lay length = hexagonal / shorter lay length = circular True concentric ➔ Equilay Concentric n (reversed lay stranding n or SZ stranding) n n n ➔ Conventional n Concentric n n Concentric stranded conductors with same lay direction are generally known as Unilay. Concentric stranded conductors with different lay directions (reversed or S/Z lay) are known as True concentric. different lay directions same lay length manufactured in two working steps very round construction different lay directions different lay lengths for each working step manufactured in two working steps very round construction Reversed lay or SZ stranding S ➔ left hand lay Z ➔ right hand lay Direction of stranding 21 Stranded Conductors 22 www.leoni-special-conductors.com Concentric Stranded Conductors Concentric and electrical conductors Type II to ASTM B 286. Product Range / Construction Available as plain, tin plated, silver plated and nickel plated copper wires. Alternative wire sizes are available subject to applicable minimum order quantities. 7 wire strands are particularly suited to high frequency data cables. Electrical conductors Type II in to ASTM B 286 (Examples) AWG No. Nom. cross-section Construction No. of wires x Ø of wires Ø of stranded conductor Weight Yield mm kg/km km/kg 7 x 0.079 7 x 0.102 7 x 0.127 7 x 0.160 7 x 0.203 7 x 0.254 7 x 0.320 7 x 0.404 0.28 0.33 0.41 0.51 0.63 0.78 0.99 1.27 0.315 0.524 0.813 1.290 2.080 3.250 5.160 8.220 3.175 1.908 1.230 0.775 0.481 0.308 0.194 0.122 19 x 0.071 19 x 0.079 19 x 0.102 19 x 0.127 19 x 0.160 19 x 0.203 19 x 0.254 19 x 0.287 19 x 0.361 19 x 0.455 0.35 0.43 0.56 0.68 0.84 1.06 1.32 1.50 1.85 2.36 0.07 0.854 1.44 2.23 3.53 5.68 8.93 11.36 17.86 28.57 1.531 1.171 0.694 0.448 0.283 0.176 0.112 0.088 0.056 0.035 37 x 0.25 37 x 0.32 37 x 0.40 1.71 2.18 2.75 17.4 26.3 43.6 0.057 0.038 0.023 mm2 7-wire conductors 32 30 28 26 24 22 20 18 0.034 0.06 0.09 0.14 0.23 0.35 0.56 0.90 19-wire conductors 30 28 26 24 22 20 18 16 14 12 0.072 0.093 0.16 0.24 0.38 0.62 0.96 1.23 1.95 3.09 37-wire concentric stranded conductors 14 12 10 1.87 2.97 4.53 Stranded Conductors www.leoni-special-conductors.com 23 Concentric Stranded Conductors Concentric stranded conductors, metric dimensions. Metric dimensions (example) Nominal cross-section Construction no. of wires x Ø of wire mm2 Ø of conductor Weight Yield mm kg/km km/kg 0.21 0.30 0.39 0.45 0.54 0.60 0.75 0.90 1.20 1.37 1.53 0.247 0.504 0.852 1.130 1.585 2.020 3.150 4.540 8.060 10.130 12.727 4.049 1.984 1.174 0.885 0.631 0.495 0.317 0.220 0.124 0.099 0.079 0.25 0.50 0.75 0.90 1.00 1.50 1.85 2.00 2.28 2.55 0.3 1.35 3.03 4.35 5.38 12.20 18.52 21.28 27.78 34.48 3.001 0.74 0.33 0.230 0.186 0.082 0.054 0.047 0.036 0.029 2.6 4.2 6.6 8.4 13.3 16.2 21.4 26.6 35.6 42.5 0.385 0.239 0.152 0.119 0.075 0.062 0.047 0.038 0.029 0.024 7-wire conductors 0.028 0.055 0.093 0.12 0.18 0.22 0.34 0.50 0.88 1.14 1.42 7 x 0.071 7 x 0.10 7 x 0.13 7 x 0.15 7 x 0.18 7 x 0.20 7 x 0.25 7 x 0.30 7 x 0.40 7 x 0.455 7 x 0.51 19-wire conductors 0.04 0.15 0.33 0.48 0.60 1.34 2.04 2.39 3.09 3.88 19 x 0.05 19 x 0.10 19 x 0.15 19 x 0.18 19 x 0.20 19 x 0.30 19 x 0.37 19 x 0.40 19 x 0.455 19 x 0.51 37-wire concentric stranded conductors 0.30 0.47 0.75 1.00 1.50 2.00 2.50 3.00 4.00 4.50 37 x 0.102 37 x 0.127 37 x 0.160 37 x 0.180 37 x 0.226 37 x 0.250 37 x 0.287 37 x 0.320 37 x 0.370 37 x 0.404 0.69 0.88 1.12 1.26 1.58 1.75 2.01 2.24 2.59 2.83 37 wire strands may be used in thin wall insulation constructions. “LEONI Smooth-Bunch” with its extremely round construction offer an excellent alternative to traditional 37 wire strands (see page 25). 24 Stranded Conductors www.leoni-special-conductors.com Semi-concentric Conductors This type of conductor provides the advantages of a concentric conductor in terms of its smooth surface and roundness. Yet it is not tied to conventional concentric construction (1 + 6 + 12 + 18, etc.). Product range / construction Available made of bare, tin plated, nickel plated or silver plated copper wires. Cross sections can thus be tailored to the specific requirements of our customers. Examples of semi-concentric conductor construction 12-wire 16-wire Semi-concentric conductors are suited especially to cables with thin-walled insulation. 24-wire 30-wire Conductor examples Nominal cross section Construction No. of wires x wire dia. Conductor dia. nom. Weight nom. mm kg/km 21 x 0.127 16 x 0.203 24 x 0.203 32 x 0.203 30 x 0.254 50 x 0.254 56 x 0.30 84 x 0.30 80 x 0.404 0.66 0.93 1.13 1.31 1.59 2.05 2.56 3.13 4.12 2.415 4.802 7.334 9.949 14.447 23.357 36.453 54.650 94.448 mm2 0.25 0.5 0.75 1 1.5 2.5 4 6 10 Alternatively, LEONI offers this product range with particularly round “LEONI Smooth-Bunch” conductor construction (see page 25). Stranded Conductors www.leoni-special-conductors.com LEONI Smooth-Bunch Using a special manufacturing process “LEONI SmoothBunch” conductors have a compact and precise round construction. Product Range / Construction Available in plain, tin plated, silver plated and nickel plated copper wire. Standard constructions are listed below. Different cross-sections can be supplied if required. “LEONI Smooth-Bunch” conductors are particularly suitable for thin wall extrusion using high value insulation materials. Cables made using these conductors can have the smallest possible overall diameters. 16-wires 24-wires Examples of smooth bunch constructions Example construction types Nominal cross-section Construction (No. of wires x Ø of wires) Ø of conductor (Nom. value) Weight (Nom. value) mm kg/km 0.50 16 x 0.203 0.874 4.802 0.75 24 x 0.203 1.062 7.334 1.00 32 x 0.203 1.231 9.949 mm2 1.50 30 x 0.254 1.494 14.447 2.50 50 x 0.254 1.927 23.357 4.00 56 x 0.30 2.406 36.453 6.00 84 x 0.30 2.942 54.650 10.00 80 x 0.404 3.873 94.448 16.00 133 x 0.404 4.991 158.639 84-wires 25 26 LEONI news www.leoni-special-conductors.com LEONI Histral® RoHS compliant LEONI has successfully created a 100 % cadmium free alloy. It is superior to conventional copper cadmium, both in terms of its electrical and mechanical properties. LEONI Histral® is a registered trademark of LEONI Draht GmbH. Key benefits: High tensile strength in soft condition Rm > 415 N/mm2 elongation >7 % in hard condition Rm > 700 N/mm2 High conductivity in soft condition ≥ 80 % according to ASTM B 624 in hard condition > 70 % IACS Excellent in flexlife properties Good solderability High temperature resistance retains tensile strength up to 400 °C Good corrosion resistance More detailled information on LEONI Histral® is provided in our Histral brochure which is available for download under www.leoni-special-conductors.com EU Prohibits Use of Cadmium Until now copper cadmium has been used for electrical conductors which have to exhibit high mechanical strength. Since EU law has now banned the use of cadmium in any form in motor vehicles and domestic appliances, LEONI has developed its own high strength cadmium free alternative alloy, which is free of harmful substances – LEONI Histral®. LEONI Histral® is currently available as single wire, strand, braid or tinsel using wires as fine as 0.08 mm. LEONI Histral® is available in both hard and soft condition, with a bare, nickel and silver surface. www.leoni-special-conductors.com LEONI keeps you up-to-date We offer high quality electrical conductors for cable engineering as well as for special applications in electrical engineering and in electronics. Our engineers are constantly working on ways to improve our products, extending our product range with new materials and constructions and developing innovative solutions to satisfy the many and varied needs of the cable industry. The LEONI Special Conductors business unit is the right partner for special constructions. Please feel free to contact us. In addition we would recommend that you visit our web site www.leoni-special-conductors.com Our newsletter will inform you either by post or e-mail about the most recent developments in the wire marketplace and in our business unit. Please register at special-conductors@leoni.com so that you will not miss any updates. LEONI news 27 LEONI Draht GmbH Business Unit Special Conductors Treuchtlinger Strasse 20 91781 Weissenburg Germany Phone +49 (0)9141-918-240 Fax +49 (0)9141-918-101 E-mail special-conductors@leoni.com www.leoni-special-conductors.com